Automated material conveying device for hardware stamping parts

A technology for stamping parts and feeding materials, applied in the field of metal stamping parts processing and application, can solve the problems of large output, small size of five stamping parts, and inability to fully automate processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

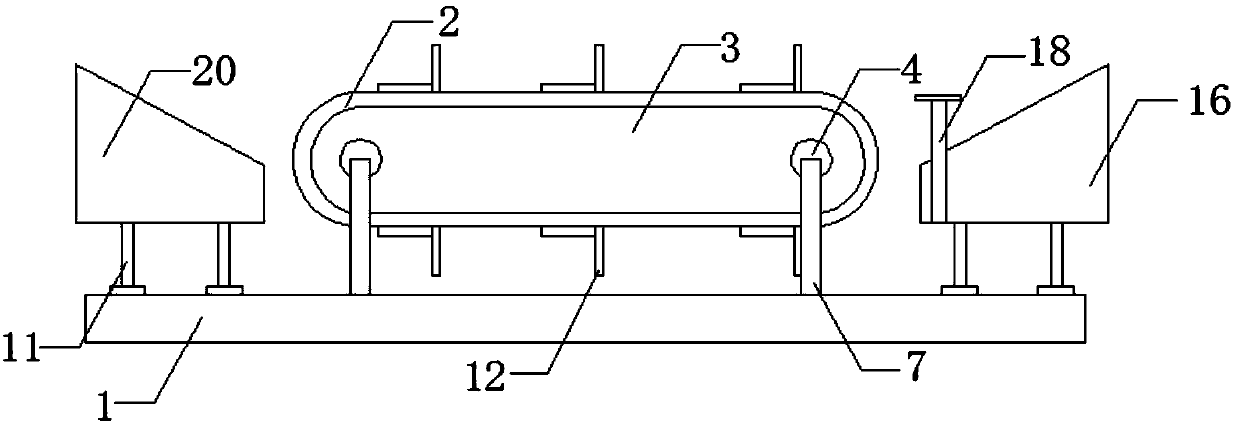

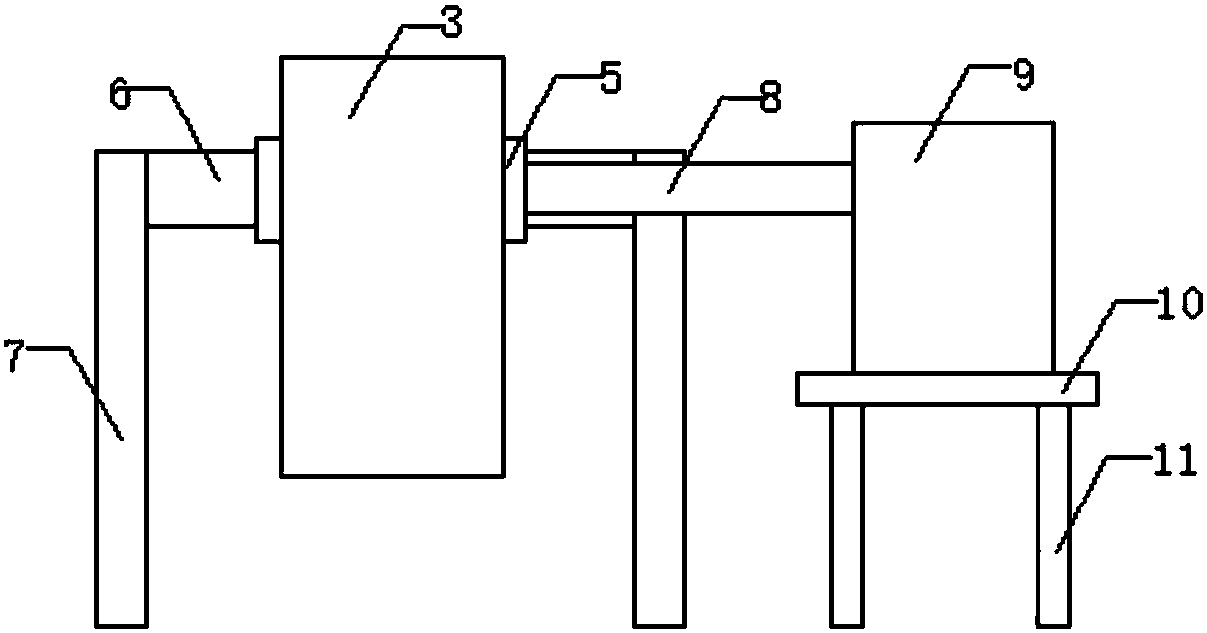

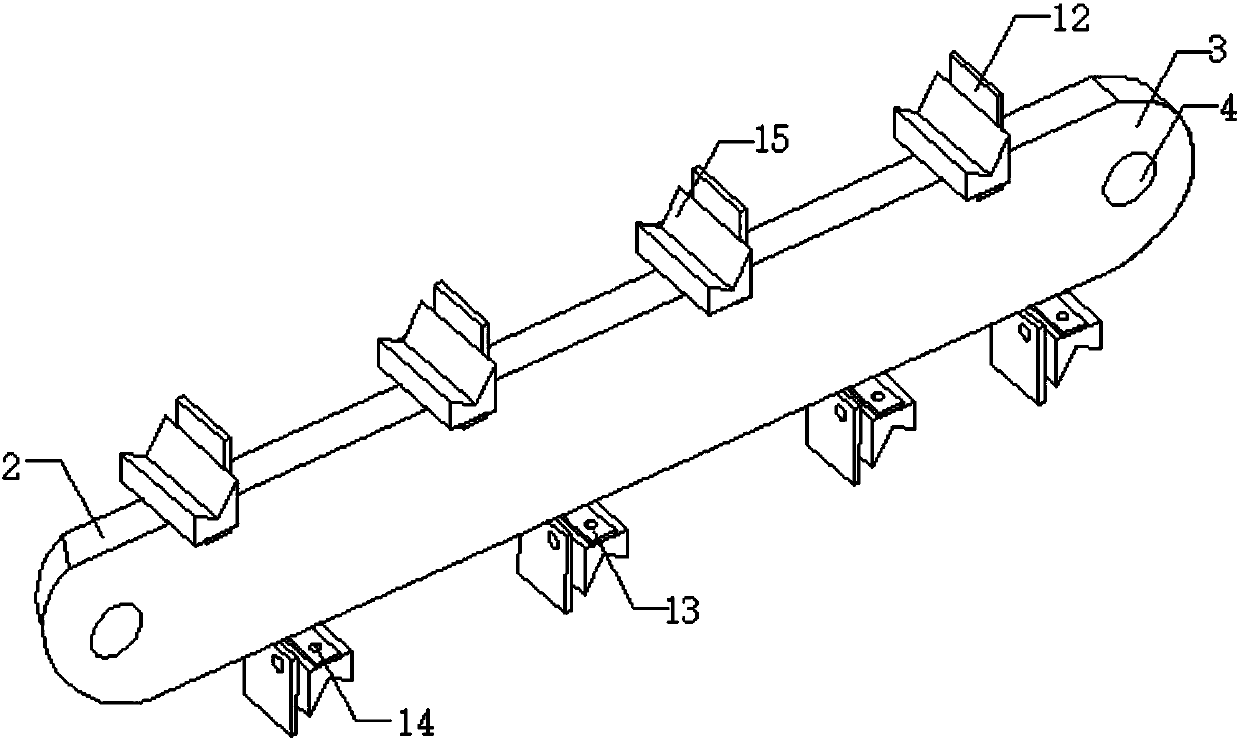

[0026] see Figure 1-6 As shown, an automatic feeding device for metal stamping parts includes a bottom plate 1, a wheel shaft 3, a cross bar 6, a rotating shaft 8, a support plate 10, a vertical plate 12, a screw hole 14, a raw material tank 16, a baffle plate 18 and Outlet chute 20, the base plate 1 is provided with a vertical bar 7, and the top of the vertical bar 7 is horizontally connected to a cross bar 6, and the other end of the cross bar 6 is connected to the adapter block 5, and the adapter block 5 is located in the connection hole 4, the connection hole 4 is located on the wheel shaft 3, by setting the motor 9 and the rotating shaft 3 connected to the pulley 2, the motor 9 rotates, thereby driving the pulley 2 to rotate together, so that on the one hand, it not only provides the rotation of the pulley 2 On the other hand, it is possible to control the speed of the motor 9, thereby adjusting the feeding speed for metal stamping parts, and the outer circumference of t...

Embodiment 2

[0028] read on Figure 1-6 As shown, compared with the above-mentioned embodiment, a rotating shaft 8 runs through the inside of the horizontal bar on one side of the wheel shaft 3, and the other end of the rotating shaft 8 is connected to a motor 9, and the motor 9 is movably connected to the wheel shaft 3 through the rotating shaft 8, through The motor 9 is provided, thus giving the pulley 2 a source of power when rotating. The bottom end of motor 9 is provided with support plate 10, and the bottom end of support plate 10 is provided with support leg 11, and the bottom end of raw material tank 16 is also provided with support leg 11, and the bottom end of support leg 11 is positioned on base plate 1, by The legs 11 are provided, thus making it more stable on the base plate 1 . The pulley 2 is vertically provided with several vertical plates 12, and the bottom end of the vertical plate 12 is horizontally provided with several horizontal plates 13, and the vertical plate 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com