Deep-frying device for food processing

A food processing and frying technology, applied in food ovens, applications, food science, etc., can solve the problems of insufficient heating of food, insufficient heating of oil, single function, etc., to avoid deposition or adhesion, and to improve frying. Efficiency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

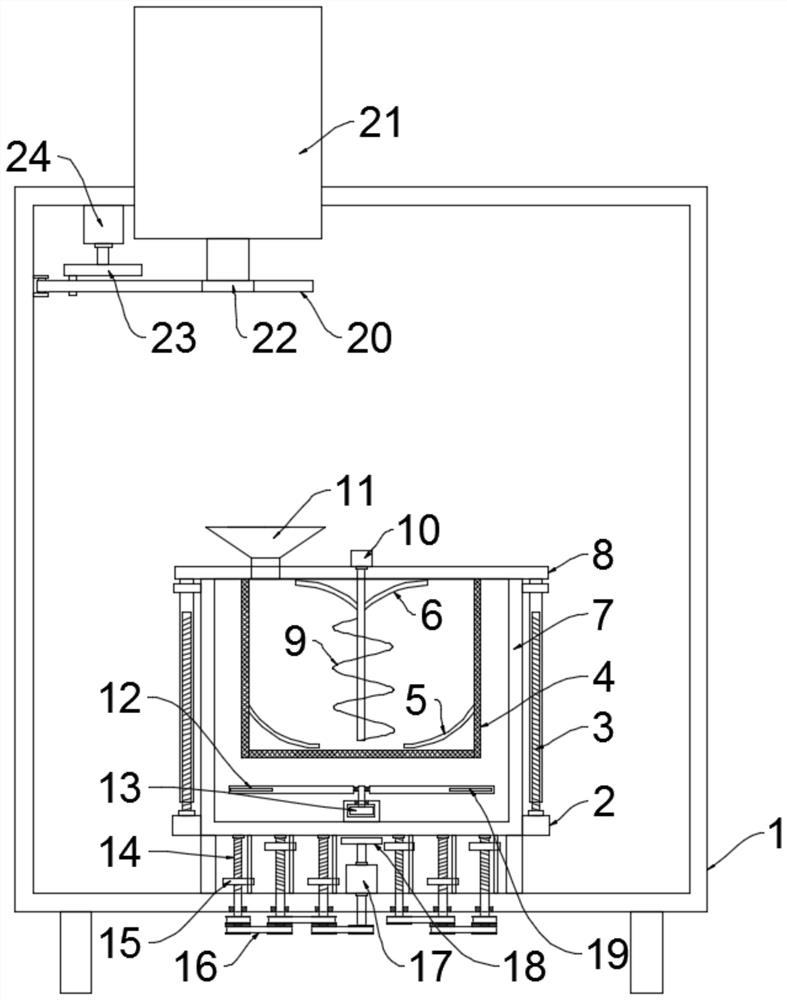

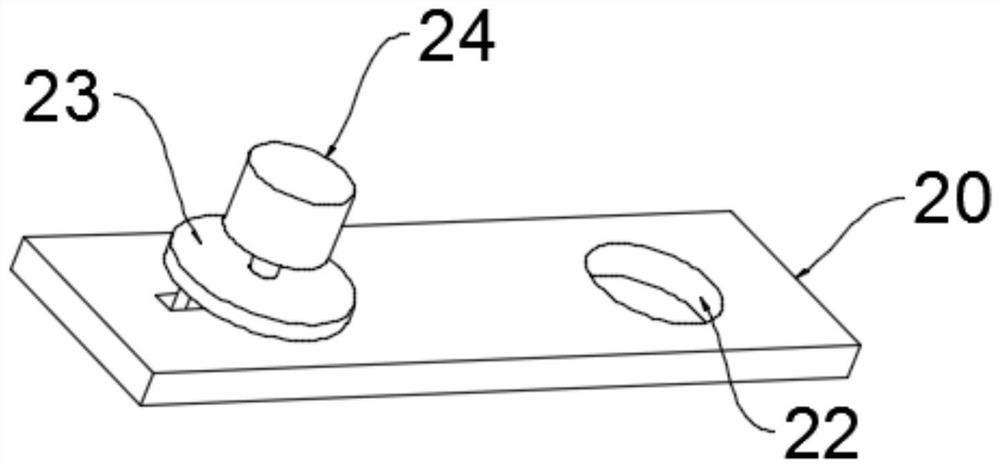

[0024] see Figure 1~2 , in an embodiment of the present invention, a frying device for food processing, including a frame 1 and a frying unit, the bottom of the frame 1 is evenly and symmetrically fixed with supporting legs, and the frying unit includes an oil drum 7 and a The net cylinder 4 for placing food also includes a stirring assembly, and a plurality of heating elements are installed at circumferential intervals on the inner wall of the oil barrel 7 for heating the hot oil in the oil barrel 7, and the top of the oil barrel 7 is provided with a cover 8. The lower surface of the cover body 8 is fixedly installed with the mesh tube 4 located in the oil barrel 7, and the side of the cover body 8 is provided with a feed hopper 11 communicating with the inner cavity of the mesh barrel 4. In order to facilitate the movement of the mesh barrel 4 out of the oil barrel 7 A lifting assembly for driving the cover 8 to lift is connected between the oil barrel 7 and the cover 8. In...

Embodiment 2

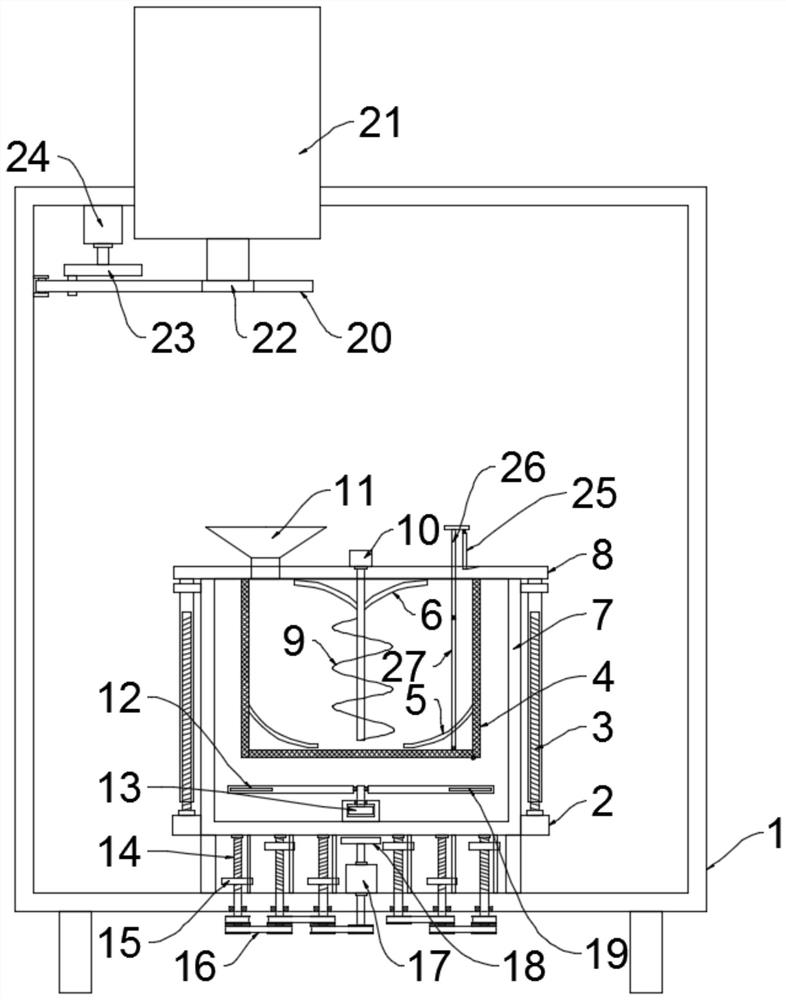

[0028] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that further, in order to quickly take out the fried food in the net tube 4, the bottom of the net tube 4 is a door body, and one end of the door body is connected to the net tube 4 in rotation. The door body is hinged with a connecting rod 27, the top of the connecting rod 27 is hinged with a drive rod 26, the drive rod 26 runs through the top of the cover 8 and extends to the top of the cover 8, the top of the drive rod 26 is fixed with a top plate, and the lower surface of the top plate is hinged to a limited extent. Position rod 25, the limit rod 25 is initially in a vertical state, and the cover body 8 is provided with an arc-shaped groove that cooperates with the limit plate, and the center of the arc-shaped groove is located at the hinge point between the limit rod 25 and the top plate , after the food is fried, manually rotate the limit lever 25 to break away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com