Adjusting device for differential mechanism of straight flat seaming machine

A technology of a differential mechanism and an adjustment device, which is applied to the cloth feeding mechanism, sewing machine components, sewing equipment and other directions, can solve the problems of high cost, inconvenient use, complex structure, etc., and achieves low production cost, reasonable design and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

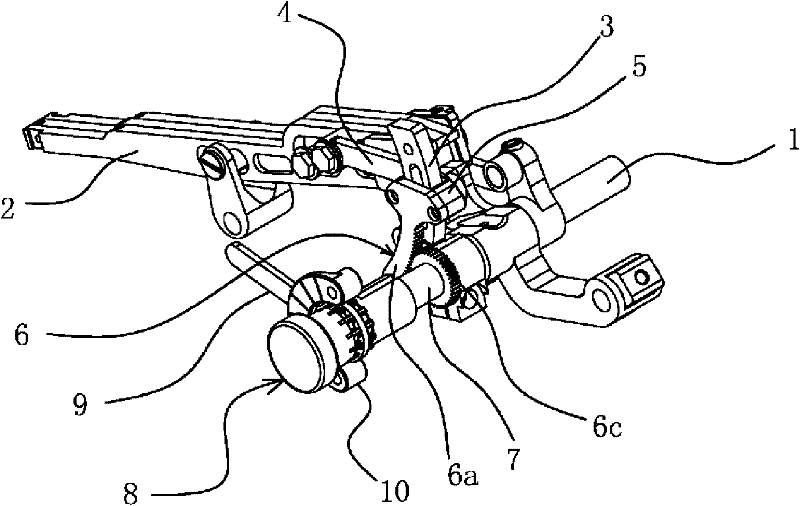

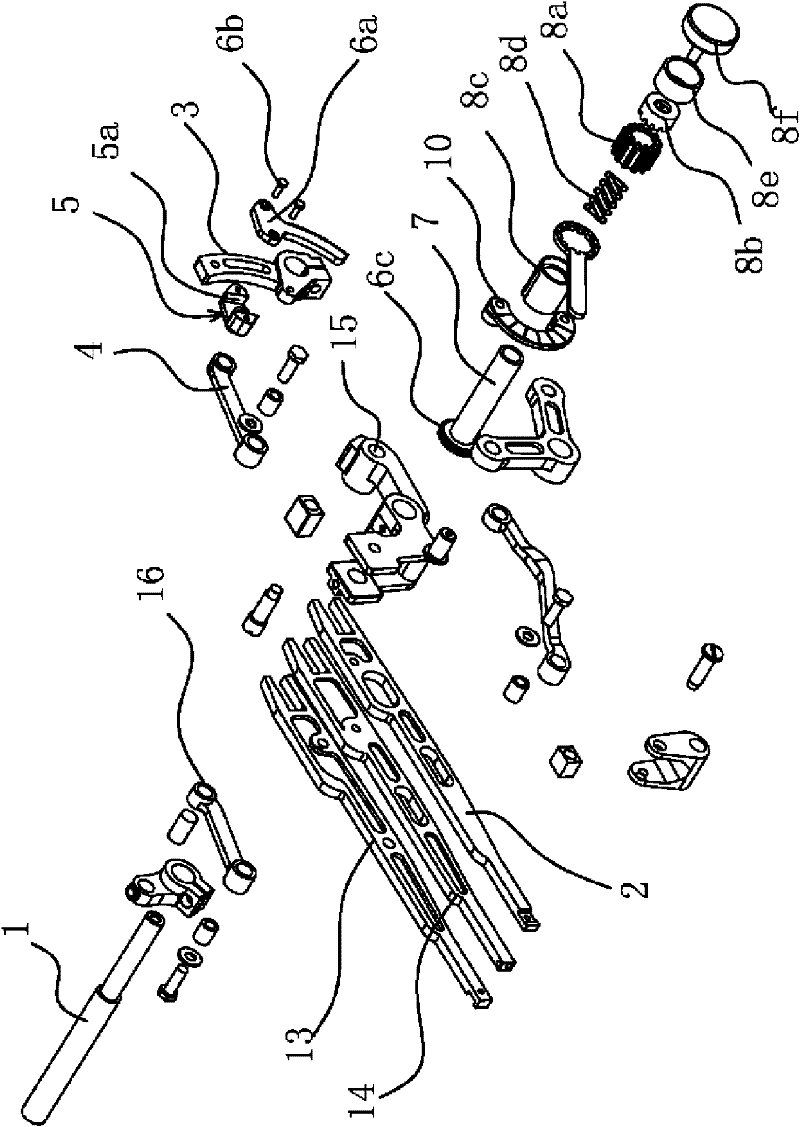

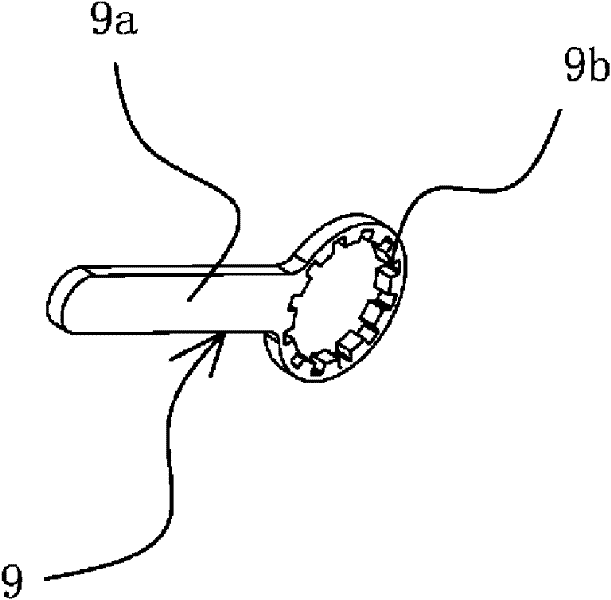

[0028] Such as figure 1As shown, the differential mechanism of the straight-through interlock sewing machine includes a differential bracket 2 arranged on the frame and a feed shaft 1 for driving the differential mechanism, and there is also a side-by-side arrangement with the differential bracket 2 The main tooth frame sheet and the needle guard tooth frame sheet 14, the differential tooth frame sheet 2 is provided with a differential feeding tooth, and the main tooth frame sheet is provided with a main feeding tooth. An arc-shaped differential crank 3 is fixed on the feeding shaft 1, and a connecting rod 4 is arranged between the differential crank 3 and the differential bracket piece 2, and one end of the connecting rod 4 is hinged with the differential bracket piece 2, The adjustment device is arranged at the other end of the connecting rod 4 and the differential crank 3, and includes a slider 5 that can slide along the differential crank 3, the other end of the connecting...

Embodiment 2

[0035] The general content of this embodiment is the same as that of Embodiment 1, the difference is that, as Figure 4 As shown, the adjustment assembly 8 in this embodiment includes a polygonal column 11 sleeved on the sleeve 7 and fixed in the circumferential direction. In this embodiment, a hexagonal shape is used. Of course, as another solution, a quadrangle or a cylinder can also be used. Pentagon, one side of the cylinder 11 is provided with a shaft sleeve 8c between the positioning gear 6c, and the other side of the cylinder 11 is provided with a fastener 2 8f for axially positioning the cylinder 11, and a fastener 2 8f It is axially screwed with the end face of the feeding shaft 1. As another solution, the column body 11 can be replaced by an outer hex nut. The user can effectively rotate the sleeve 7 by clamping the polygonal cylinder 11 with a wrench.

Embodiment 3

[0037] The general content of this embodiment is the same as that of Embodiment 1, the difference is that, as Figure 5 As shown, the adjustment assembly 8 includes a plurality of positioning surfaces 12 for wrench positioning on the sleeve 7 by means of material removal, and the end surface of the sleeve 7 is provided with a fastener 2 8f that can block its outward movement. Part two 8f is axially screwed with the feed shaft 1 end face. In this solution, the user directly uses a wrench to clamp the positioning surface 12 on the sleeve 7 to rotate the positioning gear 6c on the sleeve 7, and the fastener 2 8f mainly plays a role in limiting the axial position of the sleeve 7. effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com