Patents

Literature

35results about How to "Adjust the feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

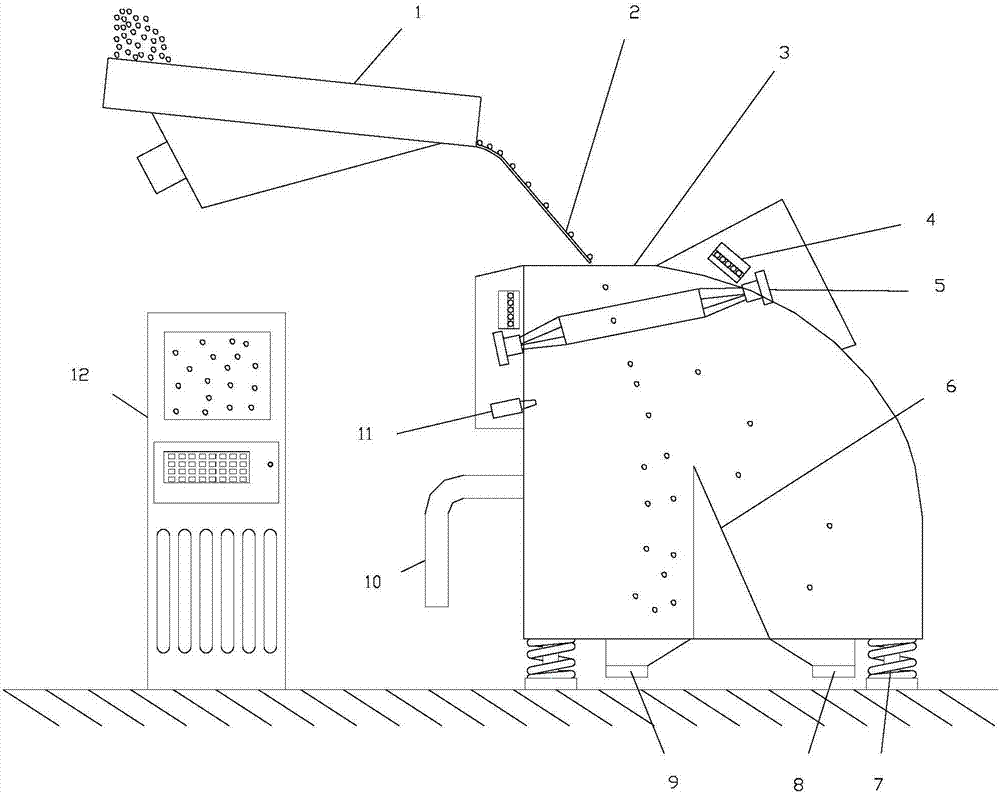

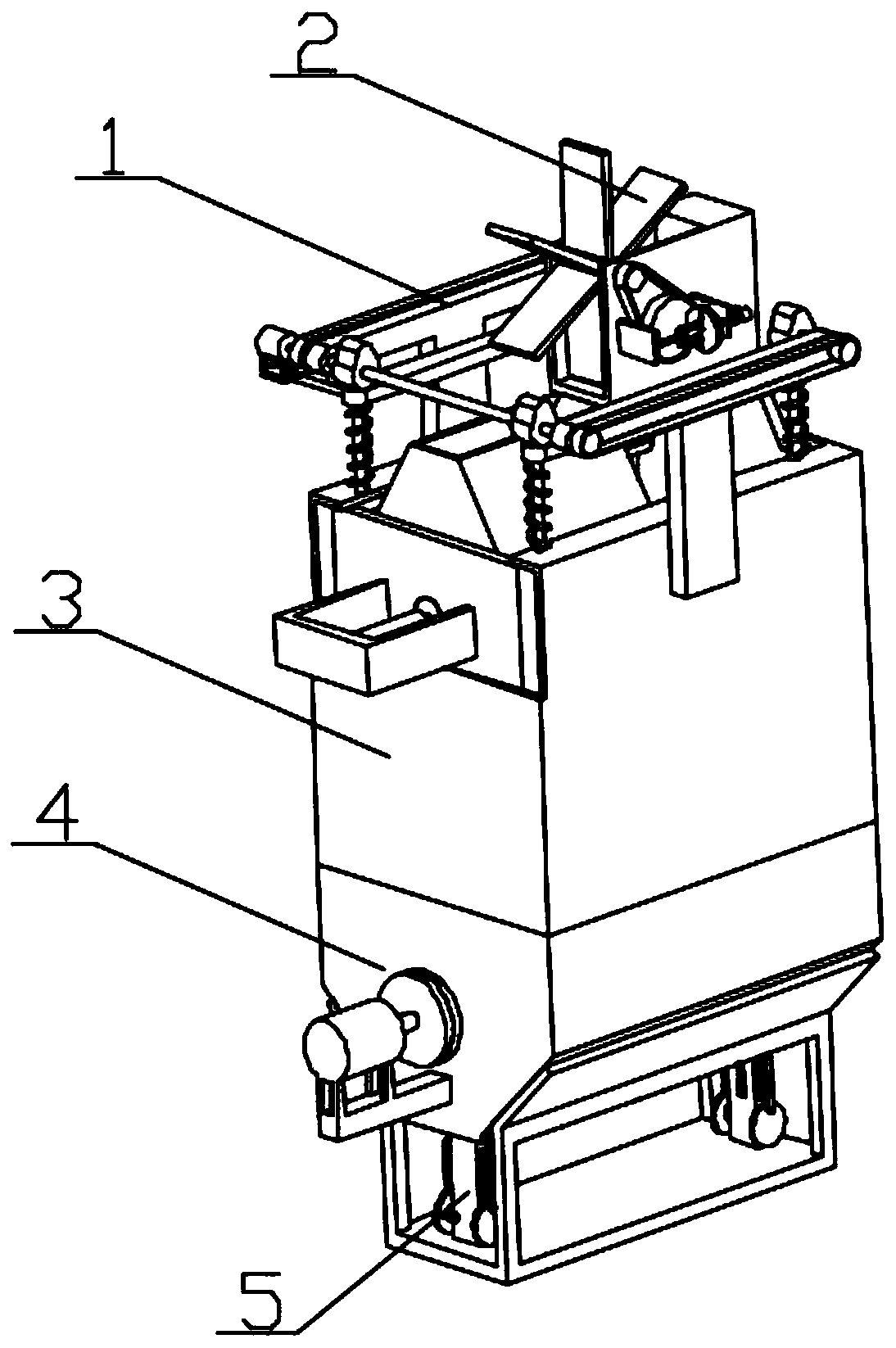

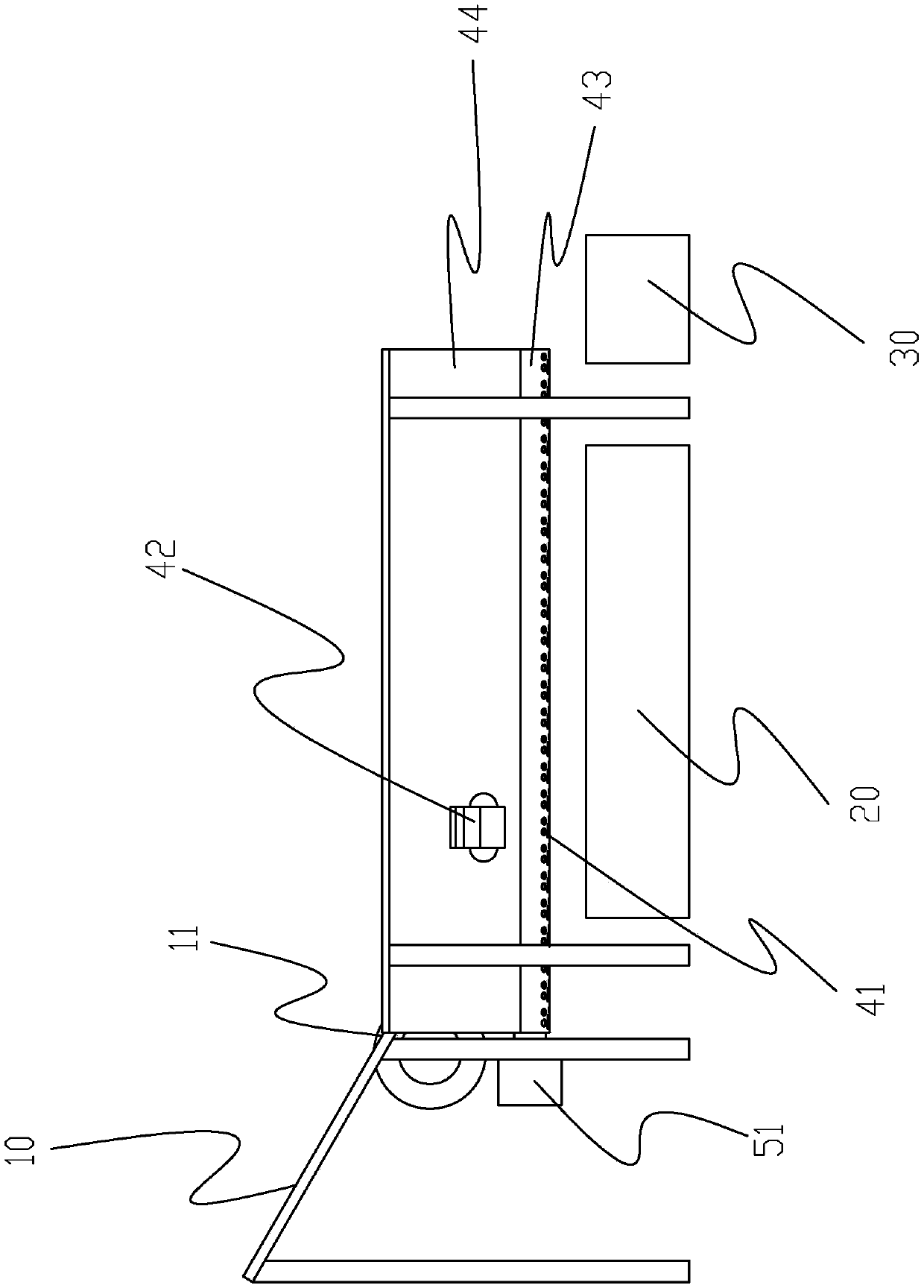

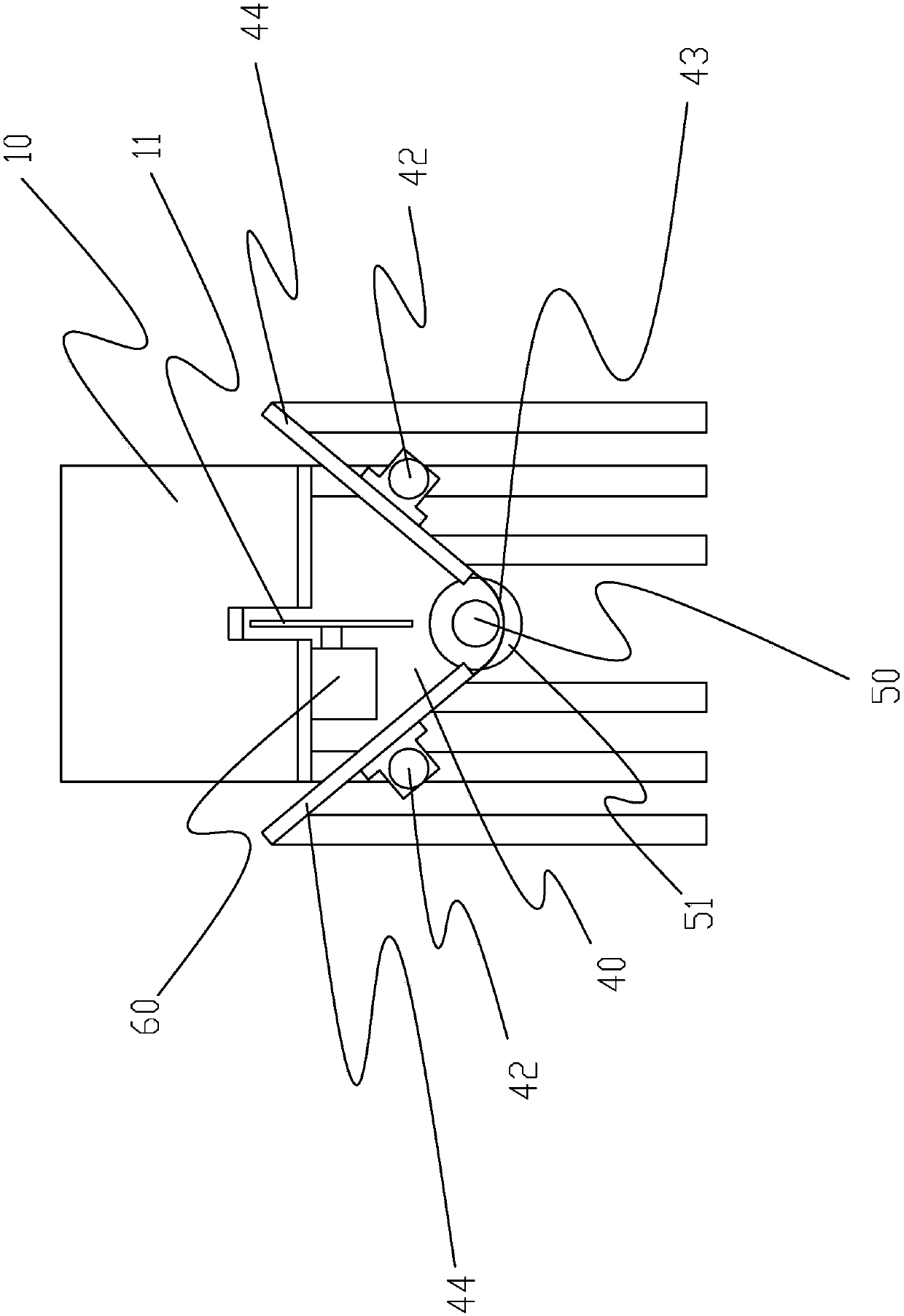

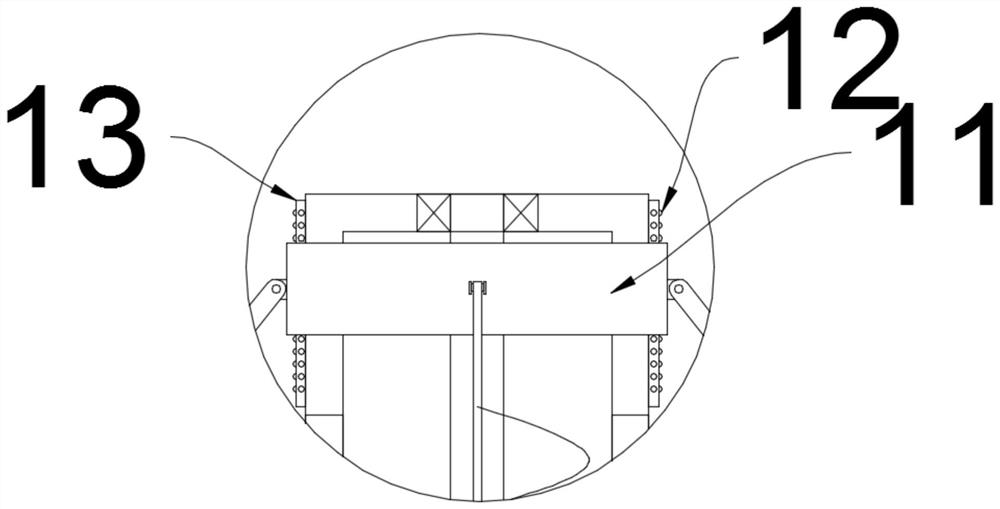

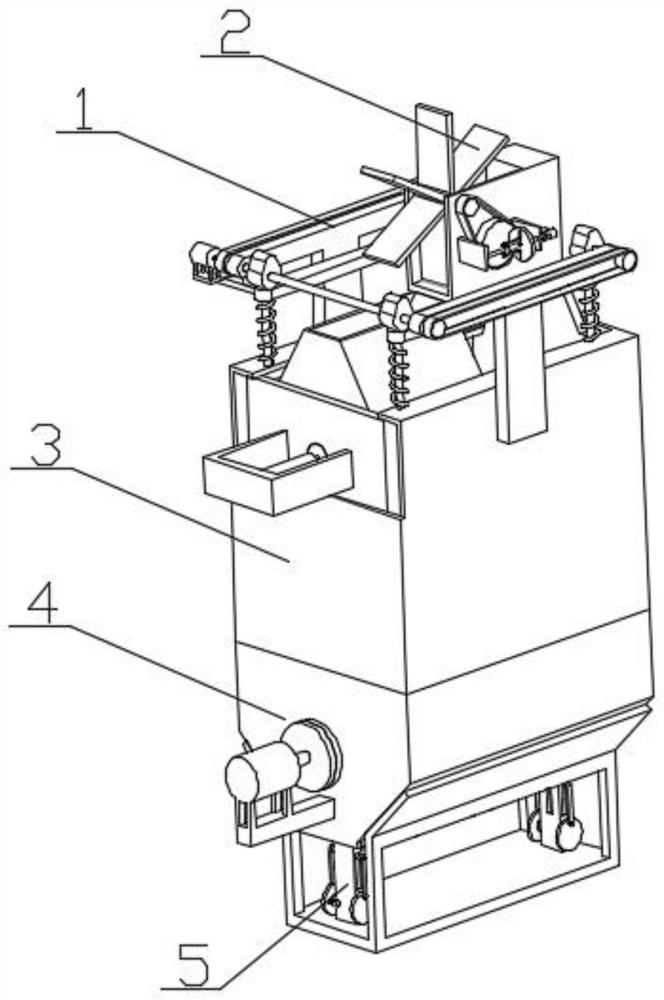

Construction waste color sorting equipment

The invention relates to construction waste color sorting equipment. The construction waste color sorting equipment comprises a feeding device, a main machine box and a control device. The feeding device comprises a vibration feeding hopper and a chute which is fixed to the lower end of the front portion of an outlet of the vibration feeding hopper, and the lower portion of the chute is aligned with a feeding inlet of the main machine box. A light source, a high-speed camera and a nozzle are fixed to the inner side wall, close to the main machine box, of the feeding inlet and electrically connected with the control device. A material separating plate is fixed to the bottom inside the main machine box and can separate crushed materials which are blown out through the nozzle and fall from the feeding inlet of the main machine box, and the portions, at the two ends of the material separating plate, of a bottom plate inside the main machine box are provided with a lightweight crushed material outlet and a heavy crushed material outlet correspondingly. The construction waste color sorting equipment is precise in sorting, adapts to severe working environments and can be used for sorting bricks of various sizes and concrete.

Owner:CA LONG ENG MACHINERY CO LTD

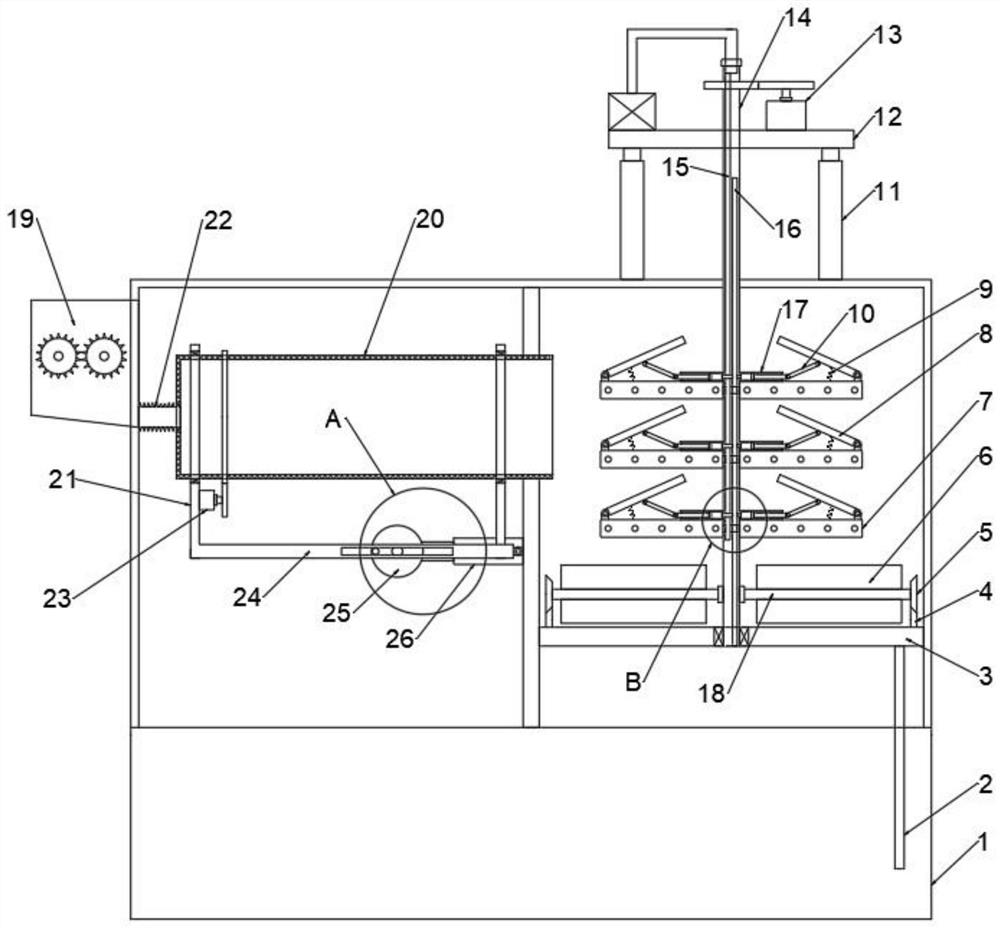

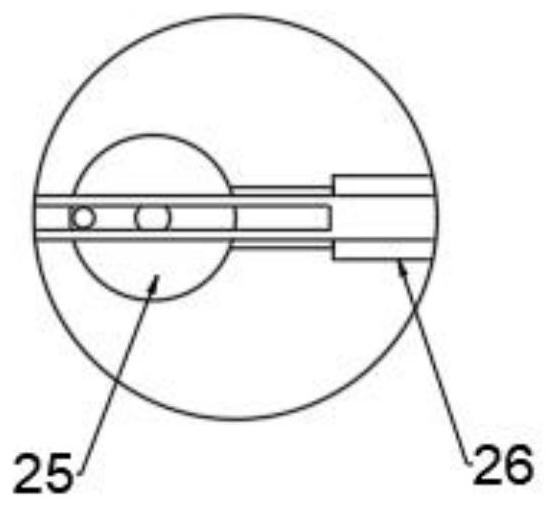

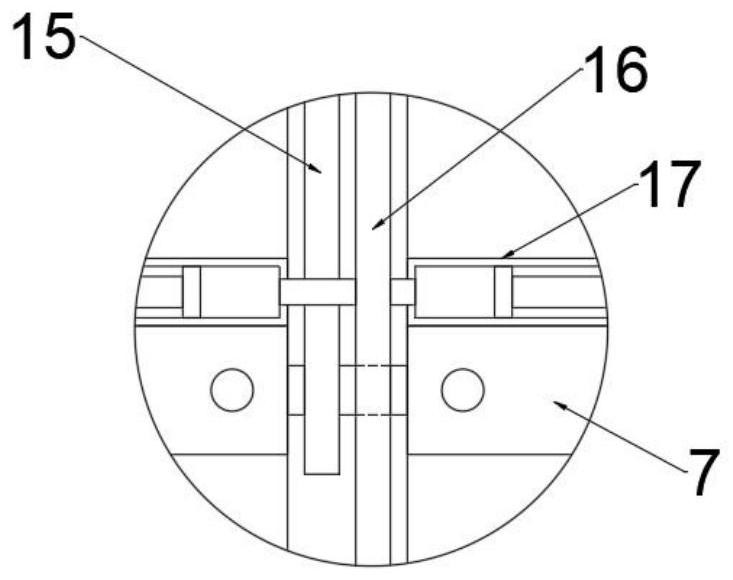

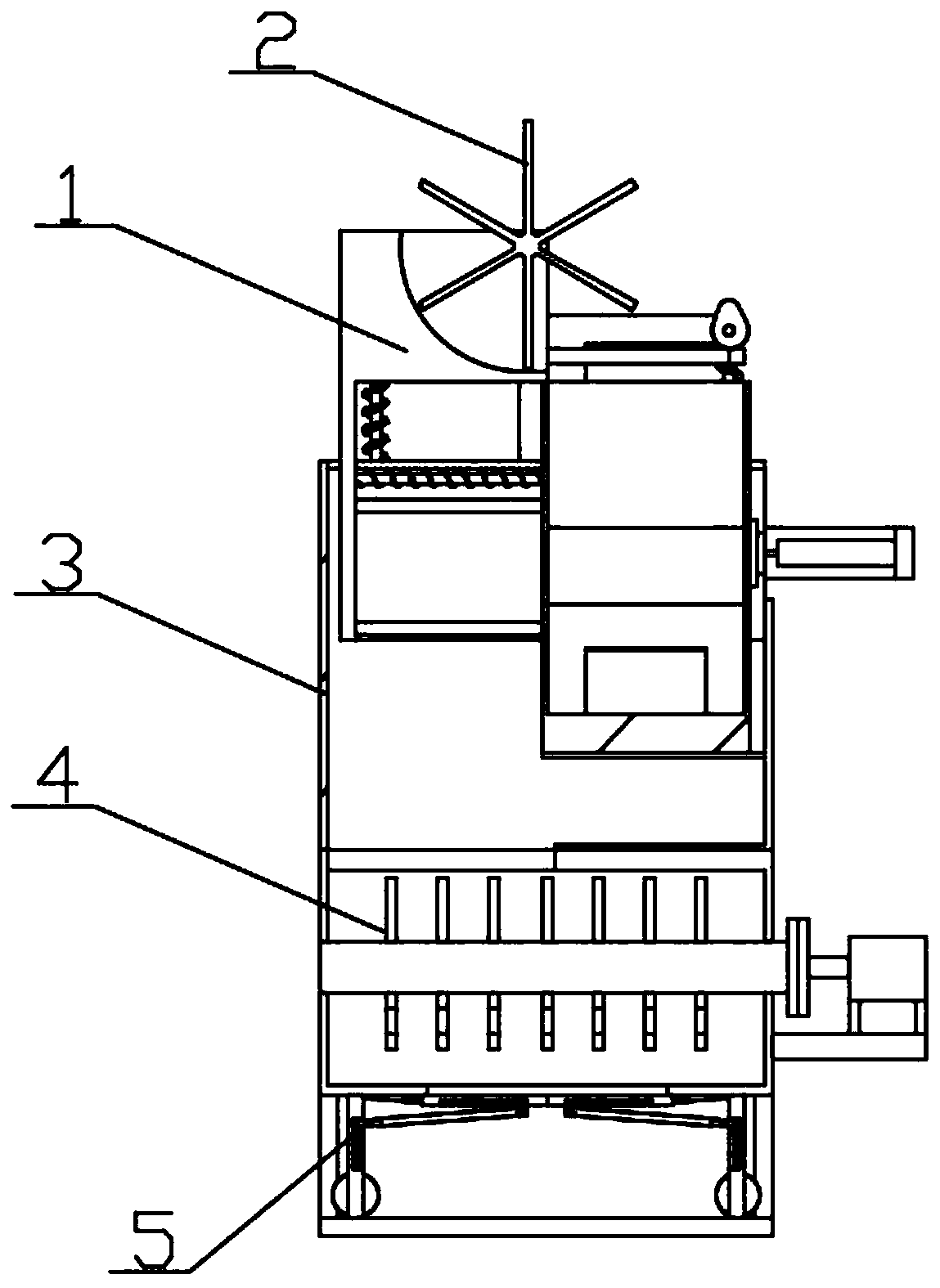

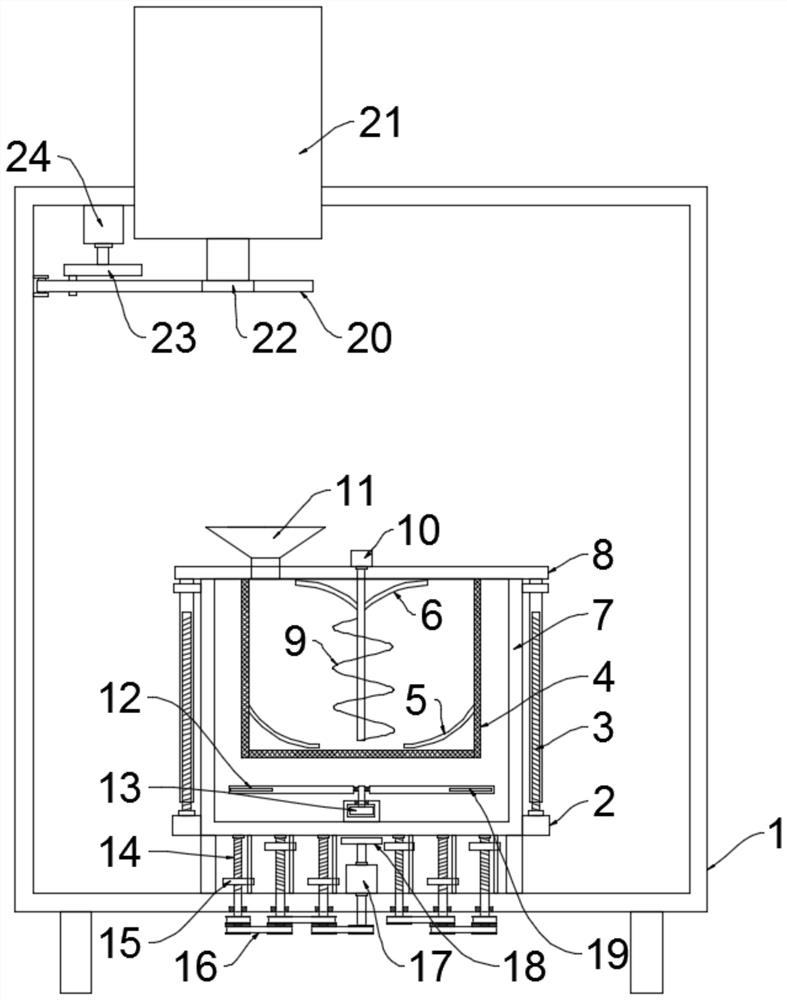

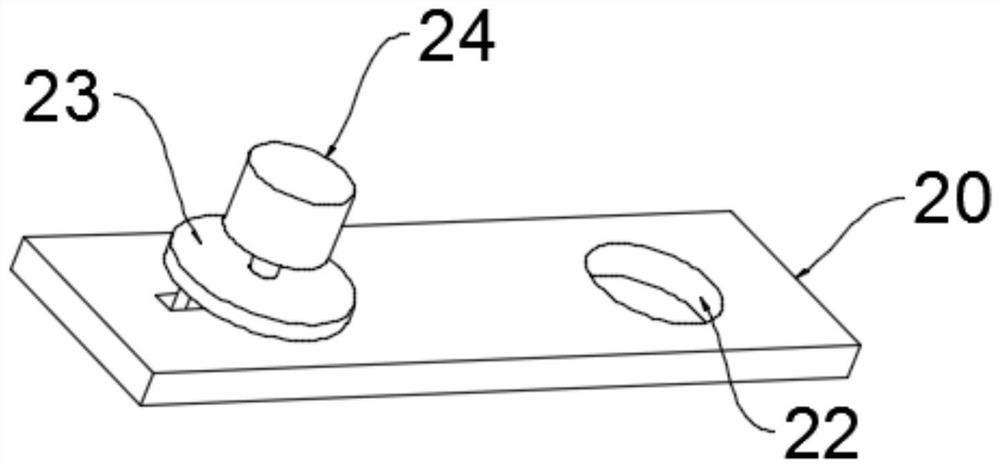

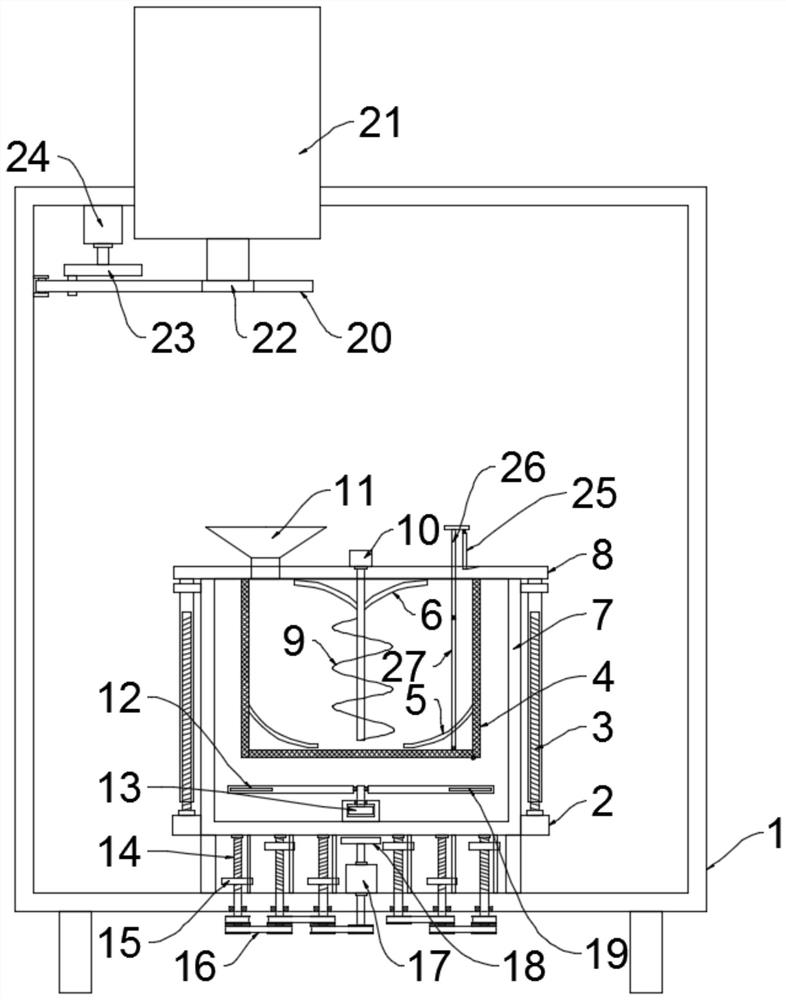

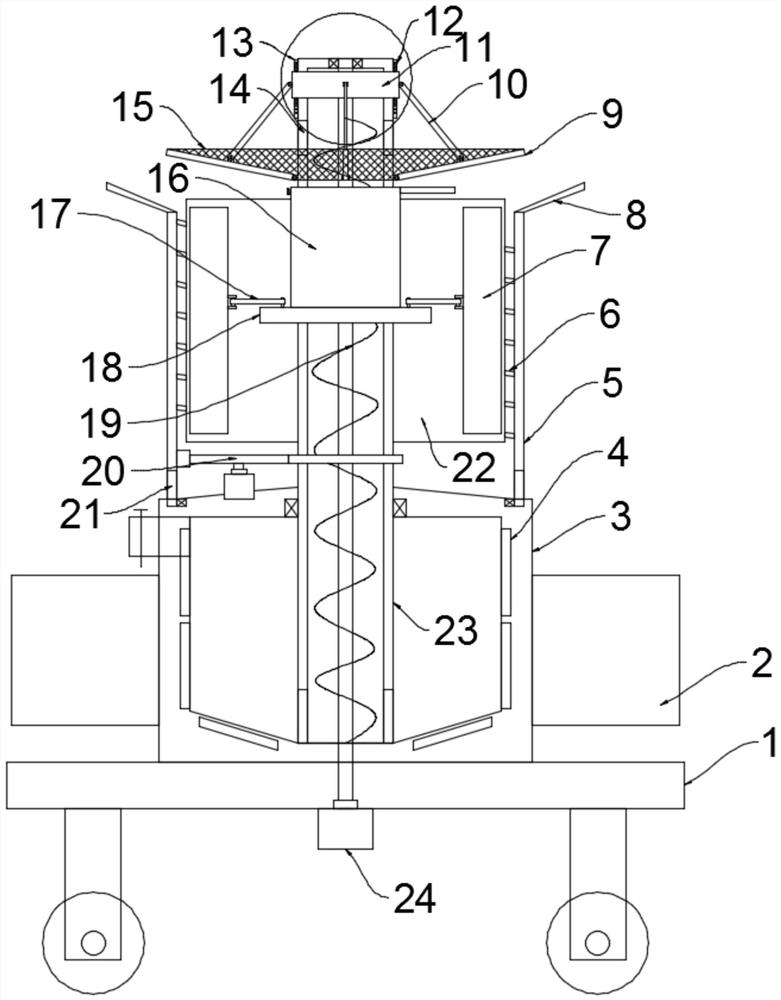

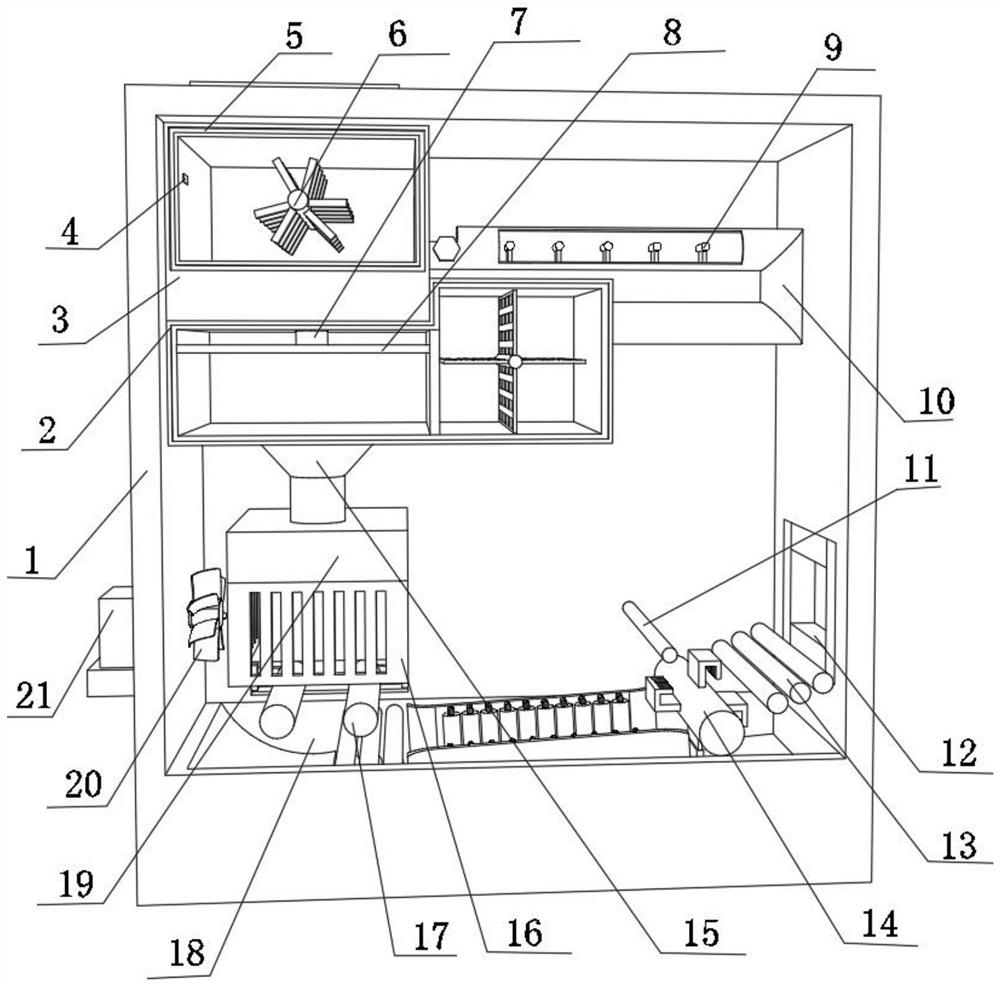

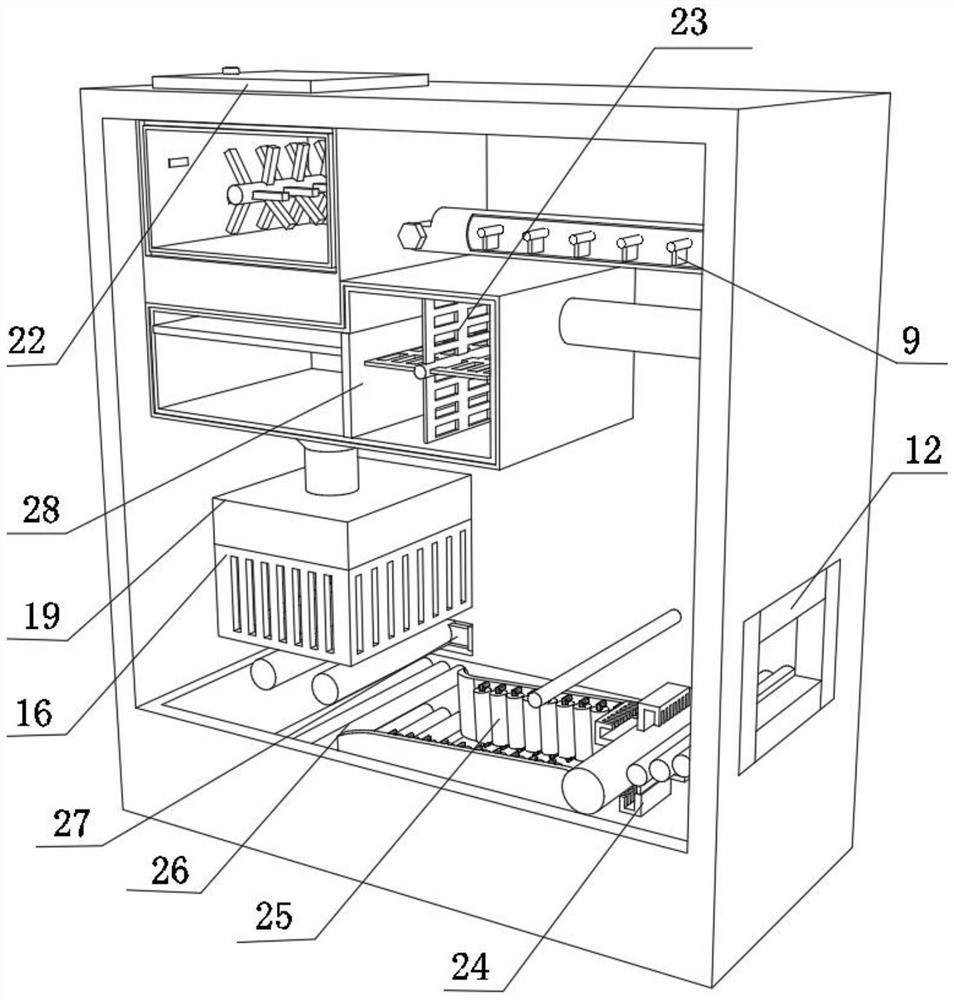

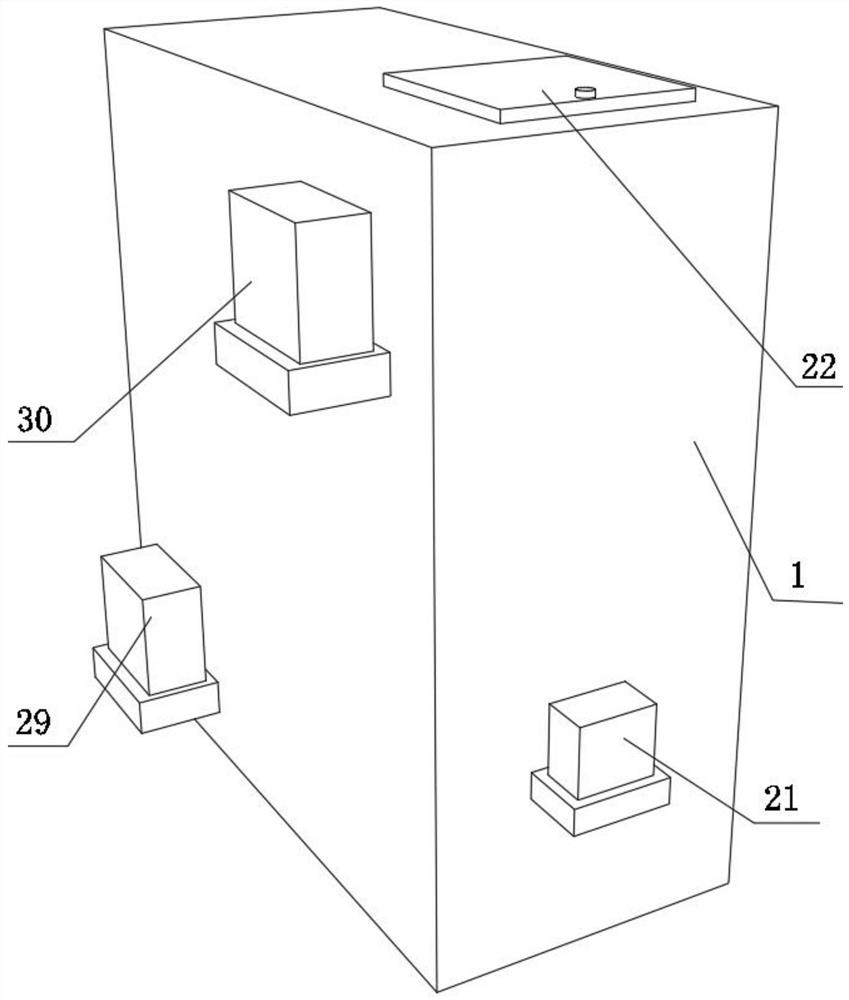

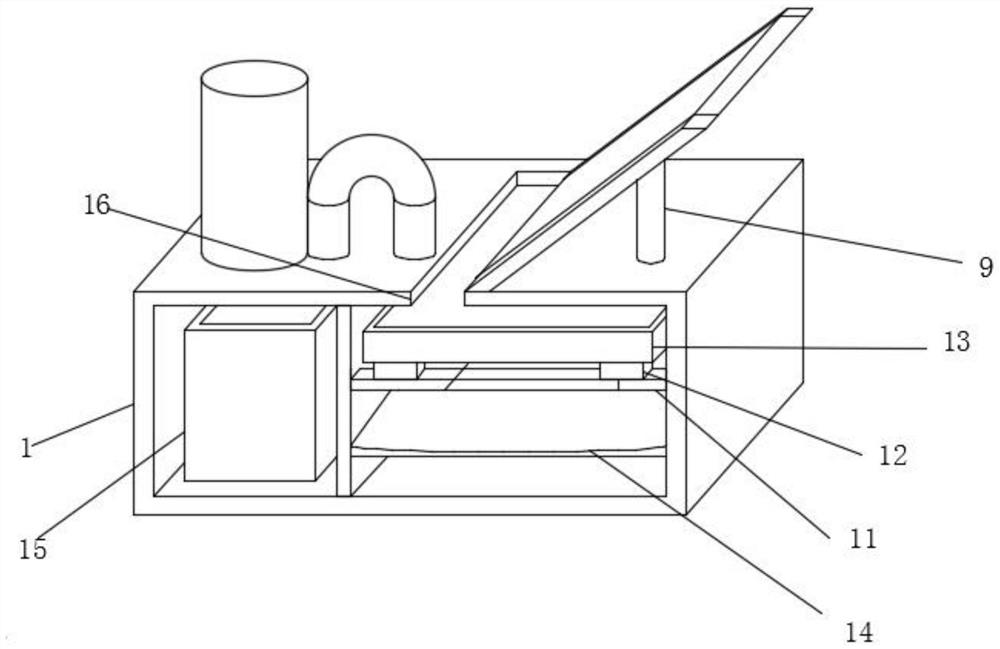

Waste lithium ion battery recycling device and method with flue gas purification function

PendingCN114739120AImprove drying efficiencyExpand the mixing rangeTransportation and packagingRotary stirring mixersElectric machineryElectrical battery

The invention discloses a waste lithium ion battery recovery processing device with a flue gas purification function, the waste lithium ion battery recovery processing device comprises a box body and a drying unit, a drying cavity is arranged in the box body, the drying unit comprises an air heater and a stirring assembly, and the stirring assembly comprises a stirring shaft, a stirring rod, a first driving mechanism for driving the stirring shaft to rotate and a movable plate; a filtering cavity is formed in the position, located on one side of the drying cavity, in the box body, a filtering unit is arranged in the filtering cavity, the filtering unit comprises a filtering barrel, a supporting plate, a second driving mechanism for driving the filtering barrel to rotate, a swing rod, a rotating disc and a second electric push rod, a drying unit is arranged, the stirring range is further expanded, and the drying efficiency is improved; the filtering unit is arranged, intermittent discharging is achieved, a second motor is driven to move through a second electric push rod, the second motor drives a rotary disc to move, the relative position of the rotary disc and a swing rod is adjusted, then the swing amplitude of the swing rod is adjusted, the effect of adjusting the inclination angle of a filtering cylinder is achieved, the discharging speed is adjusted, and different use requirements are met.

Owner:湖南金凯循环科技有限公司

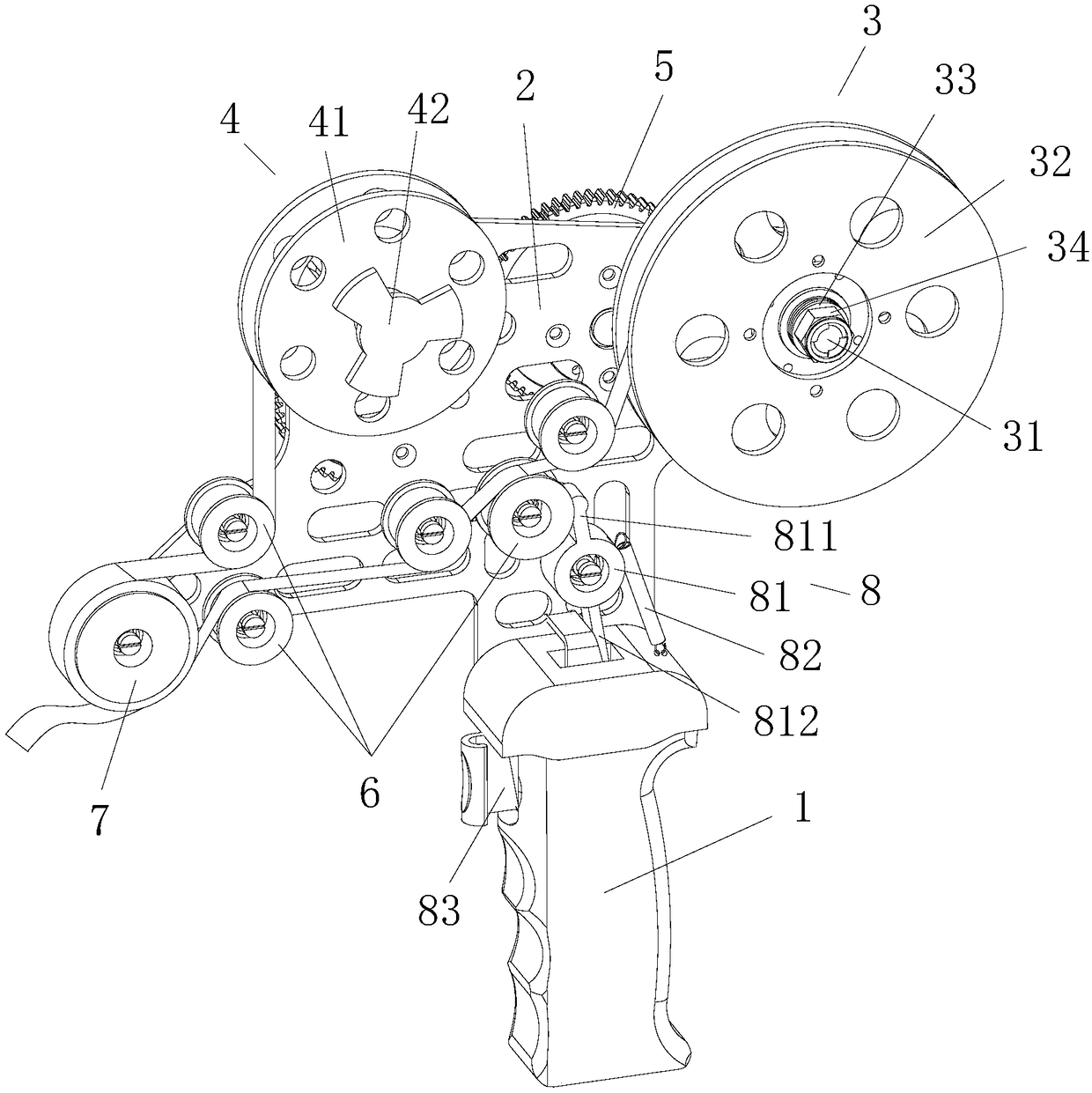

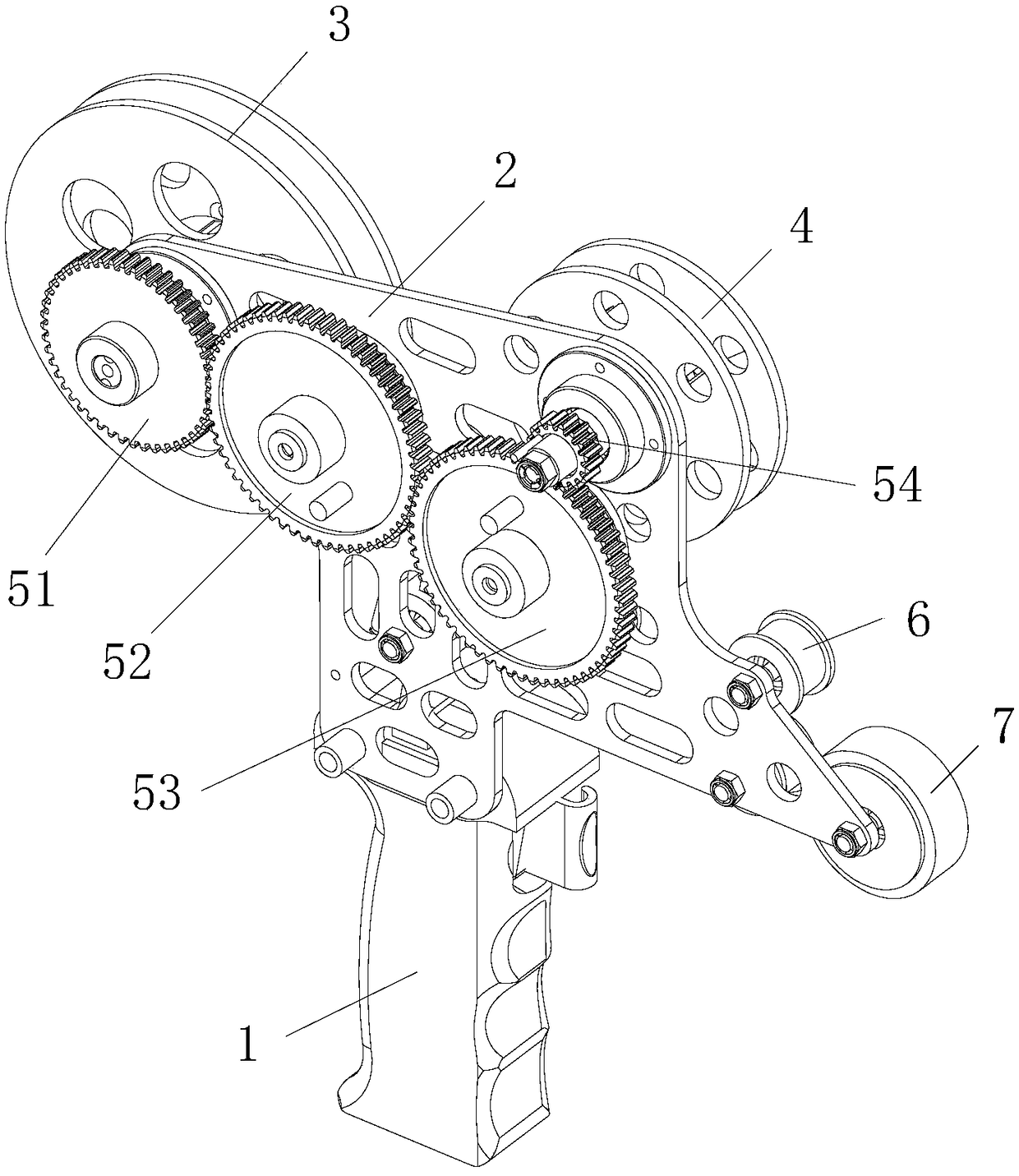

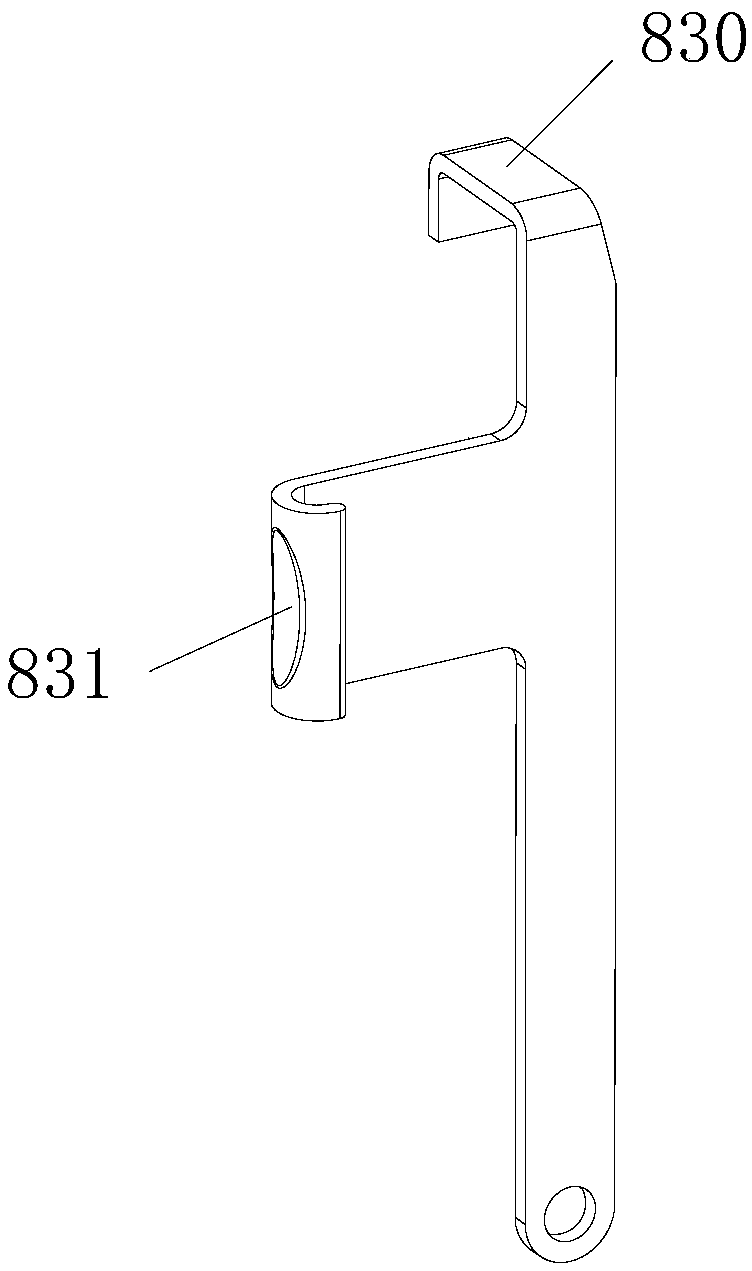

Hand-held adhesive tape pasting machine

The invention discloses a hand-held adhesive tape pasting machine. The hand-held adhesive tape pasting machine comprises a handle, a gear plate, an unwinding assembly, a winding assembly, a gear transmission assembly, guide rollers, an anti-adhesion pressure wheel and a locking assembly; the gear plate is installed at the upper end of the handle; the unwinding assembly and the winding assembly areinstalled on the upper portion of the gear plate in an inserting mode and are in transmission connection through the gear transmission assembly; the guide rollers and the anti-adhesion pressure wheelare installed on the gear plate in an inserting mode; adhesive tape on the unwinding assembly sequentially passes through the guide rollers and the anti-adhesion pressure wheel, and backing paper ofthe adhesive tape is wound around the winding assembly after passing one of the guide rollers; and the gear plate is further provided with the locking assembly. In this way, the hand-held adhesive tape pasting machine is compact in structure, capable of achieving gear transmission and stable in operation, the unwinding speed can be adjusted, the winding speed is higher than the unwinding speed, and slipping is prevented.

Owner:昆山三智达自动化设备科技有限公司

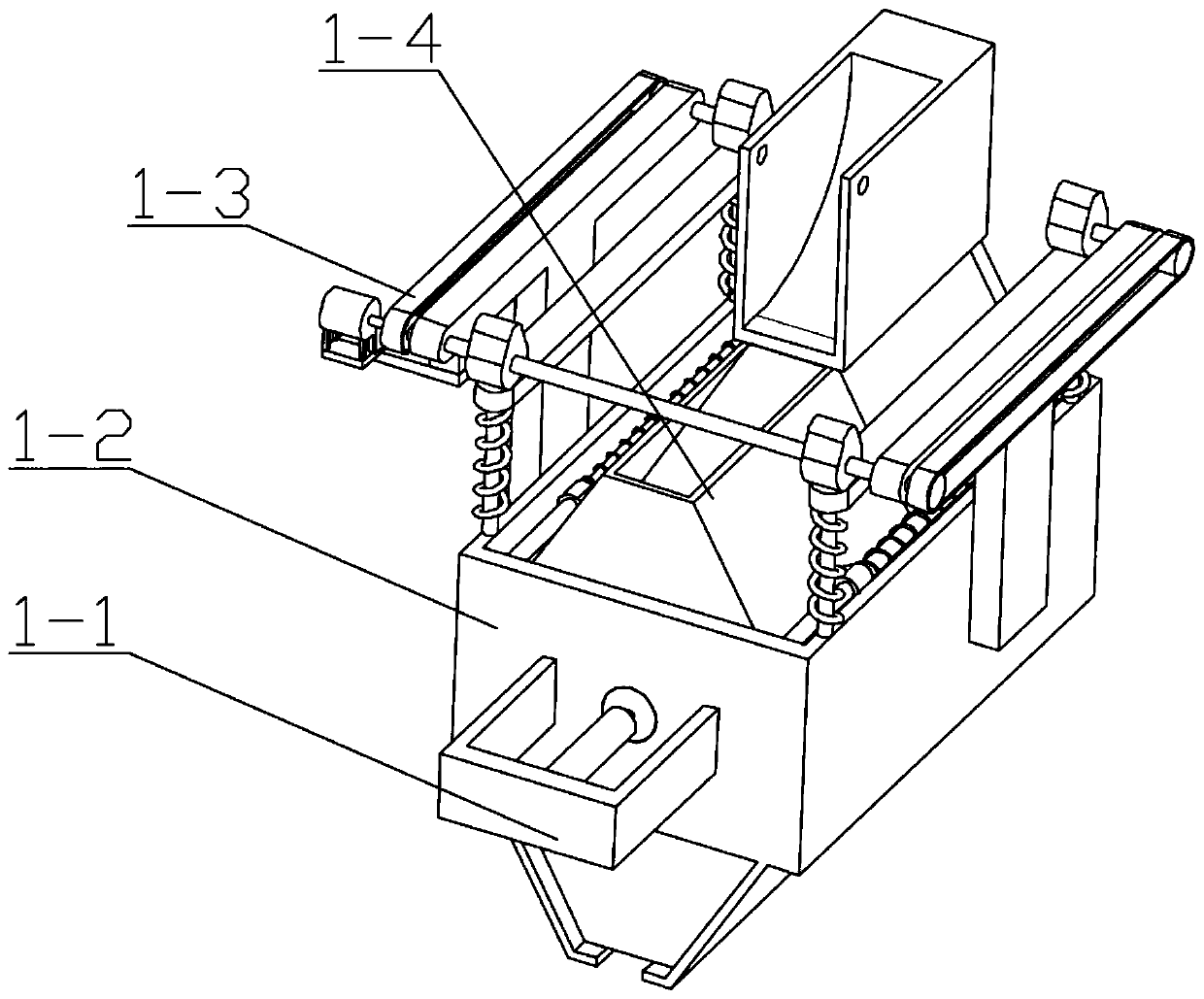

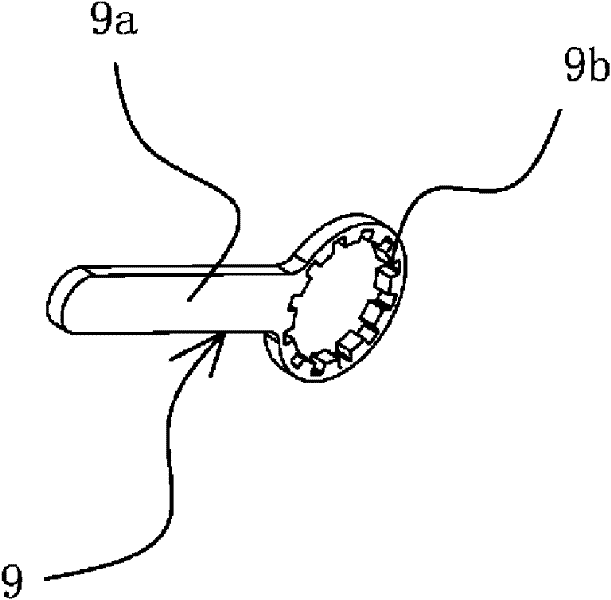

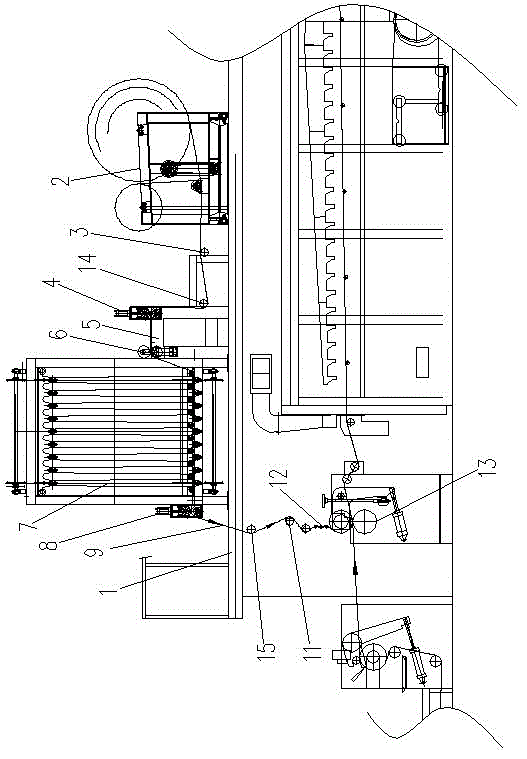

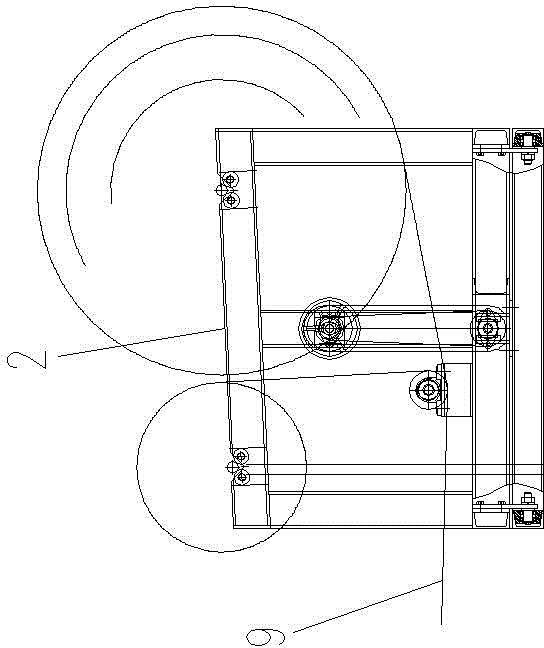

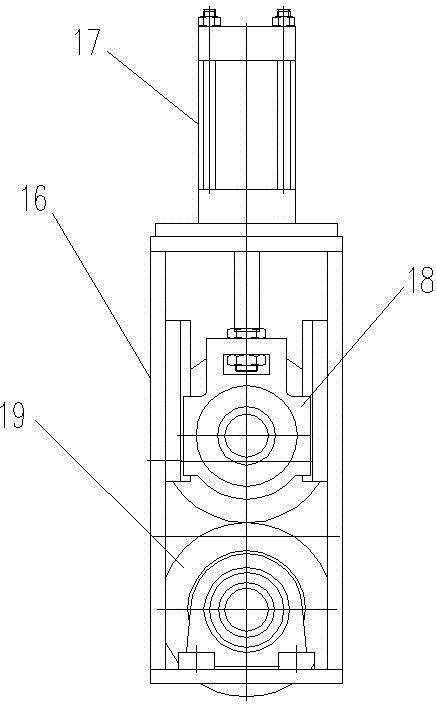

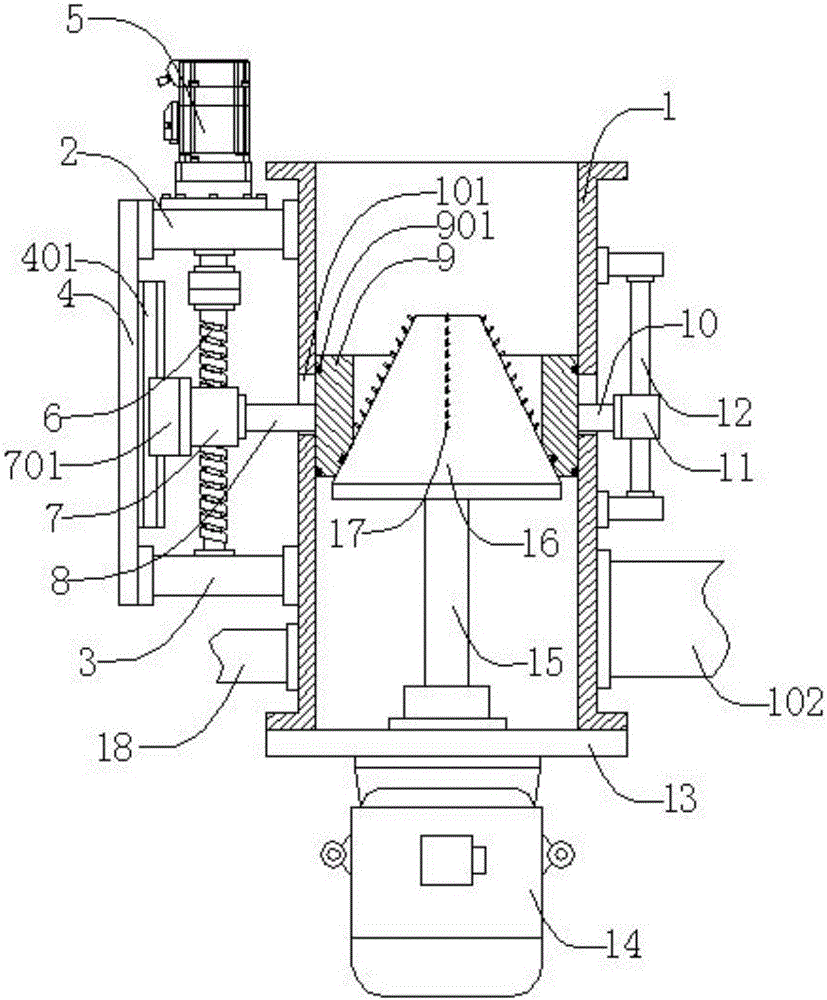

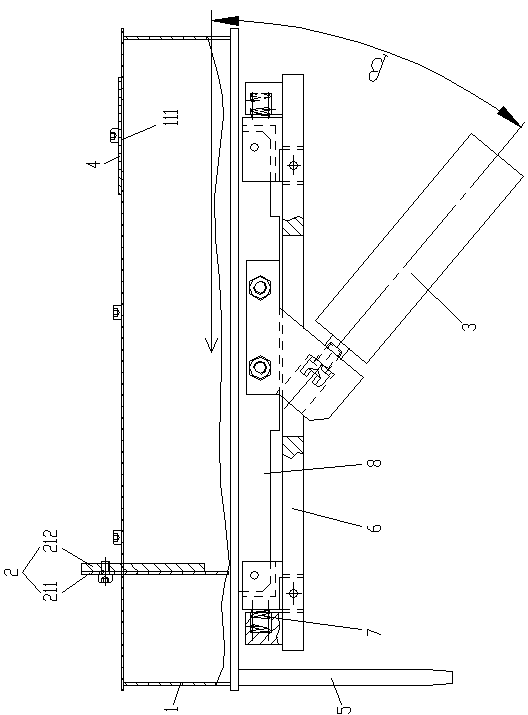

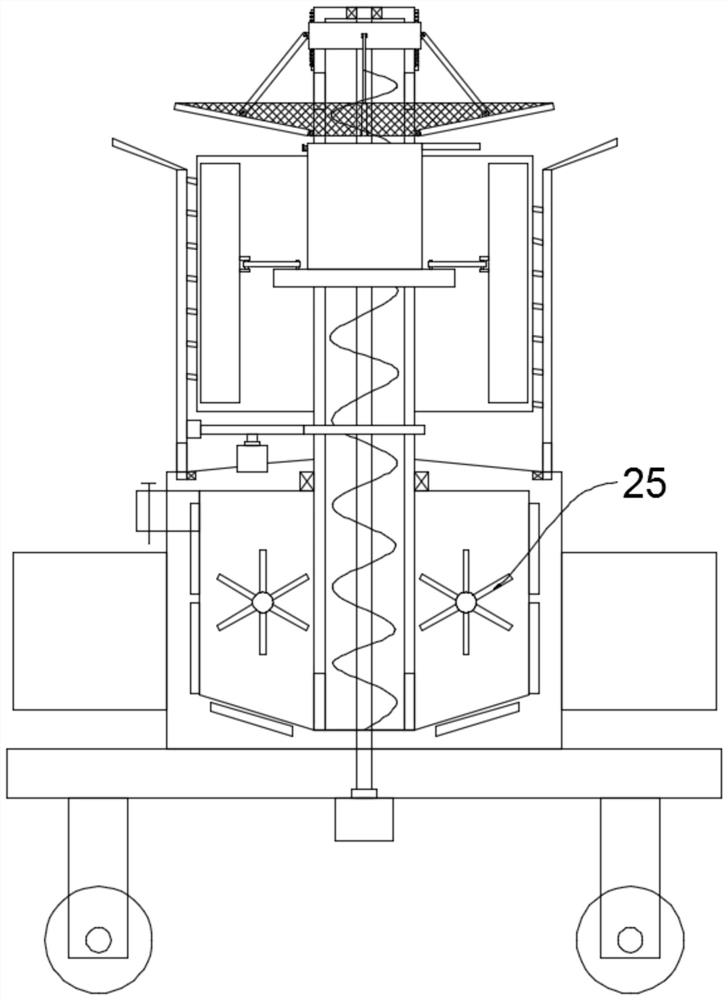

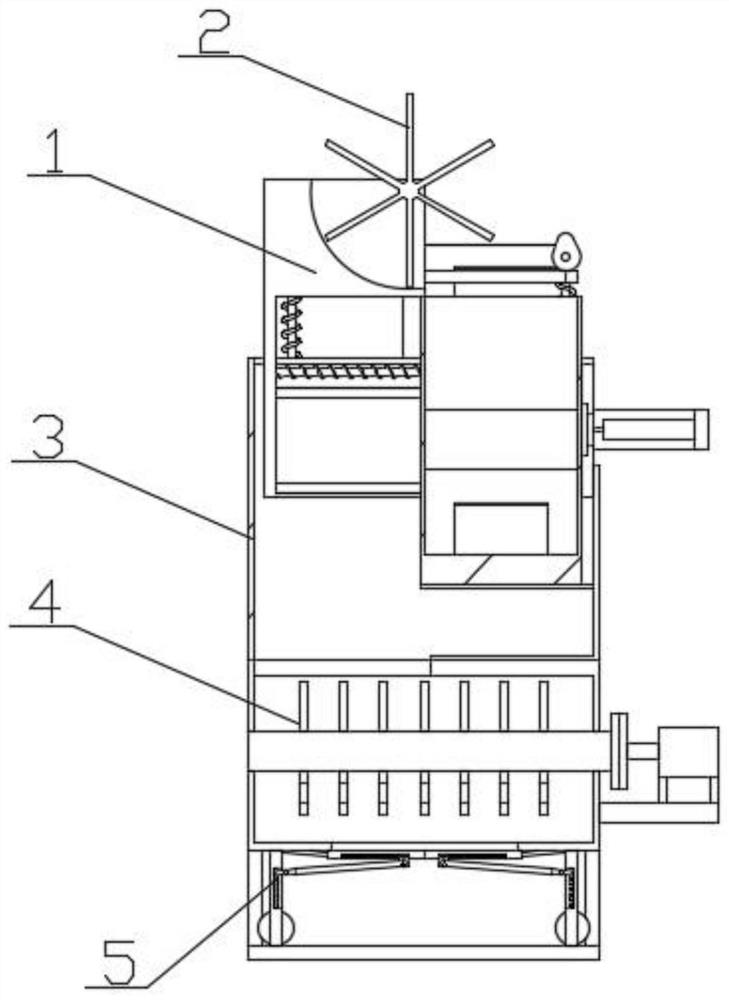

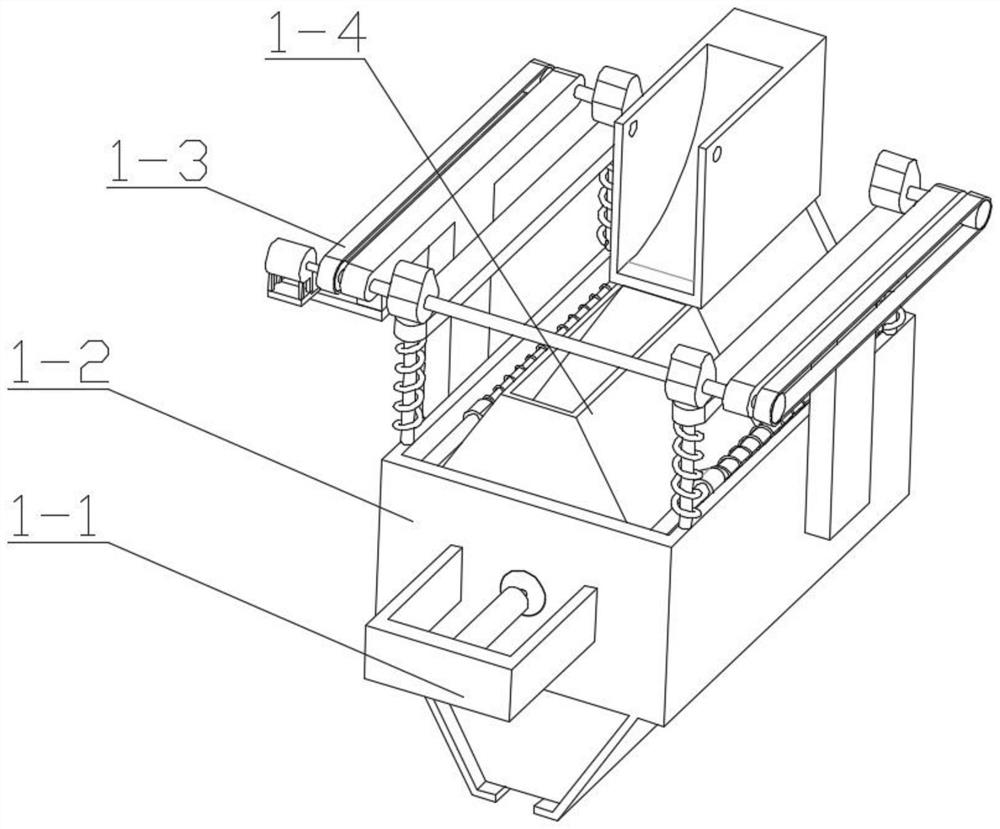

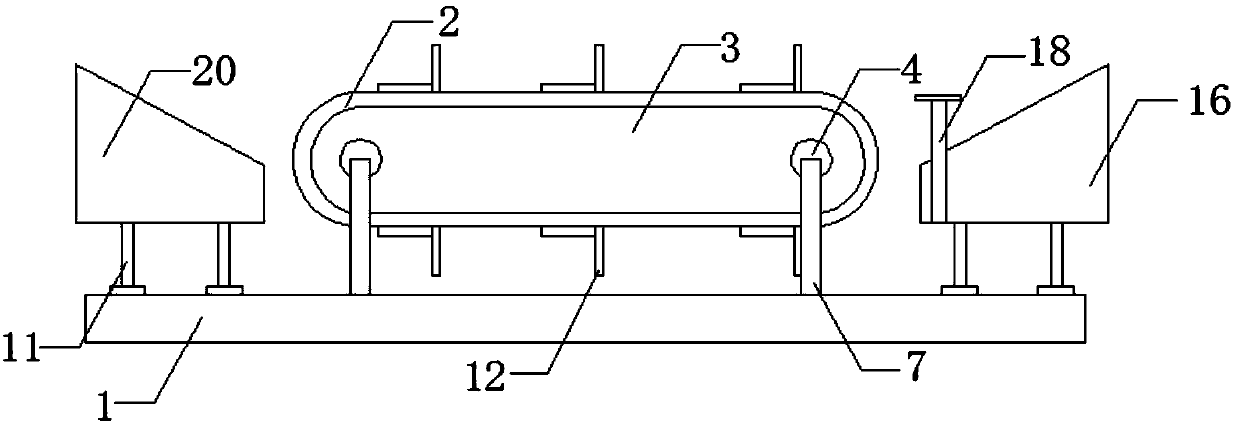

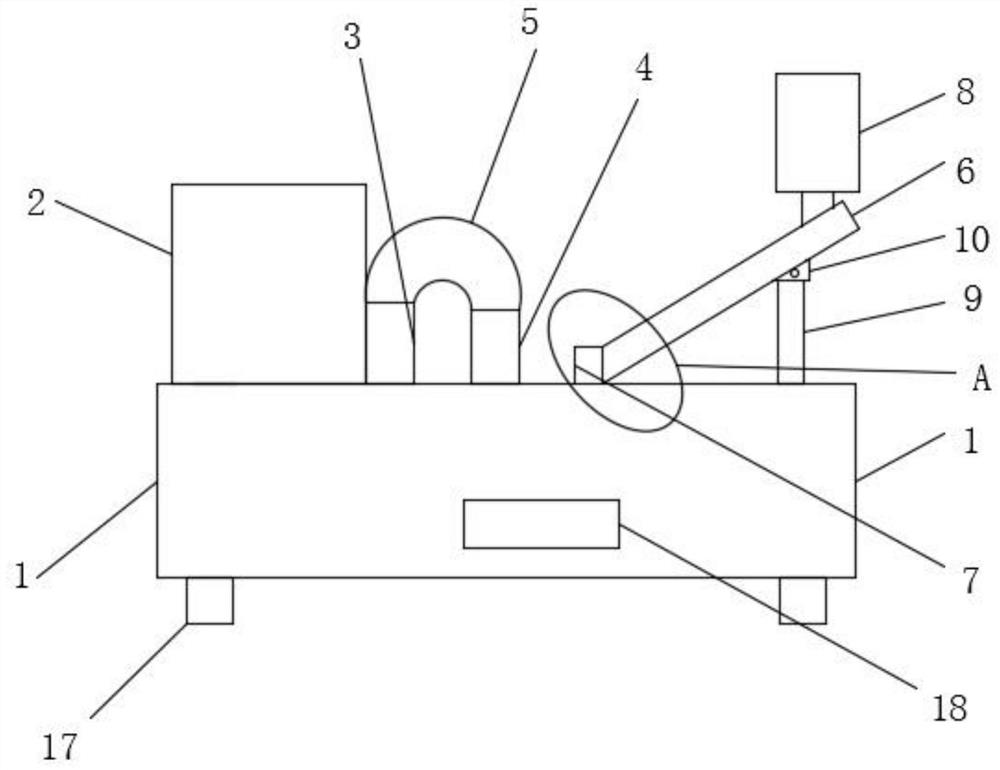

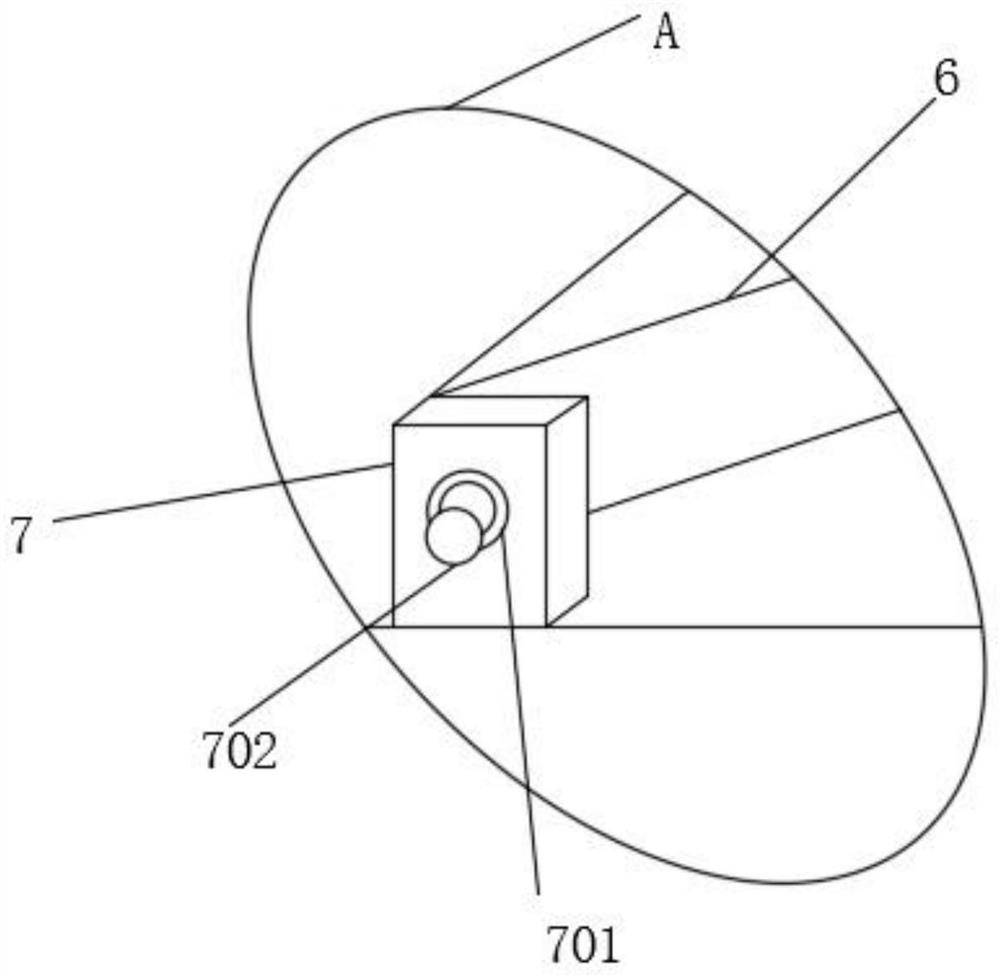

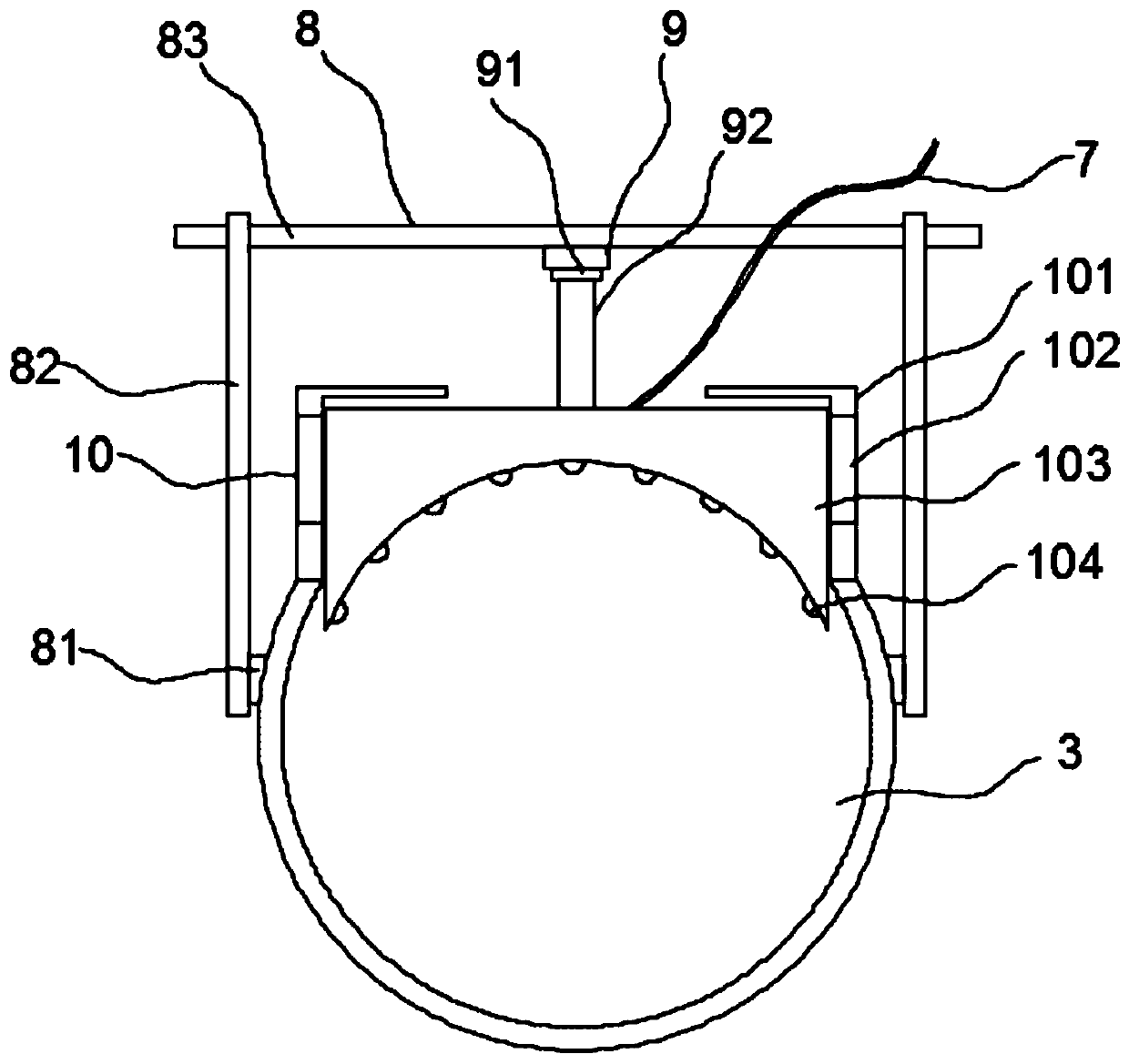

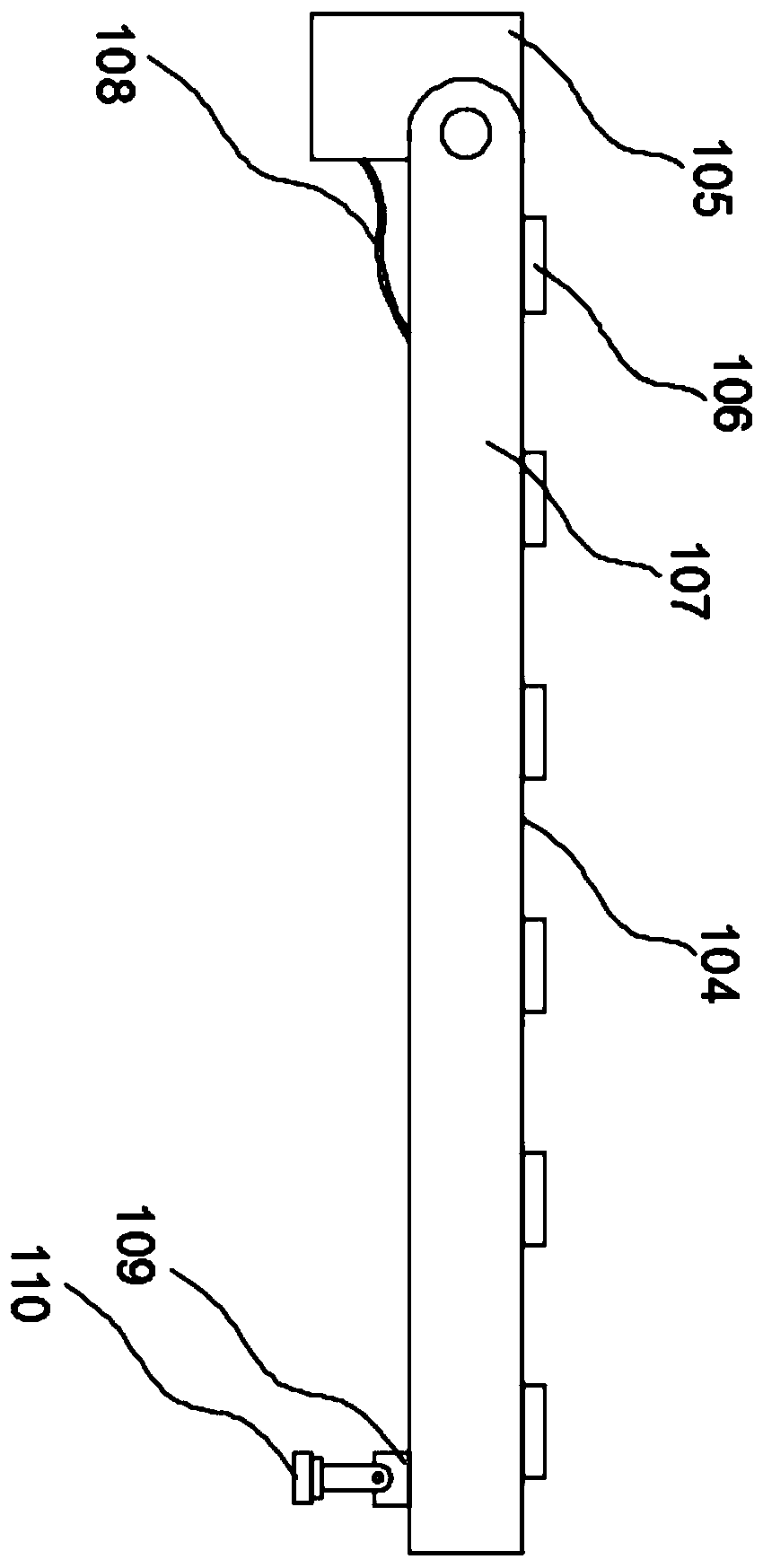

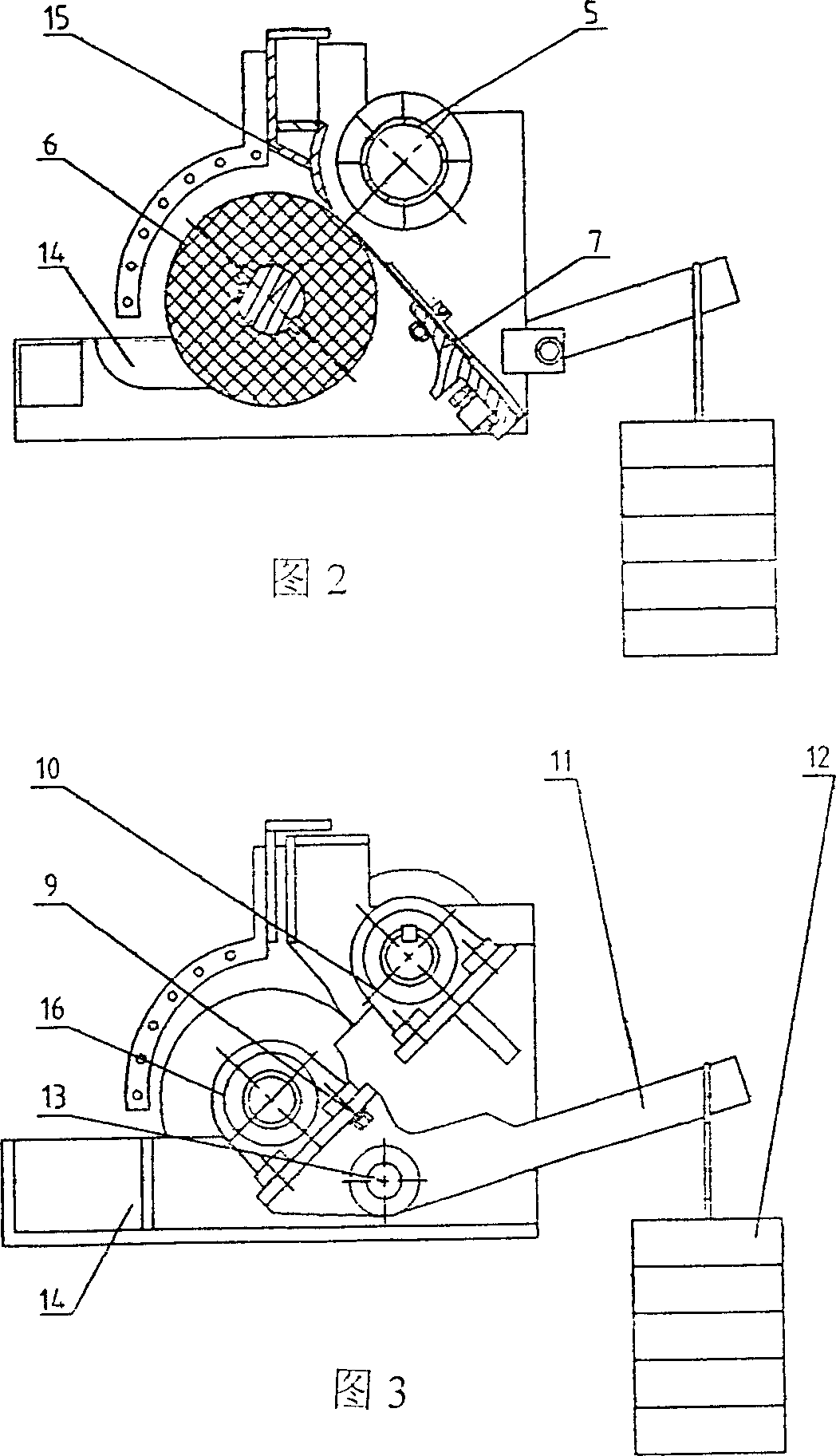

Needle tube recycling and processing device

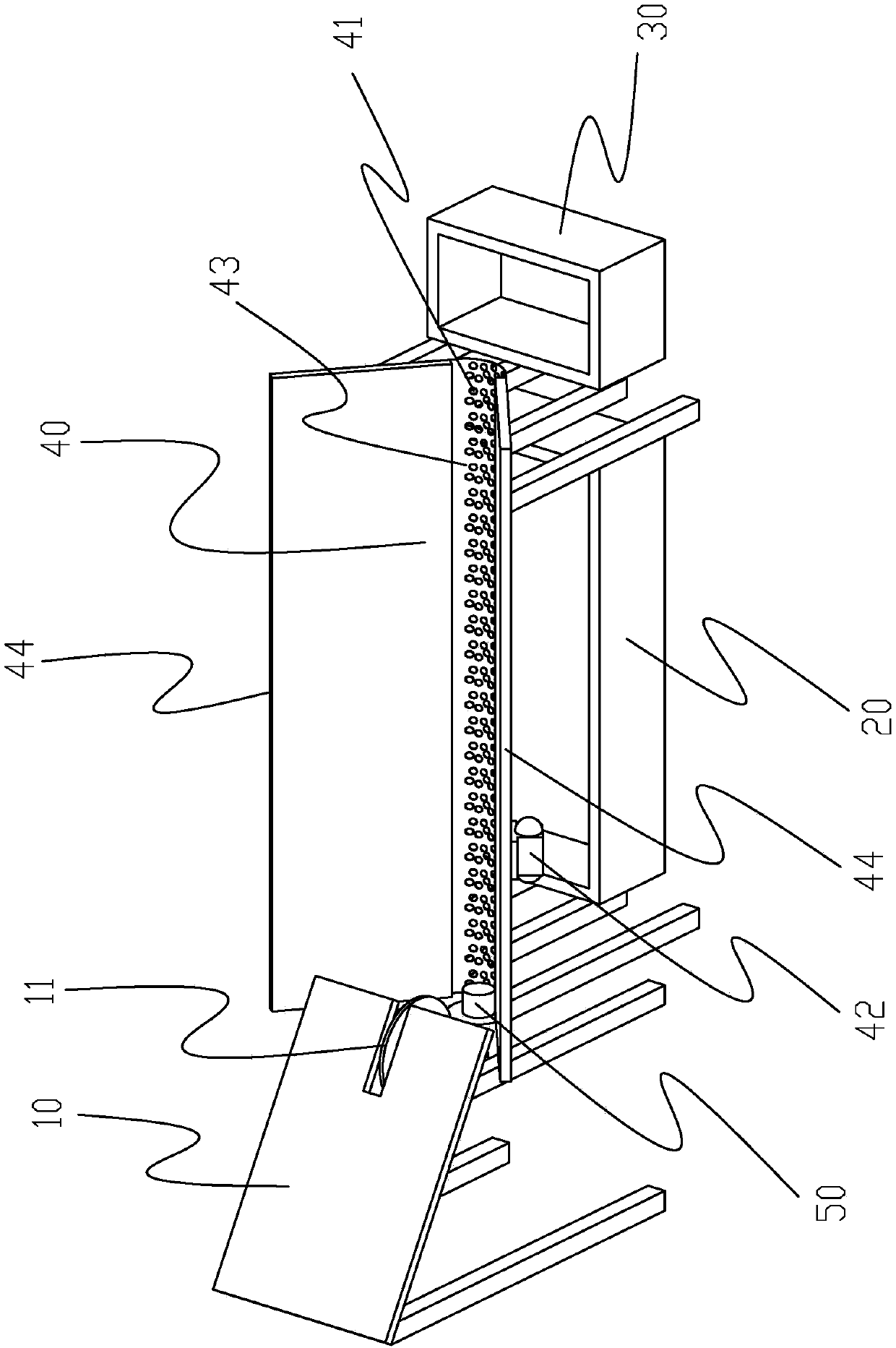

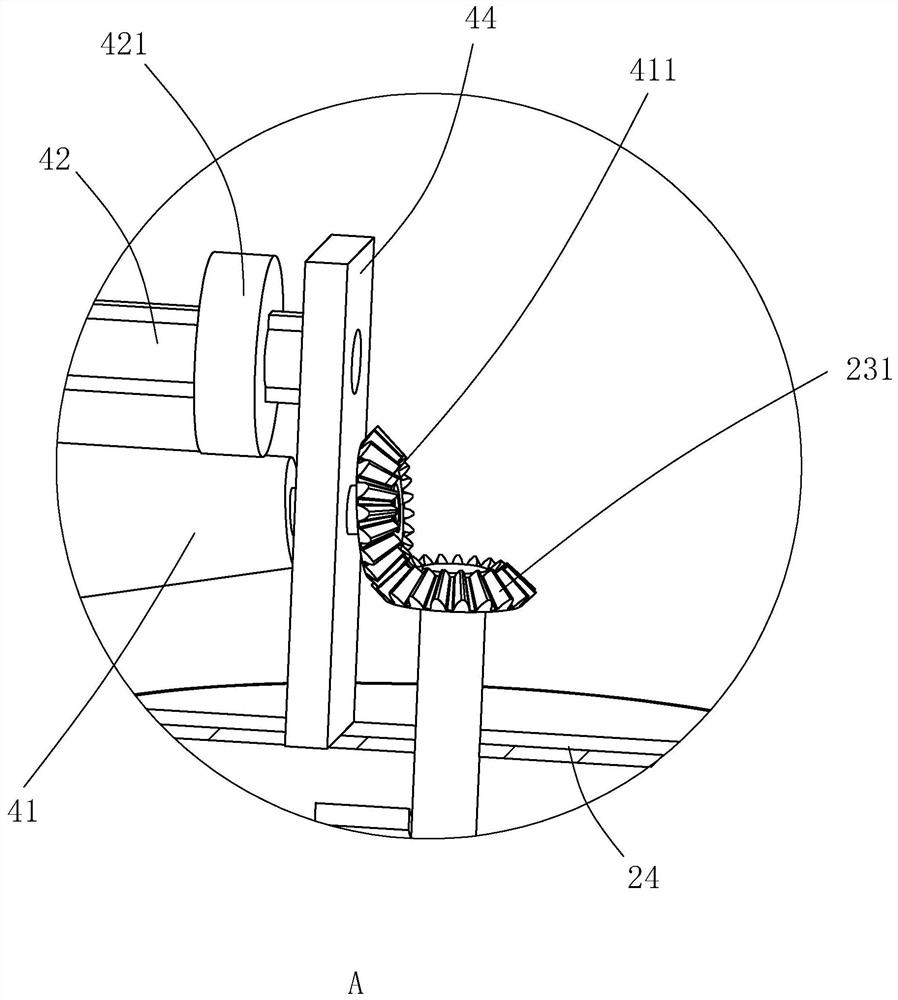

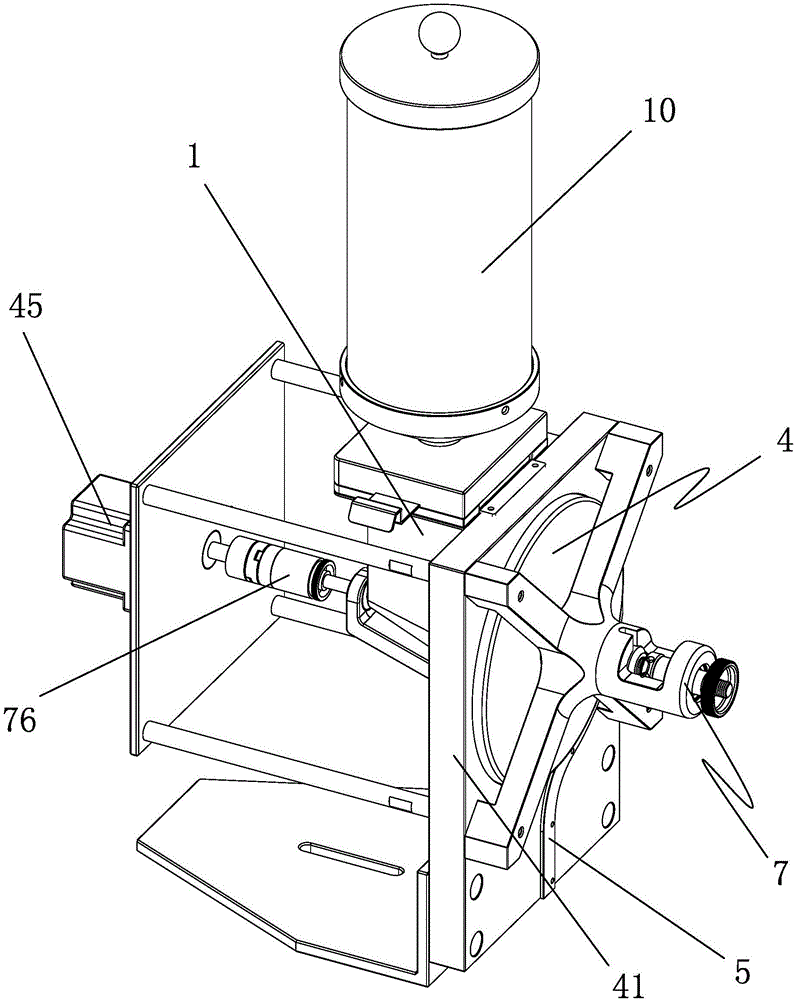

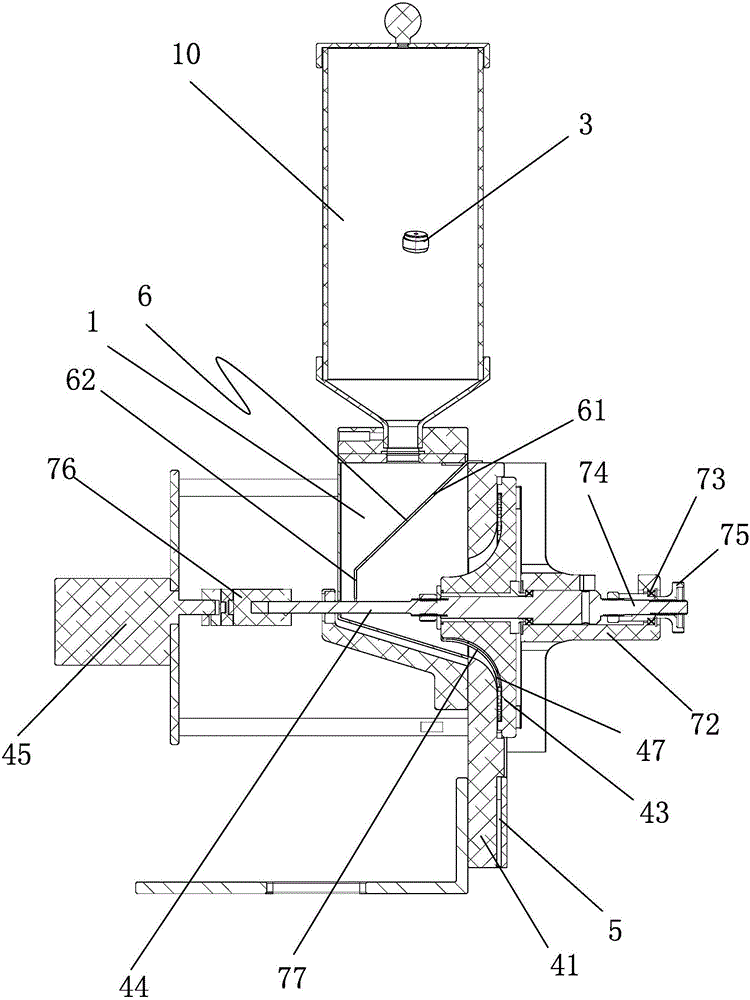

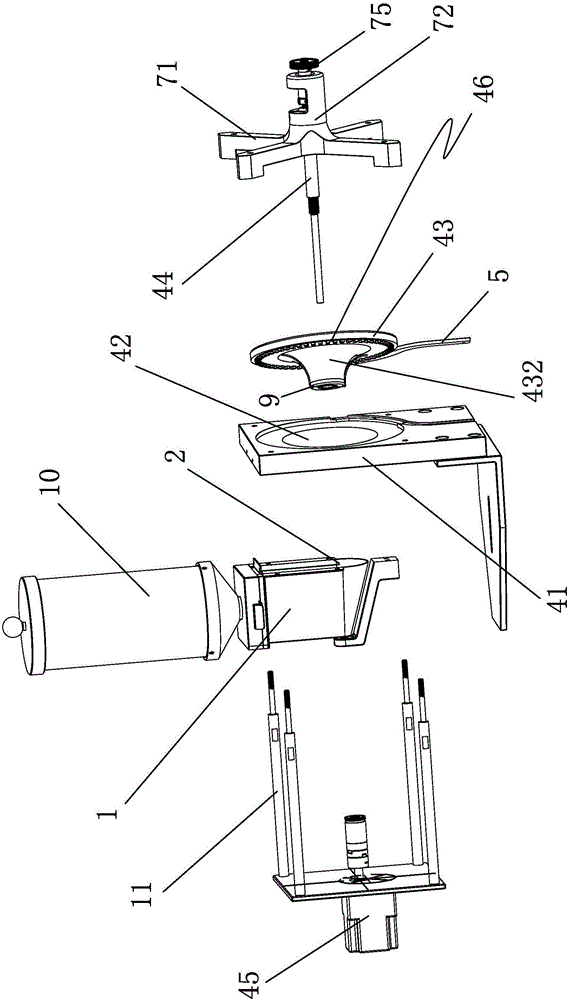

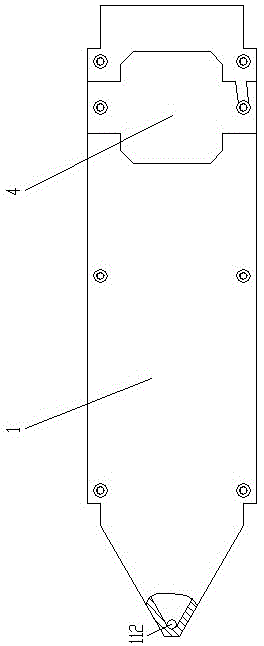

ActiveCN110694744ASmooth feedingAdjust the feeding speedIntravenous devicesGrain treatmentsProcess engineeringStructural engineering

The invention relates to a recycling processing device, in particular to a needle tube recycling and processing device. The device comprises a hopper mechanism, a stirring and feeding mechanism, a shell mechanism, a crushing mechanism and an opening and closing door mechanism so that the device can ensure smooth feeding, the device can ensure that needle tubes can not leak out while feeding, the device can adjust the feeding speed, the device can prevent blockage, the device can crush the needle tubes, the device can automatically control discharging, the hopper mechanism is connected with thestirring and feeding mechanism, the hopper mechanism is connected with the shell mechanism, the shell mechanism is connected with the crushing mechanism, and the crushing mechanism is connected withthe opening and closing door mechanism.

Owner:高建华

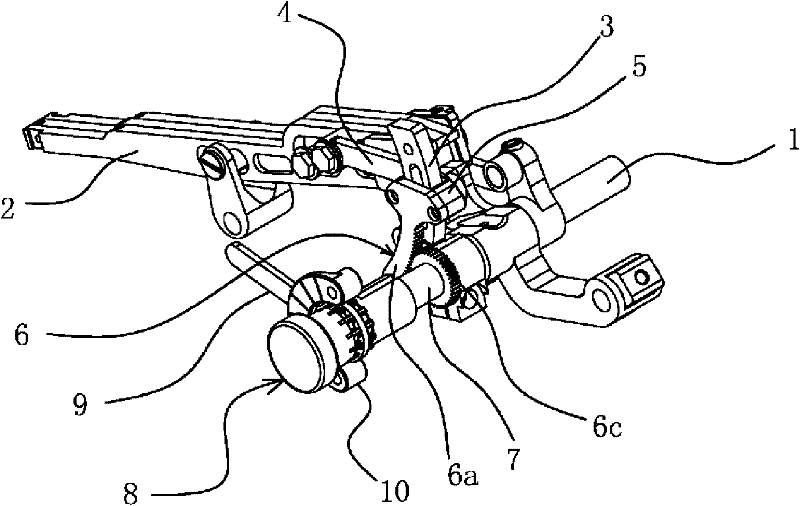

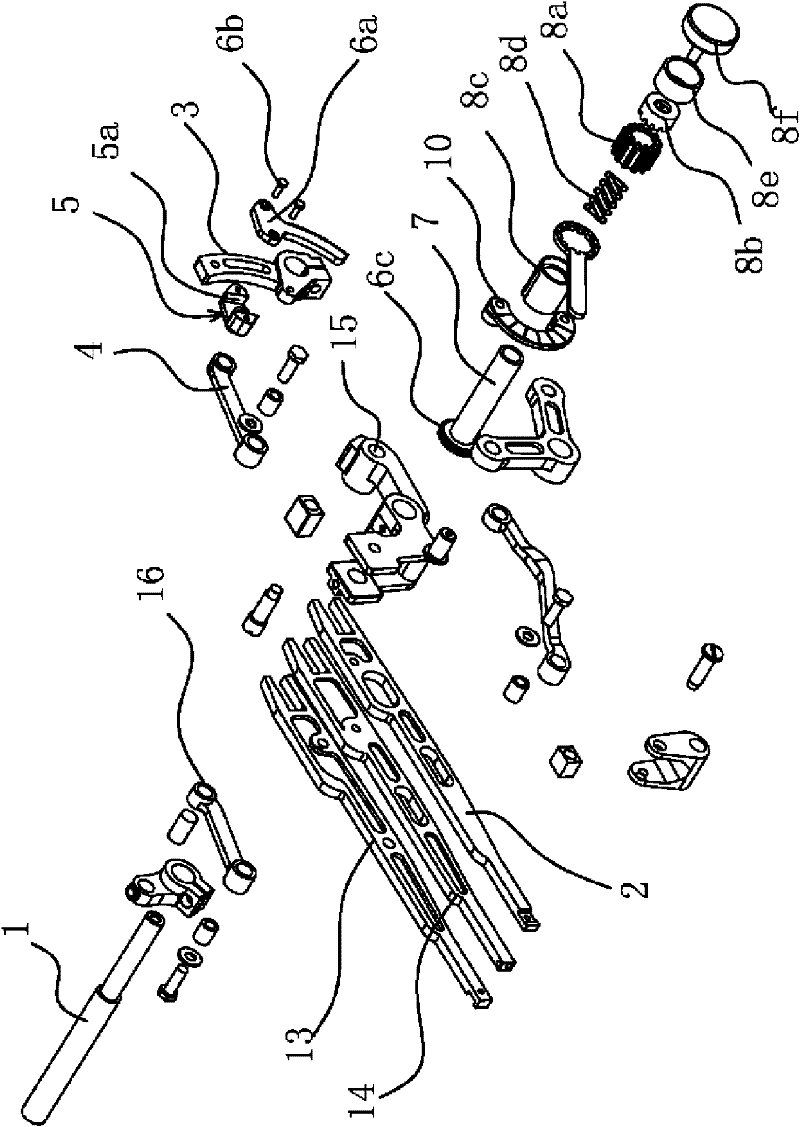

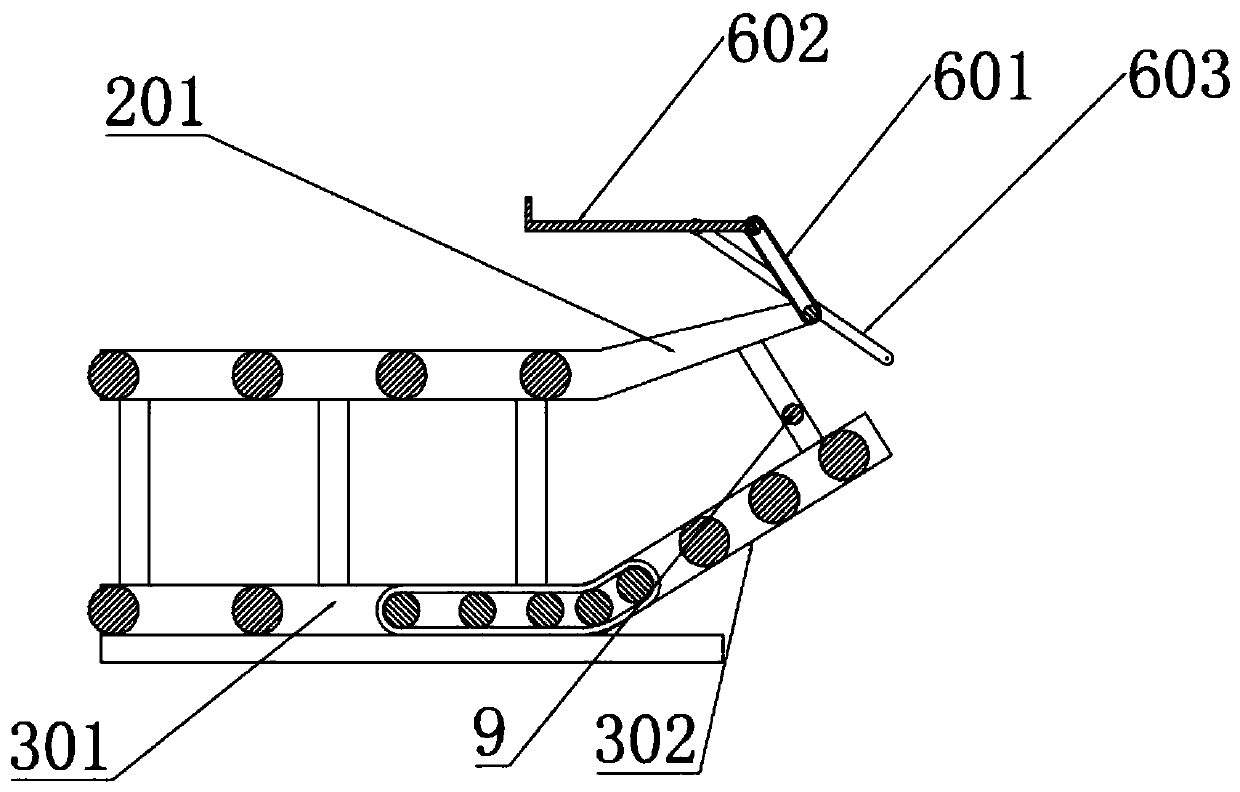

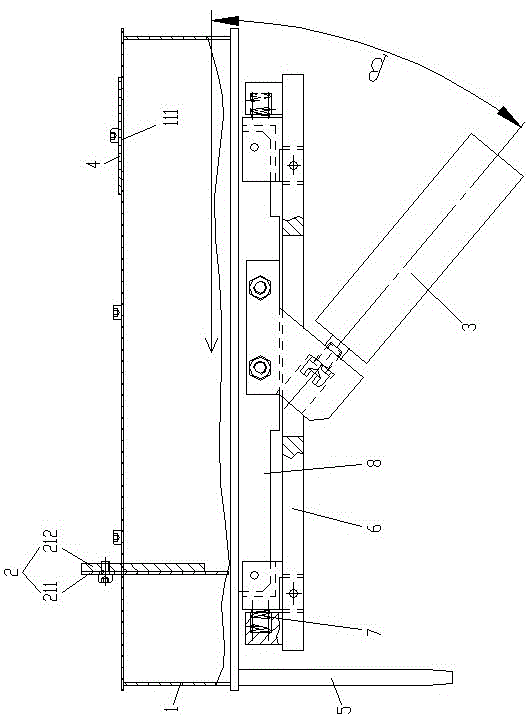

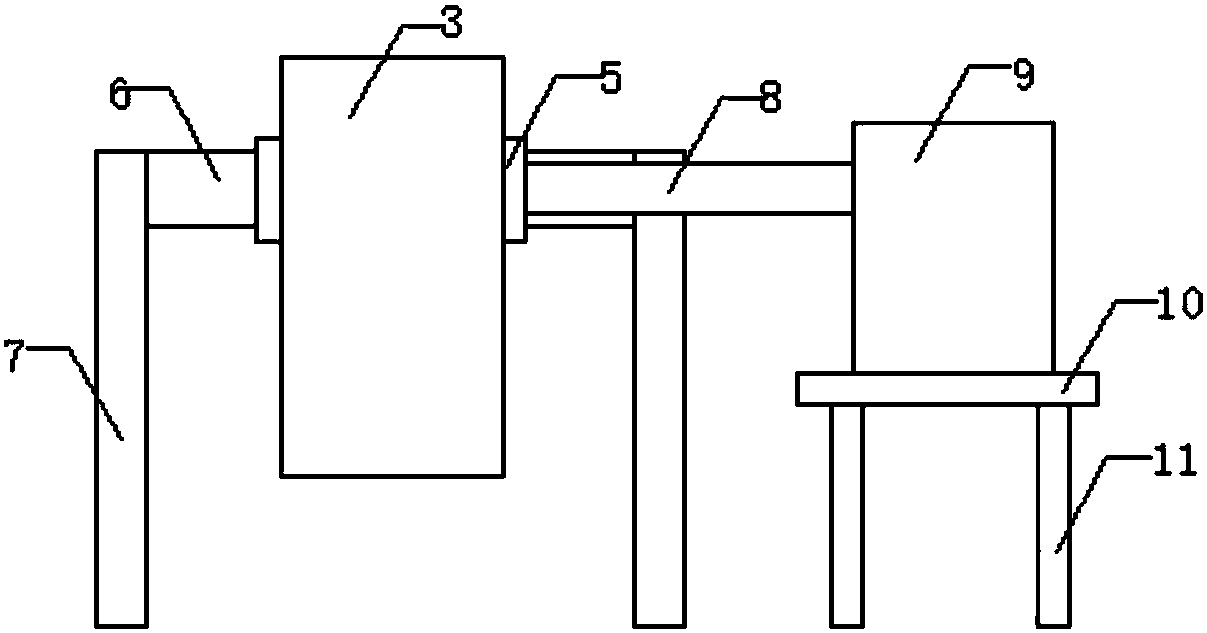

Adjusting device for differential mechanism of straight flat seaming machine

ActiveCN101649529BAdjust the feeding speedSimple structureWork-feeding meansControl theoryCrankshaft

The invention provides an adjusting device for a differential mechanism of a straight flat seaming machine, belonging to the field of mechanical technology. The invention solves the technical problem that an adjusting device of the prior differential mechanism has complicated structure, high cost, inconvenient use and the like. In the adjusting device for the differential mechanism of the straight flat seaming machine, a differential crankshaft is fixed on a feeding shaft, a linkage rod is arranged between the differential crankshaft and a differential tooth frame sheet, and one end of the linkage rod is articulated with the differential tooth frame sheet. The adjusting device is arranged on the other end of the linkage rod and the differential crankshaft, comprising a slide block capableof sliding along the differential crankshaft, the other end of the linkage rod is articulated with the slide block, the slide block is provided with a positioning structure capable of sliding along the differential crankshaft when needing the adjustment, and after the adjustment is finished, the slide block is fixed on the differential crankshaft to be stationary. The adjusting device can effectively adjust the feeding speed of the differential mechanism and has simple structure and reasonable design. The differential crankshaft is provided with a scale board that can achieve measurable adjustment.

Owner:浙江振盛缝制机械有限公司

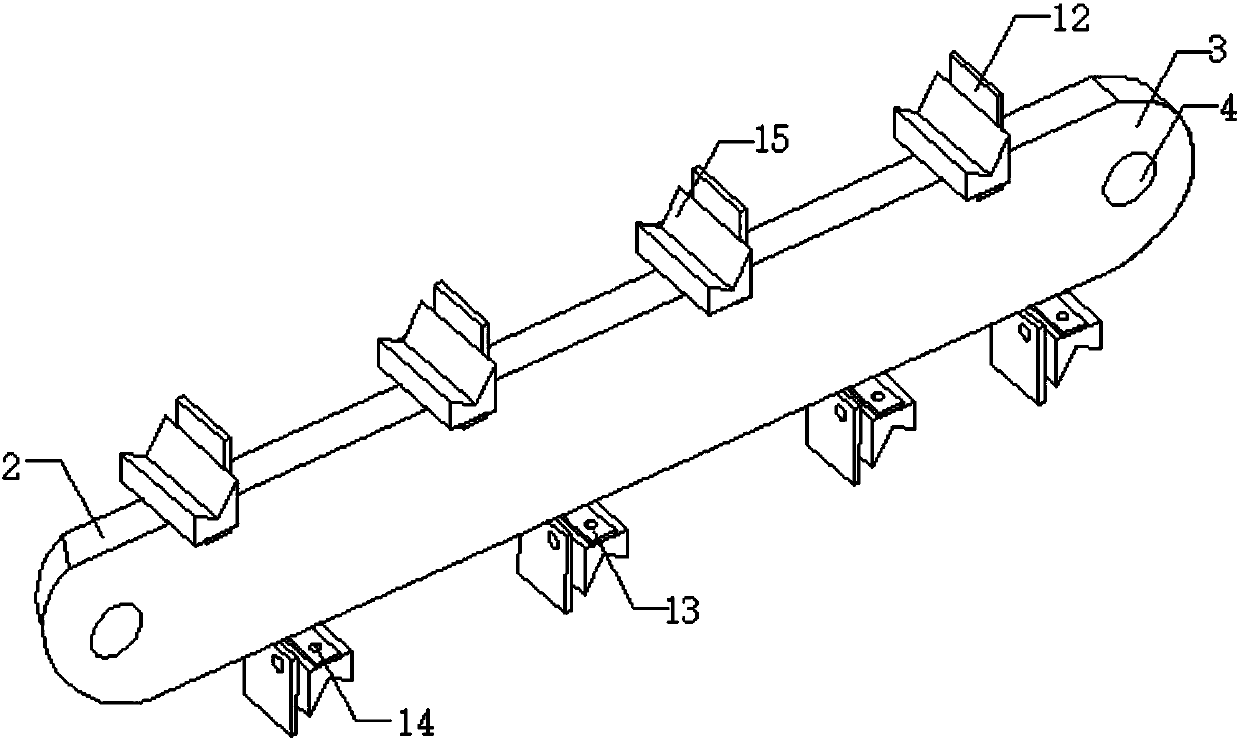

Automatic fabric placing and laminating device of artificial leather and PVC (polyvinyl chloride) floor

ActiveCN102632021BSimple structureAchieve fitLiquid surface applicatorsCoatingsPolyvinyl chlorideEconomic benefits

The invention discloses an automatic fabric placing and laminating device of artificial leather and a PVC (polyvinyl chloride) floor. The automatic fabric placing and laminating device comprises an operation platform, wherein the operation platform is sequentially provided with a dual-station unwinding mechanism, a fabric supporting roller, a first traction device, a fabric receiving platform, a pressing device and a fabric storage device along the movement direction of a base fabric; a second traction device is arranged on the fabric outlet side of the fabric storage device; a driving spiral fabric unfolding device, a triple-finger edge spreader and a laminating mechanism are orderly arranged under the operation platform along the movement direction of the base fabric, and the base fabric is sent out by the second traction device, and enters the laminating mechanism after being unfolded by the driving spiral fabric unfolding device and sent out by the triple-finger edge spreader. By adopting the automatic placing and laminating device disclosed by the invention, automatic fabric placing and laminating can be achieved, the automatic degree of production is improved, the labour cost is saved, and the economic benefit is particularly prominent in the environment of labour tension and rising labour cost at present. According to the automatic fabric placing and laminating device, quality fluctuation caused by manual operation in the past also can be avoided, and the product quality can be stabilized and improved.

Owner:XINXIANG DINGXIN MACHINERY

Deep-frying device for food processing

InactiveCN112056333AEvenly heatedFull and even contactTransportation and packagingBaking ovenElectric machineryEngineering

The invention discloses a deep-frying device for food processing, relates to the technical field of food processing, and mainly aims to solve the problems of insufficient and non-uniform heating of foods in an existing deep-frying device. The deep-frying device comprises a machine frame and a deep-frying unit, wherein the deep-frying unit comprises an oil barrel and a net barrel used for containing foods; the deep-frying device further comprises an agitating assembly, wherein the agitating assembly comprises a double-shaft motor, a first magnet, a second magnet, a turbulence rod, reciprocatingscrew rods, third magnets and fourth magnets; a stirring assembly used for stirring the foods is mounted on a cover body, and the stirring assembly comprises a first motor, a lifting auger, arc-shaped top covers and arc-shaped bottom rings and is provided with a frying unit; and when the double-shaft motor drives the reciprocating screw rods to rotate, the height position of each third magnet onthe corresponding reciprocating screw rod is continuously changed, so that the deflection range of the turbulence rod is changed, the agitating range is expanded, and the agitating efficiency is further improved; and the stirring assembly is arranged, through continuous circulation, movement of the foods is facilitated, food deposition or adhesion is avoided, and the deep-frying efficiency is improved.

Owner:吕瑞雪

Automatic unpacking device for urea bags

PendingCN108045680AEasy to operate and dredgeAvoid cloggingBags openingUnpacking by cuttingEngineeringMaterial storage

The invention discloses an automatic unpacking device for urea bags. The automatic unpacking device for urea bags comprises a bag guide plate, a material storage box, a bag storage box and a materialdropping groove. The two transverse ends of the material dropping groove are a feeding end and a bag outlet end separately. The bag guide plate is obliquely arranged above the feeding end of the material dropping groove. Urea bags can slide to the feeding end of the material dropping groove along the bag guide plate. The bag storage box is arranged below the bag outlet end of the material droppinggroove. A plurality of material dropping holes allowing passing of urea are formed in the bottom of the material dropping groove. The material storage box is arranged below the material dropping groove. The automatic unpacking device for urea bags further comprises a vibration motor which is arranged on the material dropping groove and used for driving vibration of the material dropping groove, and a cutter. The cutting direction of the cutter is transverse. The cutter is arranged on the bag guide plate and upwards extends out of the upper surface of the bag guide plate. The automatic unpacking device for urea bags also comprises a bag pushing rod arranged at the feeding end of the material dropping groove and a telescopic motor or air cylinder used for driving the bag pushing rod to transversely push urea bags from the feeding end of the material dropping groove to the discharging end. The automatic unpacking device for urea bags has the advantage of automatic unpacking.

Owner:HUAQIAO UNIVERSITY

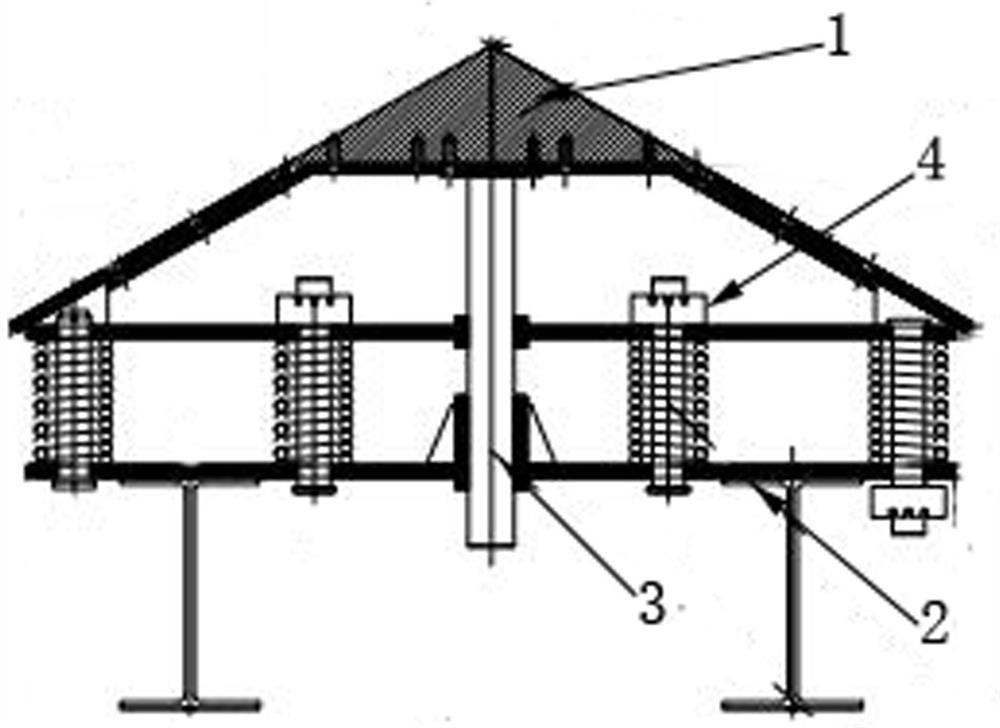

Gravel roadbed construction equipment

InactiveCN112323579AImprove work efficiencyShock frequency reducedRoads maintainenceReciprocating motionArchitectural engineering

The invention relates to the technical field of pavement construction, in particular to gravel roadbed construction equipment which comprises a machine body, a hopper arranged on the machine body andused for containing macadam and a plurality of wheels rotationally arranged on the machine body, a discharging opening is formed in the bottom of the hopper, and the discharging opening communicates with a plurality of discharging pipes. The machine body is provided with a pressing plate used for compacting gravels, and the machine body is provided with a driving assembly used for driving the pressing plate to do reciprocating motion in the direction perpendicular to the road surface. The construction equipment has the effect of improving the construction efficiency.

Owner:广东宏骏建筑工程有限公司

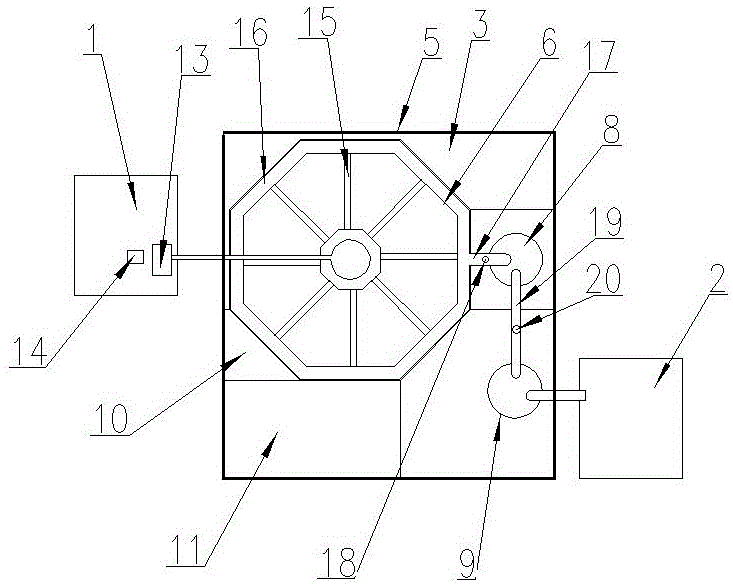

Cloud point feeding device

InactiveCN106141607ASimple structureSmooth supplyMetal working apparatusEngineeringMechanical engineering

The invention discloses a fog point feeding device, which is characterized in that: it comprises a feeding hopper, a connecting slot hole communicating with the inner cavity of the feeding hopper is arranged on one side of the feeding hopper, and a connecting slot hole is arranged in the connecting slot hole. There is a material-distributing and discharging turntable assembly that enables the fog points to enter and output in a predetermined direction, and a discharge rail that communicates with the material-distributing and discharging turntable assembly is connected to the hopper. The purpose of the present invention is to overcome the deficiencies in the prior art, and to provide a fog point feeding device with a simple structure and capable of directional feeding of fog points.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

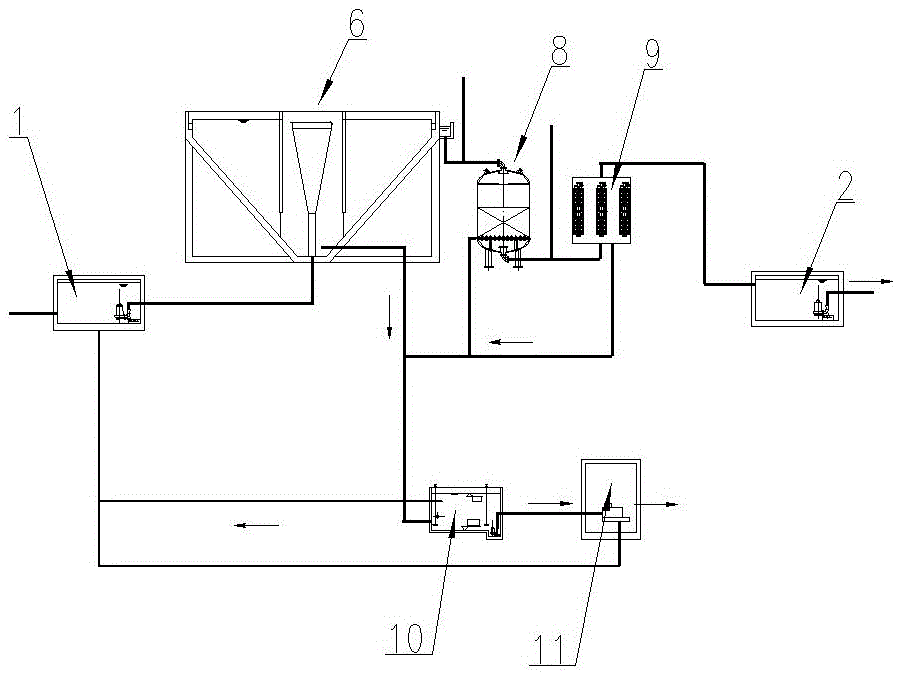

Method and device for treating and recycling mine wastewater by using purified diatomite

InactiveCN106830468ASimple processEasy to operateWaste water treatment from quariesWater/sewage treatment by irradiationAutomatic controlWater quality

The invention relates to a method for treating and recycling mine wastewater by using purified diatomite; the method comprises the following steps: firstly, the mine wastewater is collected via a water absorbing tank firstly, then the wastewater is evenly stirred by a stirrer, next the wastewater is lifted to a purified diatomite reactor by a submersible sewage pump, at the same time, purified diatomite is added to the wastewater before the submersible sewage pump, and the wastewater and the purified diatomite achieves full contact, adsorption and polymerization through intense stirring of the pump in the lifting process; and in the purified diatomite reactor, suspended matters, oil pollutants, a part of COD and metal ions in the wastewater are subjected to reaction and are evenly mixed for adsorption and polymerization, then the treated wastewater is classified and is subjected to mud water separation in the purified diatomite reactor, and water in a gutter groove is disinfected by ultraviolet rays and then reaches the water quality standard of urban miscellaneous water. The method can realize full-automatic control, has simple process flow, and realizes unmanned management. The method can reuse the resources and realize the purposes of high efficiency, energy saving and resource regeneration.

Owner:郭晓辉

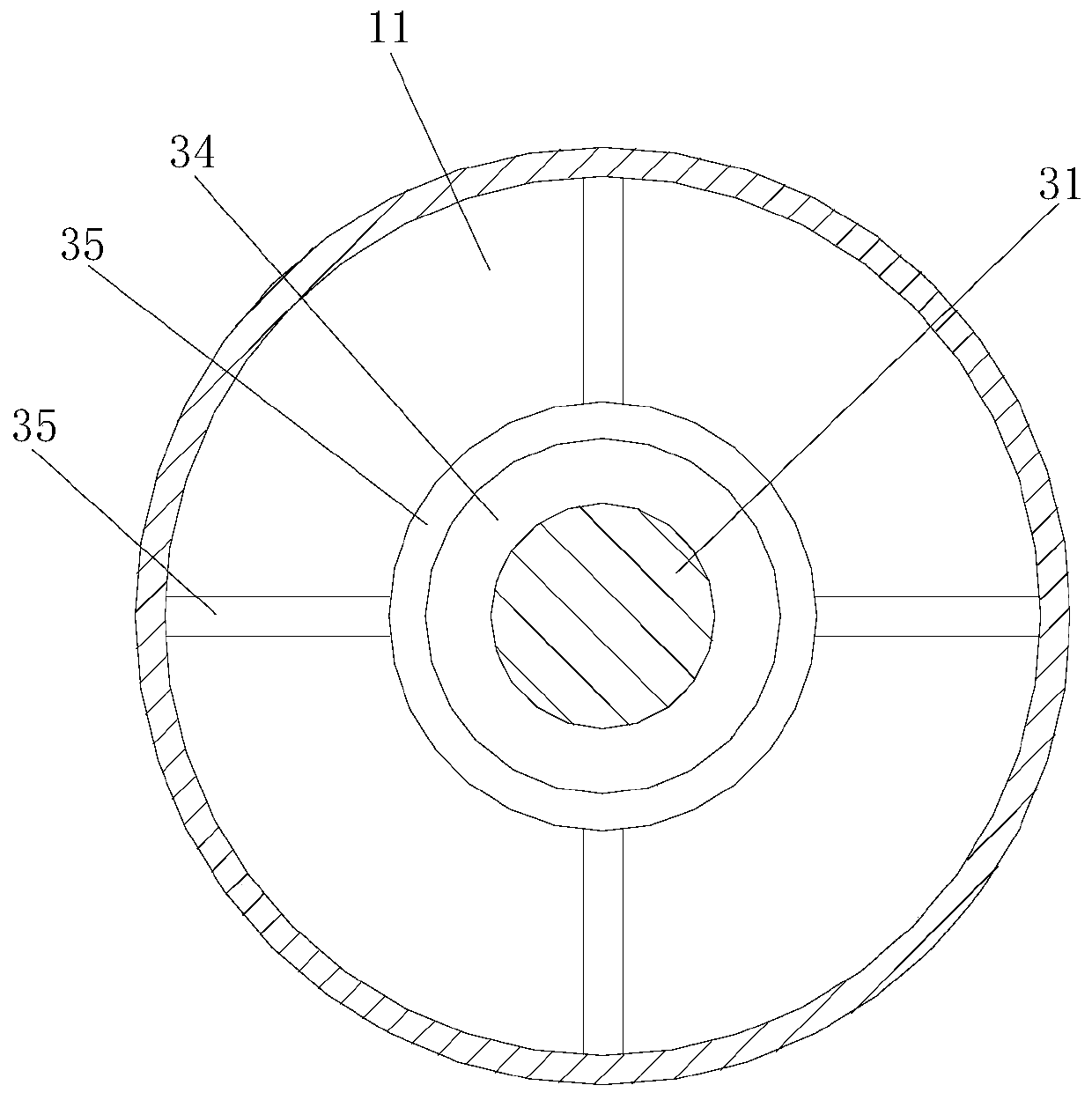

Adjusting device for powder transportation

InactiveCN106743677AImprove modification efficiencyAdjustable spacingBulk conveyorsMotor driveCompressed air

The invention discloses an adjusting device for powder transportation. The adjusting device comprises a pipe body, an upper supporting seat, a lower supporting seat, a supporting plate, a servo motor, a screw rod, a feed nut, a left connecting rod, a sliding sleeve, a right connecting rod, a guide block, a guide rod, a plug plate, a motor, a rotating shaft, a tapered discharge head, a plurality of harrow pins and an air pipe, wherein the servo motor drives the feed nut to move upwards through the screw rod, the sliding sleeve is driven to move upwards along the guide rod, and a tapered transition surface arranged on the sliding sleeve and the tapered discharge head are separated; the angle of the servo motor is arranged, so that the distance between the tapered transition surface and the tapered discharge head can be adjusted, and the discharge speed is adjusted; the motor drives the tapered discharge head to rotate through the rotating shaft; the harrow pins arranged on the tapered discharge head scatter powder falling from the sliding sleeve; compressed air is input into the pipe body through the air pipe; and compressed air discharges powder from a conveying pipe. According to the adjusting device, the structure is simple, the discharge speed can be automatically adjusted, caked powder can be scattered, and the powder modification efficiency is improved.

Owner:安徽金鼎新材料有限公司

Fluoroaniline wastewater treatment device and method

InactiveCN113185046AImprove stirring efficiencyIncrease the feeding speedTransportation and packagingRotary stirring mixersGear driveEngineering

The invention discloses a fluoroaniline wastewater treatment device and method. The fluoroaniline wastewater treatment device comprises a box body, a discharging pipe, sealing fan blades, a planetary gear disc and a filter screen; supports are installed at the four corners of the bottom end of the box body; a feeding pipe is arranged at the top end of the box body; a heating pipe is arranged on the inner wall of the box body; a fixed frame body is installed at the top end in the box body; a first gear is arranged on the inner side of the fixed frame body; a sliding groove is formed in the top end in the box body; a first rotating shaft is arranged in the sliding groove; stirring blades are arranged on the outer wall of the first rotating shaft at equal intervals; and a first gear is arranged on the outer wall of the first rotating shaft. According to the fluoroaniline wastewater treatment device, a first stirring rod drives a second gear block to be meshed with the first gear, so that the first gear drives the first rotating shaft to perform precession, the first rotating shaft drives the first gear to rotate in the planetary gear disc, the first rotating shaft drives the stirring blades to rotate in the sliding groove, and the above structure improves the stirring efficiency.

Owner:京化(山东)精细化工有限公司

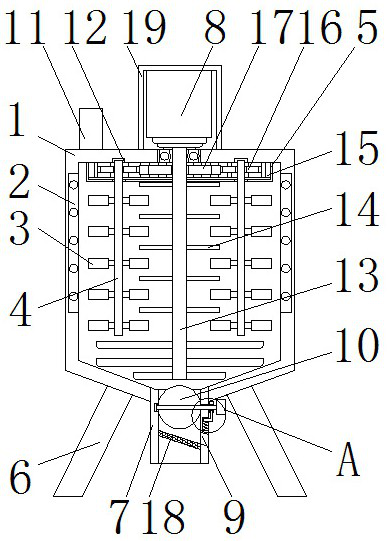

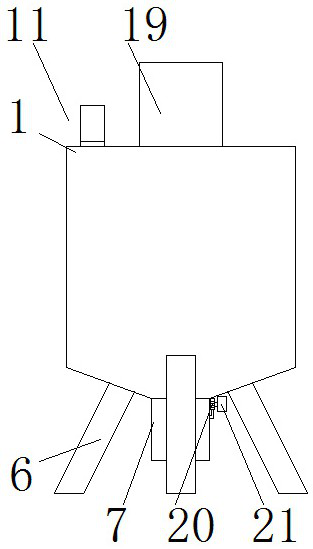

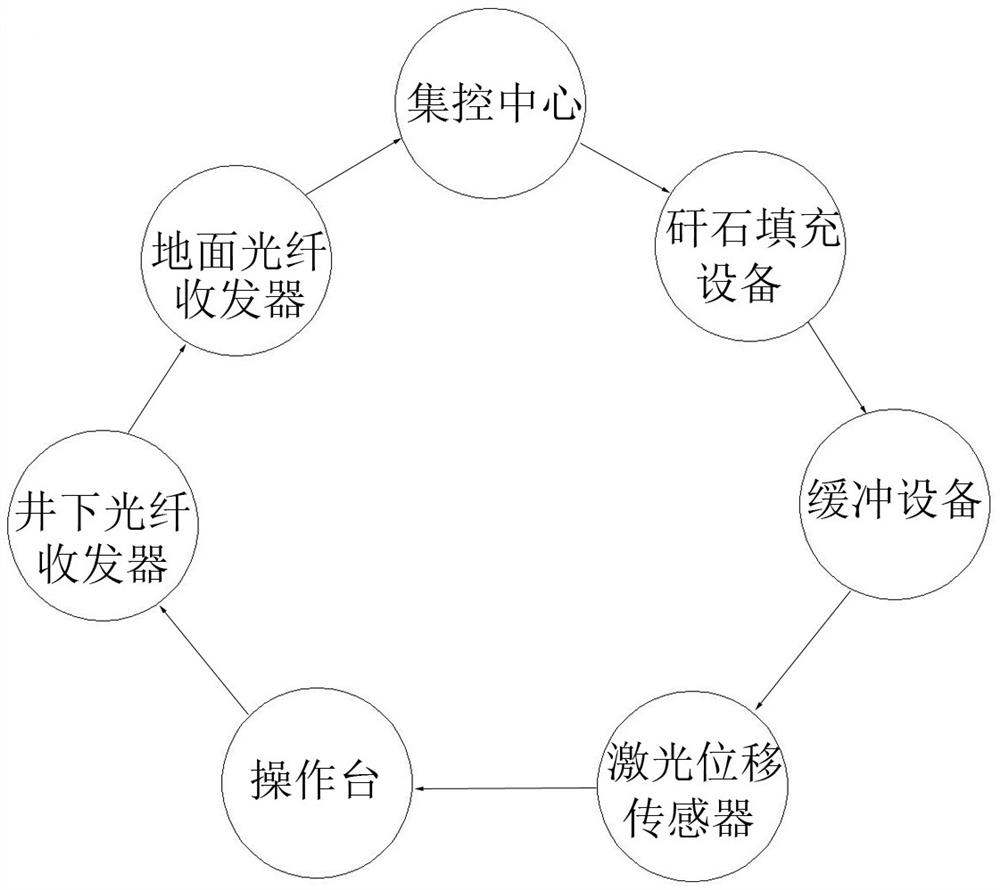

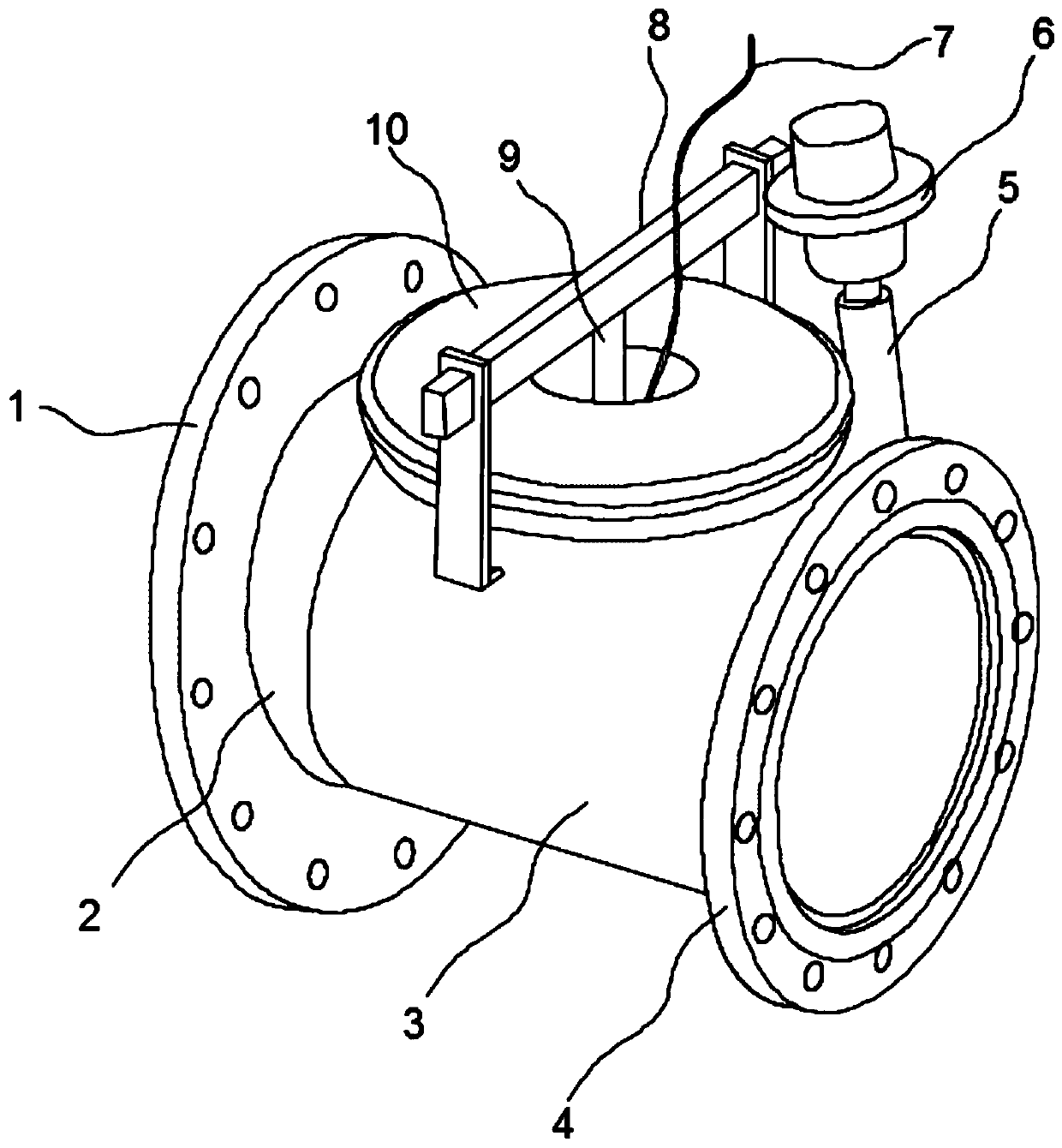

Coal mine feeding well gangue material flow impact force detection system

InactiveCN112033589AGuaranteed normal operation and service lifeIncrease productivityMining devicesUsing optical meansBuffer (optical fiber)Process engineering

The invention discloses a coal mine feeding well gangue material flow impact force detection system, relates to the technical field of coal mine filling mining detection, and solves the problems thatthe impact force of gangue material flow cannot be detected, buffer equipment is poor in working stability and short in service life. The coal mine feeding well gangue material flow impact force detection system comprises a centralized control center, gangue filling equipment, buffer equipment, a laser displacement sensor, an operation table, an underground optical fiber transceiver and a ground optical fiber transceiver. The impact force of a gangue material flow of the feeding well is detected in real time, the centralized control center can operate gangue filling equipment in real time through the PLC control cabinet, the effect of adjusting the stone discharging speed is achieved, normal work and the service life of buffer equipment are guaranteed, and therefore the production efficiency is improved.

Owner:山东康格能源科技有限公司

Powder feeder

The utility model discloses a powder feeder, which comprises a storing tank, a powder flow-quantity adjusting valve and a linear vibrator, wherein the powder flow-quantity adjusting valve is arranged on the storing tank, the linear vibrator is arranged below the storing tank and is used for vibrating the storing tank, and the linear vibrator is obliquely arranged in an intersecting structure at an acute angle of the axial direction of the linear vibrator and the horizontal advancing direction of powder in the storing tank. The flow quantity of the powder can be adjusted through the powder flow-quantity adjusting valve, so that the precision and the stability of the blanking quantity are ensured, and the blockage caused by the overlarge flow quantity is avoided; the storing tank can be vibrated through the linear vibrator, so that the powder makes parabolic movement and advances in a wavy type, the conglobation of the powder by bonding is eliminated, and therefore the density of the powder is uniform and compact, the frictional force of the powder is reduced, the steady operation, the stable flow-quantity and the smooth movement of the powder can be ensured, and the blockage of the storing tank is avoided; and the discharging end of the storing tank is V-shaped closed, and a discharging opening is arranged at a V-shaped corner part, so that the excessive powder can be prevented from being accumulated at the discharging end of the storing tank through the design of a special structure, and the blockage of the discharging opening is avoided.

Owner:CHONGQING UNIV

Fresh rice freezing and hulling device

InactiveCN112705293AFully shelledSlow downGrain huskingGrain polishingEngineeringMechanical engineering

The invention discloses a fresh rice freezing hulling device. The device comprises a hulling unit and further comprises a freezing unit, a conveying unit used for conveying grains is connected between the freezing unit and the hulling unit, the hulling unit comprises an inner barrel and an outer barrel which rotate reversely, openings are formed at the two ends of the outer barrel, and the outer barrel is concentrically arranged outside the inner barrel in a sleeving manner. A spiral barrier strip is arranged between the outer barrel and the inner barrel, the spiral barrier strip is spirally arranged from top to bottom, the spiral barrier strip is fixedly connected with the inner wall of the outer barrel, the freezing unit comprises a freezing barrel and a refrigerating sheet, the conveying unit comprises a lifting barrel and a lifting auger, and an adjusting assembly used for controlling the discharging speed is installed at the top of the lifting barrel. The adjusting assembly comprises an adjusting sleeve, a first connecting rod, a mounting rod and an elastic supporting net, the inner cylinder, the outer cylinder and the spiral barrier strip are arranged, the number of hulled grains is large, the working efficiency is improved, the grain movement speed is decreased, it is guaranteed that the grains can be fully hulled, and the quality of fresh rice is improved.

Owner:前郭县隆信种植养殖农民专业合作社

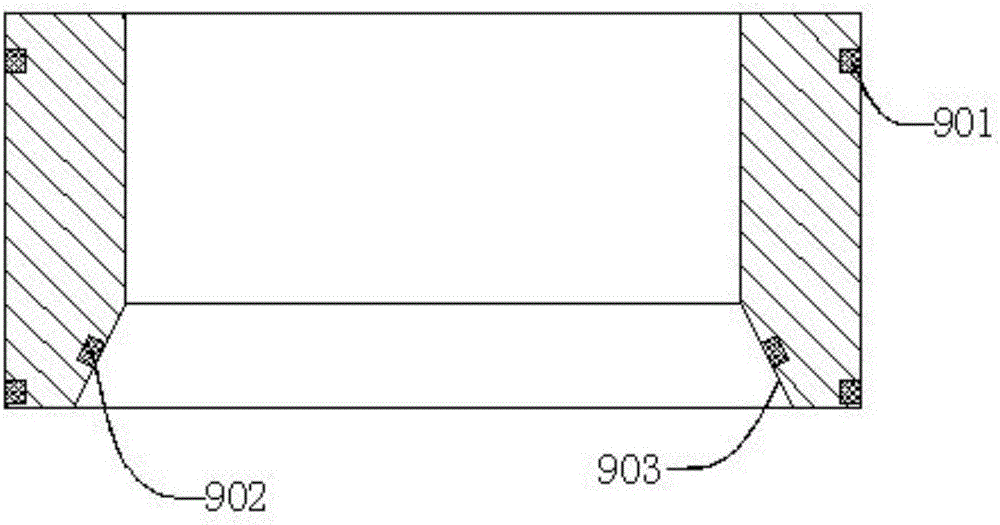

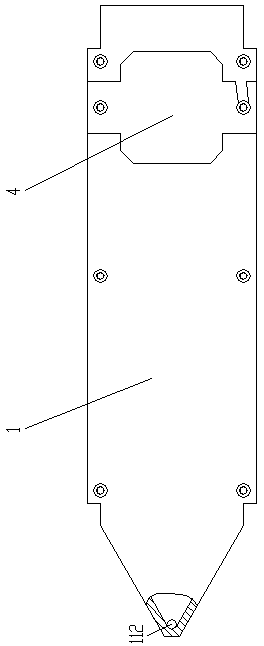

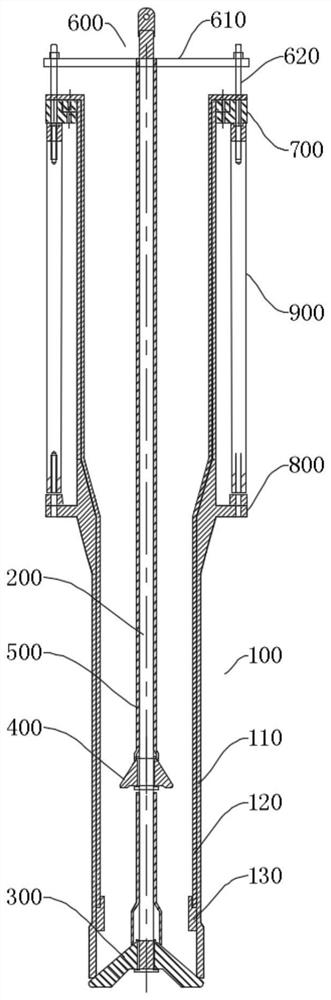

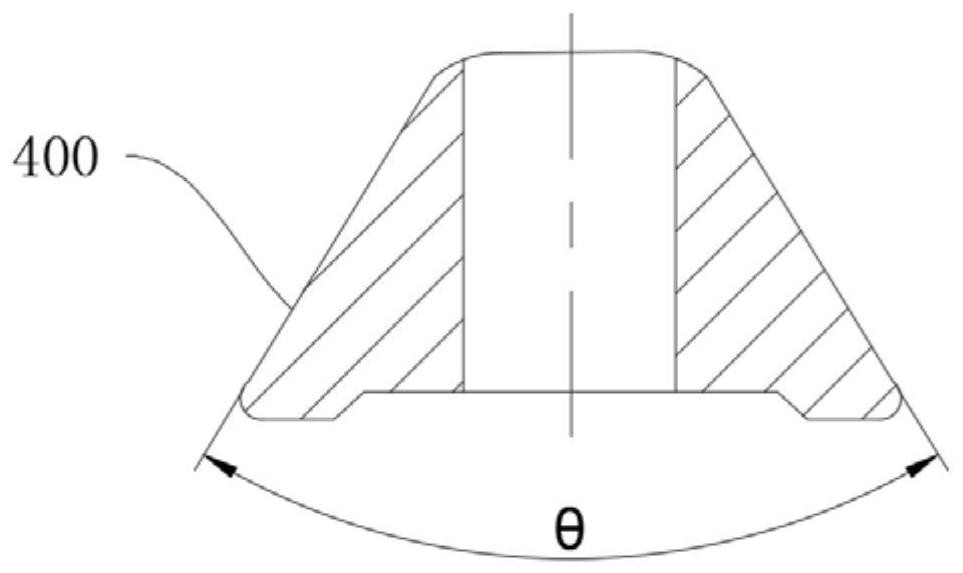

Semiconductor-grade straight-pull re-feeding cylinder

PendingCN111850679AHigh strengthExtended service lifePolycrystalline material growthBy pulling from meltEngineeringSingle crystal

The invention provides a semiconductor-grade direct-pull re-feeding cylinder, which comprises a cylinder body, a molybdenum rod and a main quartz umbrella arranged at the lower end of the cylinder body. An auxiliary quartz umbrella is further arranged on the molybdenum rod and located above the main quartz umbrella. The main quartz umbrella is also provided with a quartz cylinder which is used forisolating the molybdenum rod from the silicon material and penetrates through the auxiliary quartz umbrella; the upper end face of the cylinder body is provided with a positioning assembly used for adjusting the lifting positions of the main quartz umbrella and the auxiliary quartz umbrella. The re-feeding cylinder buffers the falling speed of the silicon material, reduces the impact of the silicon material on the main quartz umbrella, and reduces the risk of splashing of the silicon material; the descending distance is fixed so as to adjust the parachute opening height and the blanking speedof the re-feeding cylinder; the molybdenum rod is prevented from being in direct contact with the silicon material, the purity of the silicon material entering the re-feeding cylinder is ensured, andthe quality of a Czochralski single crystal is improved; the strength of the re-feeding cylinder is improved, the service life is prolonged, and the preparation cost of the re-feeding cylinder is reduced.

Owner:内蒙古中环领先半导体材料有限公司 +1

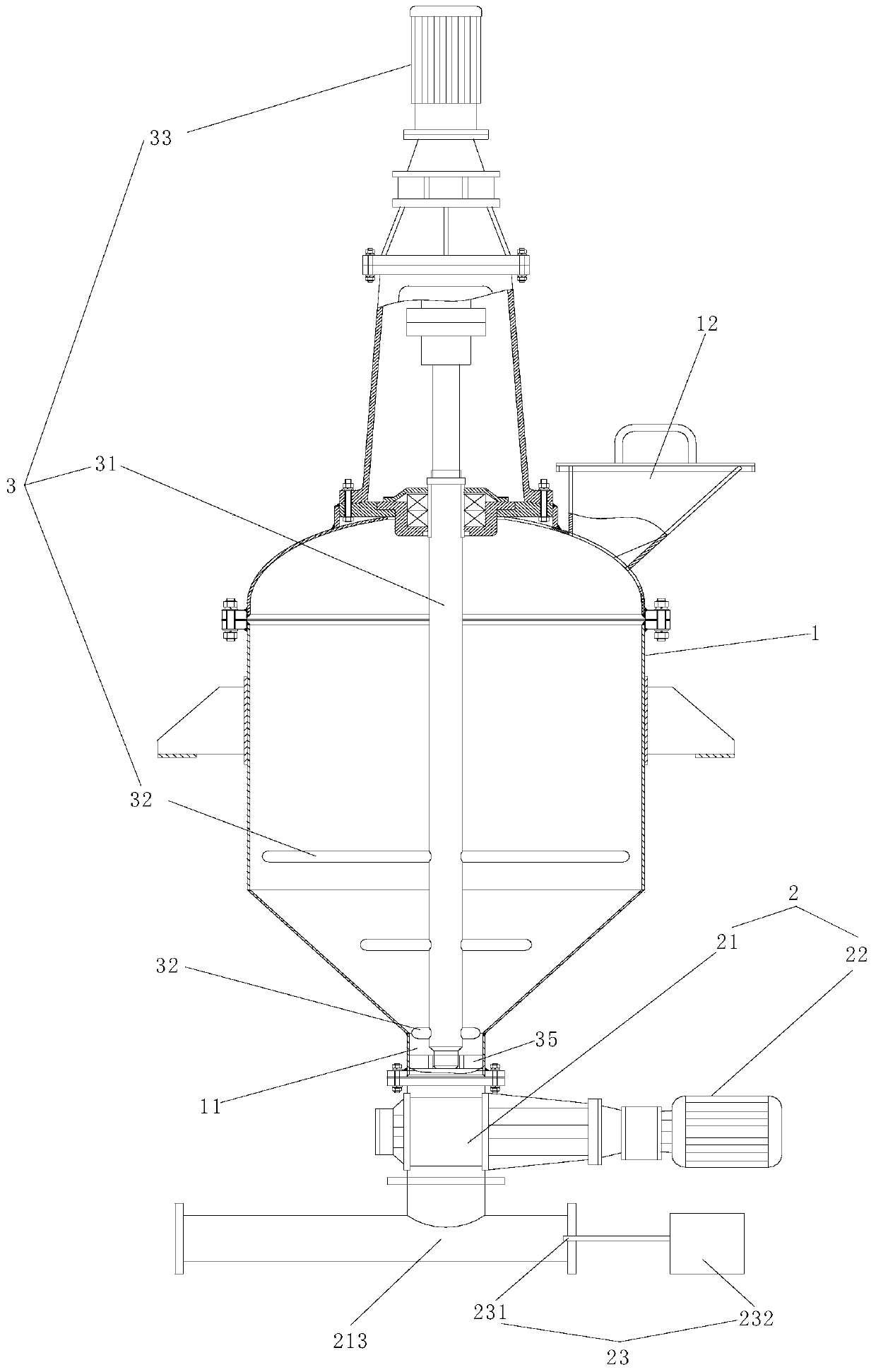

Feeding device

PendingCN109911435ALarge capacityReduce feeding timesLarge containersTank wagonsEngineeringStorage tank

The invention provides a feeding device, and relates to the technical field of material conveying devices. The technical problem that in the prior art, materials are caked, and the feeding device is blocked is mainly solved. The feeding device comprises a storage tank, a feeding structure and a stirring structure. The feeding structure is connected with a discharging opening of the storage tank sothat materials in the storage tank can be output through the feeding structure. The stirring structure is located in the storage tank so that the stirring structure can stir the materials stored in the storage tank. According to the feeding device, by arranging the stirring structure, the materials can be stirred when the feeding device supplies the materials, and therefore the materials are prevented from caked entering the feeding structure, and then the aim of preventing the materials from blocking the feeding device is achieved.

Owner:LANGFANG DEV ZONE FANHUA PETRIFACTION MACHINERY EQUIP

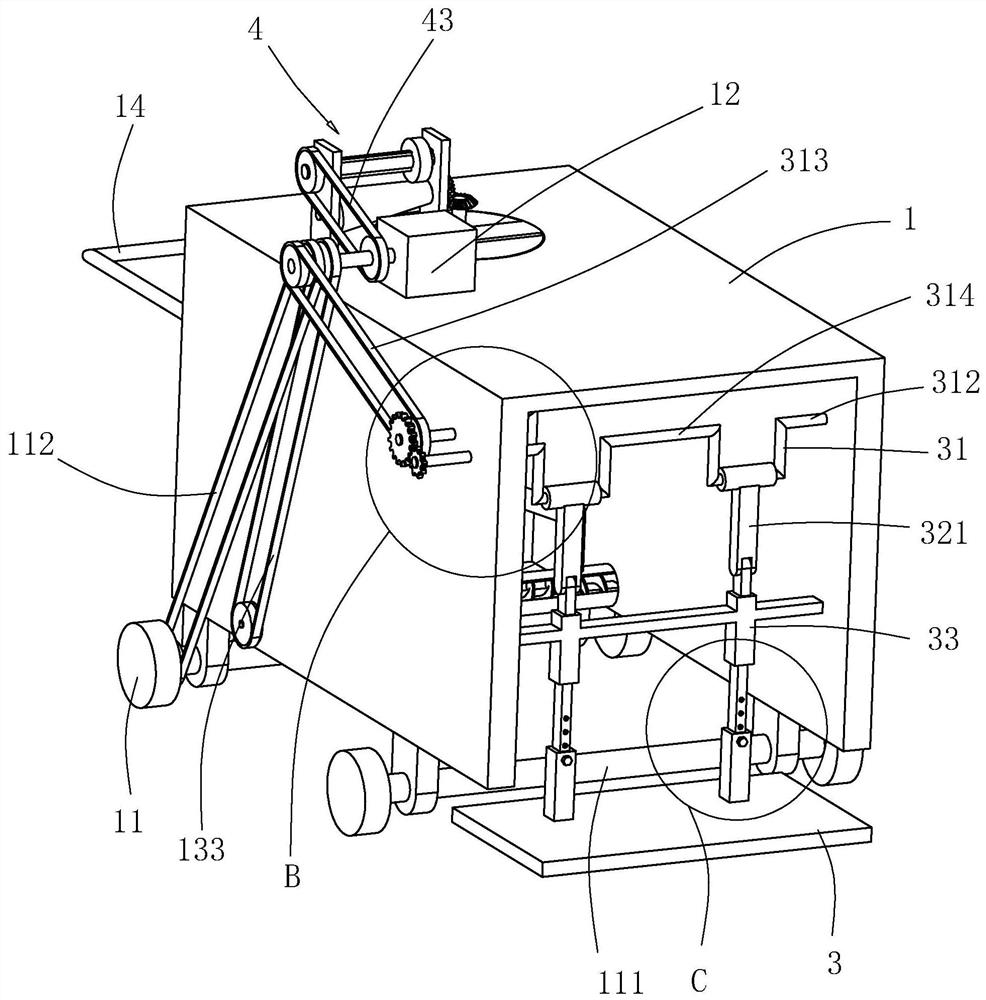

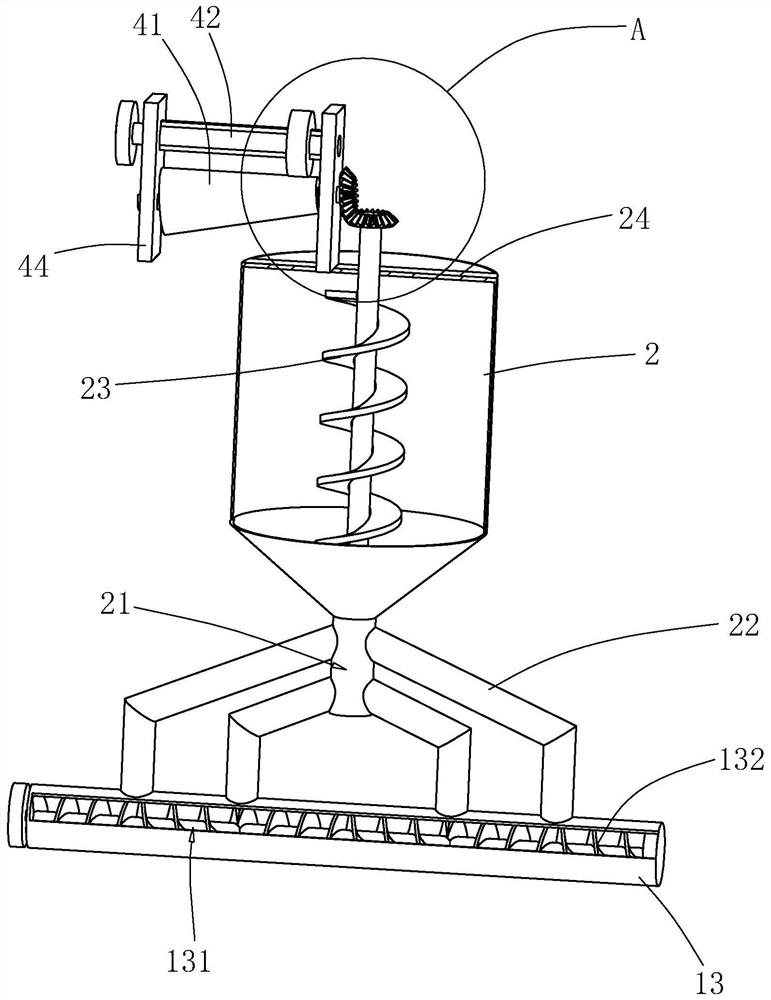

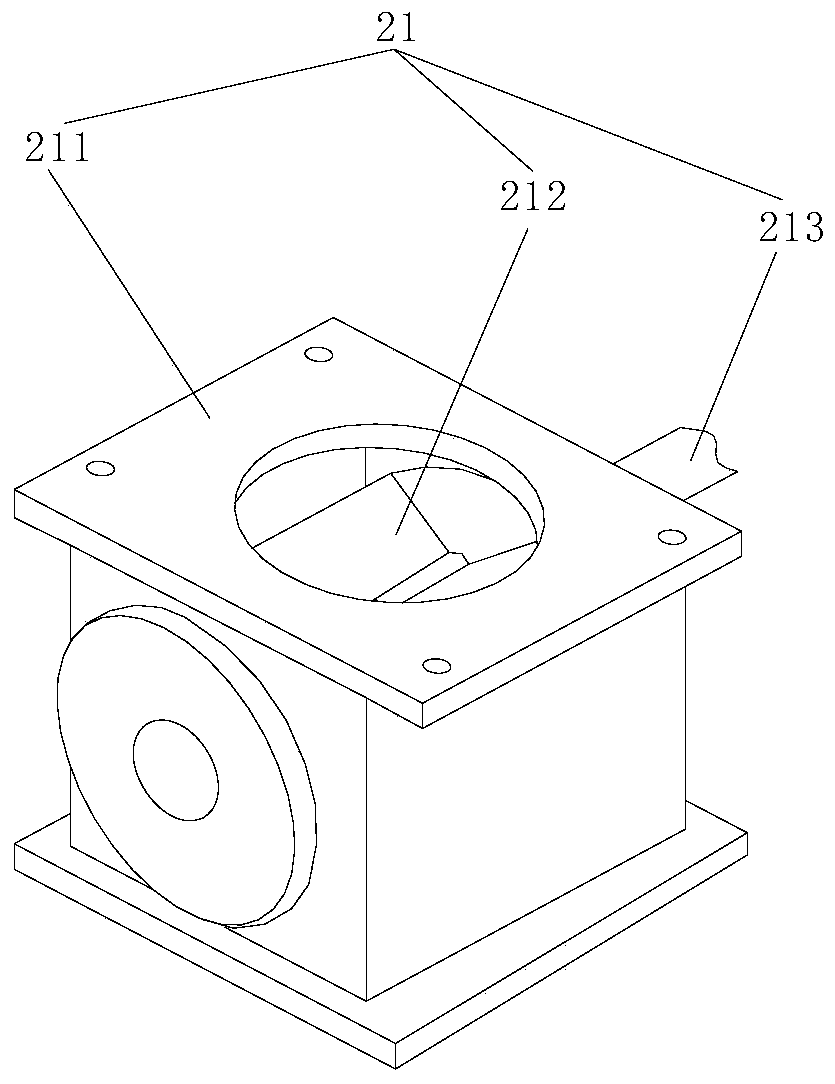

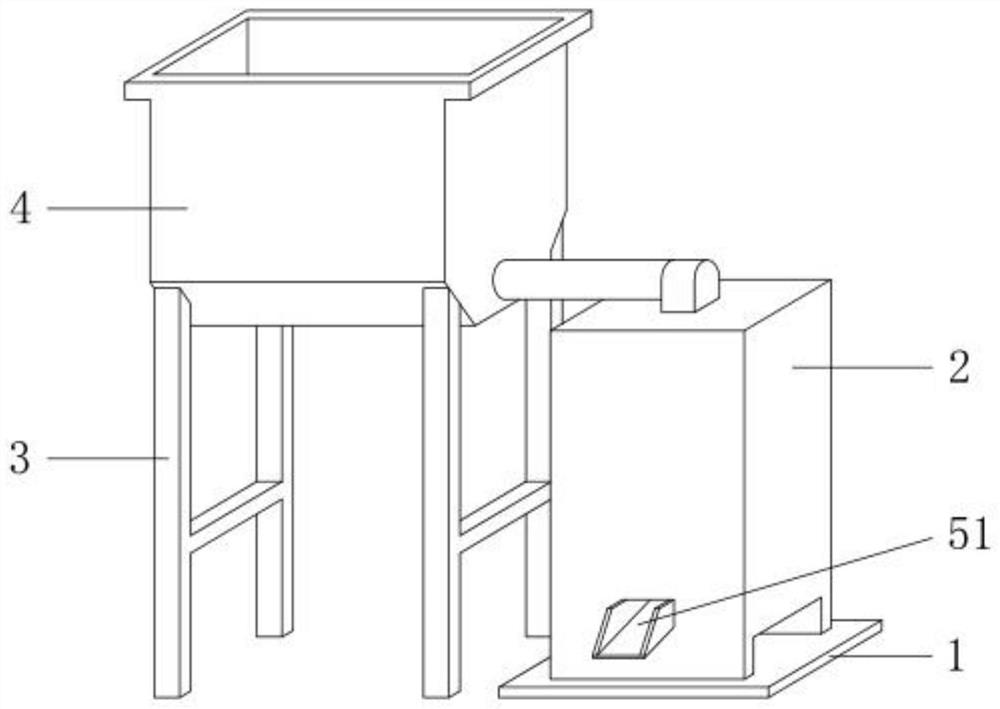

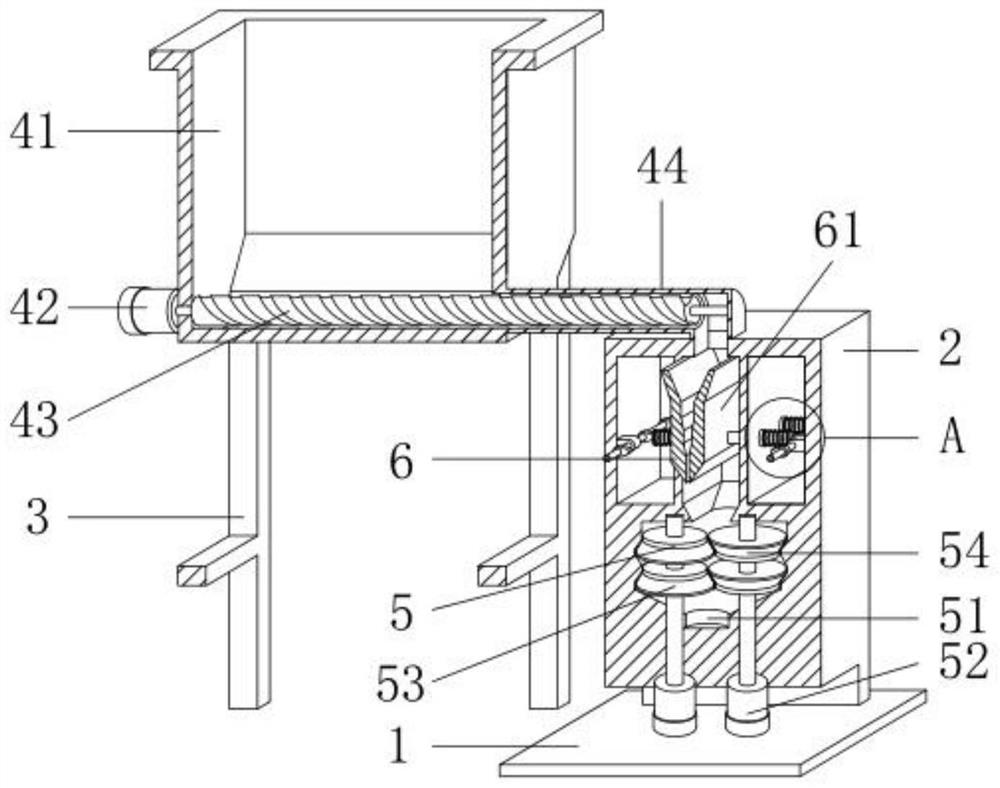

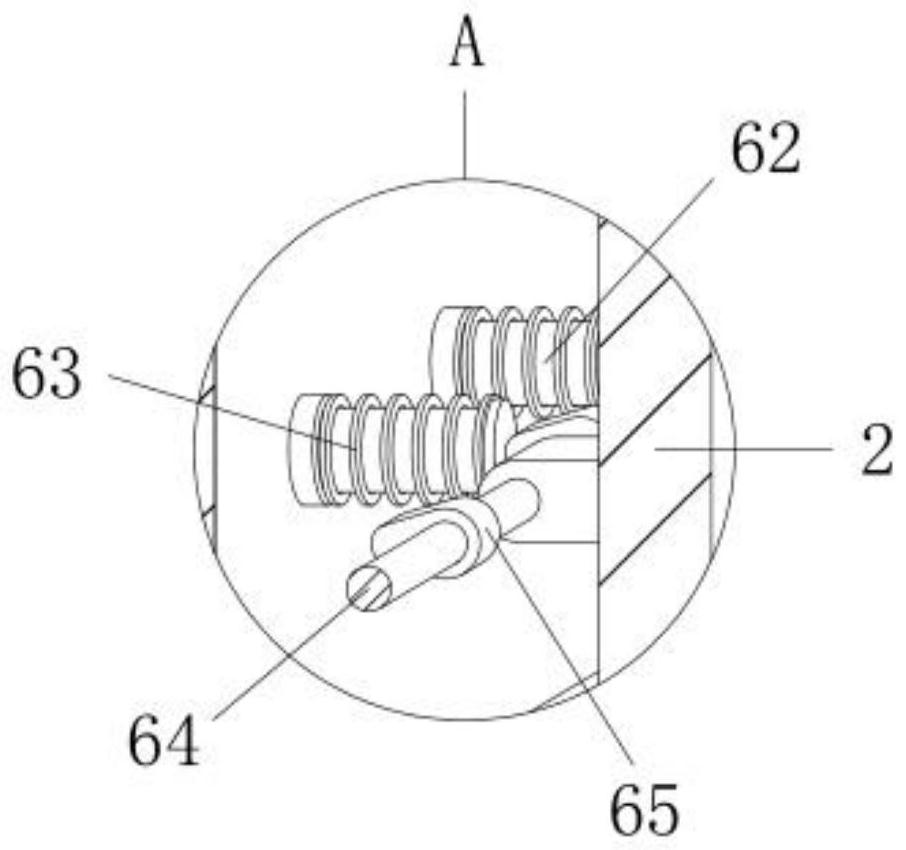

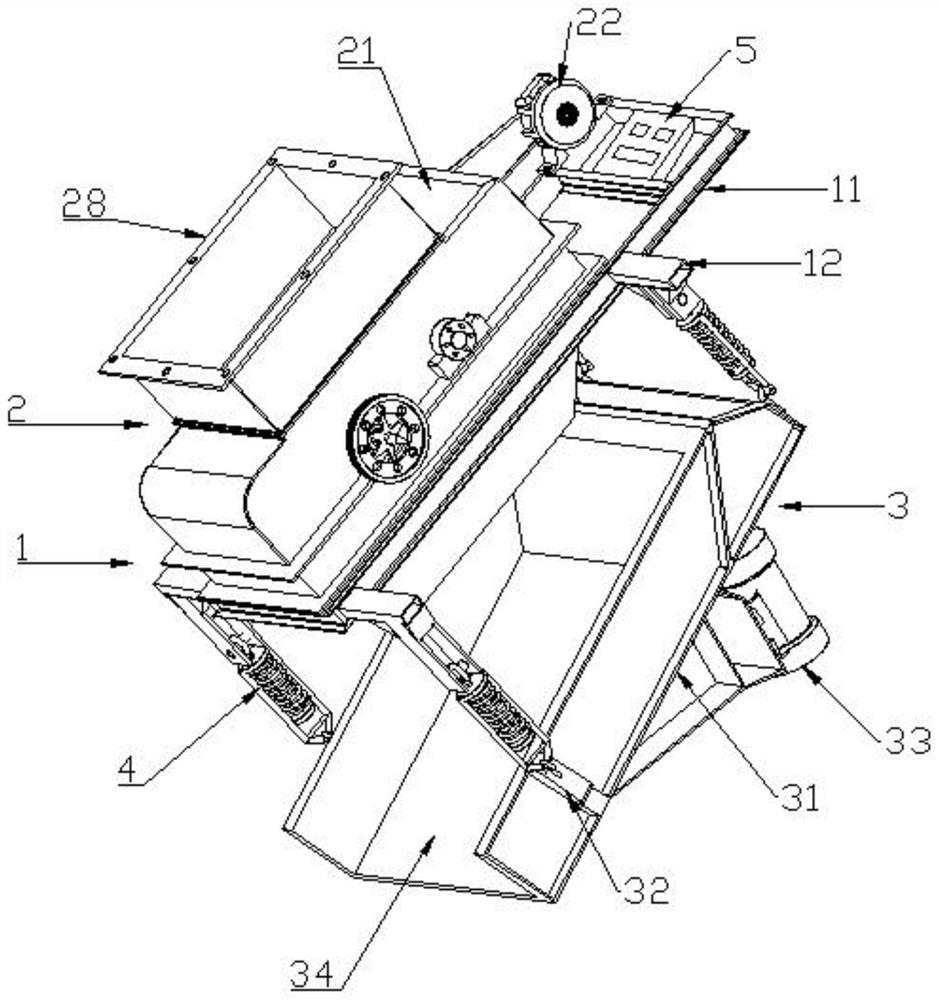

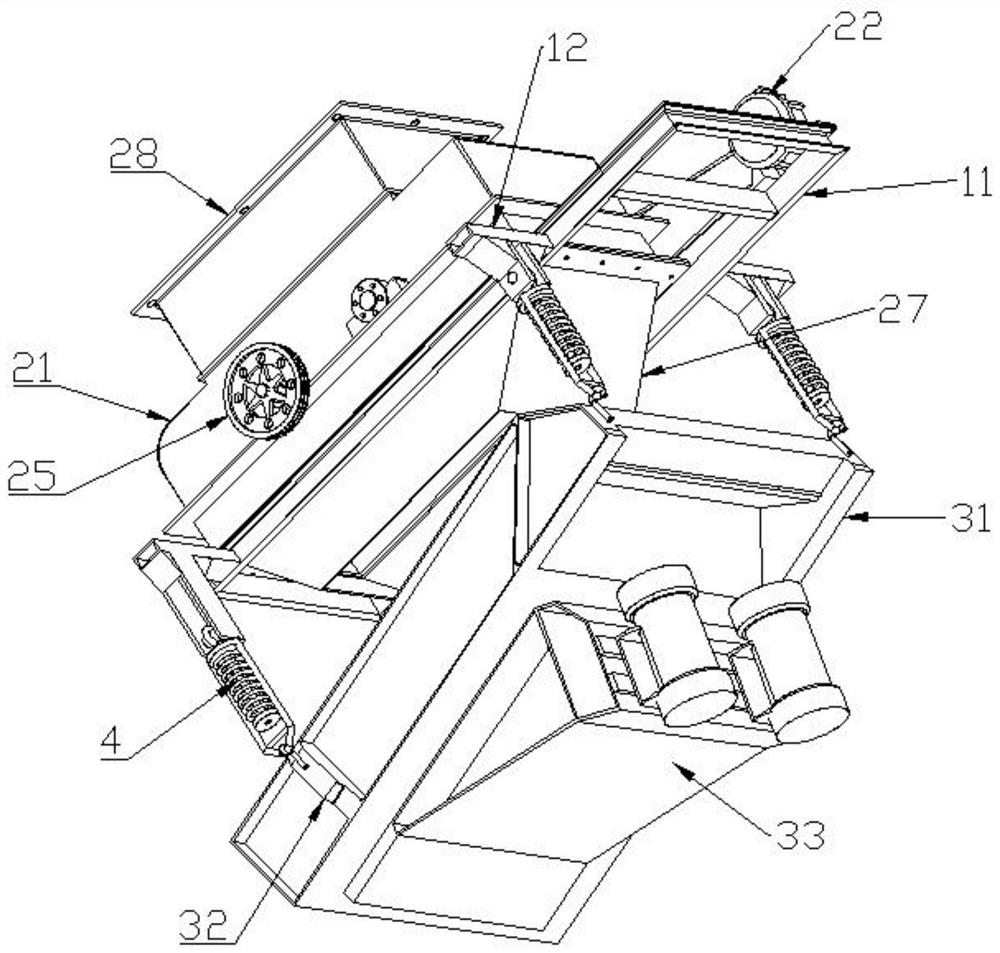

A kind of needle tube recycling and processing equipment

ActiveCN110694744BSmooth feedingAdjust the feeding speedIntravenous devicesGrain treatmentsProcess engineeringMechanical engineering

The present invention relates to a recovery treatment equipment, more specifically a needle tube recovery treatment equipment, including a hopper mechanism, a stirring feeding mechanism, a shell mechanism, a crushing mechanism, and an opening and closing mechanism. The equipment can ensure smooth feeding, The equipment can ensure that there will be no needle tube running out when feeding, the equipment can adjust the feeding speed, the equipment can prevent the material from being blocked, the equipment can crush the needle tube, and the equipment can automatically control the discharge. The mechanisms are connected, the hopper mechanism is connected with the shell mechanism, the shell mechanism is connected with the crushing mechanism, and the crushing mechanism is connected with the opening and closing door mechanism.

Owner:高建华

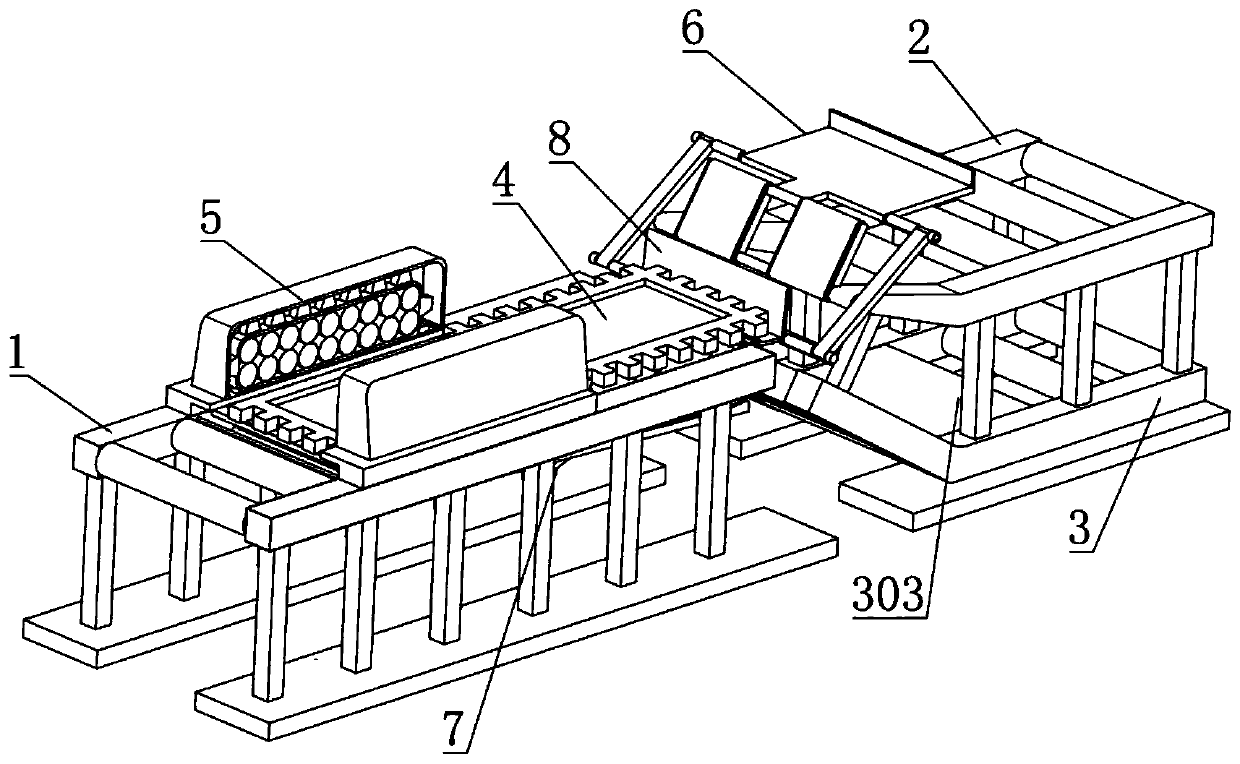

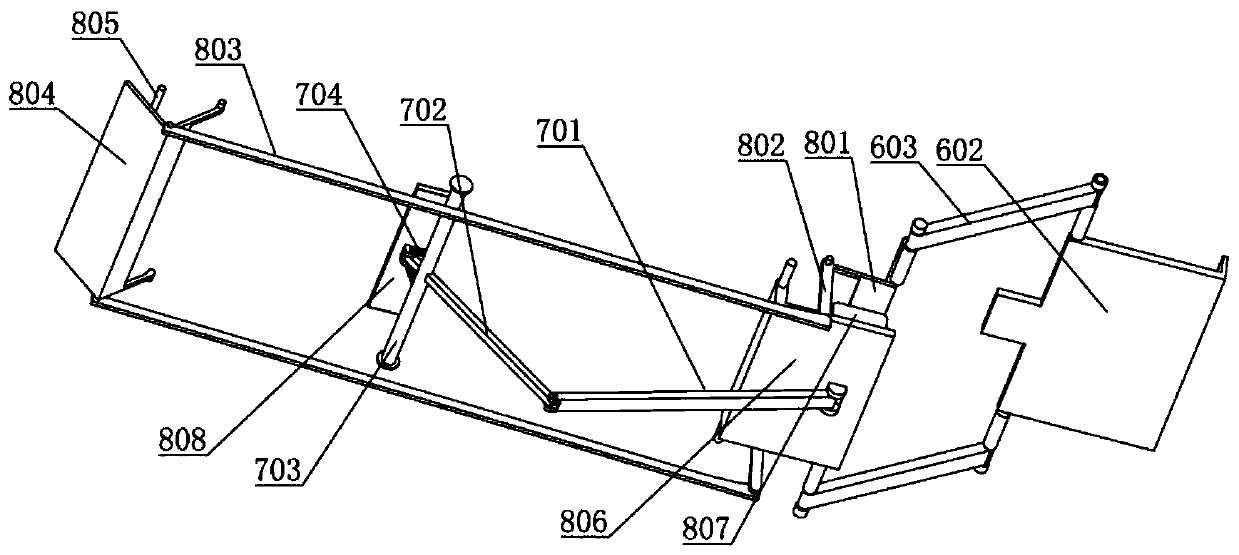

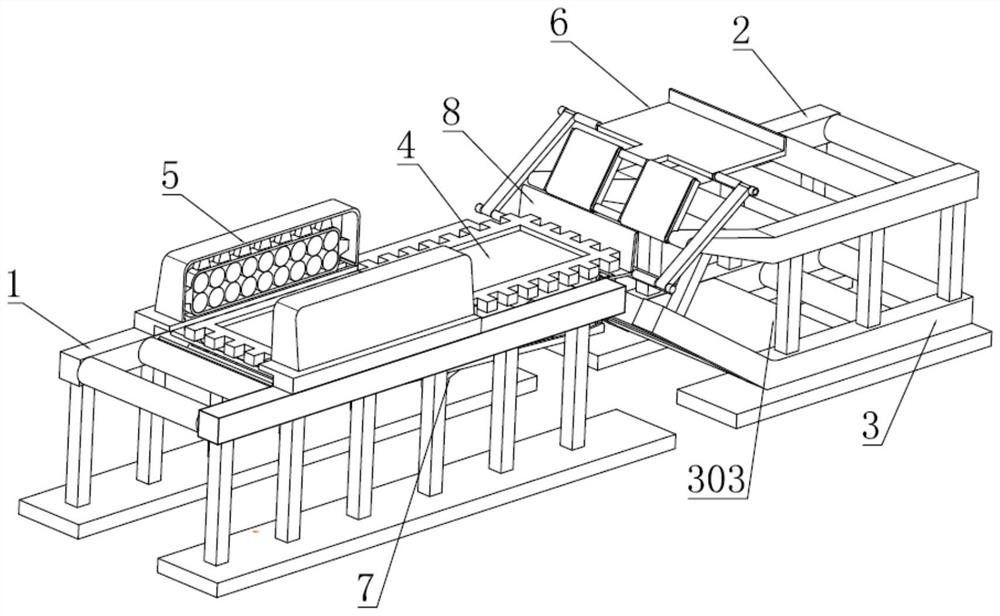

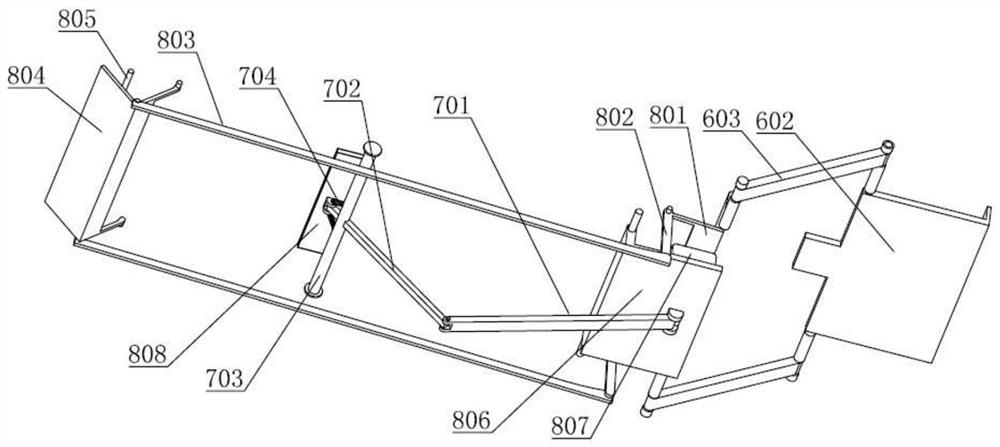

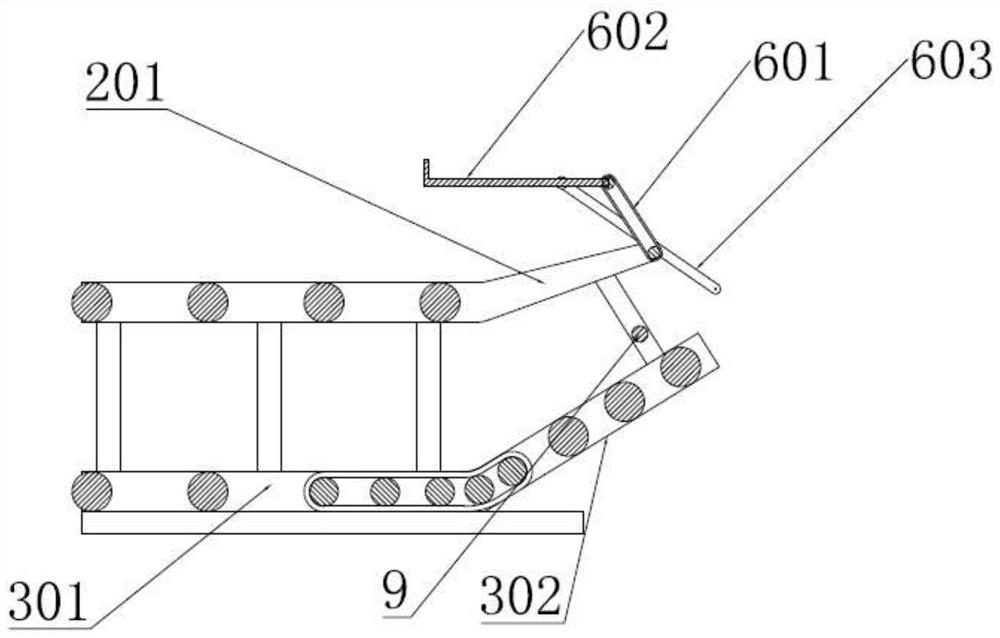

An automatic grouping device for toothed building plates

ActiveCN110963275AGood synergySolve the costConveyor partsArchitectural engineeringStructural engineering

The invention discloses an automatic grouping device for toothed building plates. The device comprises a feeding track, a discharging track, a turnover mechanism, a feeding mechanism and a grouping mechanism. The grouping mechanism comprises an L-shaped material blocking plate and an L-shaped material limiting plate, and two plates are just accommodated between the L-shaped material blocking plateand the L-shaped material limiting plate. The grouping mechanism further comprises an elastic cushion supporting plate, a connecting rod mechanism and a pressing plate, wherein the elastic cushion supporting plate is connected with the pressing plate through the connecting rod mechanism to be supported, the elastic cushion supporting plate is rotationally connected to the discharging end of the feeding track, and an elastic cushion makes contact with the bottom of the L-shaped material blocking plate. The feeding mechanism is used for feeding the plates close to the back in an initial state,and the previous plate is driven to fed upward to the turnover mechanism through the pressed L-shaped material blocking plate; and after the pressing plate is separated from the plate, the pressing plate extends out to enable the turnover plate to drive the L-shaped material blocking plate to continuously rotate, so that the next plate is downwards conveyed to the lower rail, and grouping and turnover are continuously achieved; and the structure is simple, and an extra driving mechanism is not needed.

Owner:芜湖文青机械设备设计有限公司

Cosmetic raw material crushing and grinding device

InactiveCN111940015AEasy to crushShorten processing timeCocoaGrain treatmentsPulverizerGrinding mill

The invention discloses a cosmetic raw material crushing and grinding device. The device comprises a base, a support, a shell, a conveying mechanism, a grinding mechanism and a crushing mechanism. Thebase is located at the right side of the support, the bottom of the base and the bottom of the support are located on the same horizontal plane, the shell is in screw connection with the upper surface of the base, and the conveying mechanism is arranged at the top end of the support. The conveying mechanism is in screw connection with the top end of the shell, the grinding mechanism is arranged at the bottom end of an inner cavity of the shell, and the crushing mechanism is arranged at the top end of the inner cavity of the shell. According to the cosmetic raw material crushing and grinding device, the feeding speed can be adjusted, raw materials are more convenient to crush, the load is stable, operation is stable, crushed particles obtained after cosmetic raw material crushing are uniform in size, the machining difficulty is lowered through preprocessing of the crushing mechanism, and cosmetic raw materials with different hardness can be dealt with conveniently. The grinding friction force is changed through the grinding mechanism, it is guaranteed that machining meets the requirement, time consumed by secondary machining is avoided, and the product quality is guaranteed.

Owner:陈希凯

Powder feeder

InactiveCN102874505AGuaranteed accuracyEliminate sticking and clumpingLarge containersTraffic volumeAcute angle

The utility model discloses a powder feeder, which comprises a storing tank, a powder flow-quantity adjusting valve and a linear vibrator, wherein the powder flow-quantity adjusting valve is arranged on the storing tank, the linear vibrator is arranged below the storing tank and is used for vibrating the storing tank, and the linear vibrator is obliquely arranged in an intersecting structure at an acute angle of the axial direction of the linear vibrator and the horizontal advancing direction of powder in the storing tank. The flow quantity of the powder can be adjusted through the powder flow-quantity adjusting valve, so that the precision and the stability of the blanking quantity are ensured, and the blockage caused by the overlarge flow quantity is avoided; the storing tank can be vibrated through the linear vibrator, so that the powder makes parabolic movement and advances in a wavy type, the conglobation of the powder by bonding is eliminated, and therefore the density of the powder is uniform and compact, the frictional force of the powder is reduced, the steady operation, the stable flow-quantity and the smooth movement of the powder can be ensured, and the blockage of the storing tank is avoided; and the discharging end of the storing tank is V-shaped closed, and a discharging opening is arranged at a V-shaped corner part, so that the excessive powder can be prevented from being accumulated at the discharging end of the storing tank through the design of a special structure, and the blockage of the discharging opening is avoided.

Owner:CHONGQING UNIV

Extrusion shaping device for production of polystyrene decoration strip

PendingCN113771325AEnsure dispersion finenessEnsure shaping qualityCoatingsElectric machineryElectric heating

The invention discloses an extrusion shaping device for production of polystyrene decoration strips, and relates to the technical field of photo frame decoration strip production equipment. The problem that a polystyrene material contains solid particles is solved. The extrusion shaping device specifically comprises a machine body, wherein a box door is arranged on the outer wall of the top of the machine body, a melting box is arranged on the inner wall of one side of the machine body, a crushing roller is arranged on the inner wall of one side of the melting box, a third motor is connected to the outer wall of one side of the machine body through a fixing plate, a conveying pipe is arranged on the outer wall of one side of the melting box and comprises an electric heating layer, more than four breaking plates are arranged on the circumferential inner wall of the conveying pipe, an extrusion box is arranged on the inner wall of the side, close to the melting box, of the machine body, a dispersion assembly is arranged on the inner wall of one side of the extrusion box, and a screening plate is arranged on the inner wall of the side, close to the dispersion assembly, of the extrusion box. According to the extrusion shaping device, infusible substance particles in raw materials are isolated and prevented from being extruded and molded, so that the molding quality of the materials is ensured.

Owner:LUAN YINGKE IND CO LTD

Automated material conveying device for hardware stamping parts

InactiveCN108015181AAdjust the feeding speedControl accessMetal-working feeding devicesPositioning devicesEngineeringPulley

The invention discloses an automated material conveying device for hardware stamping parts. The automated material conveying device comprises a base plate, a belt pulley, a pulley shaft, connecting holes, through connection blocks, a transverse rod, vertical rods, a rotating shaft, a motor, a support plate, support legs, vertical plates, transverse plates, threaded holes, storage plates, a raw material tank, an article inlet, a baffle, an article outlet and a discharging tank. The automated material conveying device has the beneficial effects that by means of the motor and the rotating shaft connected with the belt pulley, rotation is achieved through the motor, on one hand, a power source is provided for rotation of the belt pulley, and on the other hand, the conveying speed of the hardware stamping parts can be adjusted by controlling the rotating speed of the motor; the baffle is arranged in the raw material tank and can slide up and down in the raw material tank, and therefore, rawmaterials inside the raw material tank can be controlled to be conveyed into and out of the raw material tank; and the problem that when the conveying device does not arrive, the raw materials fall from the article outlet due to the inclined design of the raw material tank, so that disorder is caused and the device cannot be used normally can be avoided.

Owner:柳州市鑫裕塑胶有限责任公司

An environmentally friendly vibrating lateral discharge device for grain production

ActiveCN110614221BIncrease the tilt angleSmall inclination angleSievingScreeningEngineeringCyclonic spray scrubber

The invention discloses an environment-friendly vibration transverse discharging device for grain production. The environment-friendly vibration transverse discharging device comprises a device main body, a cyclone dust collector is fixedly mounted on the outer surface of the upper end of the device main body, an exhaust fan is in bolted connection with the outer surface of one side of the cyclonedust collector, a sucking pipe is arranged on one side of the exhaust fan, a conveying pipe sleeves the upper end of the sucking pipe, and the end, away from the sucking pipe, of the conveying pipe is fixedly connected with the exhaust fan; and the side, away from the cyclone dust collector, of the upper end of the device main body is provided with a pre-screening plate, mounting blocks are arranged at the front end and the rear end of the pre-screening plate correspondingly, the mounting blocks are connected with the device main body in a welded mode, connecting holes are formed in the innersurfaces of the mounting blocks, connecting shafts penetrate through the interiors of the connecting holes, and one ends of the connecting shafts are connected with the pre-screening plate in a welded mode. The environment-friendly vibration transverse discharging device has the beneficial effects that the feeding speed is adjustable, grain can be quickly treated, the effect of treating the grainis better, and the environment-friendly vibration transverse discharging device is worthier of use and promotion.

Owner:界首市云飞粮机有限公司

Assembled agricultural product quality flow detection tube

InactiveCN110487970AAdjust the feeding speedAdjusting device to adjust the speed of material guideTesting starch susbtancesFixed frameSurface mounting

The invention relates to the field of agricultural product quality detection and particularly relates to an assembled agricultural product quality flow detection tube. The detection tube comprises a through tube and a limiting component installed on a fixed frame. The limiting component is installed through the through tube. The limiting component is installed on the fixed frame through a height adjusting device, a limiting block is arranged on the limiting component, and a plurality of humidity detection components distributed in an array mode are installed on an inner surface of the limitingblock. The humidity detection components are provided with rotating arms, another ends of the rotating arms are hinged to height adjusting components, a plurality of humidity sensors are installed onupper surfaces of the rotating arms, and two ends of the through tube are equipped with a bottom mounting disc and a top mounting disc. The height of the limiting component can be adjusted through the height adjusting device, the material guiding speed of agricultural products is adjusted, after the rotating arms rotate around a fixed block, the humidity of the agricultural products at differentdepths is detected, the flowing type all-around humidity detection is achieved, and a reasonable market pricing transaction is facilitated.

Owner:刘晓鹏

An automatic grouping device for toothed building boards

ActiveCN110963275BGood synergyGuaranteed reliabilityConveyor partsArchitectural engineeringStructural engineering

The invention discloses an automatic grouping device for toothed building panels, which comprises an incoming material track and a material output track, a turning mechanism, a feeding mechanism and a grouping mechanism, and the grouping mechanism includes an L-shaped material blocking plate and an L-shaped material limiting plate , just accommodate two plates between the two, the grouping mechanism also includes an elastic pad support plate, a linkage mechanism and a pressure plate, the elastic pad support plate is supported by connecting the pressure plate through the linkage mechanism, and the elastic pad support plate rotates Connected to the discharge end of the incoming material track, the elastic pad is in contact with the bottom of the L-shaped baffle plate; the feeding mechanism feeds the rear sheet in the initial state, driving the previous sheet through the pressed The L-shaped material baffle is fed upwards to the turning mechanism, and the pressing plate is separated from the plate and stretches out so that the turning plate can drive the L-shaped material dam to continue to rotate, so that the latter plate is conveyed downward to the lower track, realizing grouping and turning. Continuous realization, simple structure without additional drive mechanism.

Owner:芜湖文青机械设备设计有限公司

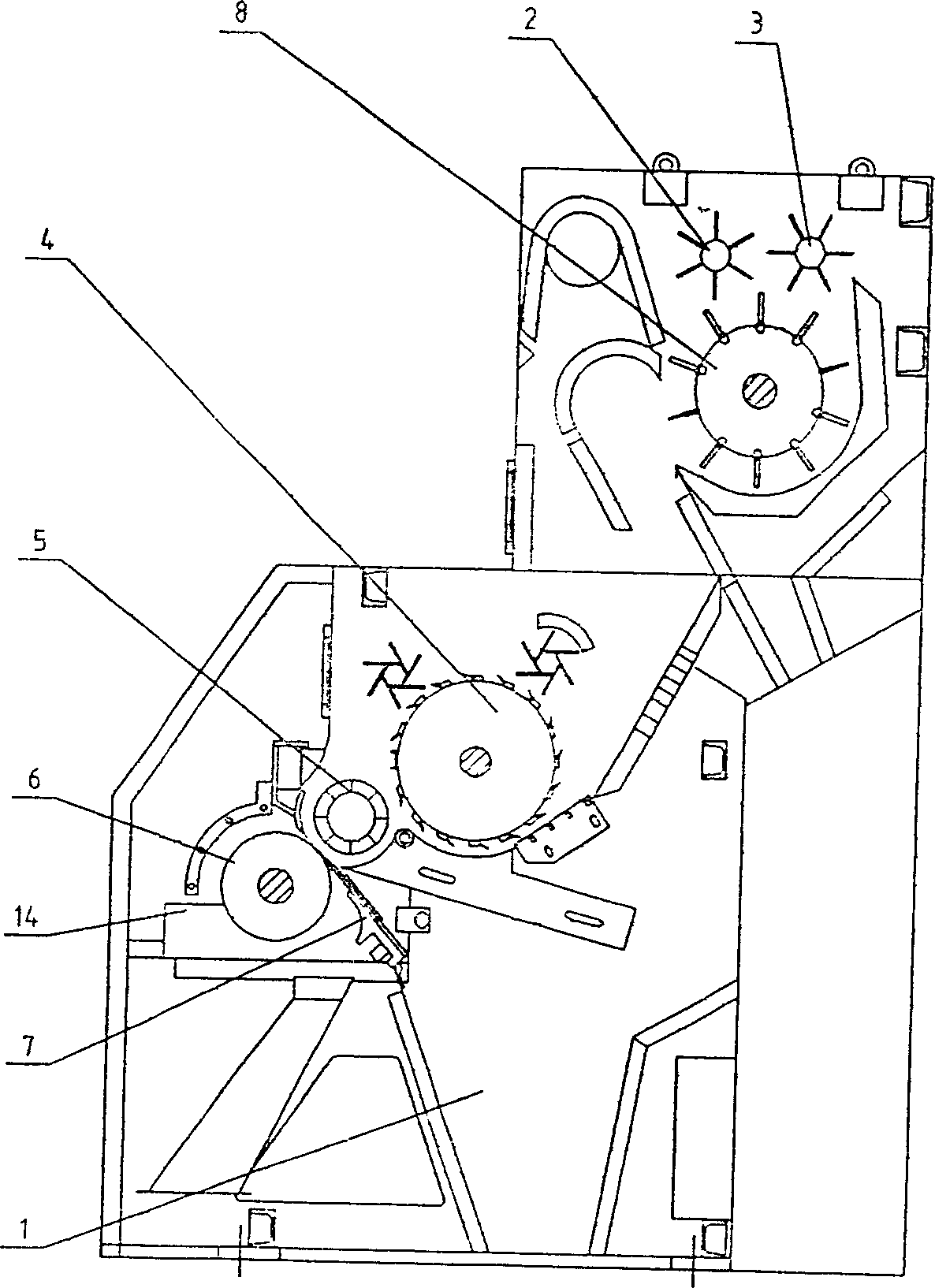

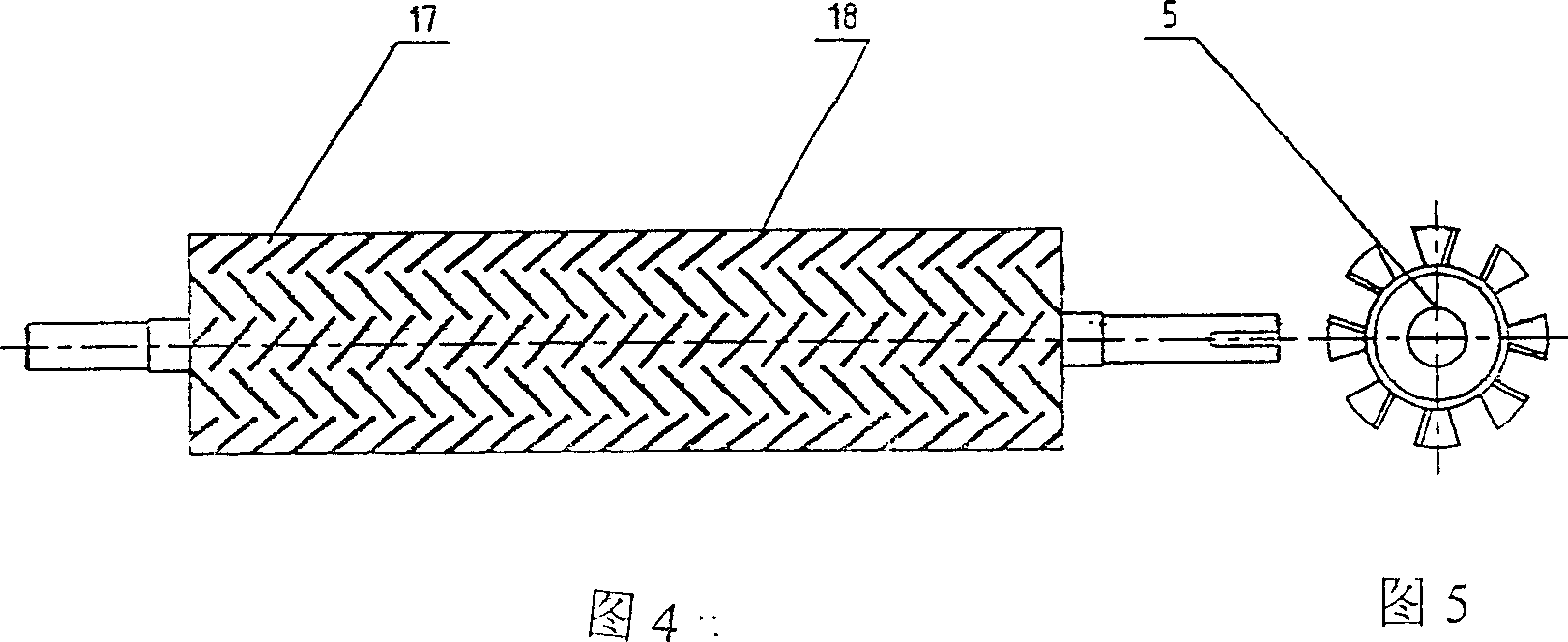

Rolling-cutter and floating-leather roller cotton gin

InactiveCN1249277CSmooth feedingAdjust the feeding speedVegetable fibre separation from seedsFiberAutomatic control

A hob type floating strap roller cotton gin is disclosed in the invention, which is a kind of seed cotton process device separating the seed cotton and cottom fibre. It comprises machine bracket combination, swallowing cotton roller combination, spinal roller combination, hob solder combination, strap roller combination, fixing sword combination, nail tooth roller combination, floating exletree combination, cotton ginning desk, frequency conversion actiyator and so on. Its swallowing cotton roller is drived by the decelerating machine controlled by the frequency conversion actiyator. The strap roller combination fixed on the cotton ginning bracket which is on the left and right wall of the bracket combination is assembled on the cotton ginning desk.

Owner:HANDAN GOLDENLION COTTON MACHINERY

A kind of preparation method of polycarbosilane

The invention provides a method for preparing polycarbosilane. The method comprises the following steps: filling an inert gas into a reaction kettle, adding metal magnesium, an organic solvent and iodine, adding chloromethylchlorosilane dropwise into the reaction kettle, React at 25°C for 3 hours to generate a polycarbosilane intermediate; add a reducing agent to the reaction kettle, the reducing agent is preferably sodium hydride, and react at 25°C for 5 hours to generate a milky white rubber-like polycarbonate Silane; liquid separation, filtration, organic phase washing and drying are carried out on the generated polycarbosilane rubber solid, and the heated polycarbosilane solid is discharged after being pulverized by the feeding device, and the generated polycarbosilane solid is processed by the feeding device The crushing and guiding material solves the problem that the unloading component is easily blocked in the prior art, and the speed of unloading can be adjusted according to the production efficiency of the material processing equipment to make it reach a reasonable state.

Owner:福建立亚化学有限公司

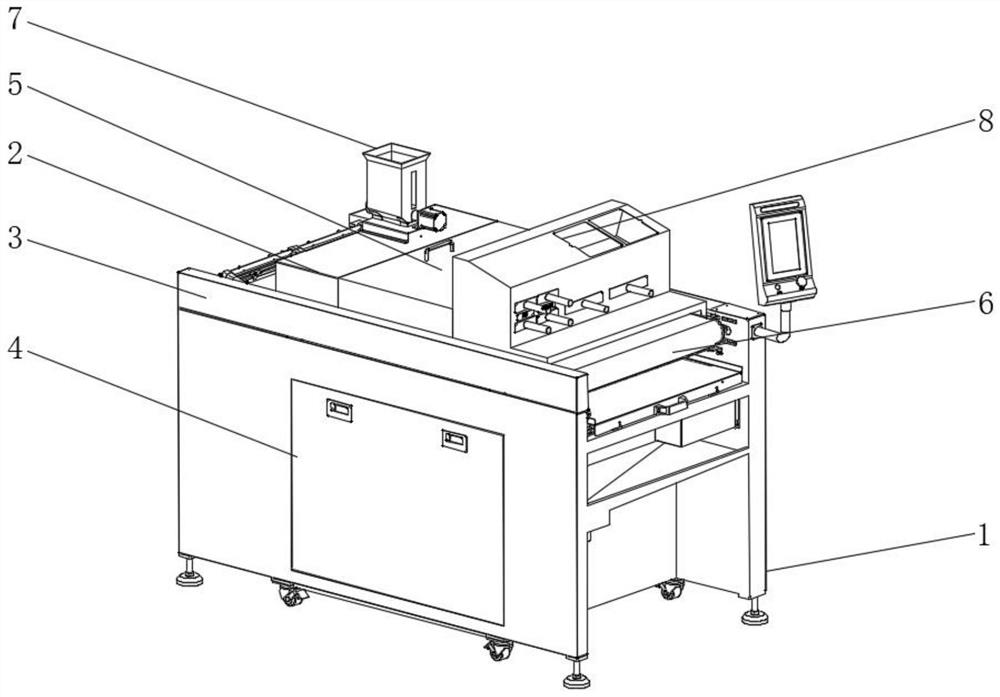

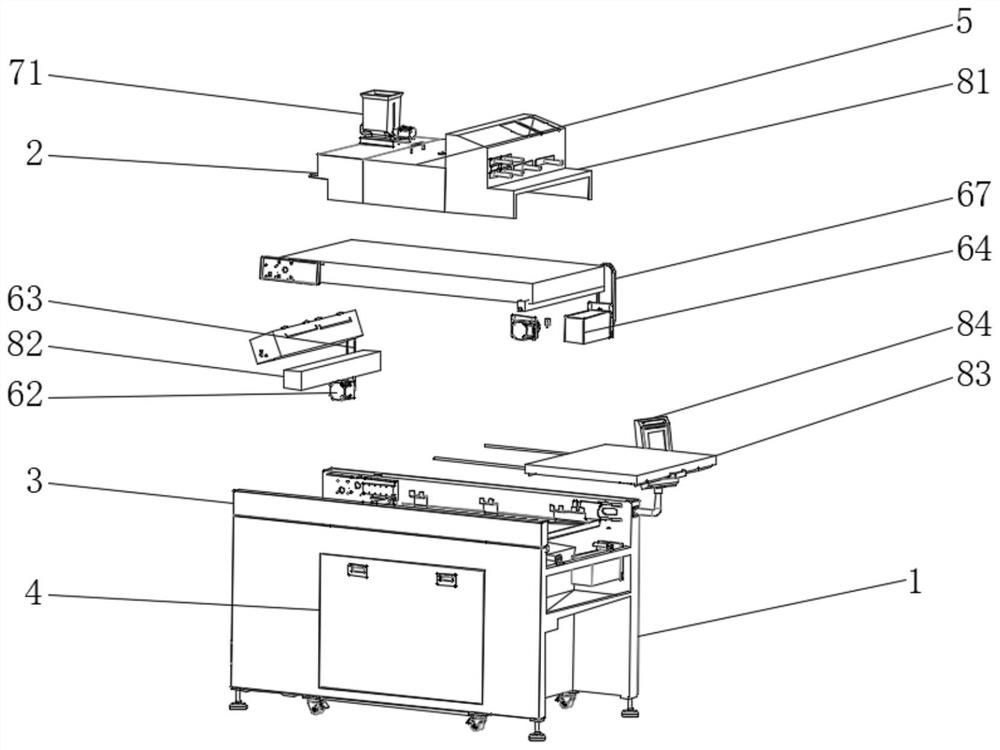

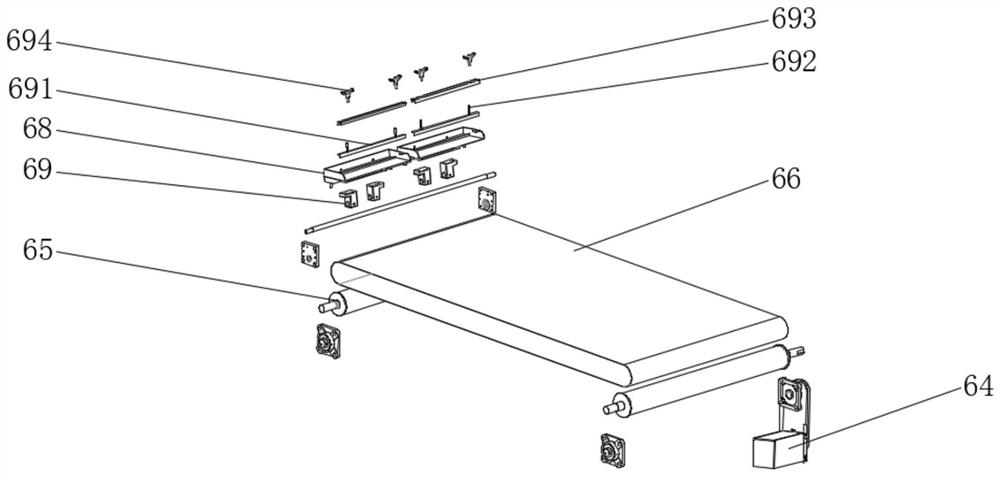

Full-automatic steamed vermicelli roll machine

PendingCN114868865ASave human effortIncrease flexibilityClimate change adaptationFood shapingProcess engineeringRice milk

The invention relates to the technical field of steamed vermicelli roll processing, and discloses a full-automatic steamed vermicelli roll machine which comprises a cabinet body, a supporting plate is connected to the top of the cabinet body, two overturning cleaning doors are movably connected to the top of the cabinet body, a protective door is arranged on the front side of the cabinet body and connected with the cabinet body through hinges, and a frame plate is fixedly connected to the top of the cabinet body. The frame plate is arranged at the top of the cabinet body, one side of the top of the cabinet body is rotationally connected with a first feeding mechanism, and the top of the cabinet body is fixedly connected with a second feeding mechanism. According to the automatic steamed vermicelli roll machine, through the design of the feeding mechanism, different feeding modes can be selected on site according to actual processing requirements in the processing process of the automatic steamed vermicelli roll machine, correspondingly, the flexibility is higher, in the feeding process, a slurry buffer plate can prevent rice slurry from splashing out, meanwhile, it is guaranteed that the interior of a slurry hanging container is evenly filled with the rice slurry, and the practicability of the automatic steamed vermicelli roll machine is improved. And the baffle moves to the feeding port to reduce the blocking range, so that the feeding speed is adjusted.

Owner:ARTOP DESIGN GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com