Rolling-cutter and floating-leather roller cotton gin

A hob-type and ginning machine technology, applied in the direction of separating plant fibers from seeds, etc., can solve problems such as increased production costs, uneven processing, and reduced production efficiency, so as to reduce consumption and production costs, avoid uneven wear, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

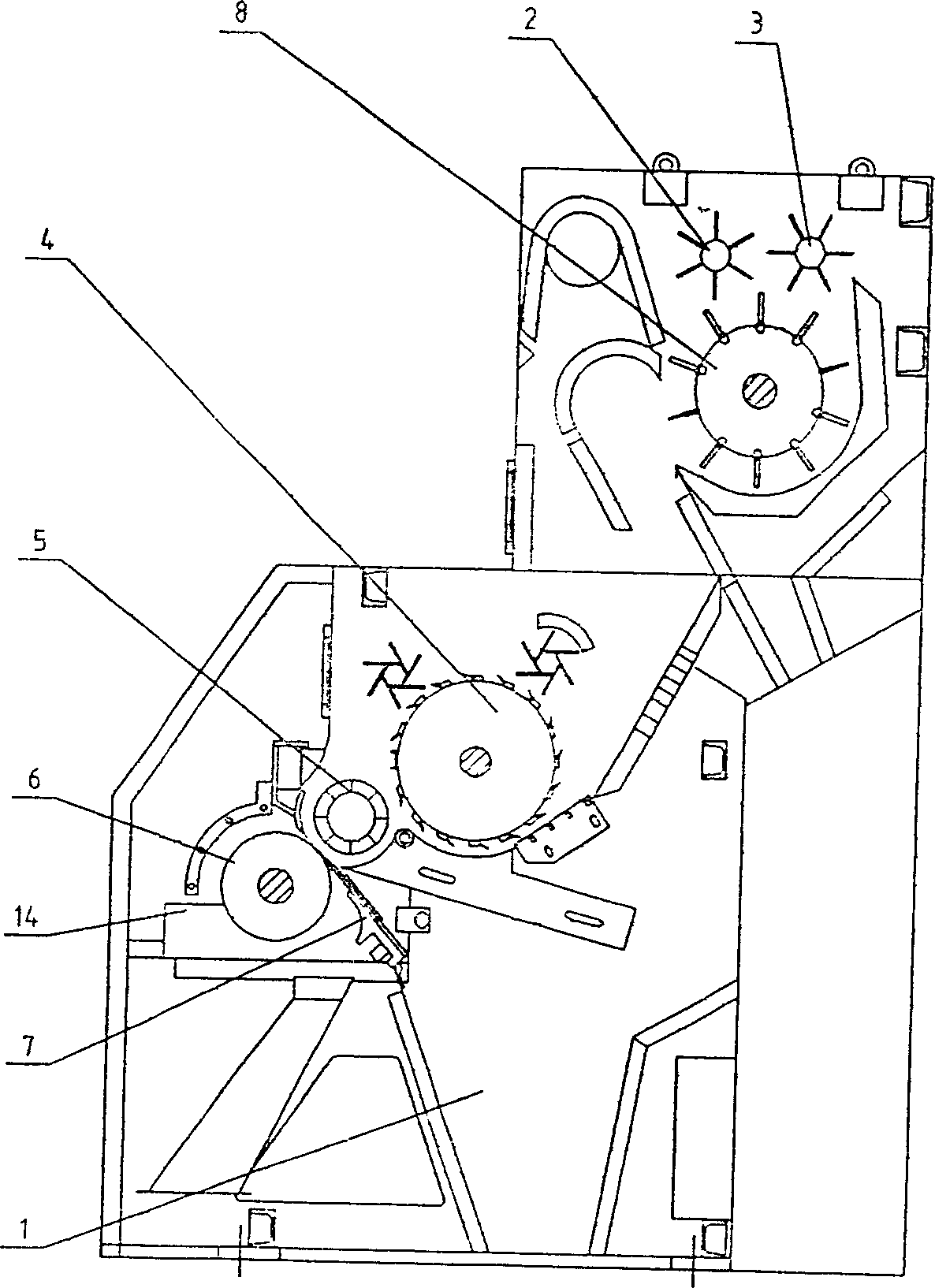

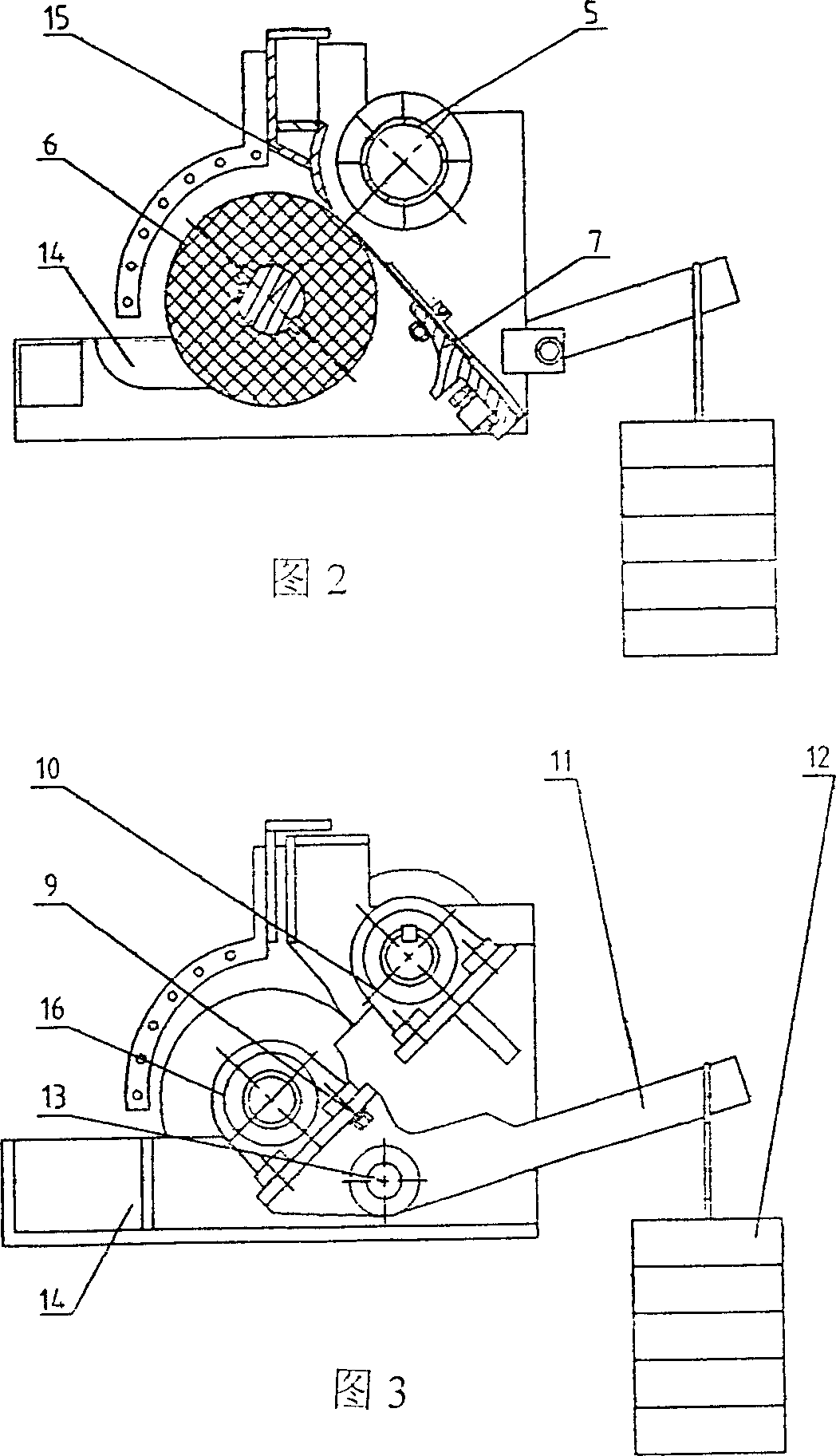

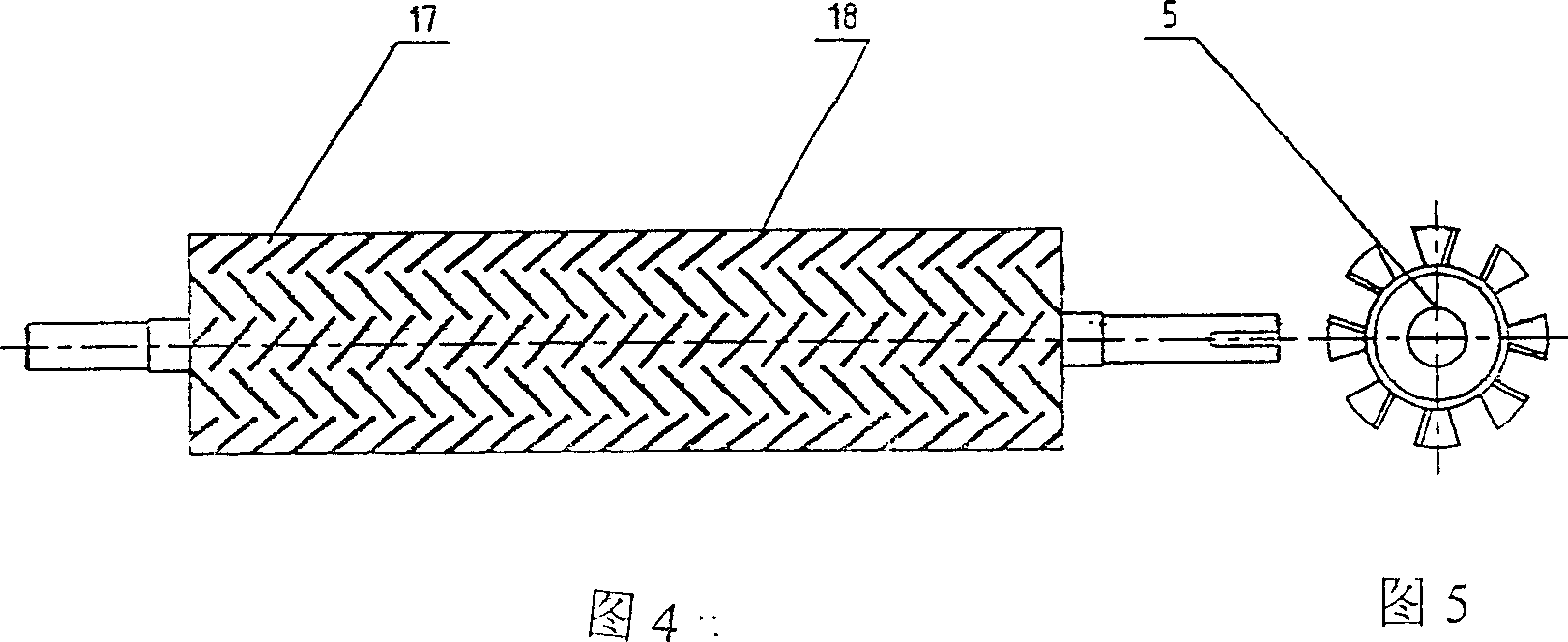

[0024] Figure 1-6 Shown: hob type floating roller gin, composed of frame combination 1, front pattern feeding roller combination 2, rear pattern feeding roller combination 3, acupuncture roller combination 4, hob 5, top roller combination 6, fixed knife combination 7 , nail tooth roller combination 8, floating bearing combination 11, embossing stand 14, frequency conversion speed regulator 23 and other components. The transmission wheel 20 mounted on the transmission shaft of the rear feeding pattern roller assembly 3 on the front and rear side walls of the frame assembly 1 and the transmission wheel 2 mounted on the planetary cycloidal pin gear motor 22 are formed by a transmission chain. Drive chain, gear transmission is installed between the front and rear flower feeding roller combinations (2, 3), the reduction motor 22 is controlled by the frequency converter 23, the control signal output line of the operation box 24 is connected with the control signal of the frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com