A kind of needle tube recycling and processing equipment

A technology for recycling and processing equipment, applied in grain processing, hypodermic injection devices, etc., which can solve problems such as easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

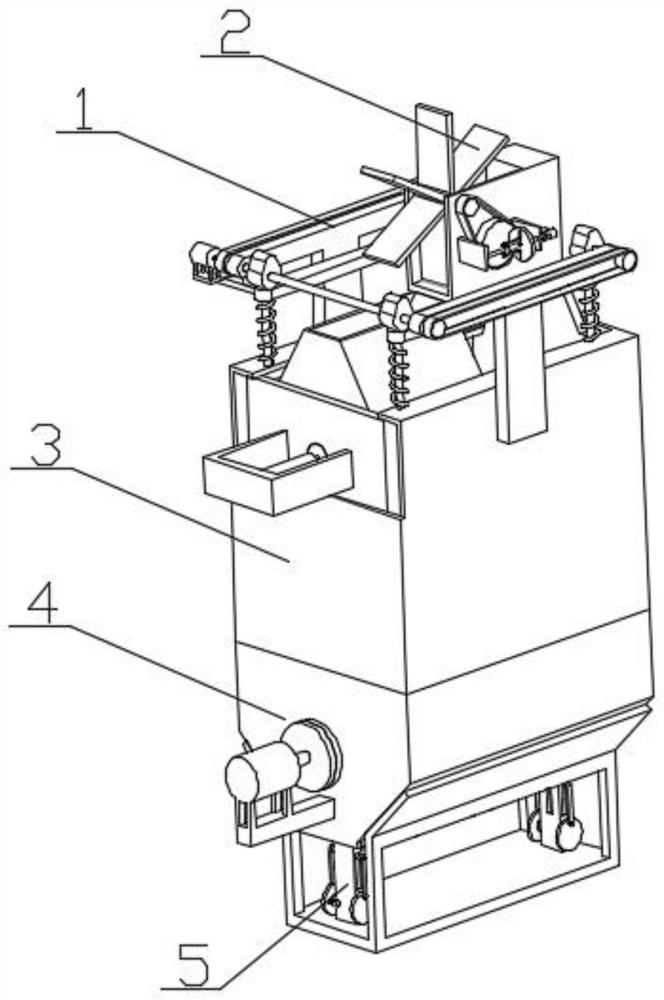

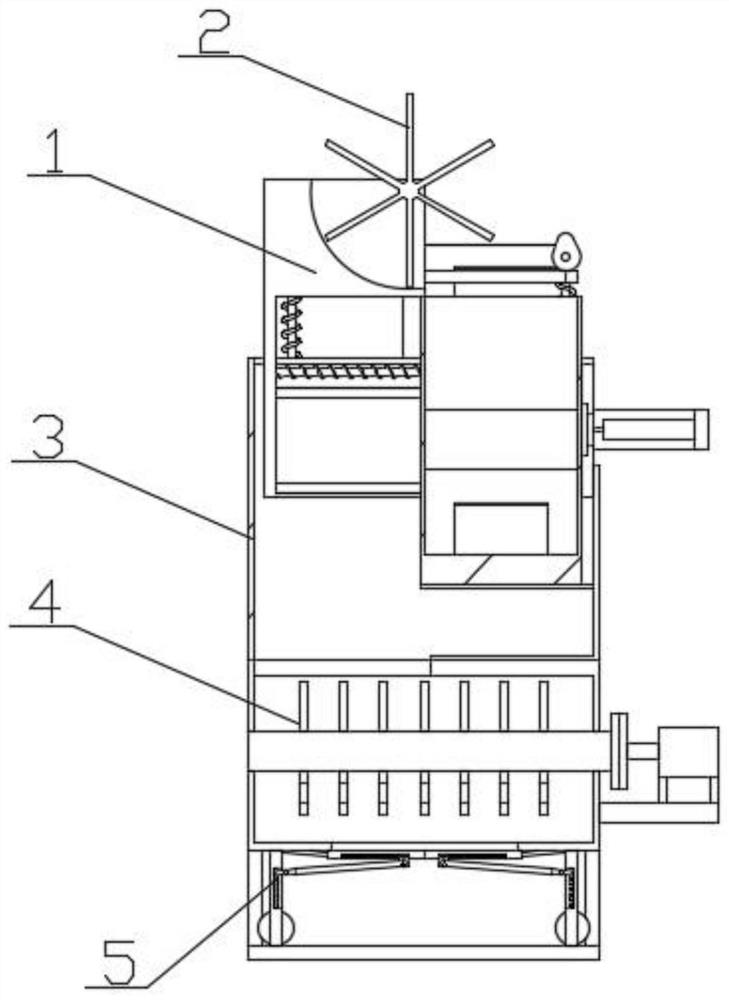

[0038] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 To illustrate this embodiment, the present invention relates to a recovery processing device, more specifically a needle tube recovery processing device, including a hopper mechanism 1, a stirring feeding mechanism 2, a shell mechanism 3, a crushing mechanism 4, and an opening and closing mechanism 5. The equipment can ensure smooth feeding, the equipment can ensure that no needle tube will run out when feeding, the equipment can adjust the feeding speed, the equipment can prevent material blocking, the equipment can crush the needle tube, and the equipment can automatically control the discharge .

[0039] The hopper mechanism 1 is connected with the agitating feeding mechanism 2 ...

specific Embodiment approach 2

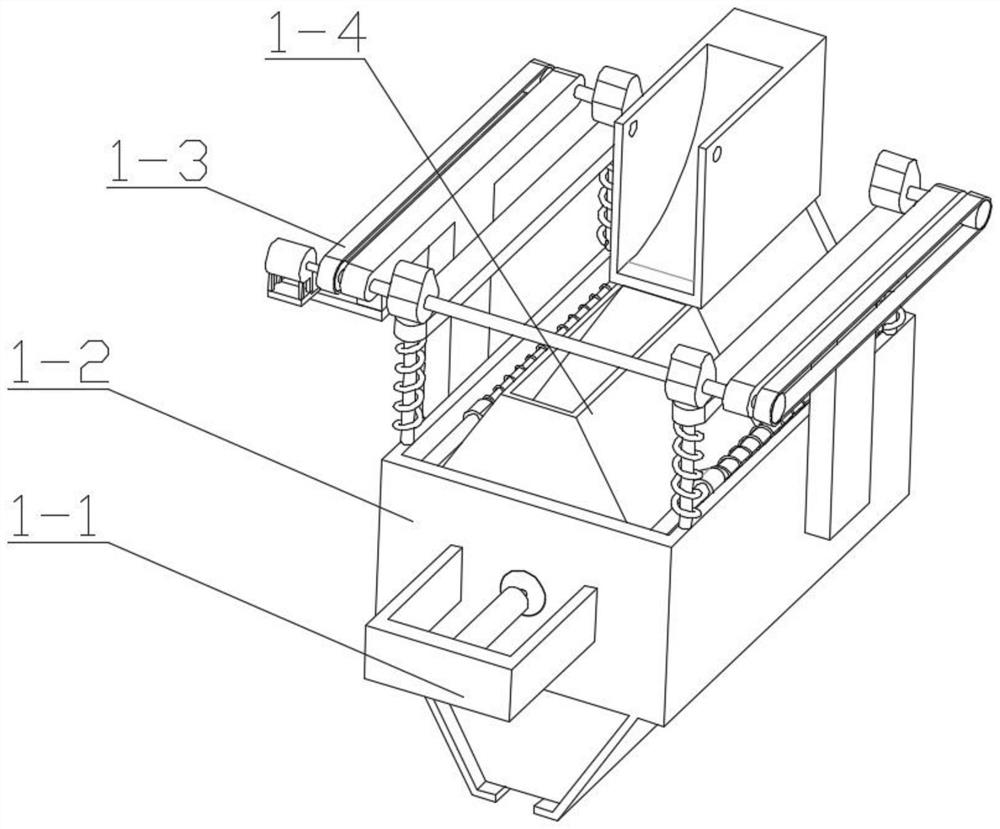

[0041] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 Describe this embodiment, this embodiment will further explain the first embodiment, the hopper mechanism 1 includes a push-pull mechanism 1-1, a bucket body mechanism 1-2, a vibration drive mechanism 1-3, a movable hopper mechanism 1-4, push-pull Mechanism 1-1 is connected with bucket mechanism 1-2, bucket mechanism 1-2 is connected with vibration drive mechanism 1-3, movable hopper mechanism 1-4 is connected with bucket mechanism 1-2, movable hopper mechanism 1-4 is connected with The push-pull mechanism 1-1 is connected; the push-pull mechanism 1-1 includes door support 1-1-1, hydraulic cylinder 1-1-2, ladder support 1-1-3, door support 1-1-1 and hydraulic cylinder 1-1 -2 connec...

specific Embodiment approach 3

[0043] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21Describe this embodiment, this embodiment will further explain Embodiment 1, the described agitation feeding mechanism 2 includes adjustment wheel mechanism 2-1, adjustment mechanism 2-2, friction wheel 2-3, transmission belt 2-4, impeller Pulley 2-5, impeller shaft 2-6, impeller 2-7, adjusting ring 2-8 with internal thread, adjusting wheel mechanism 2-1 is connected with adjusting mechanism 2-2, adjusting wheel mechanism 2-1 is connected with friction wheel 2- 3 are connected, the friction wheel 2-3 is connected with the transmission belt 2-4, the transmission belt 2-4 is connected with the impeller pulley 2-5, the impeller pulley 2-5 is connected with the impeller shaft 2-6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com