Patents

Literature

52results about How to "Reduce feeding times" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

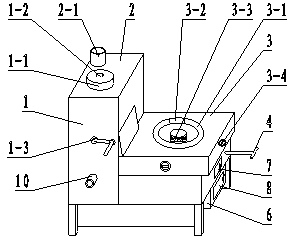

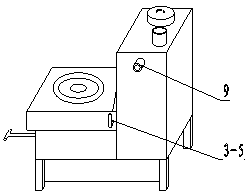

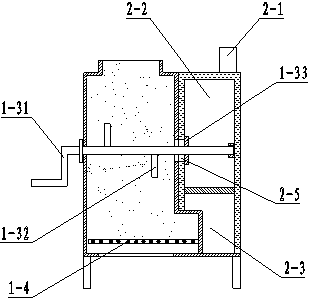

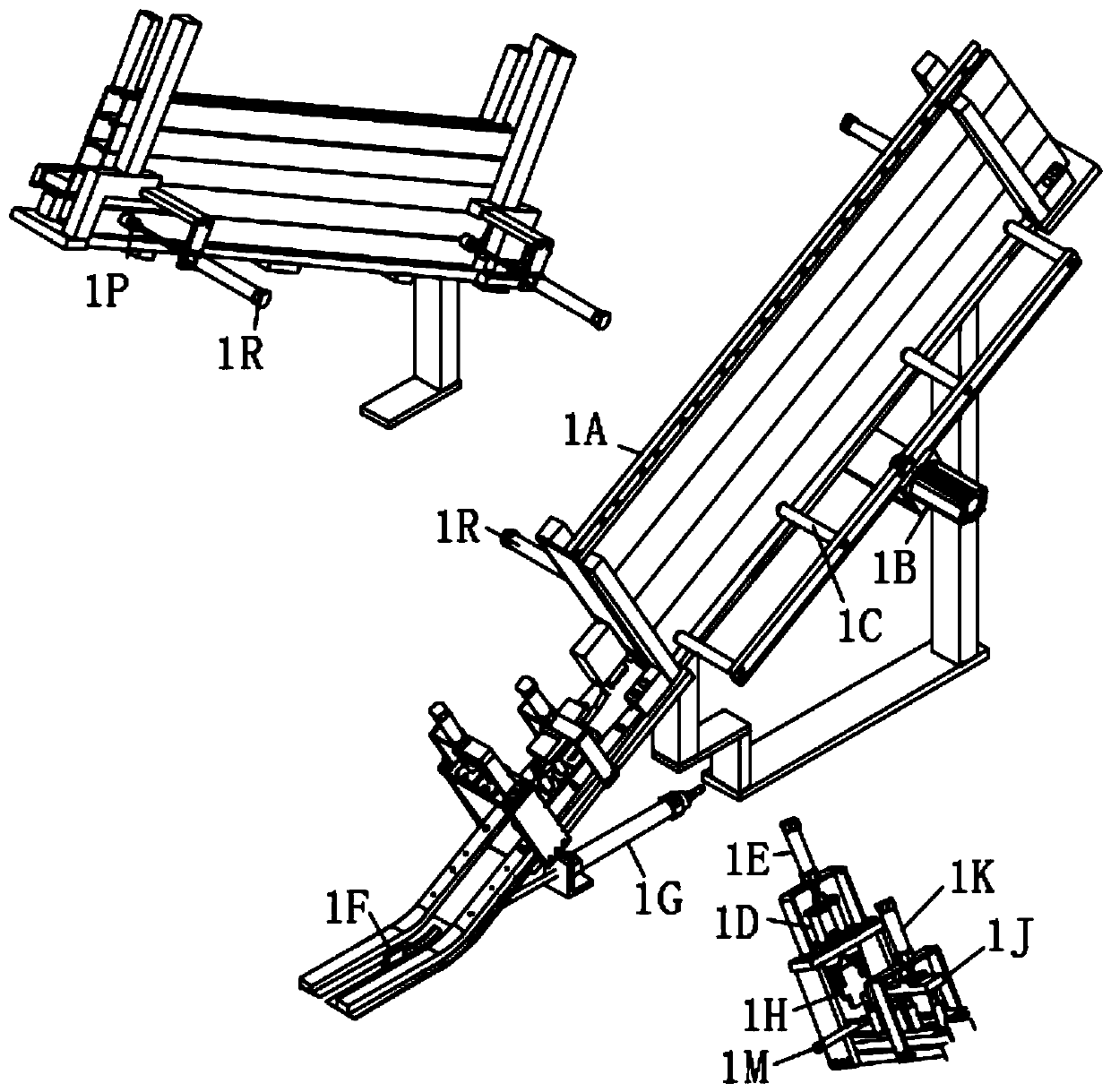

Spiral stirrup continuously and synchronously machining machine and machining method

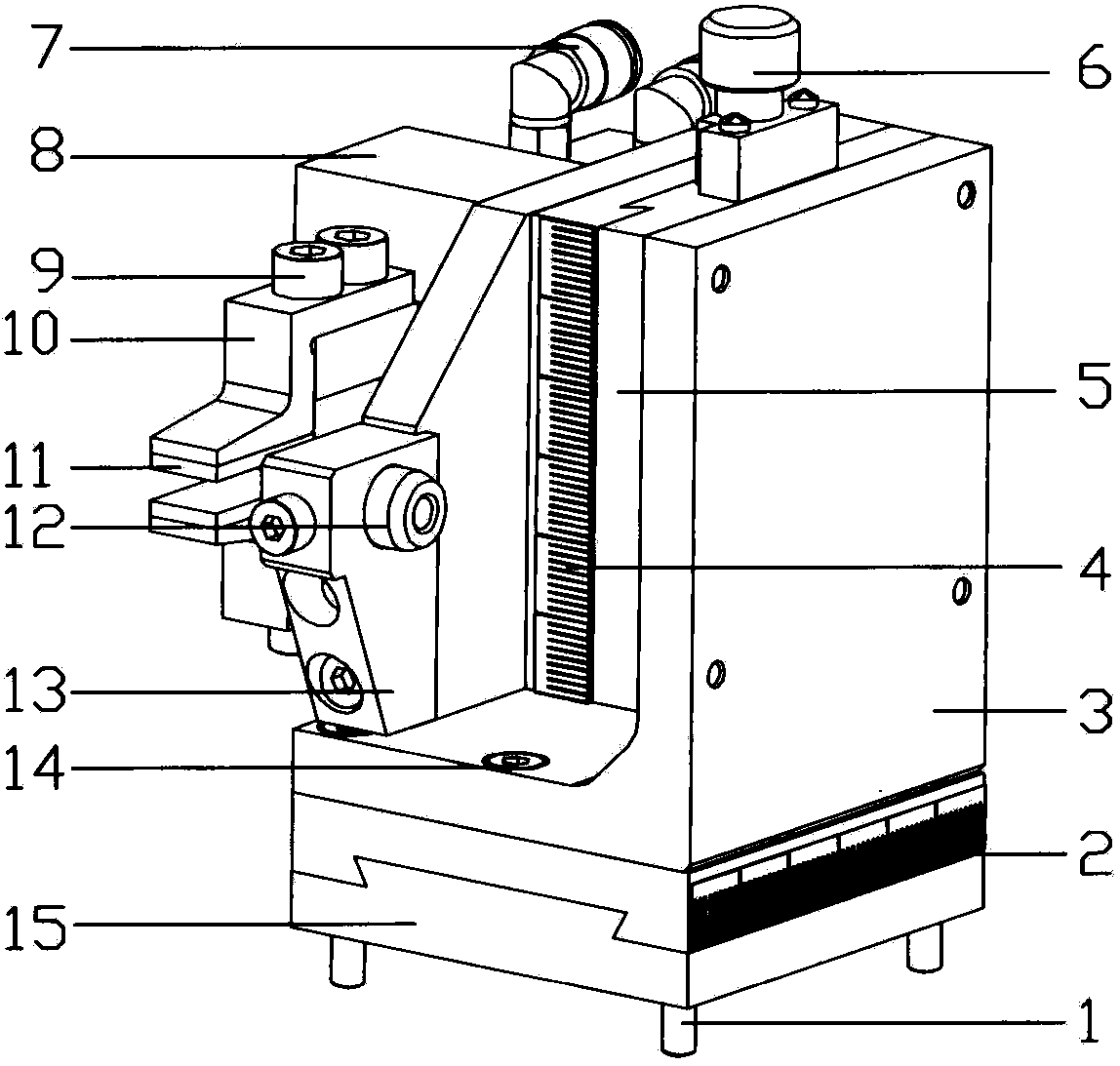

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

Fully-automatic round-head barrel hook forming machine

ActiveCN105414415AMeet production requirementsFulfill production requirementsWire articlesProduction lineControl system

The invention discloses a fully-automatic round-head barrel hook forming machine belonging to the field of wire bending machines. The fully-automatic round-head barrel hook forming machine comprises a steel wire feeding device, a handle tube feeding device, a forming device, a fetching and shaping device and a control system, wherein the handle tube feeding device is arranged in front of the forming device; the steel wire feeding device is arranged at the rear of the forming device; the fetching and shaping device is arranged in front of the forming device, is located below the handle tube feeding device and is composed of a grabbing mechanism, a locating mechanism and a shaping mechanism; and all the steel wire feeding device, the handle tube feeding device, the forming device and the fetching and shaping device are automatically controlled by the control system to sequentially finish the actions of handle tube feeding, steel wire feeding, barrel hook forming as well as fetching and shaping. By using the fully-automatic round-head barrel hook forming machine, a barrel hook not only can be fully-automatically produced, but also can be corrected and shaped after being formed to make preparation for the next installation of the barrel hook, so that the requirement of an automatic installation production line of the barrel hook is met, and the automatic level and production efficiency of vessels such as barrels and tanks are greatly increased.

Owner:CHANGZHOU PUHE PLASTIC

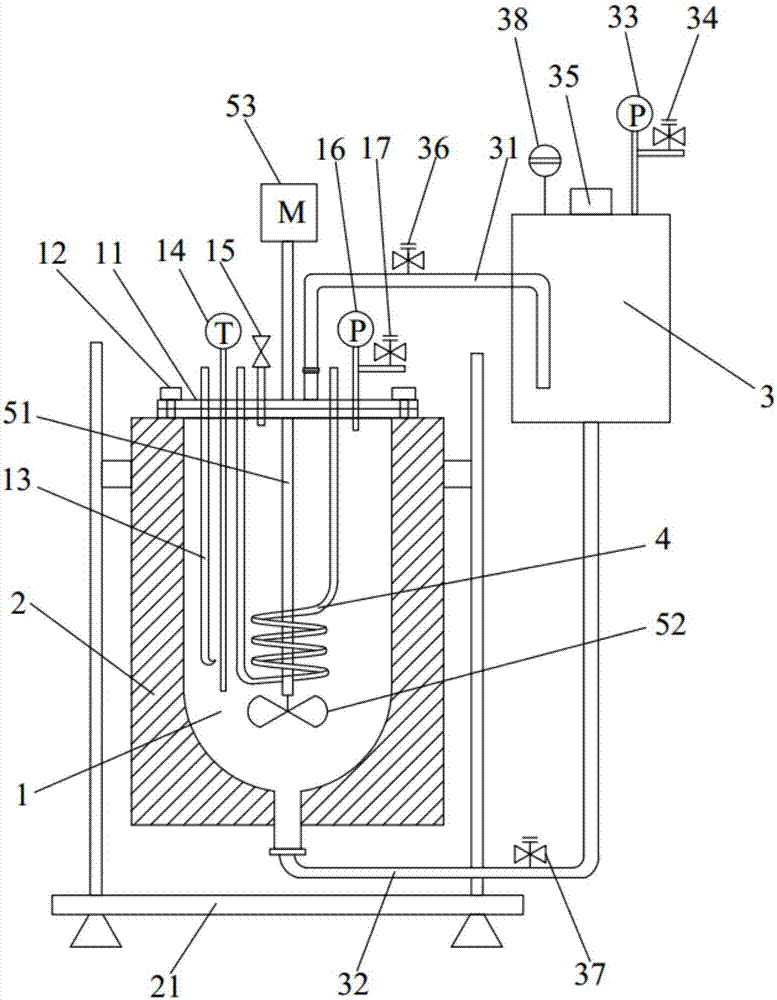

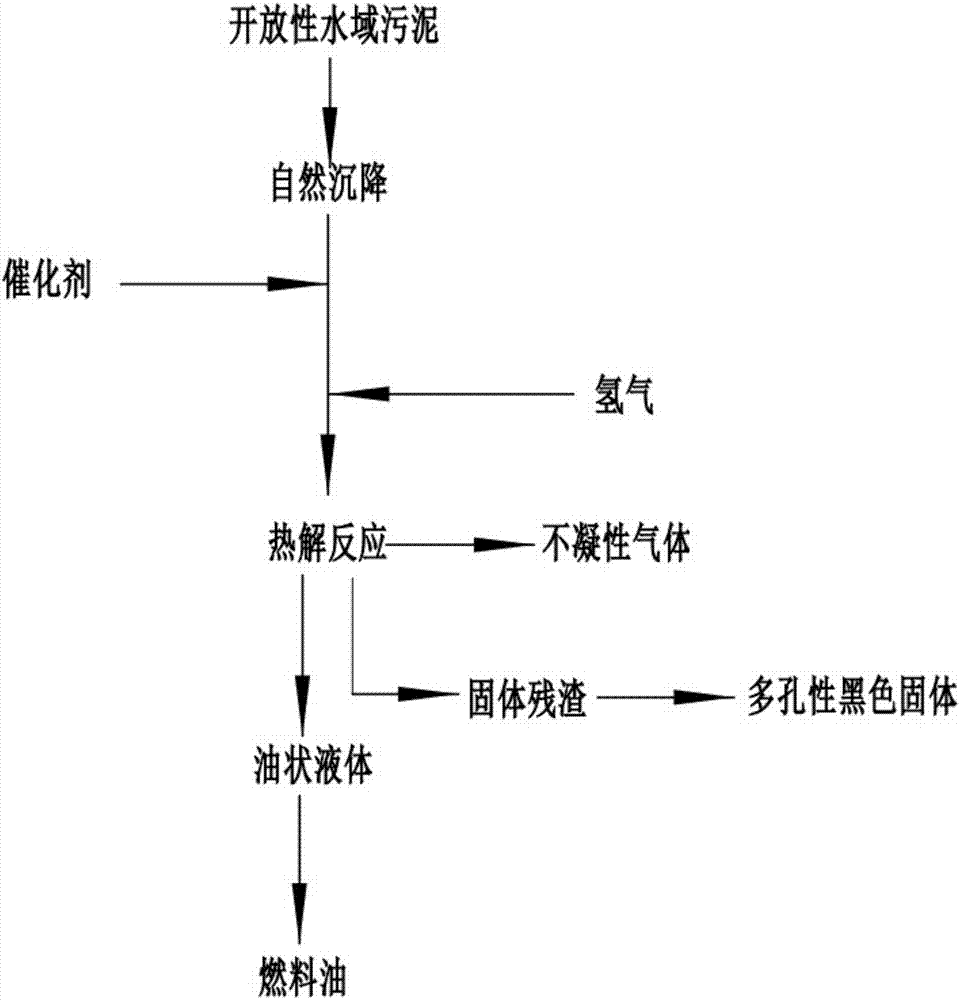

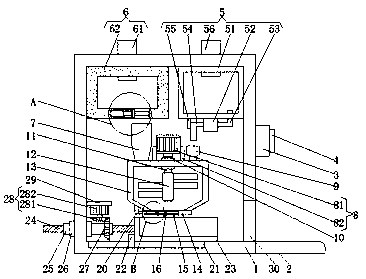

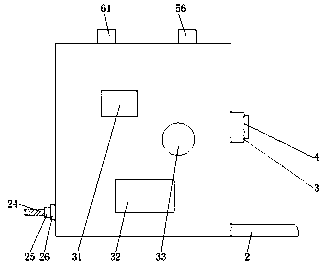

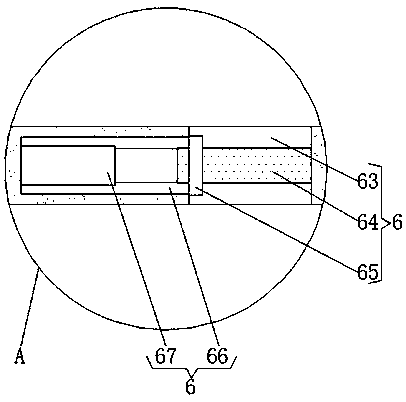

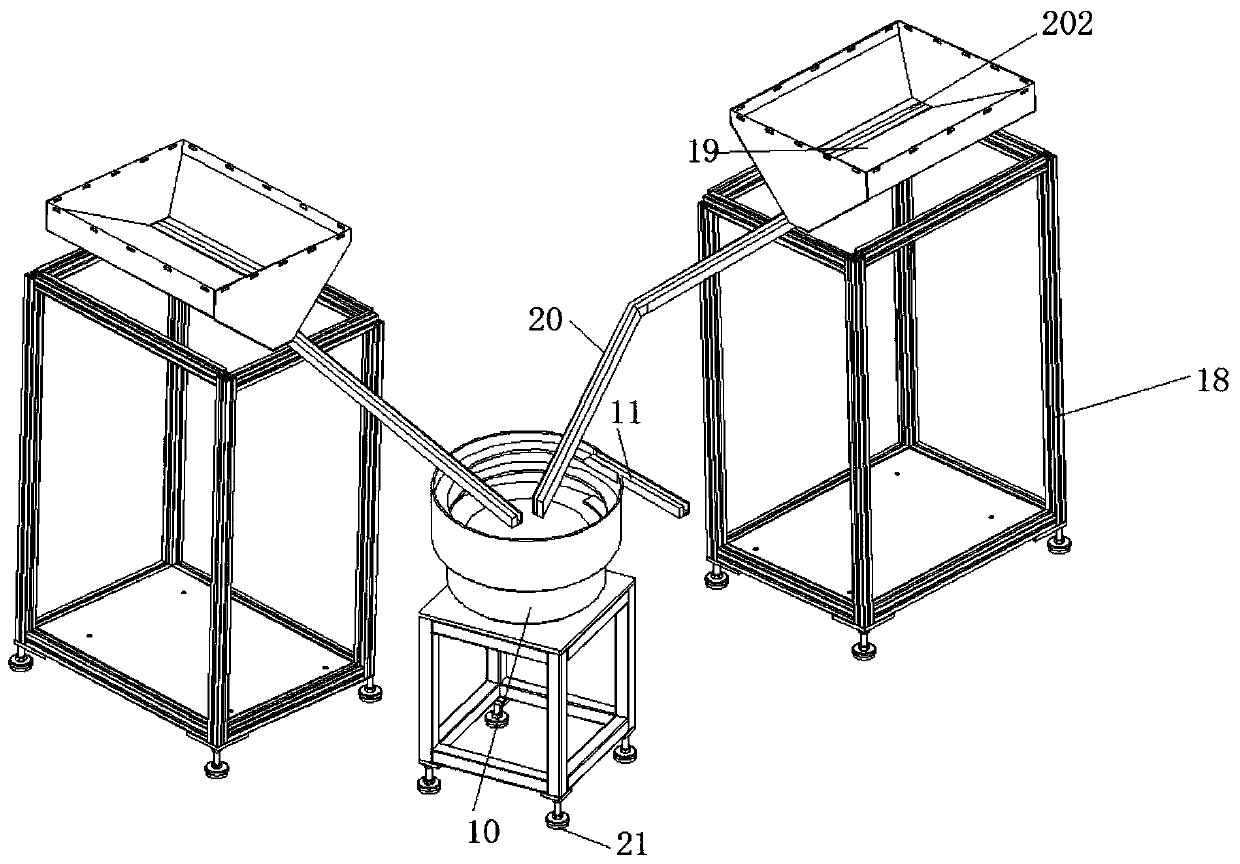

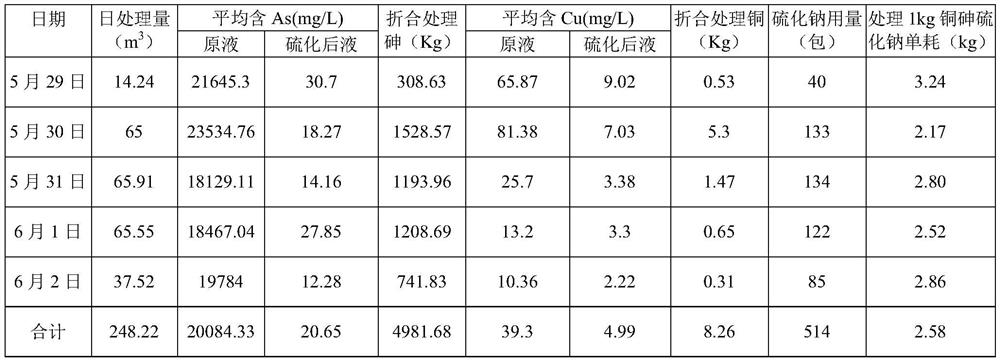

Open water area sludge treatment pyrolysis reactor and sludge treatment method

ActiveCN107382008AAchieve maximum utilizationLarge specific surface areaSludge treatment by pyrolysisByproduct vaporizationOpen waterSludge

The invention discloses an open water area sludge treatment pyrolysis reactor which comprises a reaction kettle, an electric heating device, a semi-continuous feeding device and a circulation cooling device. A stirring device is arranged inside the reaction kettle, the circulation cooling device comprises a cooling liquid circulation pool and a cooling coil, the semi-continuous feeding device comprises a feed bin communicated with the reaction kettle, the middle of the feed bin is communicated with a sludge feeding port through a feeding pipe, and the bottom of the feed bin is communicated with a discharging port through a discharging pipe. The invention further discloses an open water area sludge treatment method which includes the steps of pretreatment, pyrolysis, product separation and extraction, semi-continuous feeding, discharging and post-treatment. 40% or more of organic matters in sludge is transformed into high heating value fuel oil, the transformation rate of the organic matters reaches up to 90% or more, a large quantity of non-condensable gas, solid residues and water-phase liquid are produced, the sludge is maximally used, and environmental protection pressure is remarkably reduced.

Owner:禹城市惠福新能源有限公司

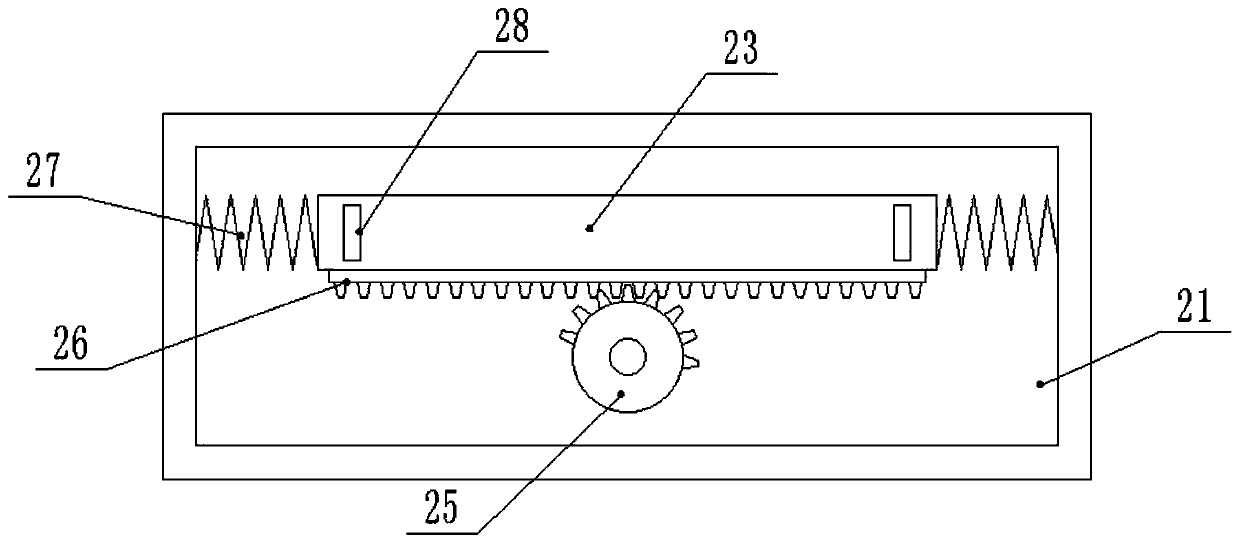

Convenient-to-use fodder mixing device for animal husbandry

InactiveCN108849573AEasy to useEasy dischargeAnimal feeding devicesAvicultureEngineeringAnimal husbandry

The invention discloses a convenient-to-use fodder mixing device for animal husbandry. The convenient-to-use fodder mixing device comprises a box body, a fodder storage device and a water conveying device; the upper surface of the inner wall of the box body is fixedly connected with the upper surface of the fodder storage device, the outer surface of the fodder storage device is clamped to the upper surface of the box body, the upper surface of the inner wall of the box body is fixedly connected with the upper surface of the water conveying device, and the outer surface of the water conveyingdevice is clamped to the upper surface of the box body; the front and back surfaces of the inner wall of the box body are fixedly connected with the front and back surfaces of a stirring box respectively, and a fodder collection hopper is clamped to the upper surface of the stirring box. According to the convenient-to-use fodder mixing device for animal husbandry, through the arrangement of the fodder storage device and the water conveying device, staff can store fodder and water in a fodder storage tank and a water tank, the fodder and the water are added by operating a first electric push rod and a water pump when needed, the fodder putting frequency of the staff is reduced, the work intensity of the staff is reduced, and the feeding efficiency is improved.

Owner:芜湖孺子牛节能环保技术研发有限公司

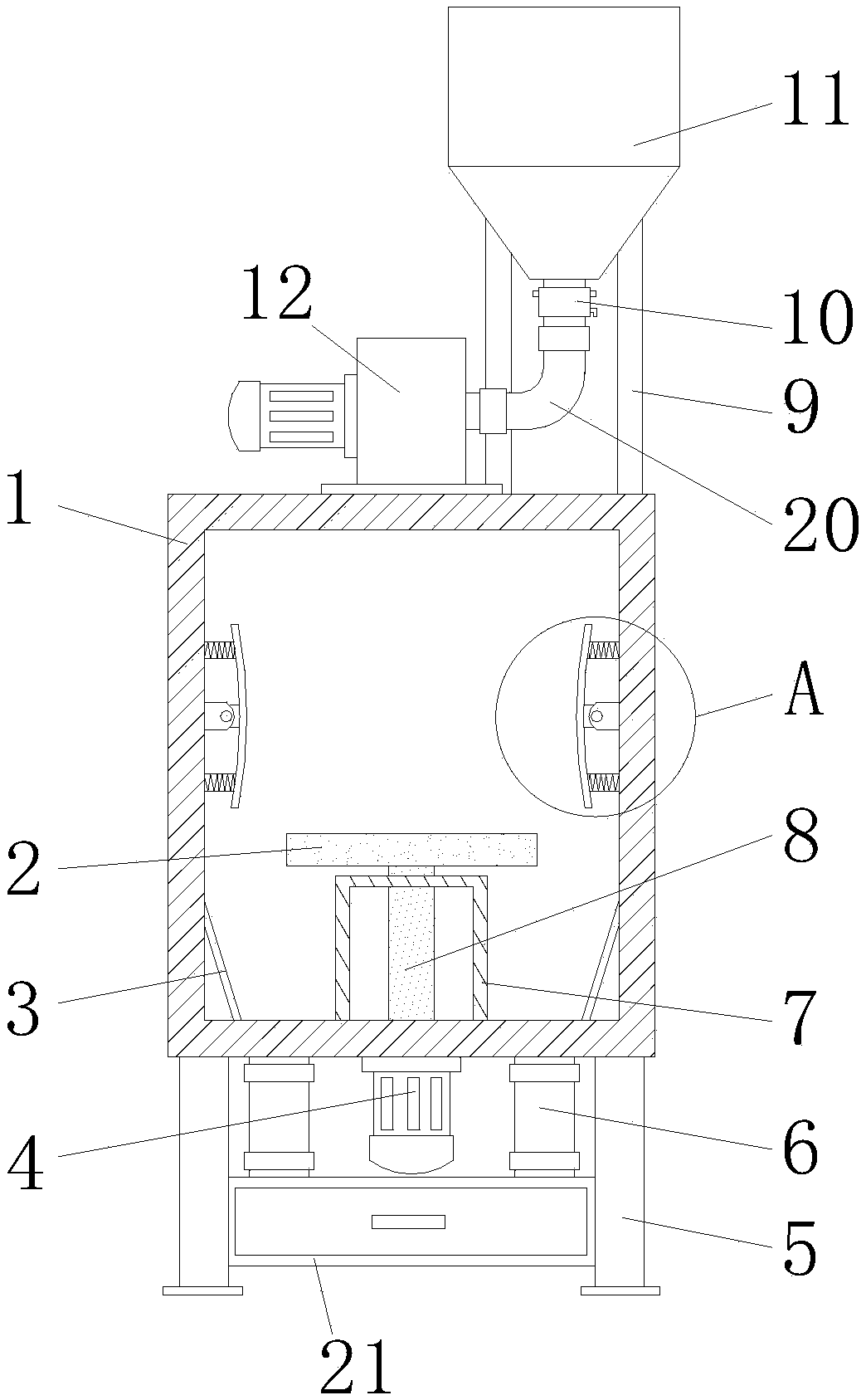

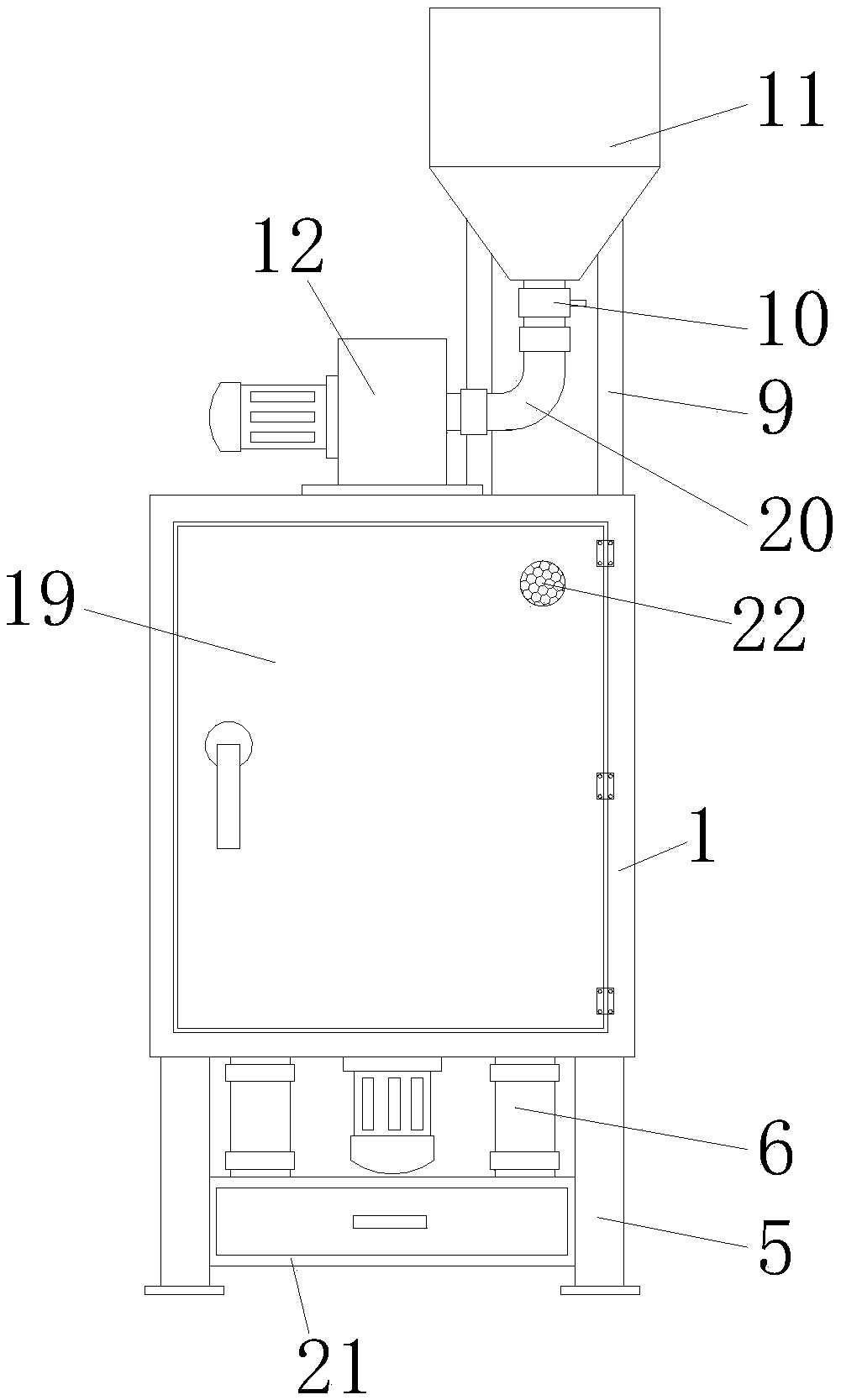

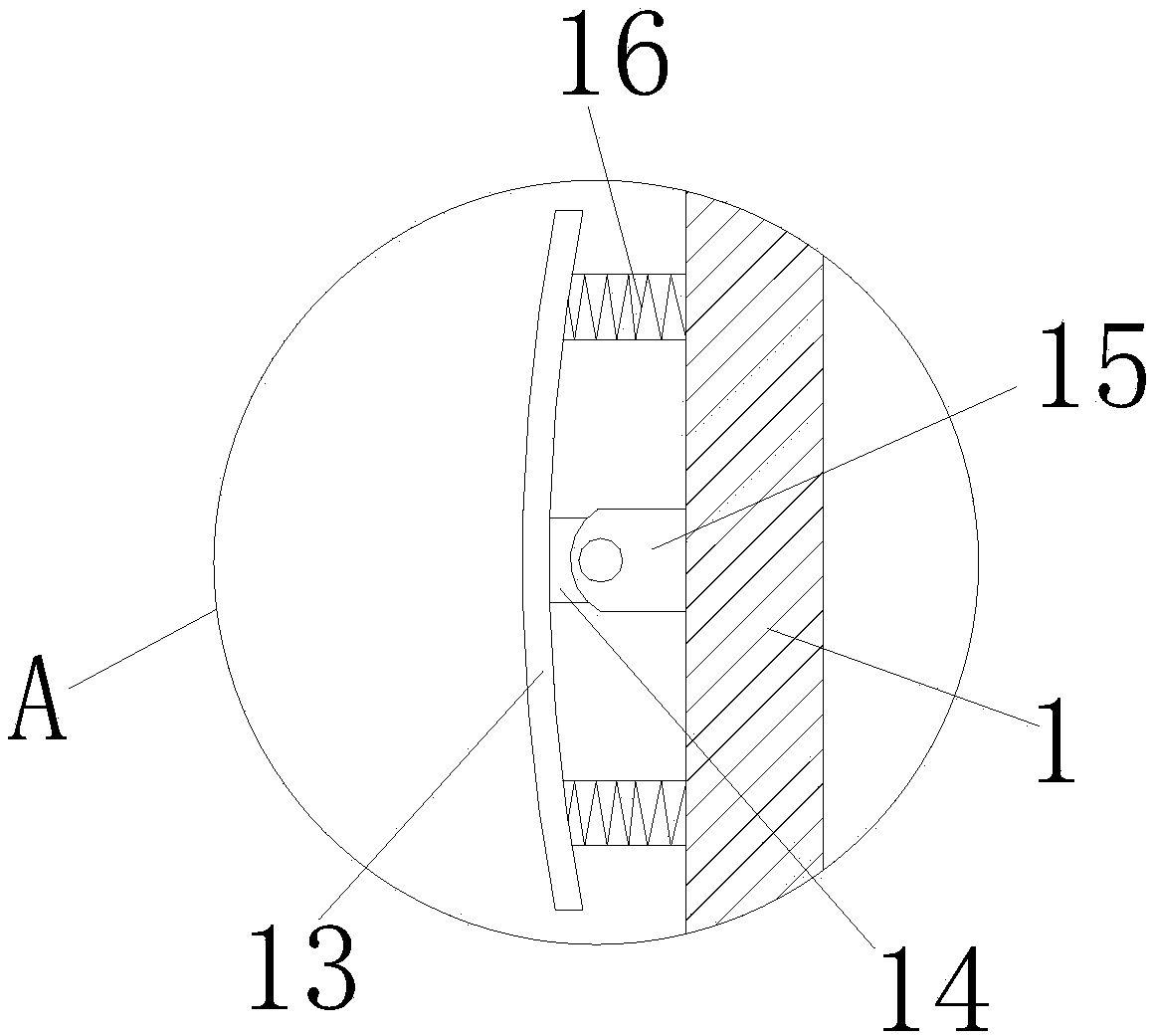

Intelligent factory shot blasting machine for vehicle parts

ActiveCN109571274AReduce outputReduce feeding timesAbrasive machine appurtenancesEffective treatmentMechanical engineering

The invention belongs to the technical field of shot blasting machines, and particularly relates to an intelligent factory shot blasting machine for vehicle parts. The intelligent factory shot blasting machine for vehicle parts comprises a tank, a workpiece placement table, baffles, a motor, mounting legs, shot guide pipes, a protection box, a rotary shaft, a support leg, a flow adjustor, a shot material box, a shot blasting device, an arc board, a connection block, a U-type connection part, springs, a convection sensor, an insertion board, a box door, a feeding pipe, a shot recycling box anda buzzer. The flow adjustor is provided to adjust the shot flow according to the conditions of workpieces needing processing, the discharging amount of shots is reduced on the condition of ensuring effective treatment of the surfaces of the workpieces, and the feeding frequency of the shots is reduced advantageously; and a rebound mechanism is provided, shots ejected to the surfaces of the workpieces at a high speed are ejected to the arc board of the rebound mechanism, at the moment, the shots are rebounded to the surfaces of the workpieces for the second time under the function of the arc board and the springs, and cleaning of the surfaces of the workpieces is facilitated.

Owner:江苏九方机械有限公司

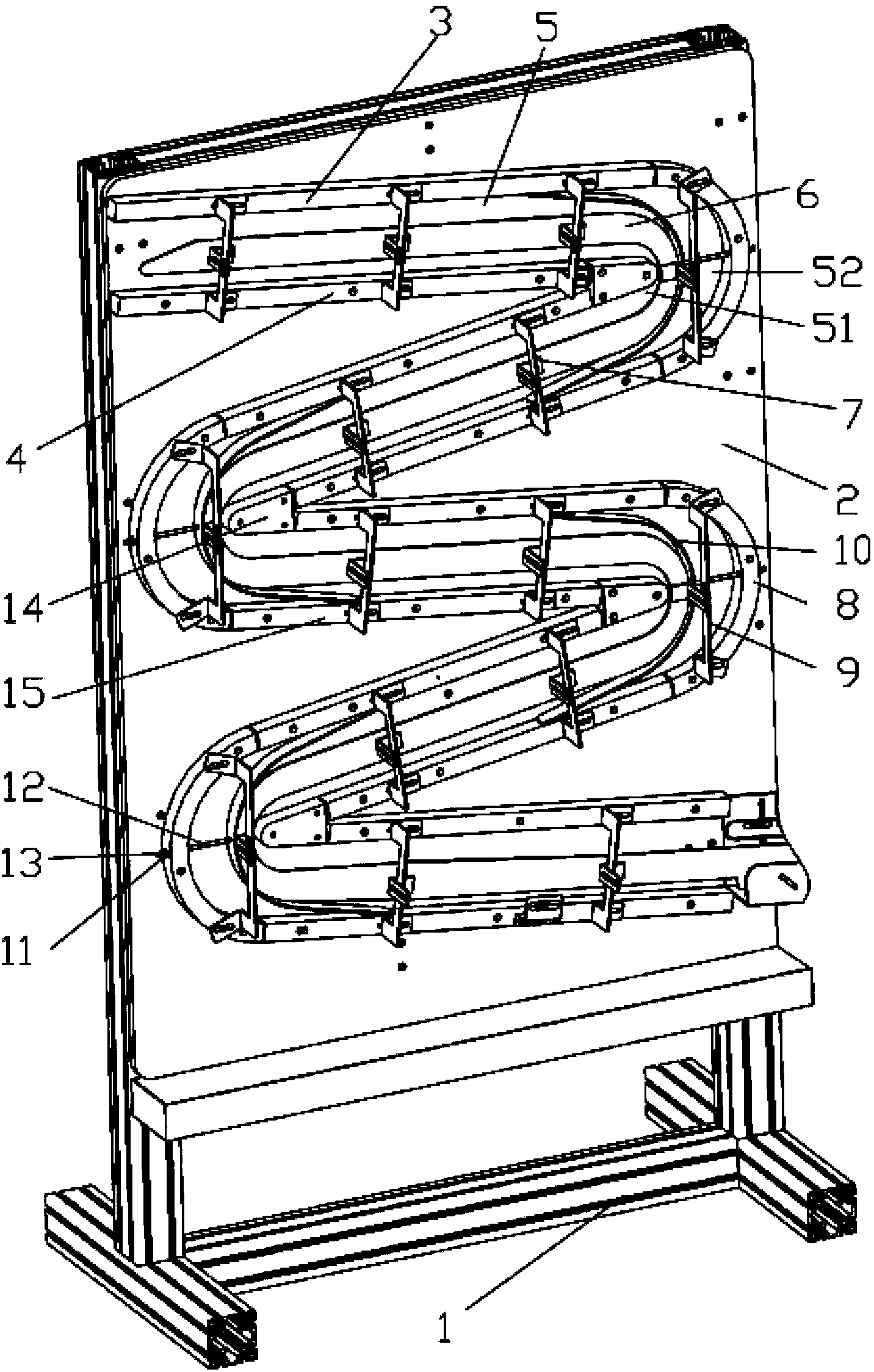

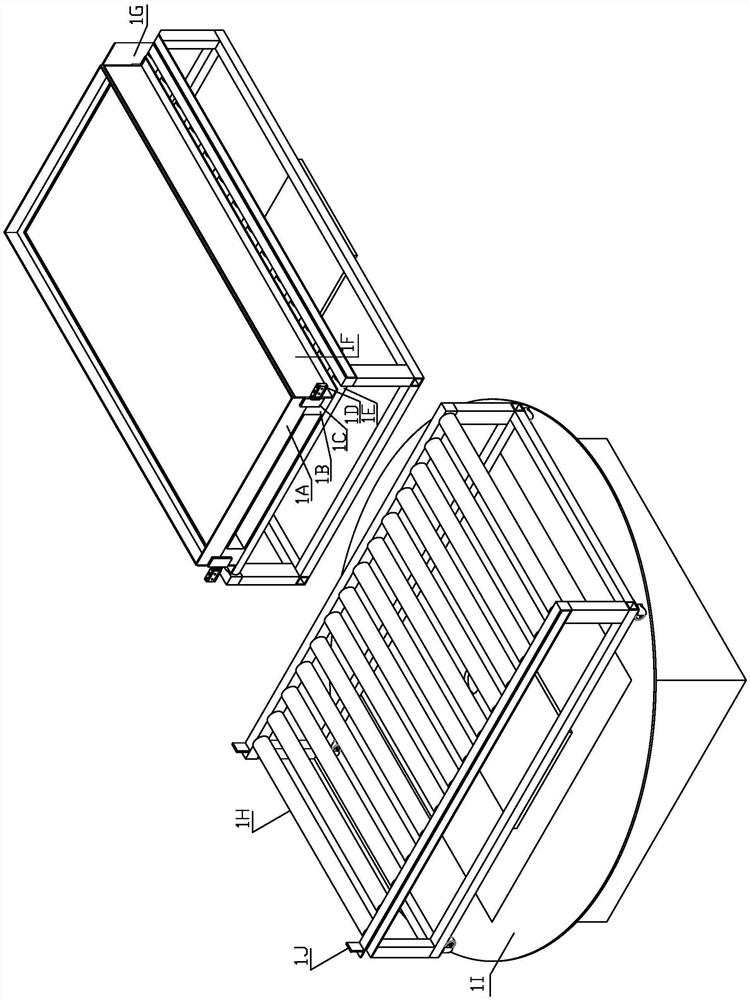

Bearing S-shaped material-loading frame

The invention discloses a bearing S-shaped material-loading frame. A panel is fixed on the material-loading frame, an upper S-shaped baffle edge and a lower S-shaped baffle edge are fixed on the panel, and a slide rail is formed between the upper S-shaped baffle edge and the lower S-shaped baffle edge. An S-shaped baffle is formed between the upper S-shaped baffle edge and the lower S-shaped baffle edge. Arc-shaped elastic pieces are fixed on the circular arc bent parts of the upper S-shaped baffle edge or the lower S-shaped baffle edge, and adjusting screw rods are connected to the side walls of the circular arc bent parts of the upper S-shaped baffle edge or the lower S-shaped baffle edge in a screwing mode. The tops of the adjusting screw rods penetrate through the inner side walls of the circular arc bent parts and then press against the middle back faces of the circular arc elastic pieces, and the tail ends of the adjusting screw rods are connected with nuts in a screwing mode. The structure is simple, the mode of the S-shaped slide rail is adopted for loading, therefore, the one-time loading quantity is large, the number of times of the loading can be reduced, and production efficiency can be improved. Meanwhile, due to the fact that the arc-shaped elastic pieces are arranged on all the circular arc bent parts to adjust the width of the slide rail, the situation that the bearing S-shaped material-loading frame is suitable for loading outer rings or inner rings of bearings with different diameters in a rolling mode, and loading quality is improved.

Owner:邯郸市卫林紧固件制造有限公司

Automatic assembling screw device

ActiveCN110394640AExtend the loading cycleReduce labor intensityMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic assembling screw device. The automatic assembling screw device comprises a equipment rack, wherein adjustable supporting legs are movably installed at the lower end of the equipment rack, adjusting screws are movably installed between the adjustable supporting legs and the equipment rack, a power switch is movably installed on the left side of the lower end ofthe equipment rack, a vibrating material falling plate is fixedly installed at the upper end of an installing base, and an assembling table is fixedly installed at the lower end of the vibrating material falling plate. According to the automatic assembling screw device, large vibrating plates which are symmetrically arranged are used as vibration feeding plates to supply screw parts, so that the screw parts inside the vibration feeding plates are kept in a sufficient state; material discharging is detected through a photoelectric sensor, operators worker is reminded that the equipment occurs abnormity, so that the workload of the operators can be reduced; an electrical signal loop is formed by two electrodes and the screws, so that an alarm effect can be achieved in the discharging processof the screws, moreover, a discharging guide rail is bent, only one screw can pass the discharging guide rail for one time, so that using is facilitate.

Owner:浙江天工紧固件股份有限公司

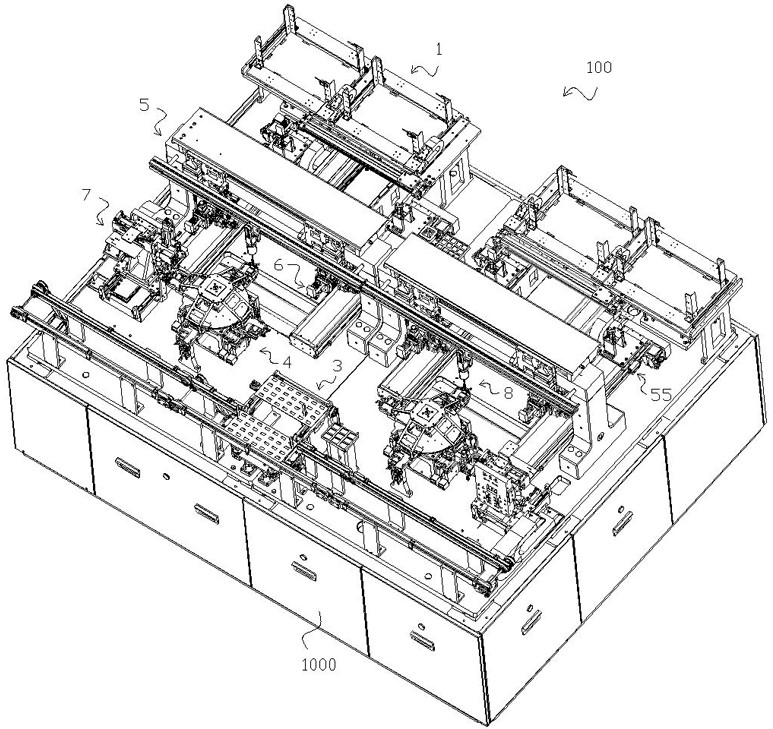

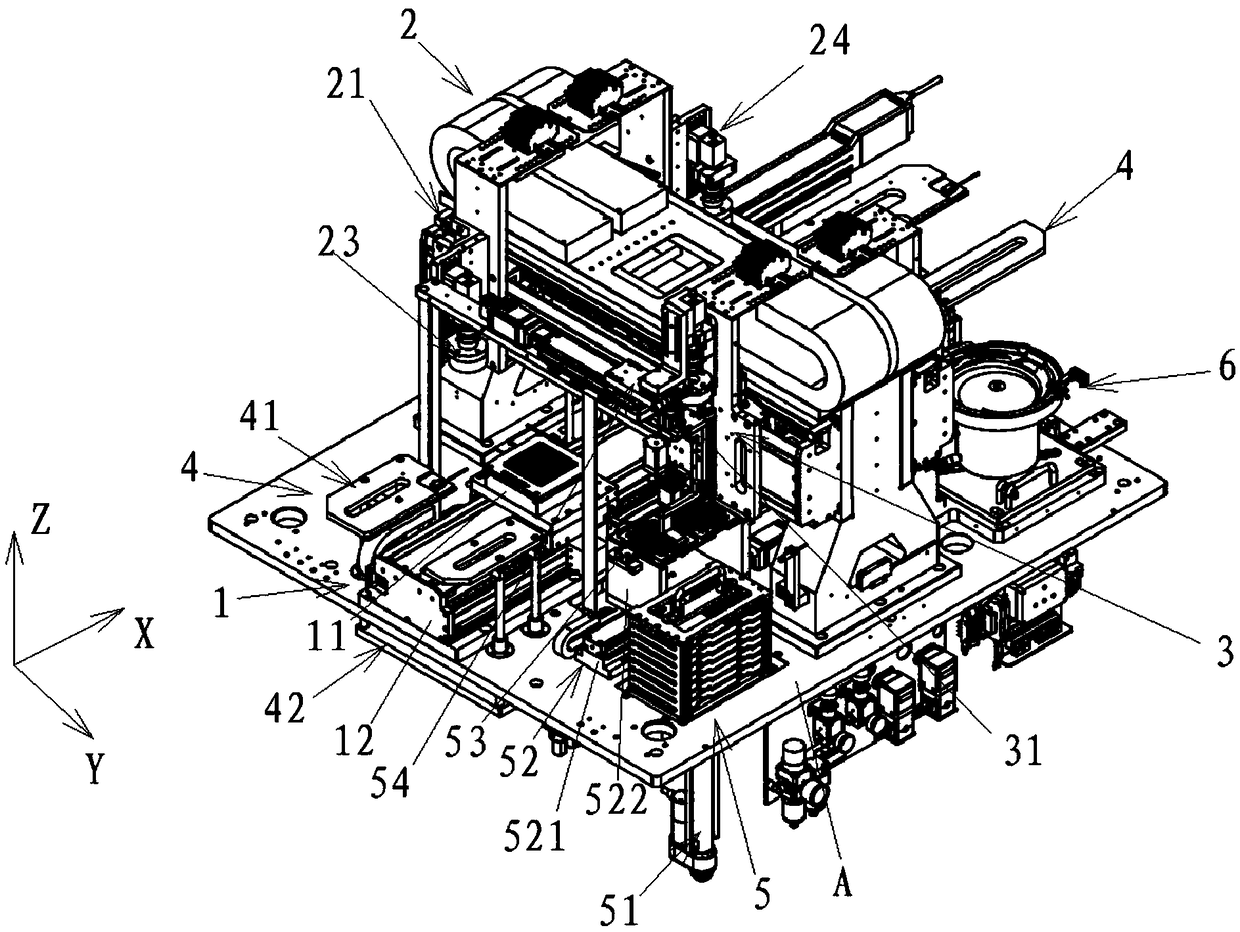

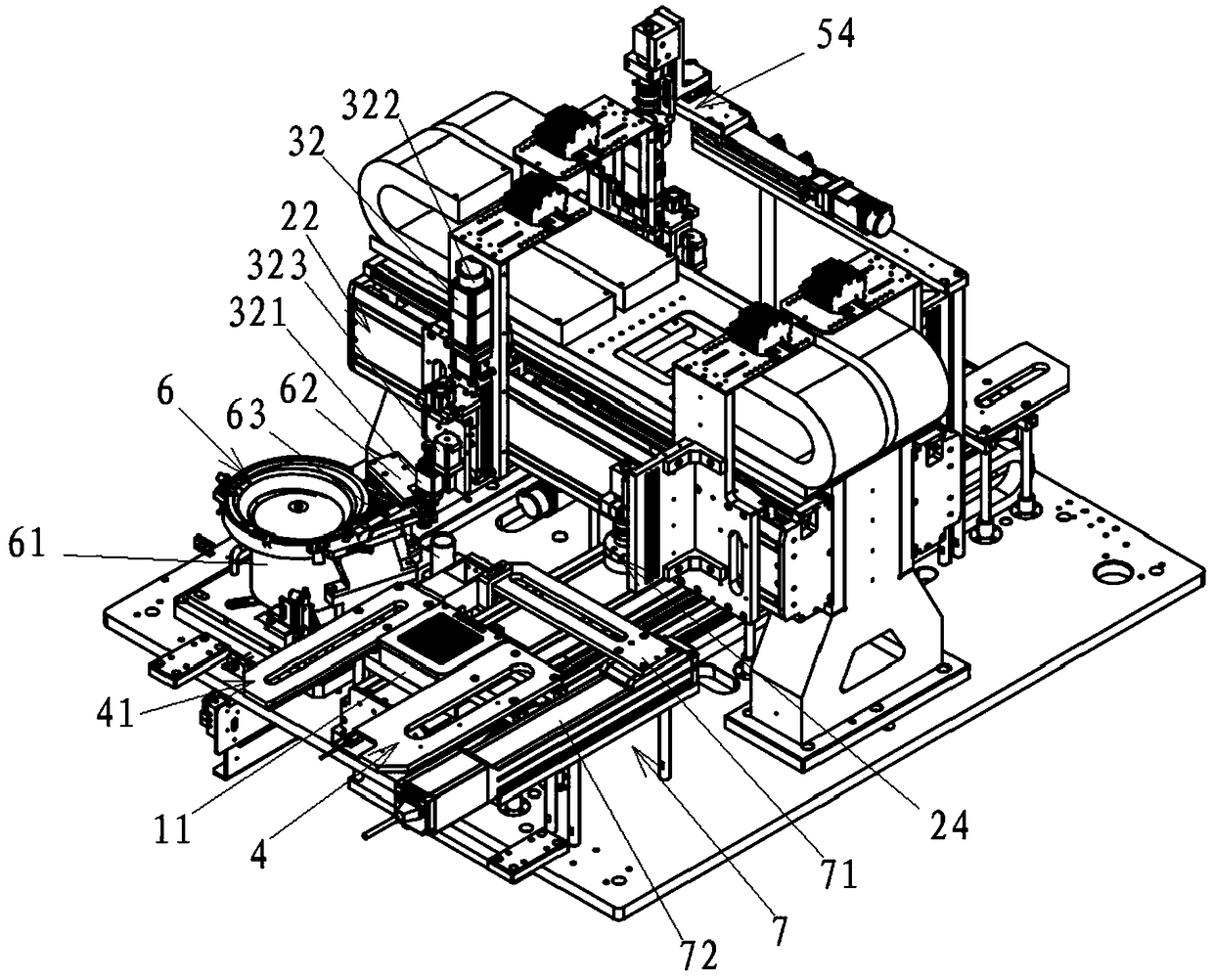

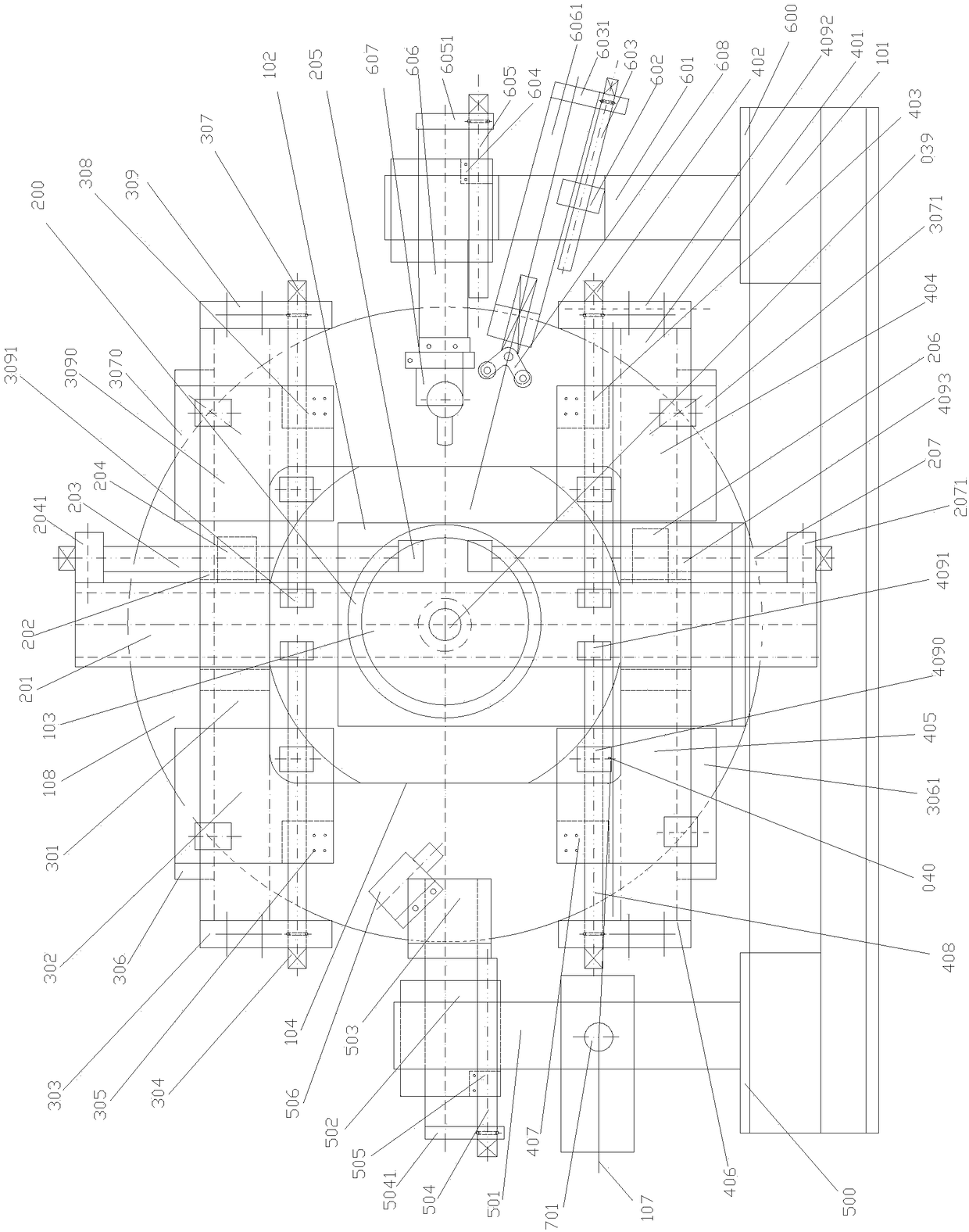

Multi-camera assembling equipment

ActiveCN113245809AImprove assembly efficiencyImprove assembly accuracyPretreated surfacesAssembly machinesElectrical and Electronics engineeringIndustrial engineering

The invention provides multi-camera assembling equipment which comprises an assembling equipment body. The assembling equipment body comprises a first base table, a rotating disc module, a first feeding module, a second feeding module, a second material part alignment module, a dispensing module and an AA module, and the second material part alignment module, the first feeding module and the dispensing module correspond to one of a plurality of working carrying tables. The second material part alignment module adjusts the posture of a second material part under the cooperation of the AA module, so that the posture of the second material part is aligned with a first material part. According to the equipment, the first material part, namely a main camera is conveyed in a rotating disc mode, operation stations corresponding to the multiple working carrying tables on a rotating disc can be operated in parallel, namely, the multiple operation stations on the rotating disc work at the same time, the phenomenon that the operation stations wait is avoided, and the assembling efficiency is improved; and in addition, the AA module is matched with the second material part alignment module, so that the camera assembly precision is further improved.

Owner:TZTEK TECH

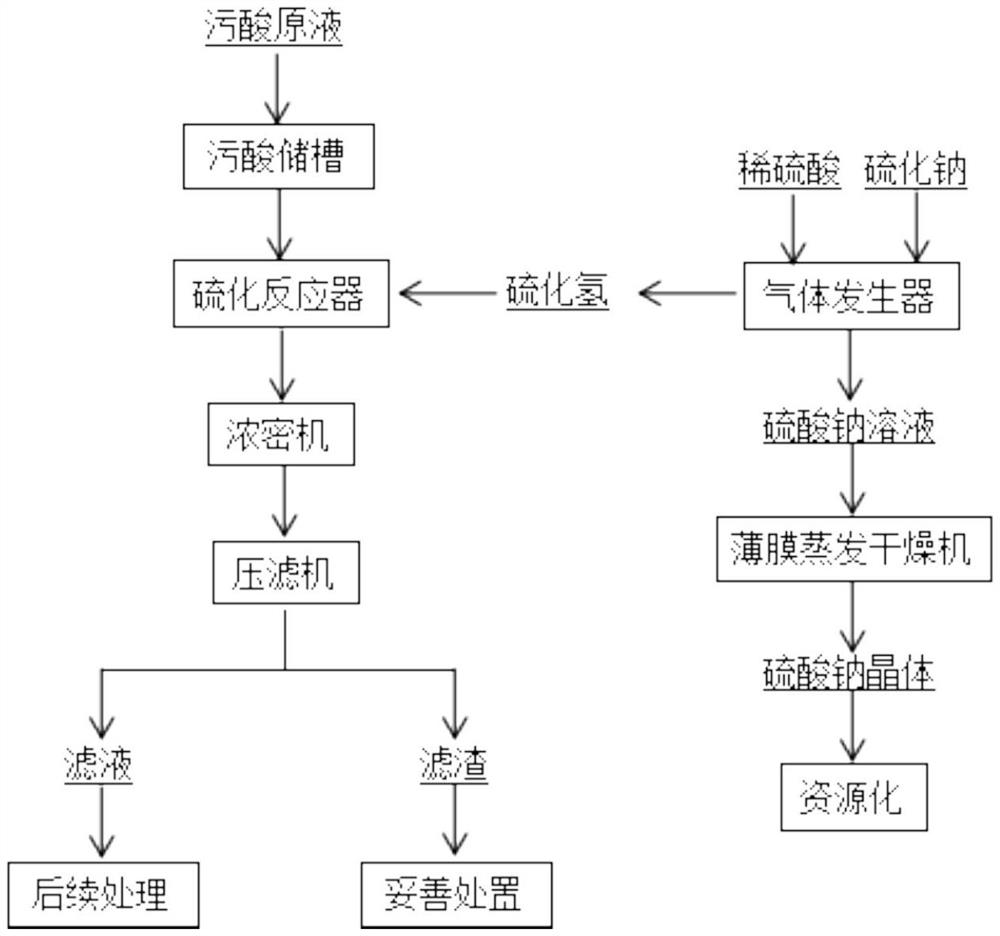

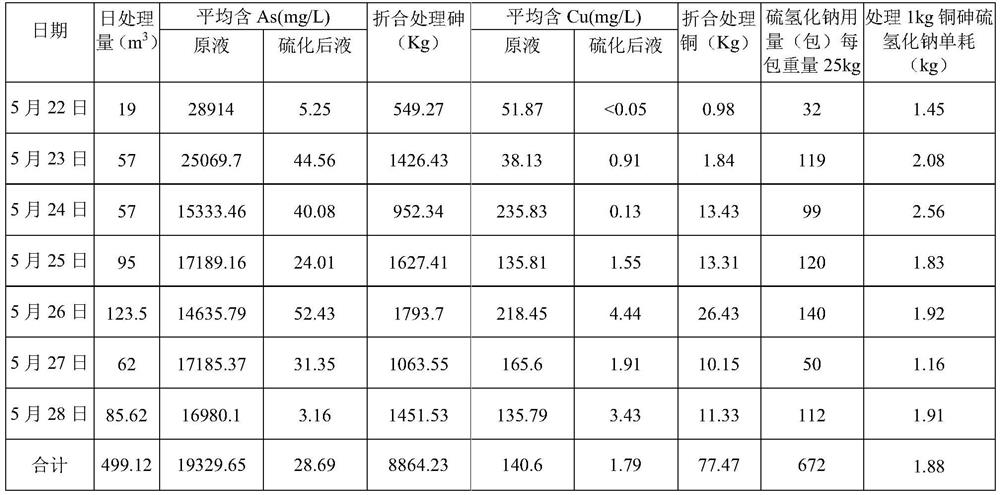

Treatment process of high-concentration arsenic-containing waste acid

PendingCN113233646ALow costLow running costWater/sewage treatment by centrifugal separationWater contaminantsSodium hydrosulfideSodium hydride

The invention discloses a treatment process of high-concentration arsenic-containing waste acid. The treatment process comprises the following steps: filtering the high-concentration waste acid by a filter, and introducing the filtered high-concentration waste acid into a waste acid storage tank; adding sodium hydrosulfide into a hydrogen sulfide gas generator, and adding a dilute sulfuric acid solution to obtain hydrogen sulfide gas; after sedimentation and solid-liquid separation, liquid in a waste acid storage tank is introduced into a vulcanization reactor through a centrifugal pump, then hydrogen sulfide gas is added, and high-concentration arsenic-containing waste acid is subjected to internal circulation through an internal circulation pump of the reactor, so that the hydrogen sulfide gas reacts with heavy metals in the liquid, and precipitates are produced; the precipitates are pumped into a thickening tank through a liquid discharge pump and is treated by a filter press, so that solid-liquid separation is realized, and standard discharge of the waste acid is realized. According to the process, comprehensive contrastive analysis is carried out from the aspects of a medicament adding mode and vulcanizing agent selection, the operation cost of a high-concentration waste acid treatment system is greatly reduced by upgrading and transforming vulcanizing agent dissolution and completing process system optimization, and meanwhile, the copper and arsenic removal efficiency is improved to reach the highest level of the copper smelting waste acid treatment process.

Owner:紫金铜业有限公司

Product prepared from seafood residues, and manufacturing method thereof

The invention discloses a product prepared from seafood residues. The product comprises, by weight, 66 to 78 parts of nori residue, 56 to 68 parts of sargassum fusiforme residue, 20 to 25 parts of minced fillet product waste residue, 5 to 10 parts of shrimp shell, 6 to 14 parts of sesame powder, 5 to 10 parts of potato powder, 6 to 12 parts of soybean powder, 2 to 8 parts of chromium nicotinate, 10 to 16 parts of honey, 0.05 to 0.15 part of a plant essential oil, 1 to 3 parts of a vitamin powder, 0.5 to 1.5 parts of vitamin C, and 0.2 to 0.8 part of a fertilizer activator.

Owner:浙江承恩食品有限公司

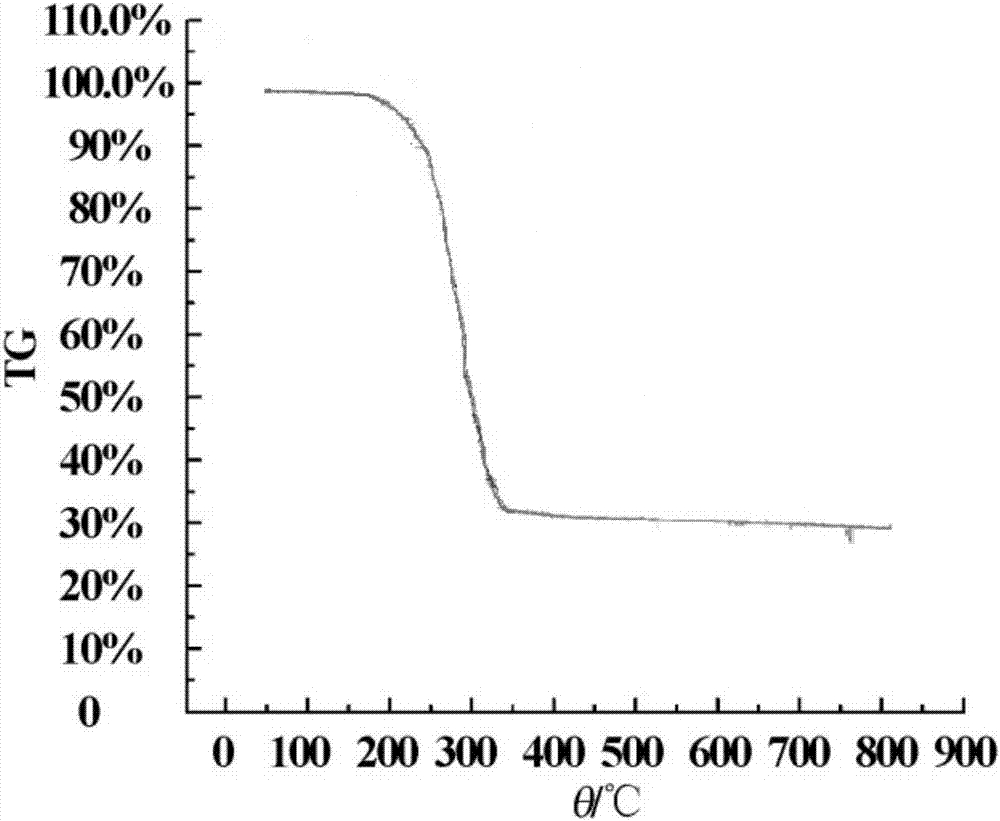

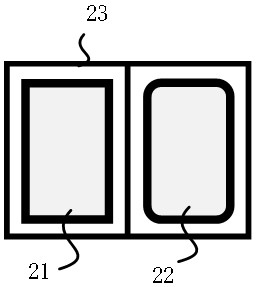

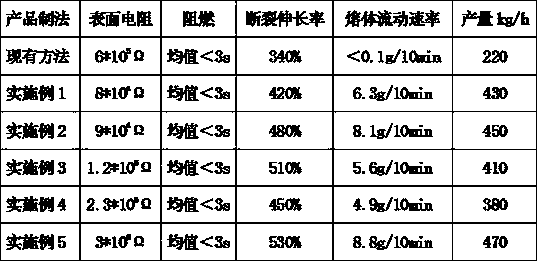

Antistatic flame-retardant master batch and preparation method thereof

The invention relates to the field of antistatic flame-retardant master batch processing, in particular to an antistatic flame-retardant master batch and a preparation method thereof. The antistatic flame-retardant master batch mainly comprises the following components in parts by mass: 20-50 parts of linear low density polyethylene (LLDPE), 2-10 parts of ethylene vinyl acetate (EVA), 1-8 parts ofpolyolefin elastomer (POE), 5-12 parts of conductive carbon black, 1-6 parts of coated red phosphorus, 0.1-4 parts of a processing aid and 2-10 parts of a compatilizer. The formula does not contain polyethylene wax or low-molecular dispersants, a conventional repeated batch-type internal mixing feeding mode is changed, and feeding frequency is reduced, so that the problem of bearing performance defects of the downstream products caused by too much additives is solved, stability of product quality is improved, and comprehensive cost is reduced. Through the arrangement of double-shaft mixing rotary shafts and through a multi-section sectional design, the edges of the mixing stirring paddles on a mixing section are of a two-edge structure, materials are uniformly mixed through the mixing section in a movement process, is subjected to exhausting, and then are sent into the extrusion granulating machine for molding, and the materials do not need to be pressed after mixing in the mixing section, so that the shear damage force to a carbon black structure in the mixing process is reduced.

Owner:SHANDONG DONGHONG PIPE IND

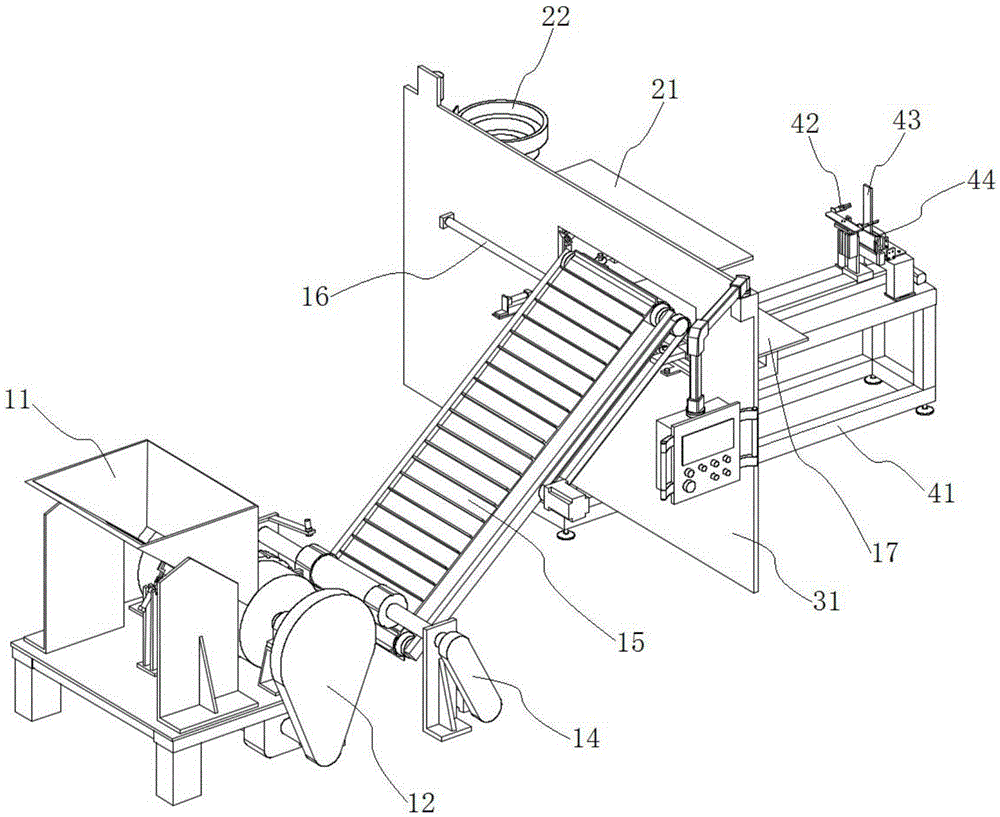

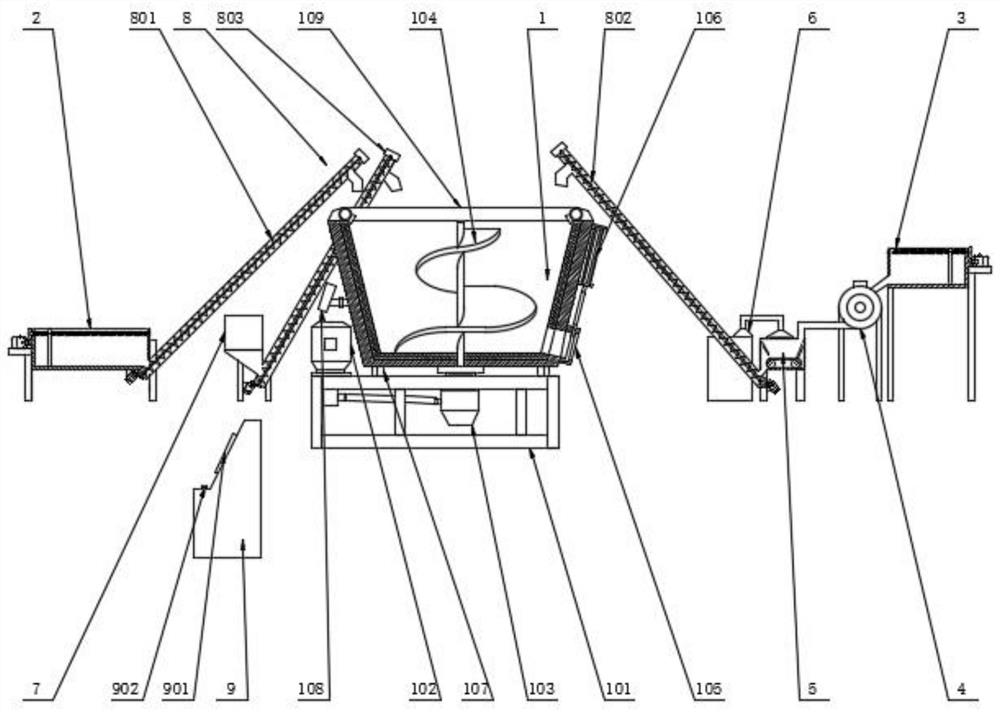

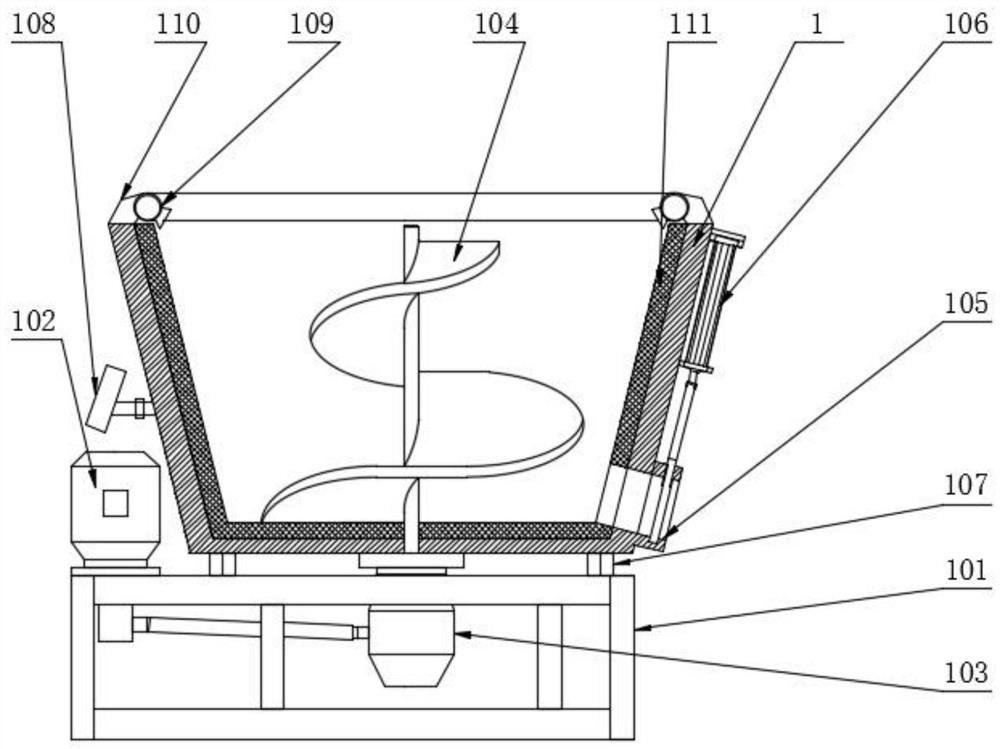

Feed stirring and preparing device for beef cattle breeding

InactiveCN111603996AImprove feeding qualityGuaranteed fresh qualityFeeding-stuffTransportation and packagingZoologyFodder

The invention discloses a feed stirring and preparing device for beef cattle breeding. The feed stirring and preparing device comprises a stirring mechanism, a first feeding mechanism, a second feeding mechanism, a pulverizer, a temporary storage box, a third feeding mechanism, a material lifting and conveying mechanism and a control cabinet, and the first feeding mechanism is used for storingforage and addingthe forage into a stirring bin of the stirring mechanism through the material lifting and conveying mechanism; the second feeding mechanism is used for storinggrain materials, the grain materials are crushed into grain powder through the pulverizer and then enter the temporary storage box, and the temporary storage box is used for outputtingthe grain powder and conveying the grain powder into the stirring bin through the material lifting and conveying mechanism; the third feeding mechanism is used for storing feed filler and feeding the feed filler into the stirring bin through the material lifting and conveying mechanism; a discharging opening is formed in the side wall of the stirring mechanism, and a weighing sensor is arranged at the bottom of the stirring mechanism; and the control cabinet is adopted for monitoringthe operation of the device. According to the feed stirring and preparing device for beef cattle breeding, automatic feeding can be achieved, stirring and preparing of feed are accurately completed, manpower is saved, and the operation cost is reduced.

Owner:黑龙江省农业科学院畜牧兽医分院

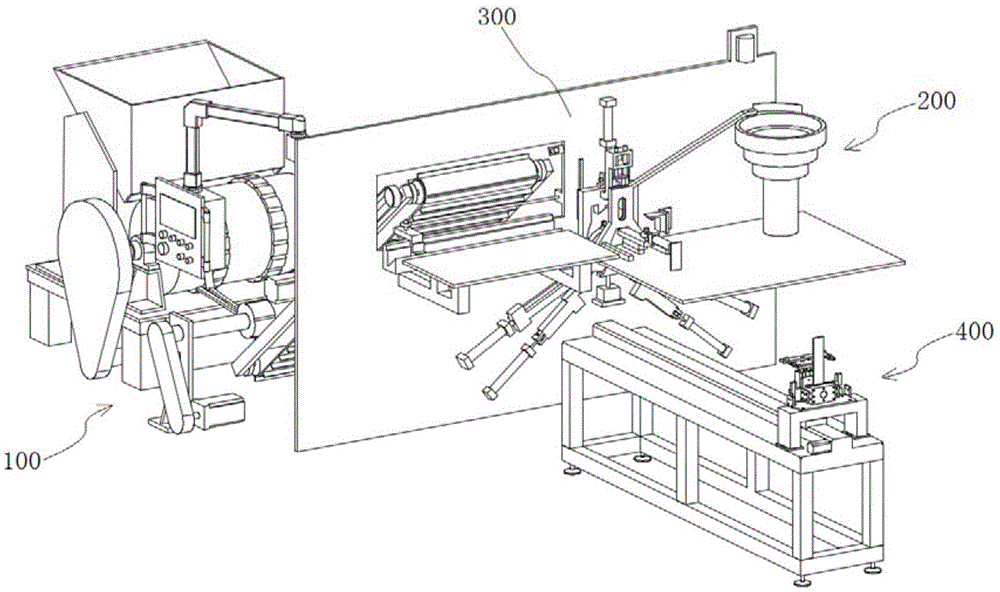

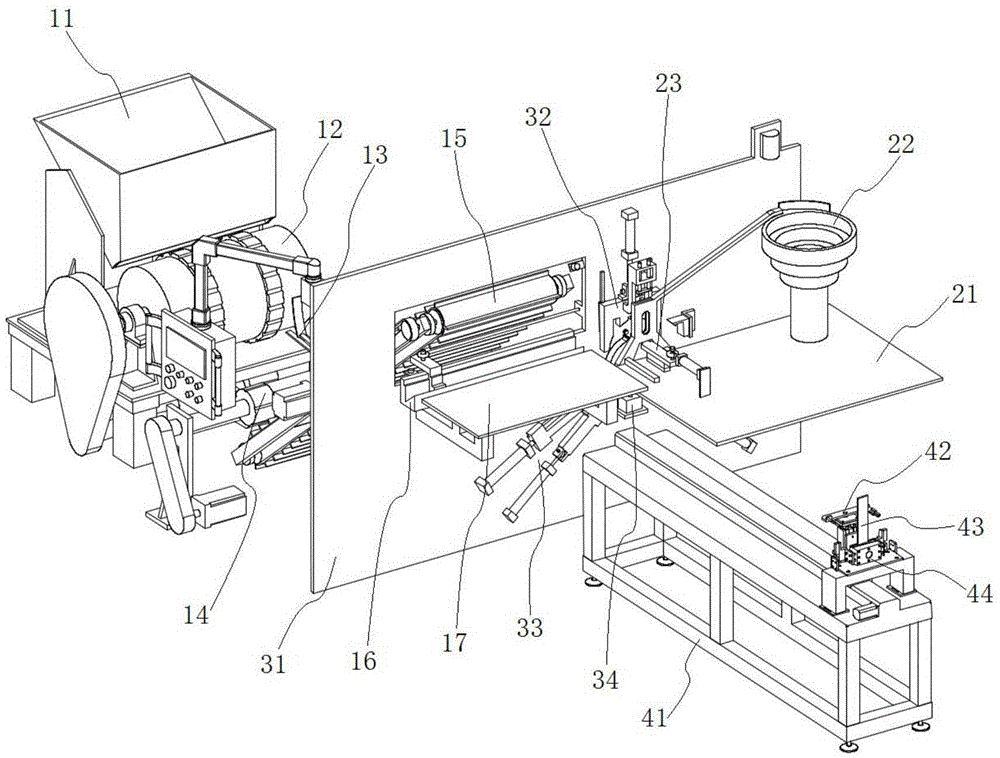

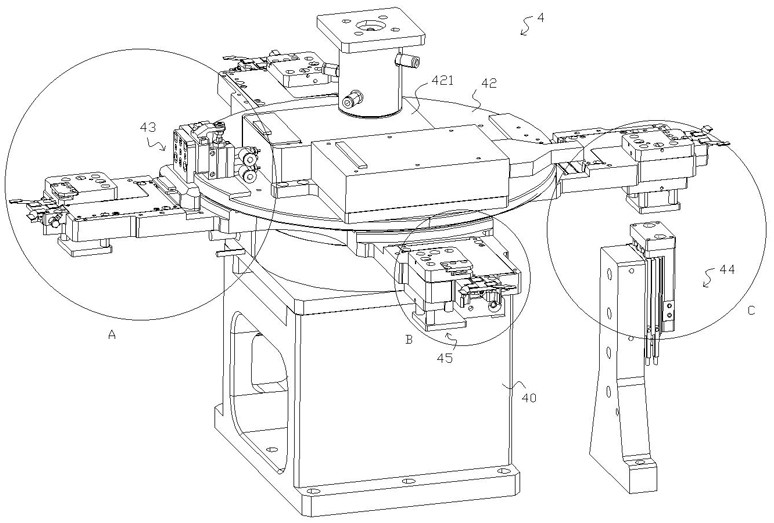

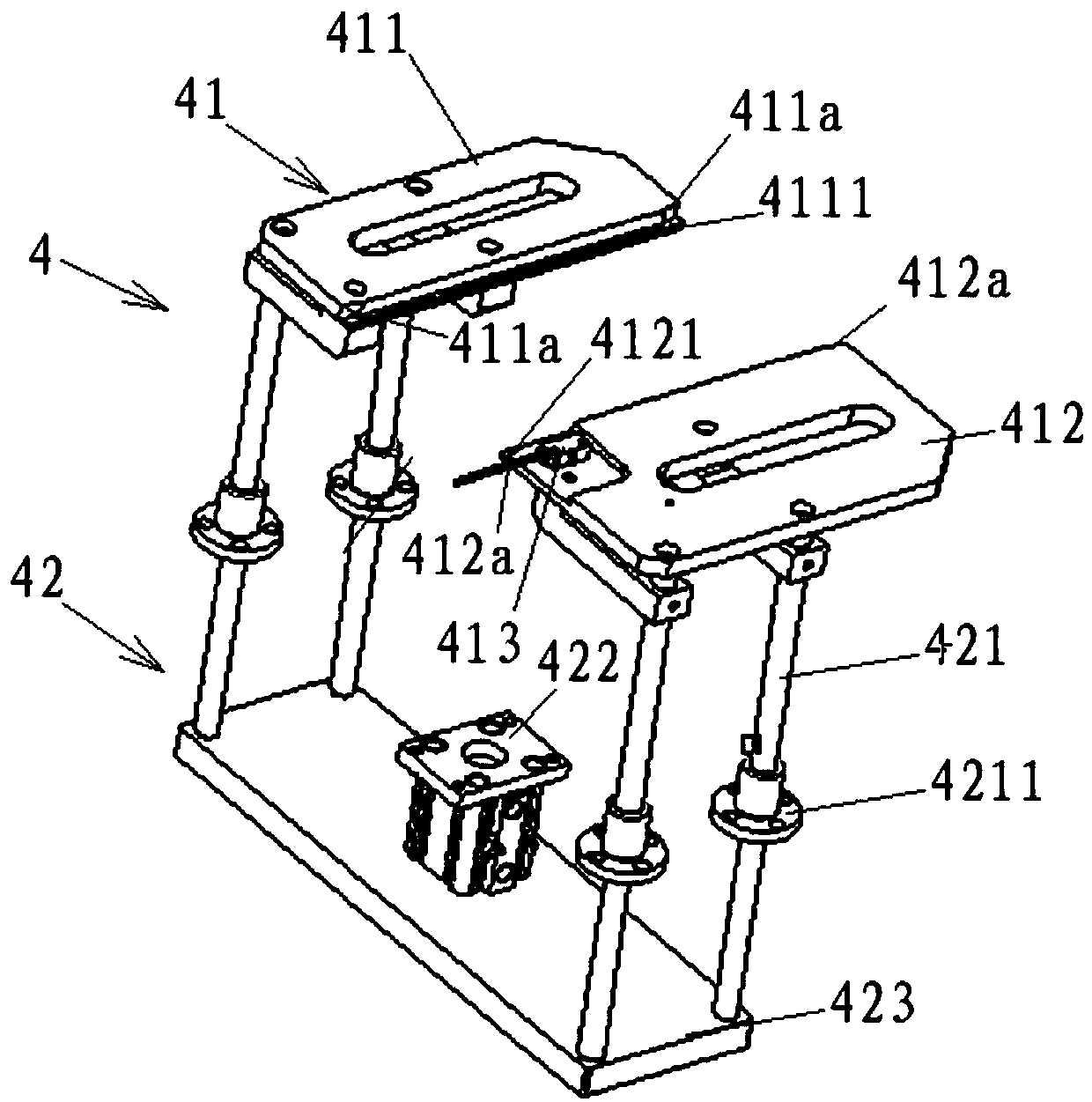

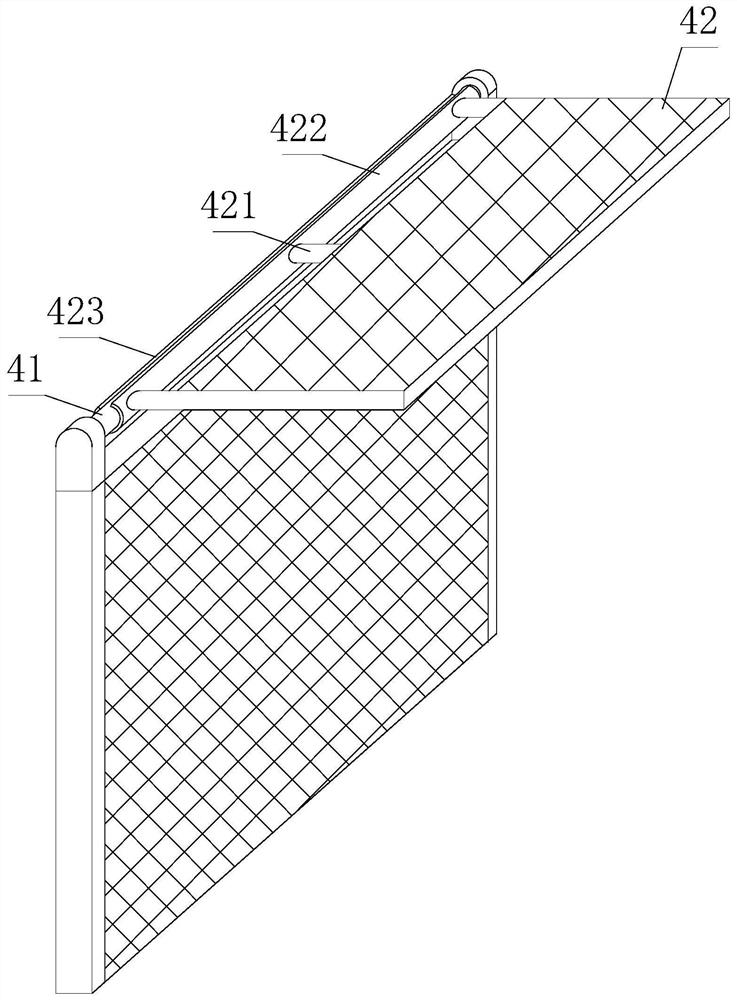

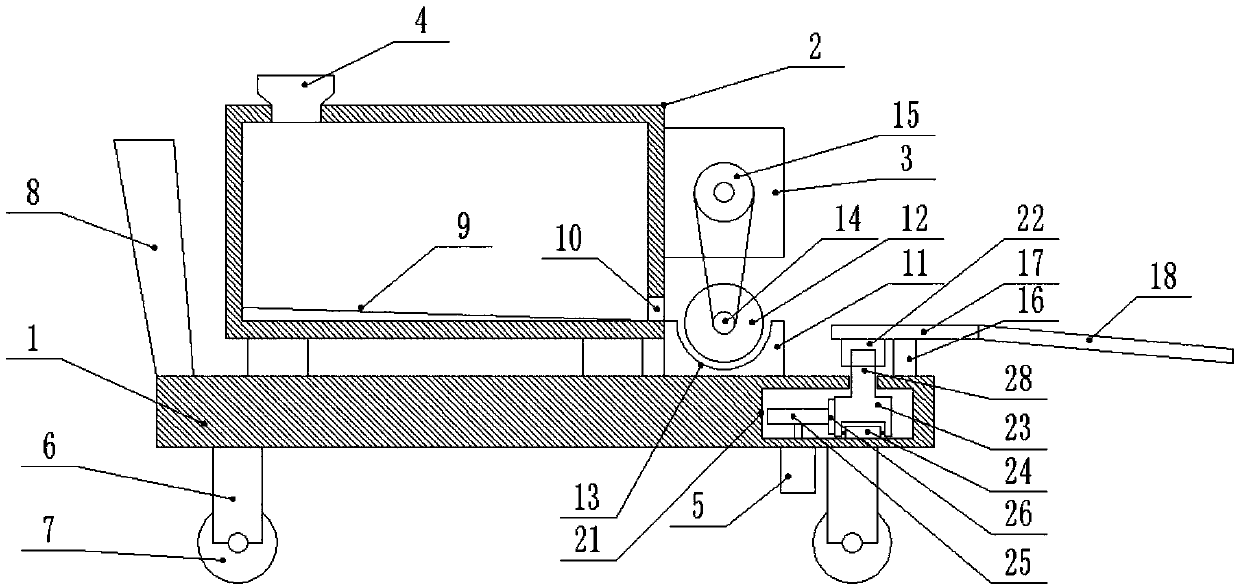

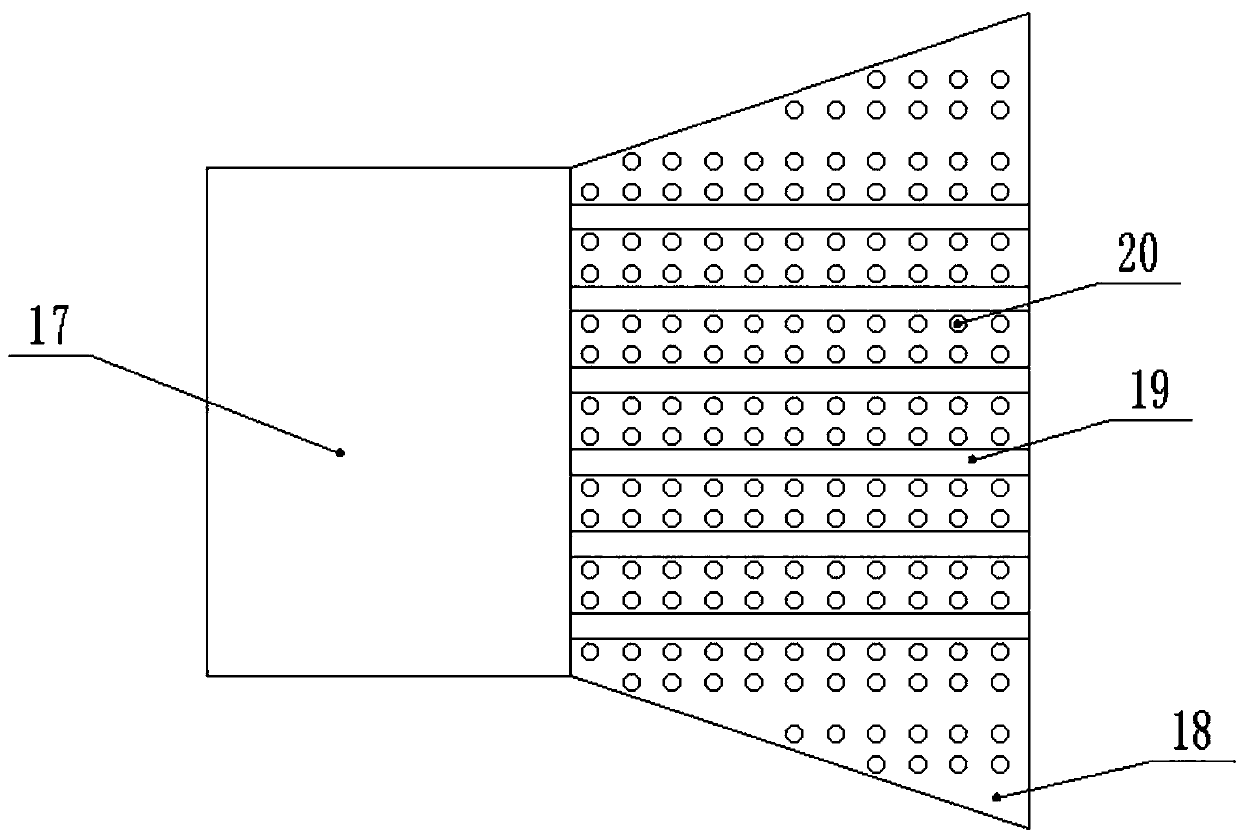

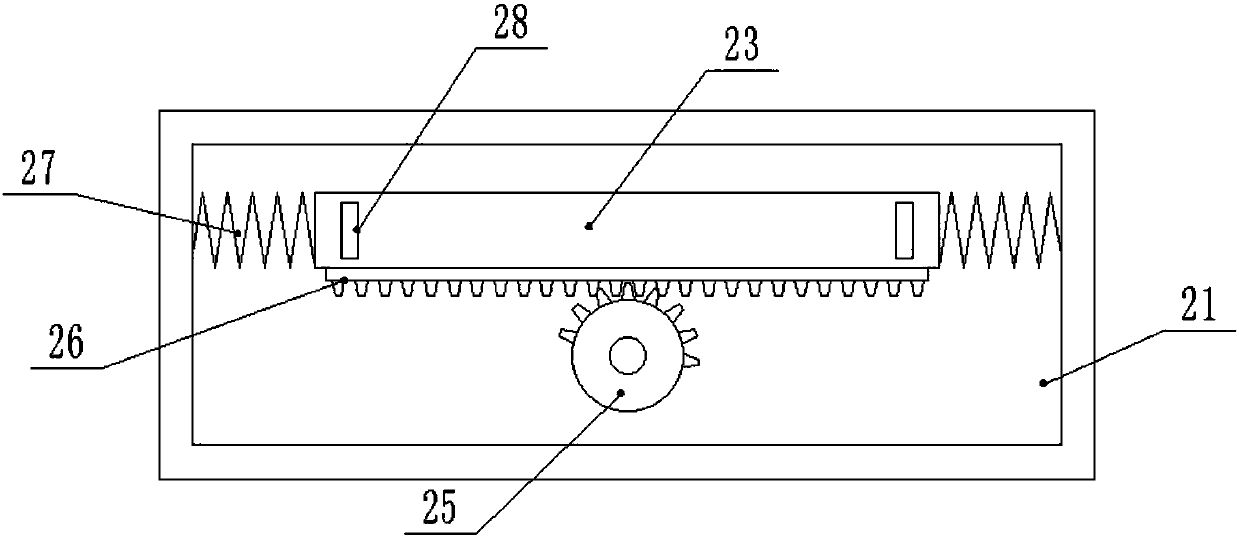

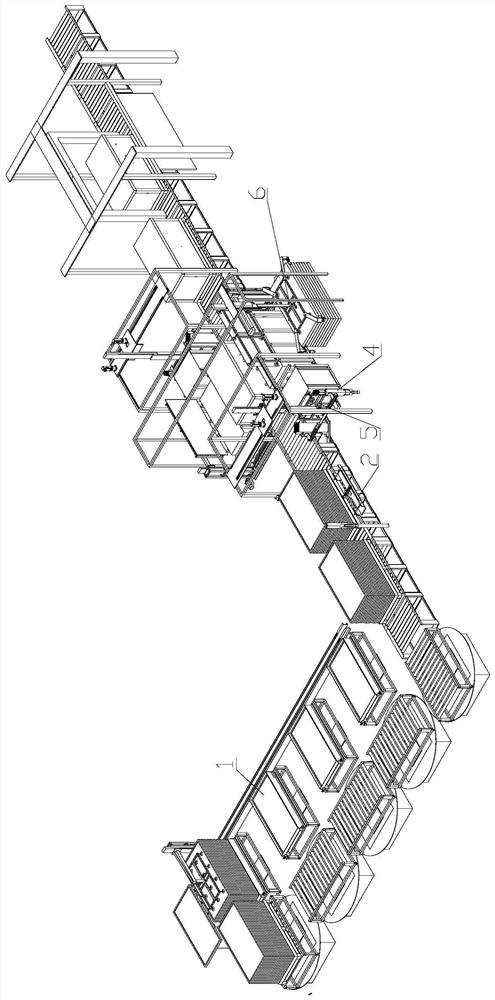

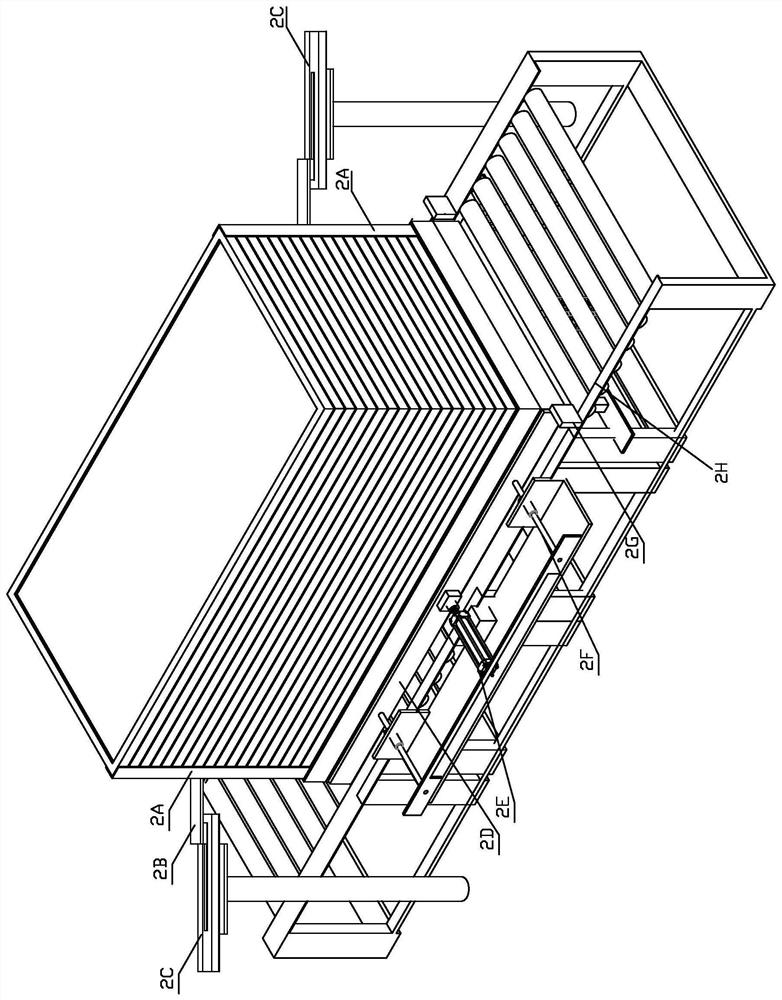

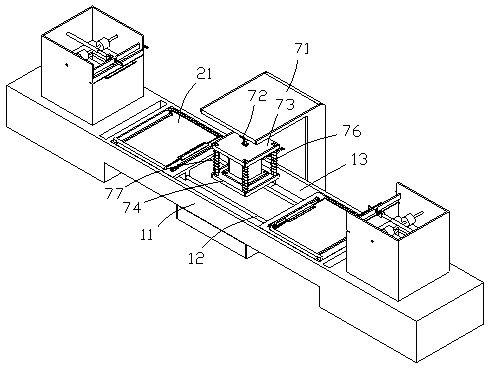

Automatic assembly device for optical lens

PendingCN109031578AImprove assembly efficiencyAvoid human involvementMountingsCamera lensEngineering

The invention relates to an automatic assembly device for an optical lens. The automatic assembly device comprises a first transmission unit (1), a second transmission unit (2), a reclaiming unit (3)and a lifting unit (4), wherein the second transmission unit (2) is arranged above the first transmission unit (1), and perpendicular to the first transmission unit (1); the reclaiming unit (3) is arranged on the second transmission unit (2); and the lifting unit (4) is arranged along the transmission direction of the first transmission unit (1). Through adoption of the automatic assembly device for the optical lens, the assembly efficiency of the optical lens can be improved greatly.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

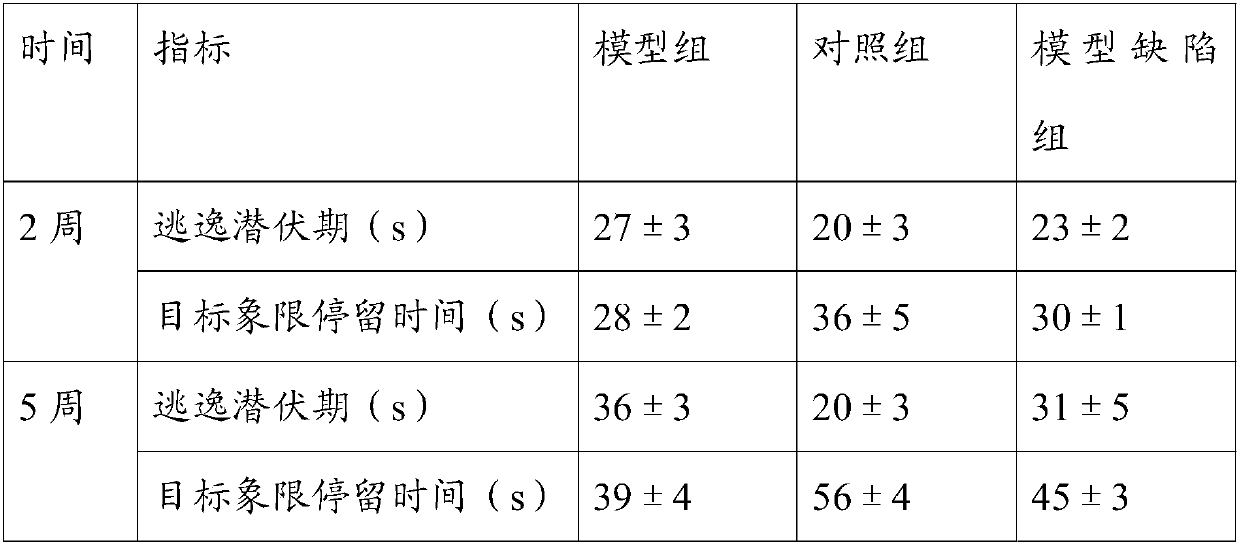

Method for establishing memory impairment animal model of environmental pollutants

InactiveCN107737138AAccelerated agingShorten the feeding timePeptide/protein ingredientsInorganic active ingredientsDiseaseAmyloid

The invention belongs to the technical field of biology and discloses a method for establishing a memory impairment animal model by environmental pollutants. Five weeks are consumed by an animal modelestablishment process, the previous three weeks serve as a low-dose administration period, the fourth week serves as a high-dose administration period, and the fifth week serves as a natural growth period, wherein a cyclic operation period includes seven days in the low-dose administration period, and three cycles are performed; the high-dose administration period has a duration of seven days; and water is freely fed during the animal model establishment period. According to the method, a low pressure oxygen environment, a manganese sulfate solution and a beta-amyloid protein solution complexfactors are taken as environmental pollutants, a progressive administration manner is adopted, lesions of a rat brain memory neuron area (a hippocampal area) are gradually induced by virtue of accumulation effects of the environment and drugs, thereby establishing a stable memory impairment animal model. The brain lesions of rats are in diffuse distribution, the reproducibility is excellent, anddiffuse brain lesions of Alzheimer disease can be well simulated.

Owner:NINGXIA MEDICAL UNIV

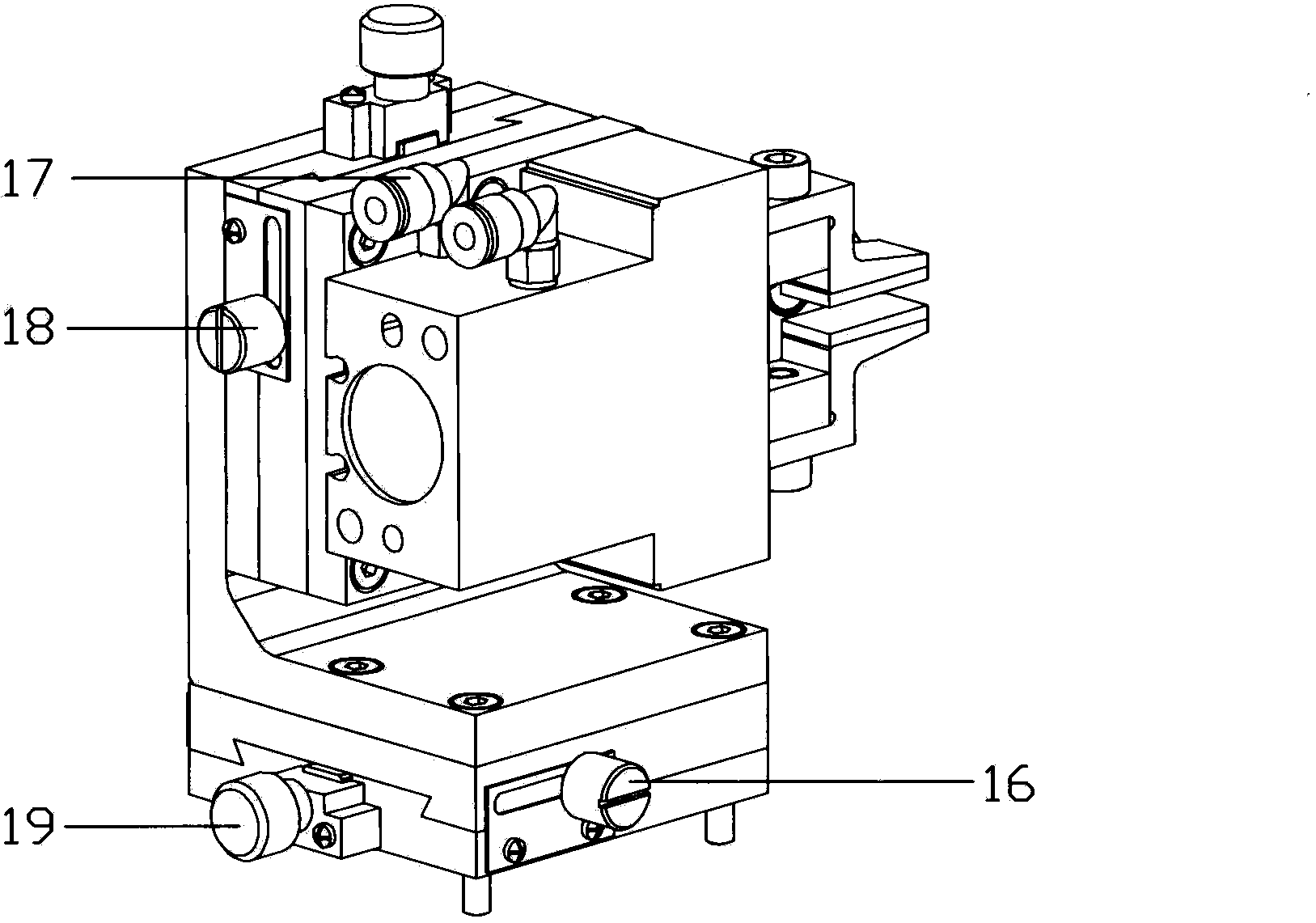

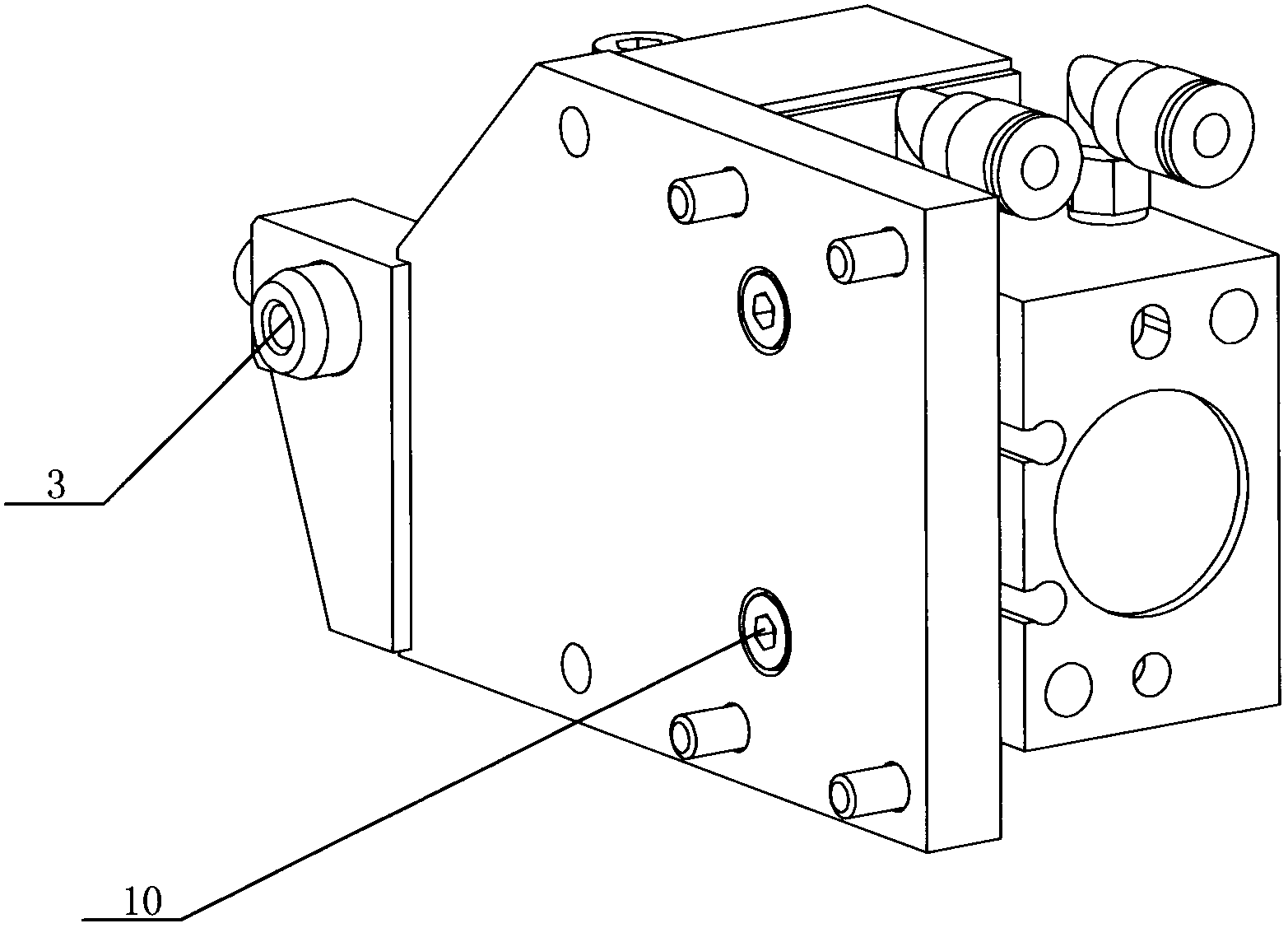

Long and thin cutter support device

InactiveCN103846743AReduce vibration effectsImprove stabilityOther manufacturing equipments/toolsGrinding work supportsSet screwEngineering

The invention discloses a long and thin cutter support device, and relates to the field of precision cutter machining equipment. The long and thin cutter support device is characterized in that manual Y-axis fixing screws are arranged on the lower sides of four corners of a manual Y-axis, a manual Y-axis scale is arranged at a side edge of the manual Y-axis, a manual Y-axis set screw is arranged on the side, which is opposite to the manual Y-axis scale, of the manual Y-axis, a manual Y-axis adjusting knob is arranged at the side edge, which is adjacent to the manual Y-axis set screw, of the manual Y-axis, a manual Z-axis mounting seat is arranged above the manual Y-axis, a manual Z-axis is connected to the upper side of the manual Z-axis mounting seat by a fixing screw of the manual Z-axis mounting seat, a manual Z-axis scale is arranged on a side of the manual Z-axis, a manual Z-axis set screw is arranged on the side, which is opposite to the manual Z-axis scale, of the manual Z-axis, and a shaft sleeve is mounted on the side of the manual Z-axis via a shaft sleeve mounting seat. The long and thin cutter support device has the advantages that the cutter machining stability can be improved, the cutter machining quality can be enhanced, the cutter machining yield can be increased, the cutter bar loading frequency can be reduced, and the cutter machining and manufacturing efficiency can be improved.

Owner:KUNSHAN YUNCO PRECISION IND TECH

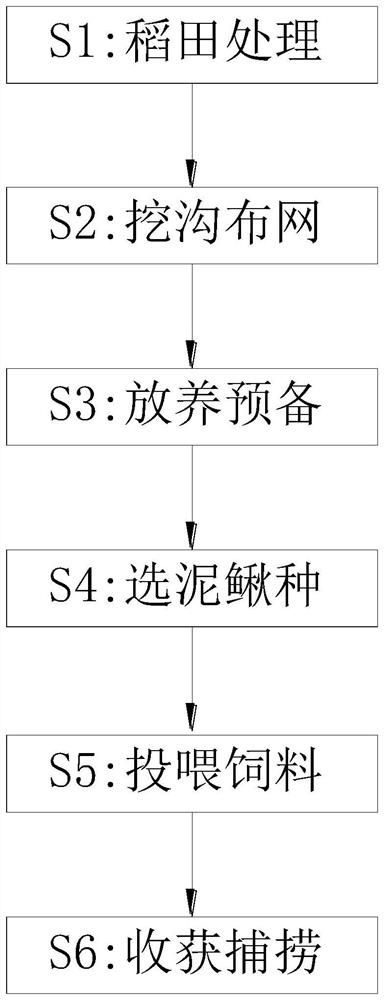

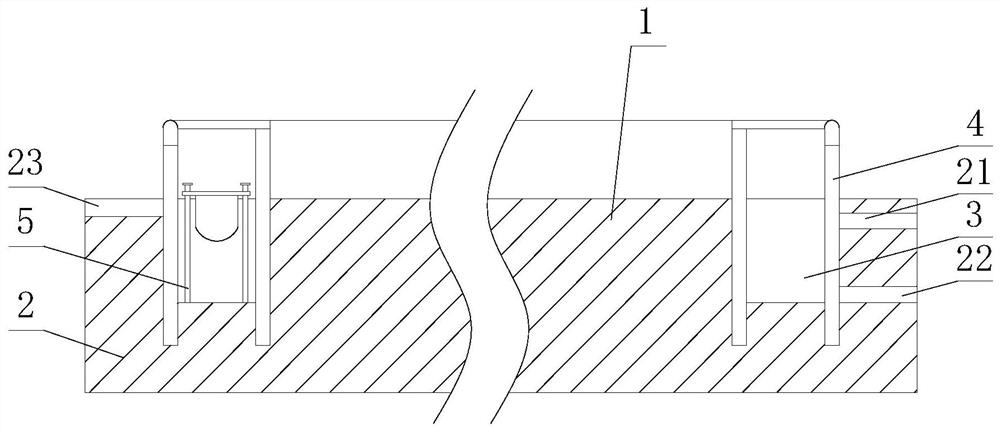

Breeding method for loaches in rice field

InactiveCN111642427AIncrease profitPrevent escapeClimate change adaptationPisciculture and aquariaPaddy fieldDitch

The invention discloses a breeding method for loaches in a rice field and a mixed breeding technology for loaches in a rice field. The scheme is proposed for the problem that a breeding method in theprior art is not flexible in feeding and affects the aquaculture production. A breeding ditch is dug around the inner side of a rice field ridge; an anti-escape net is laid on a side wall, close to the breeding ditch, of the rice field ridge; a water inlet, a water outlet and an overflow port are formed in two sides of the rice field ridge separately; the anti-escape net is attached to port locations of the water inlet, the water outlet and the overflow port separately; the lower end of the anti-escape net is buried underground and a rotary anti-bird net is arranged at the upper end; and feeding boxes of which feeding openings are adjustable in opening are uniformly arranged in the breeding ditch at intervals. The method has the advantages that the utilization rate of the rice field can beimproved, and escape of the loaches or preying of birds can be prevented. Feeding is convenient and the feeding frequency can be reduced. An adjusting hood is arranged on an outer wall of each spherical base, and the diameter of each first discharge hole can be adjusted through rotating the corresponding adjusting hood, so that the feeding requirements of feeds with different diameters are met, and the application range is wide.

Owner:TONGWEI +1

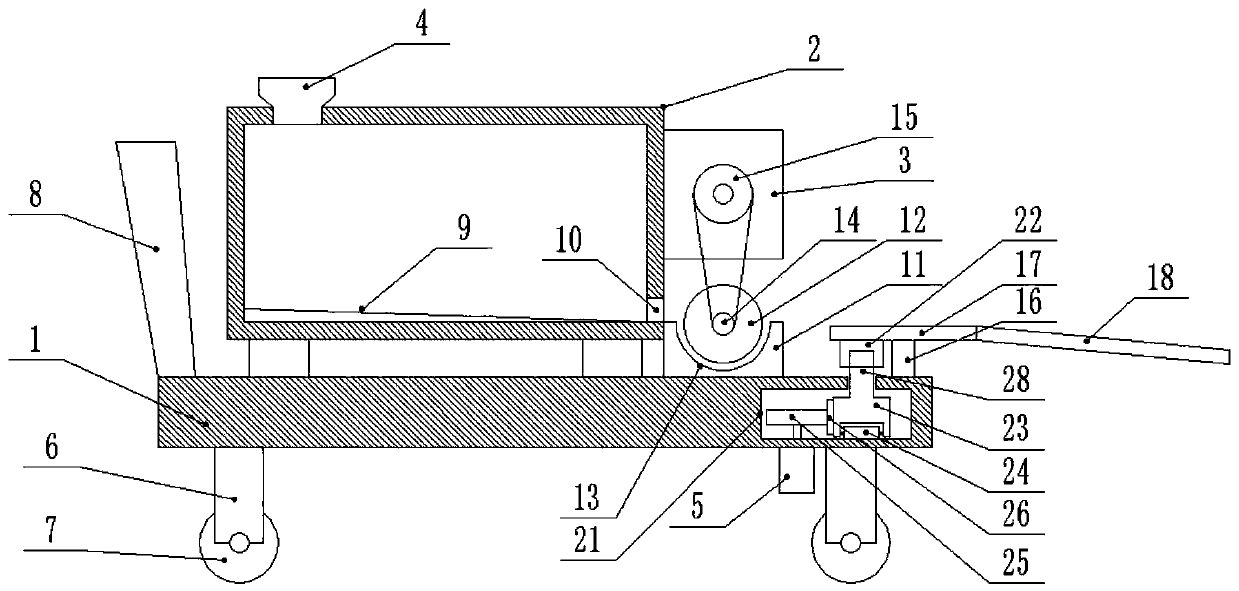

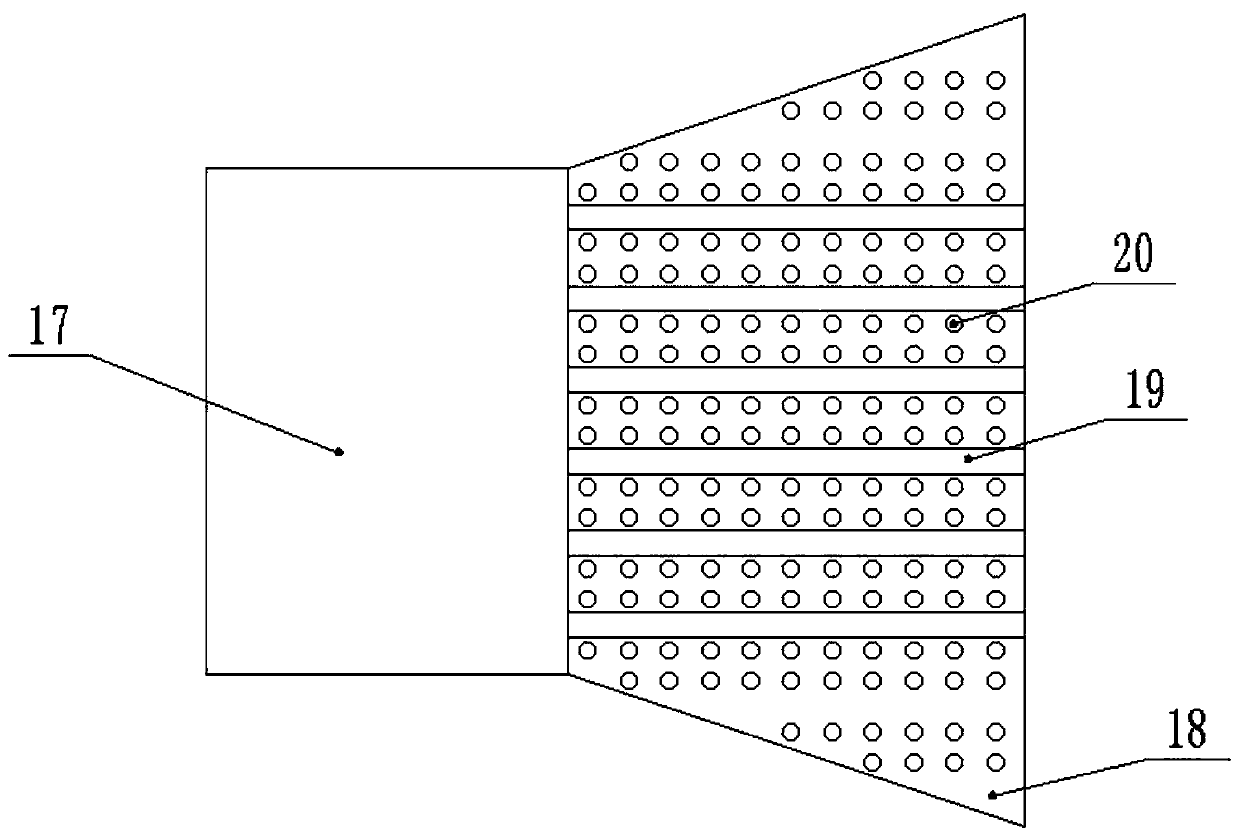

Agricultural swing type rapid fertilizing machine

ActiveCN107864728AReduce feeding timesEvenly distributedFertiliser distributersAgricultural engineeringAgriculture

The invention discloses an agricultural swing type rapid fertilizing machine. The agricultural swing type rapid fertilizing machine comprises a base, a storage box, a first motor, a feeding hopper anda second motor, wherein an inclined guiding plate is arranged at the bottom in the storage box, and a discharge port is formed in the side wall, corresponding to the lower end of the guiding plate, of the storage box; a receiving seat is fixed on the base corresponding to the outer end of the discharge port, and a downward recessed receiving groove is formed in the upper surface of the receivingseat; a horizontal guiding roller is mounted in the receiving groove; a swing mechanism is arranged on the outer side of the receiving seat. According to the agricultural swing type rapid fertilizingmachine, more fertilizer can be stored by the storage box, and feeding times of the fertilizing machine are reduced; fertilizer in the receiving groove fly out through the guiding roller, the fertilizer fly out uniformly and is spread to the surrounding, and uniform distribution of the fertilizer is facilitated; the flying-out fertilizer falls on a horizontal plate and an inclined plate, the horizontal plate and the inclined plate can swing under the action of the motors to knock out the fertilizer horizontally, so that the fertilizer moves horizontally, and action range of fertilization is expanded.

Owner:龙南天宇生态农业有限公司

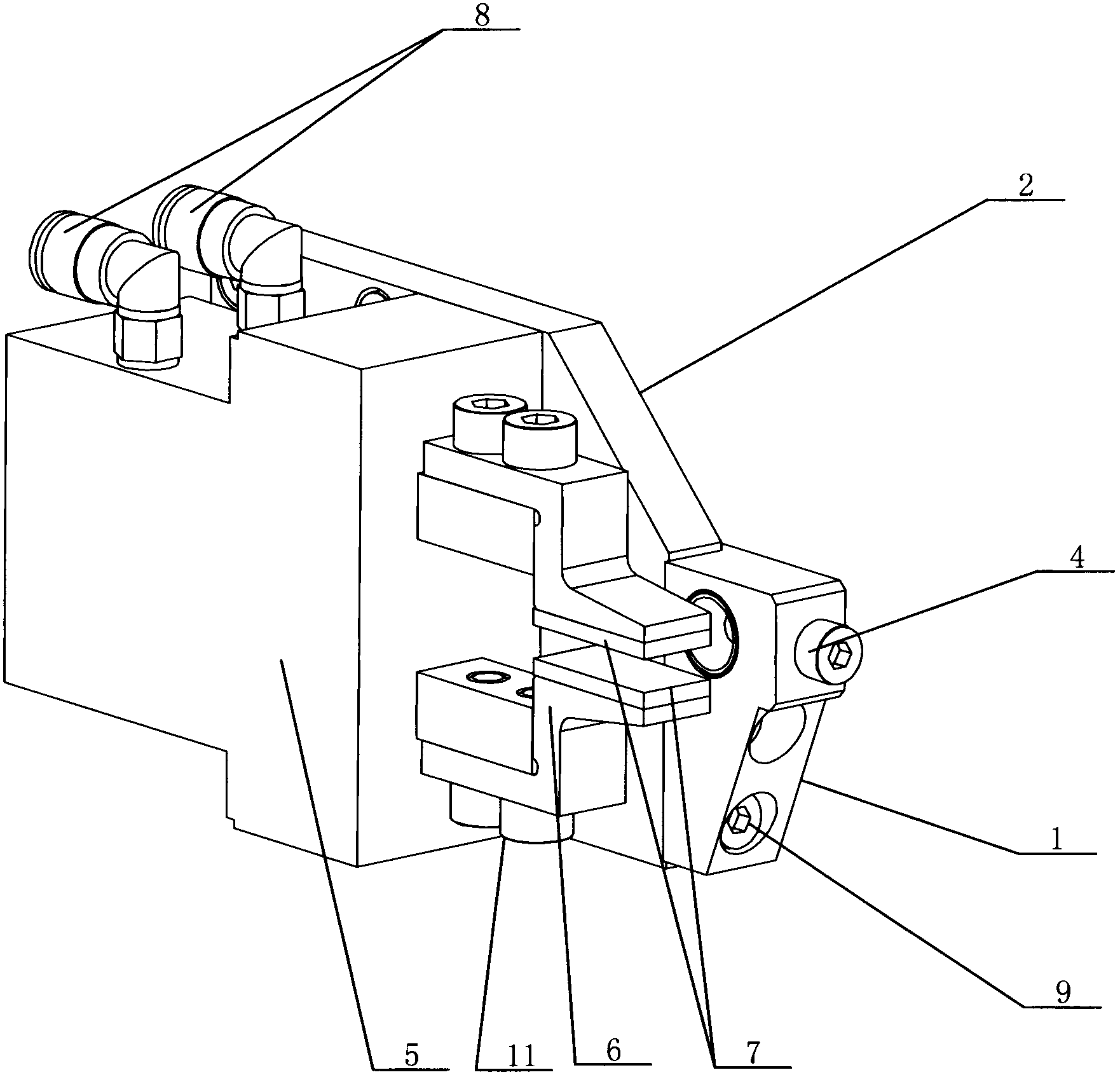

Clamp used for supporting long and thin tools

InactiveCN103846741AImprove processing qualityImprove processing yieldOther manufacturing equipments/toolsGrinding work supportsJackscrewEngineering

The invention discloses a clamp used for supporting long and thin tools and relates to the field of precise tool processing equipment. A bushing mounting seat is connected with a bushing mounting seat connection plate through a bushing mounting seat fixing bolt, a bushing is arranged on the bushing mounting seat, a bushing jackscrew is arranged outside the bushing, an air cylinder is connected with the bushing mounting seat connection plate through a cylinder fixing bolt, a parallel two-finger clamp is connected to the right side wall of the air cylinder through a parallel two-finger clamp fixing bolt, shock pads are respectively arranged on the inner wall of an upper jaw and a lower jaw of the parallel two-finger clamp, and two air pipe connectors are arranged at the upper end of the air cylinder. An automatic feeding function in tool processing can be realized, the number of feeding tool bars is reduced, tool processing and producing efficiency are improved by the adoption of modular-based design, and the clamp can be conveniently mounted on a transmitted five-axis tool grinder to be directly used as a function upgraded part.

Owner:KUNSHAN YUNCO PRECISION IND TECH

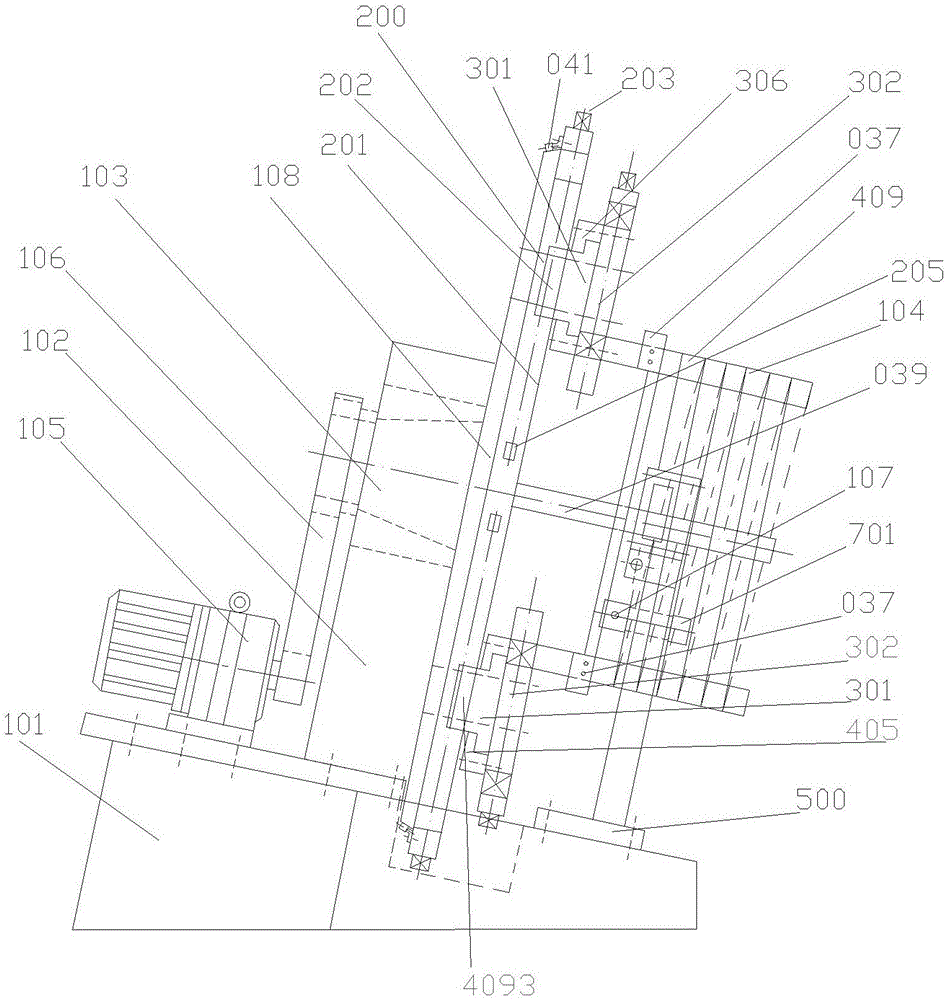

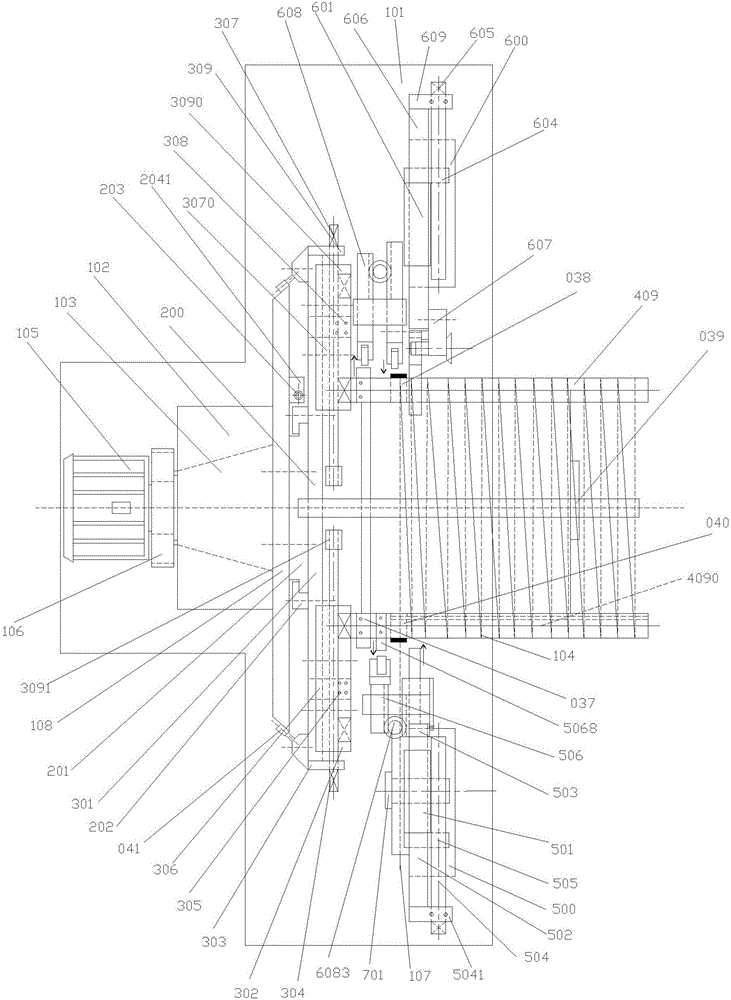

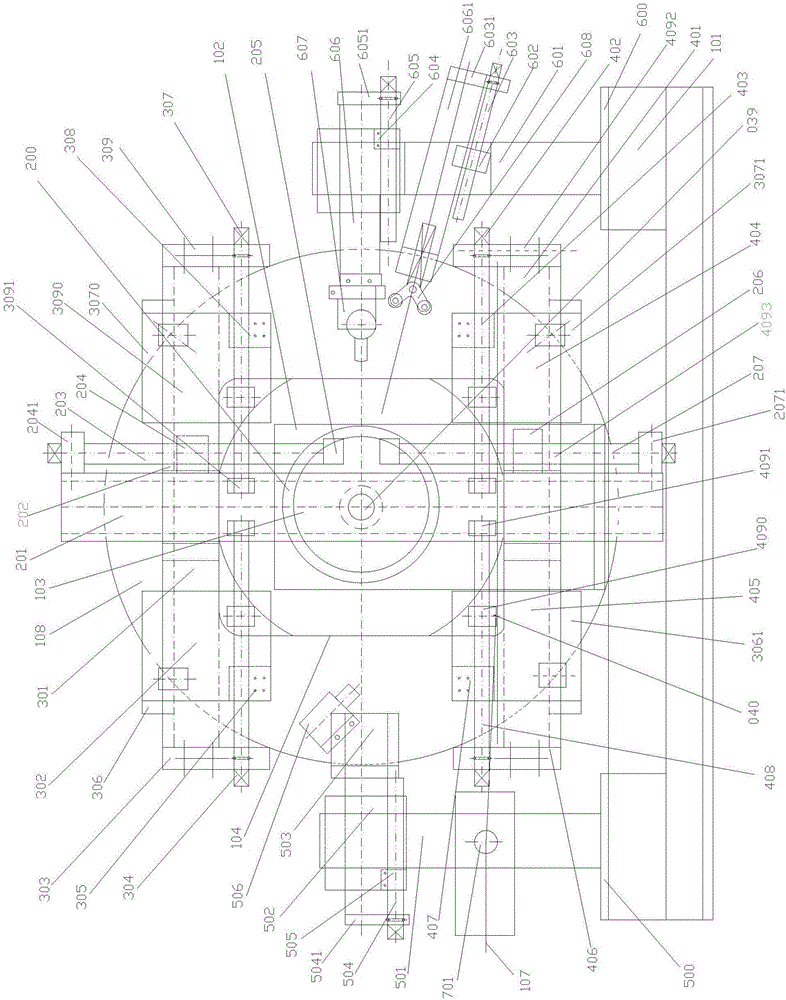

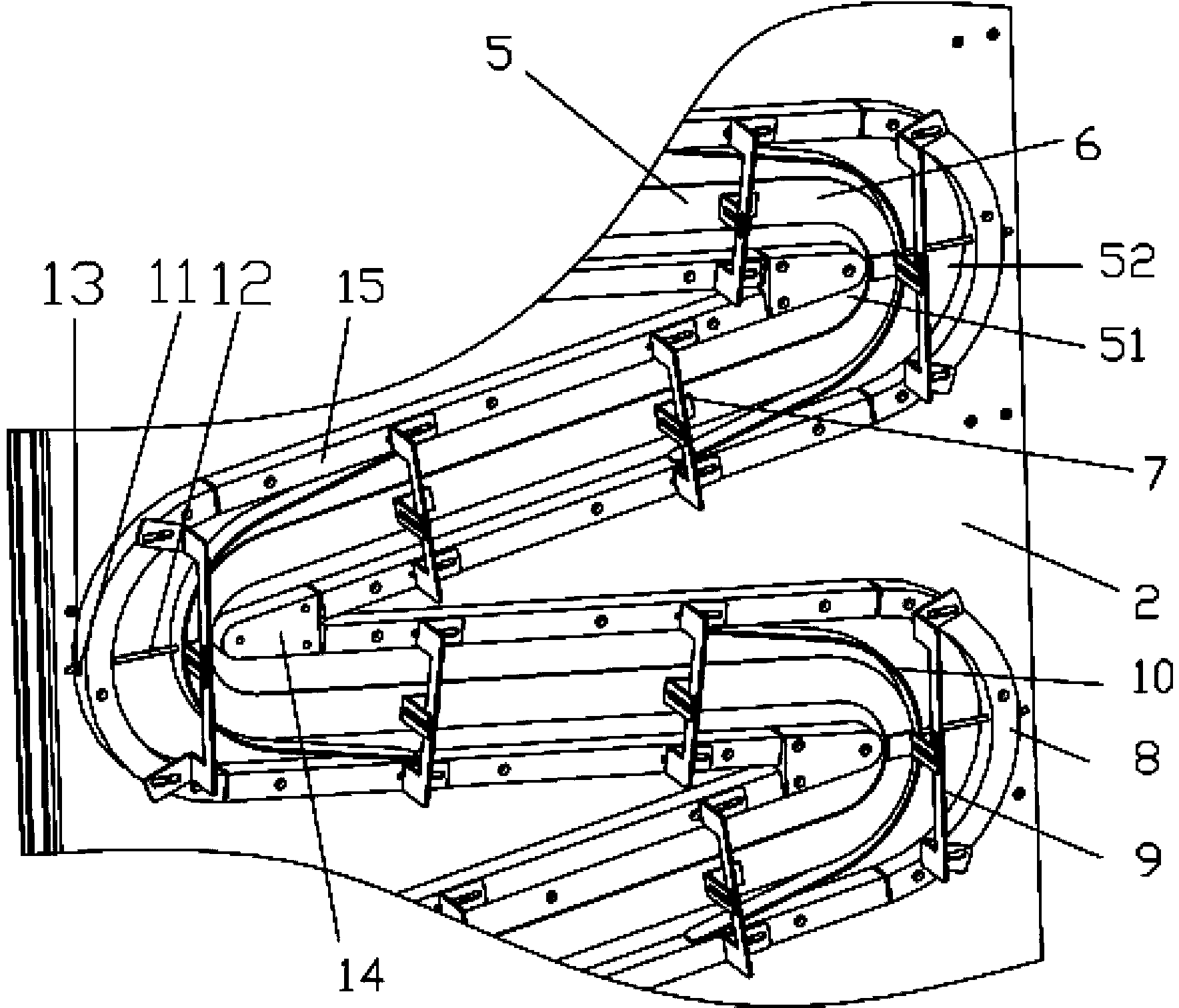

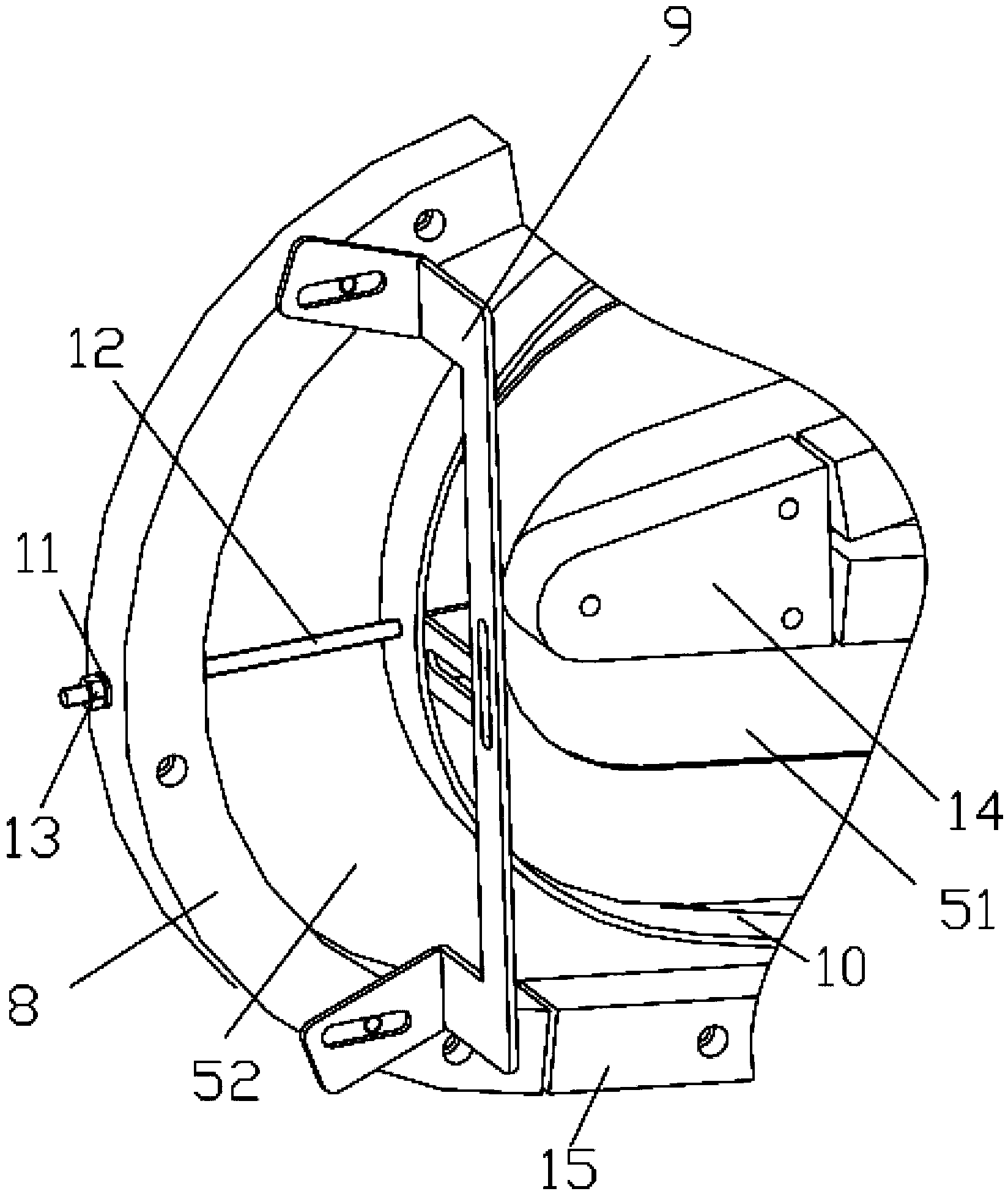

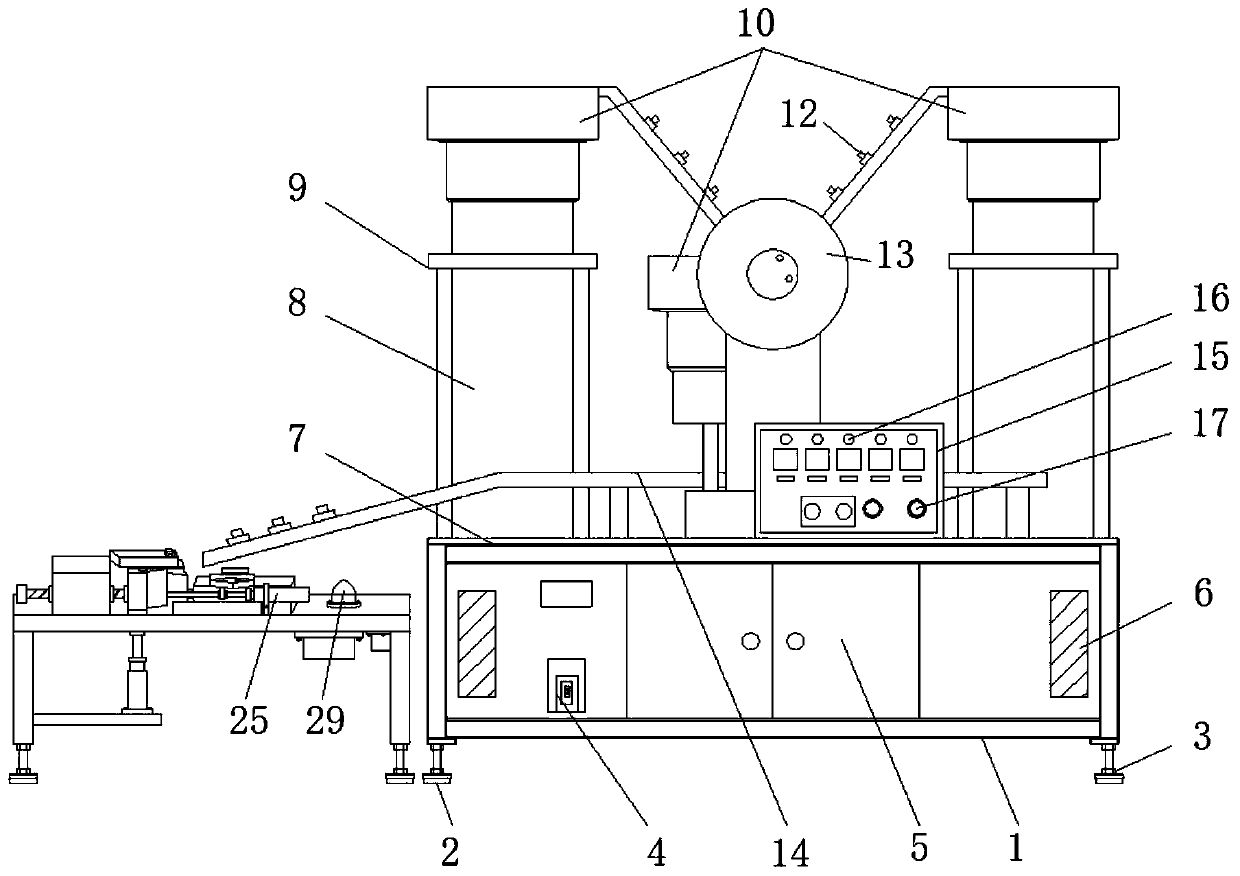

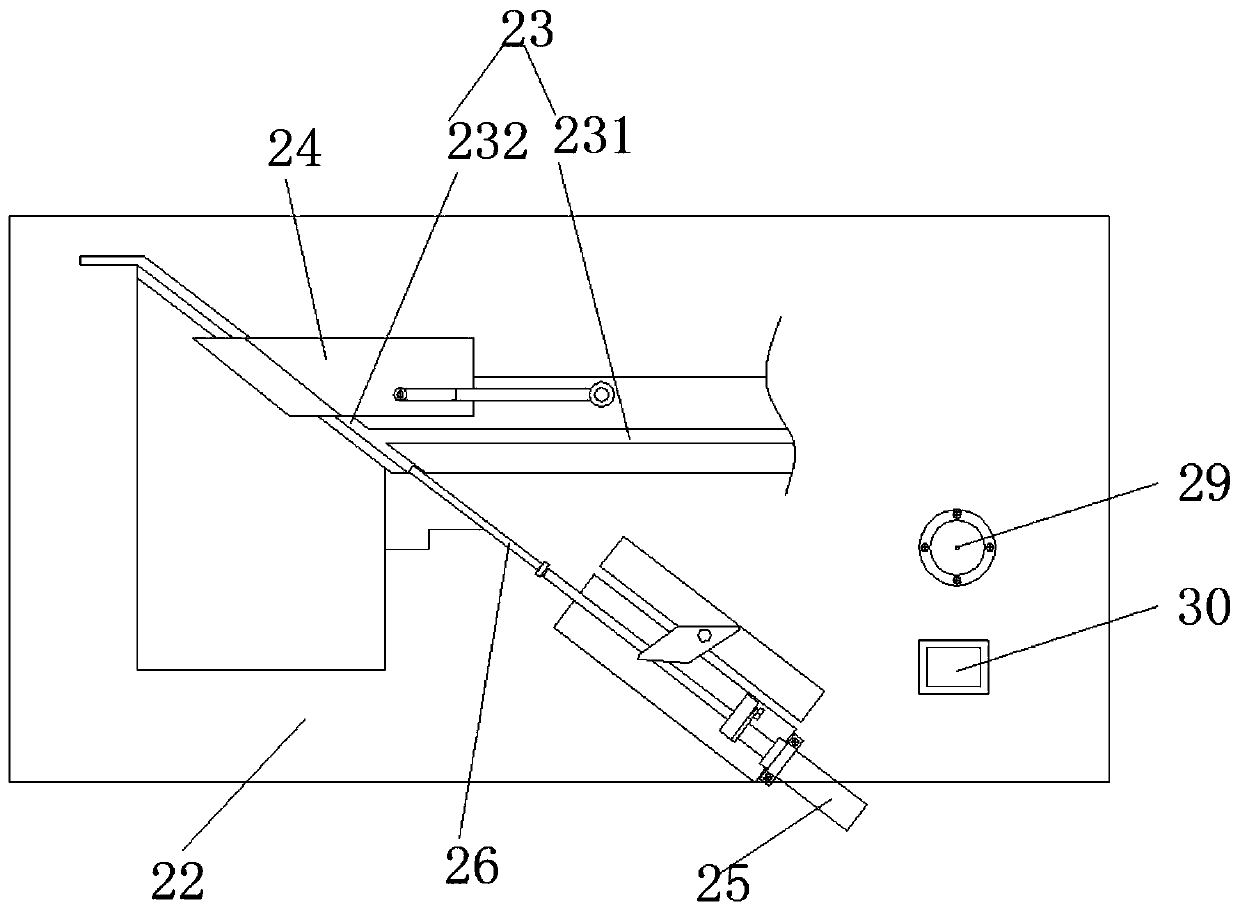

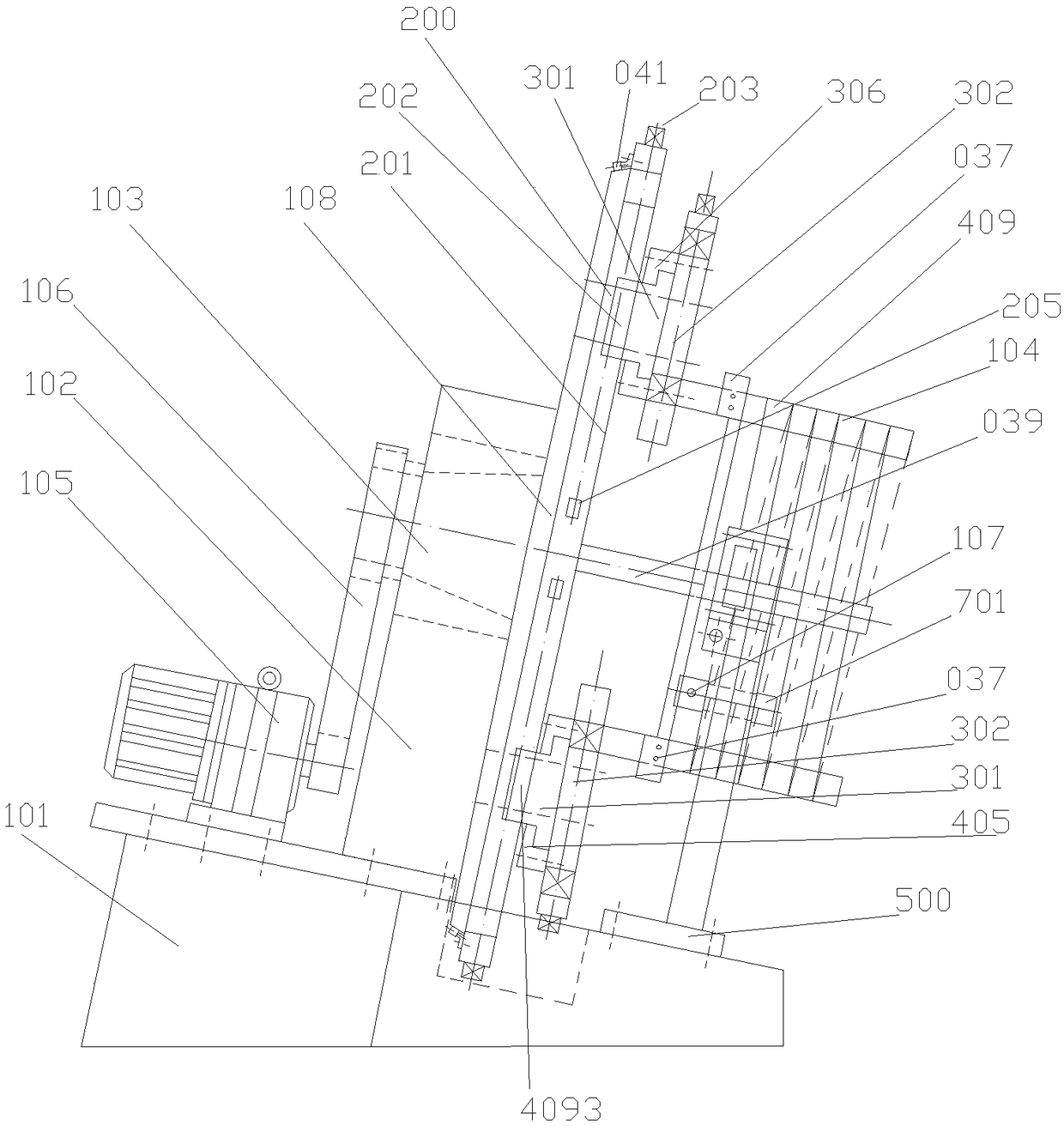

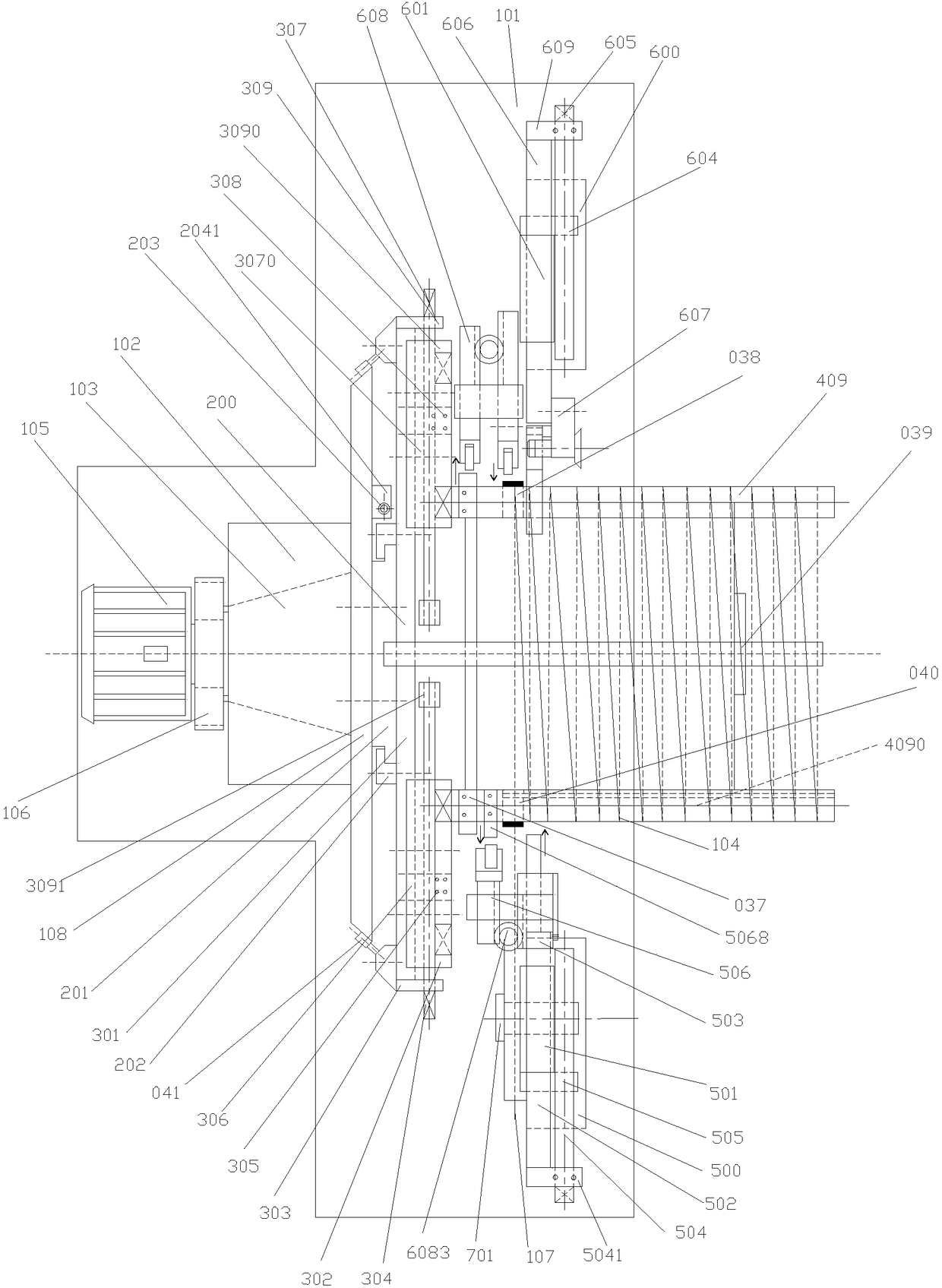

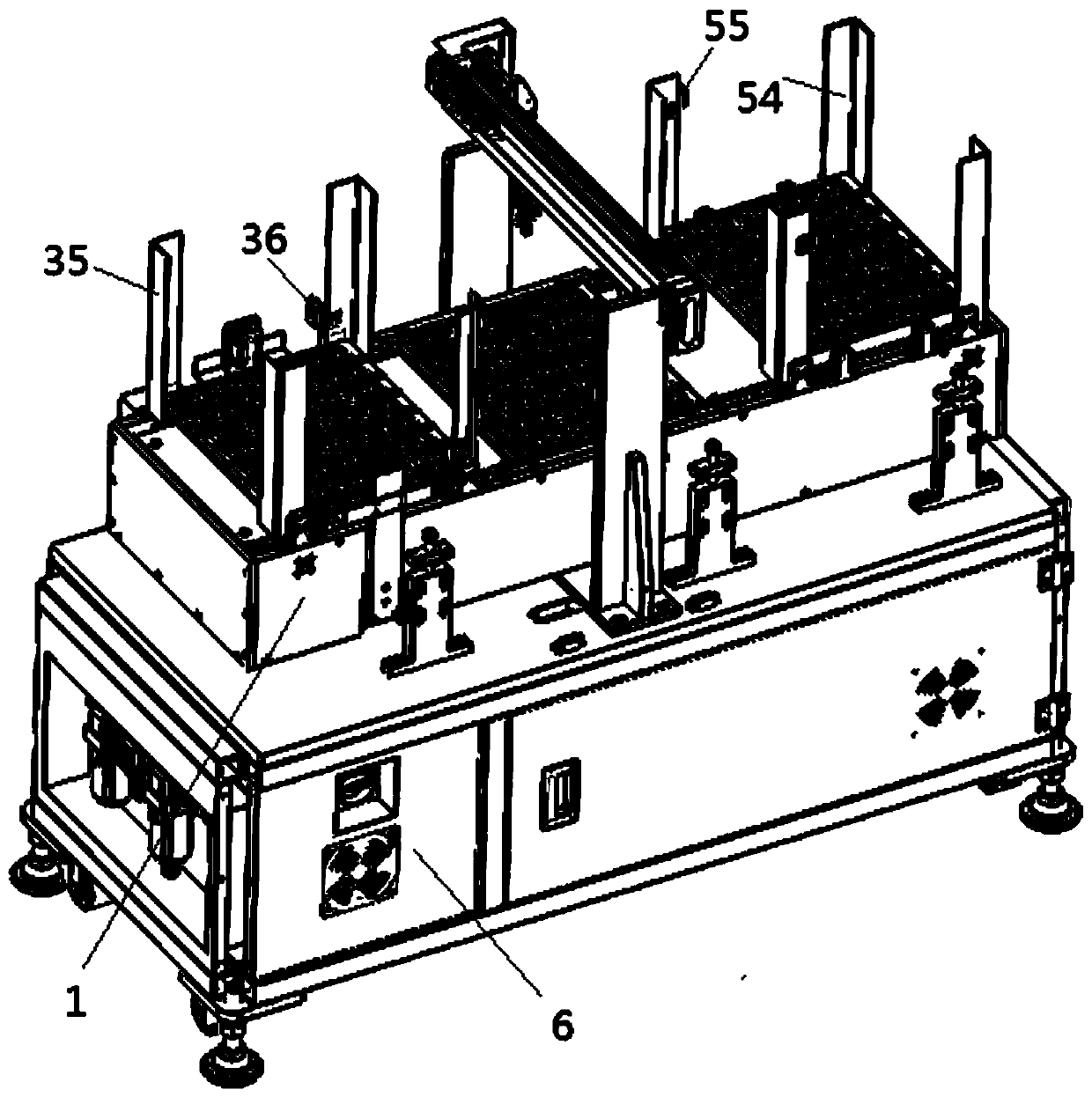

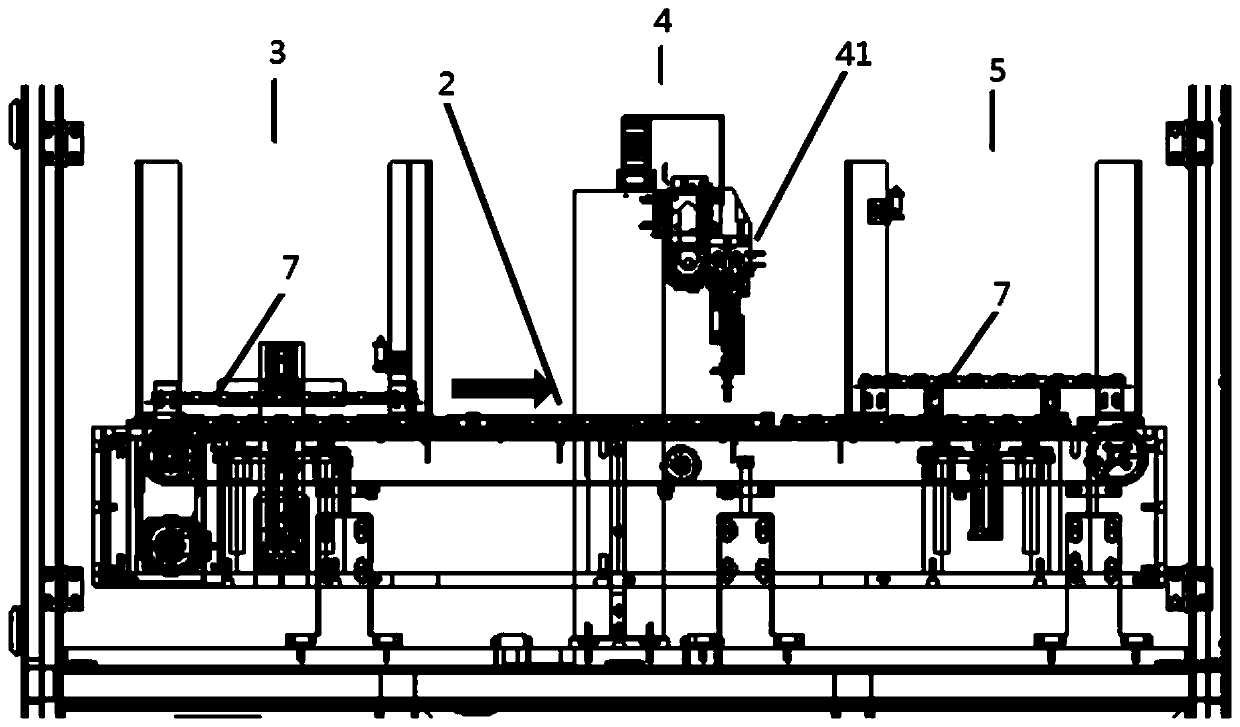

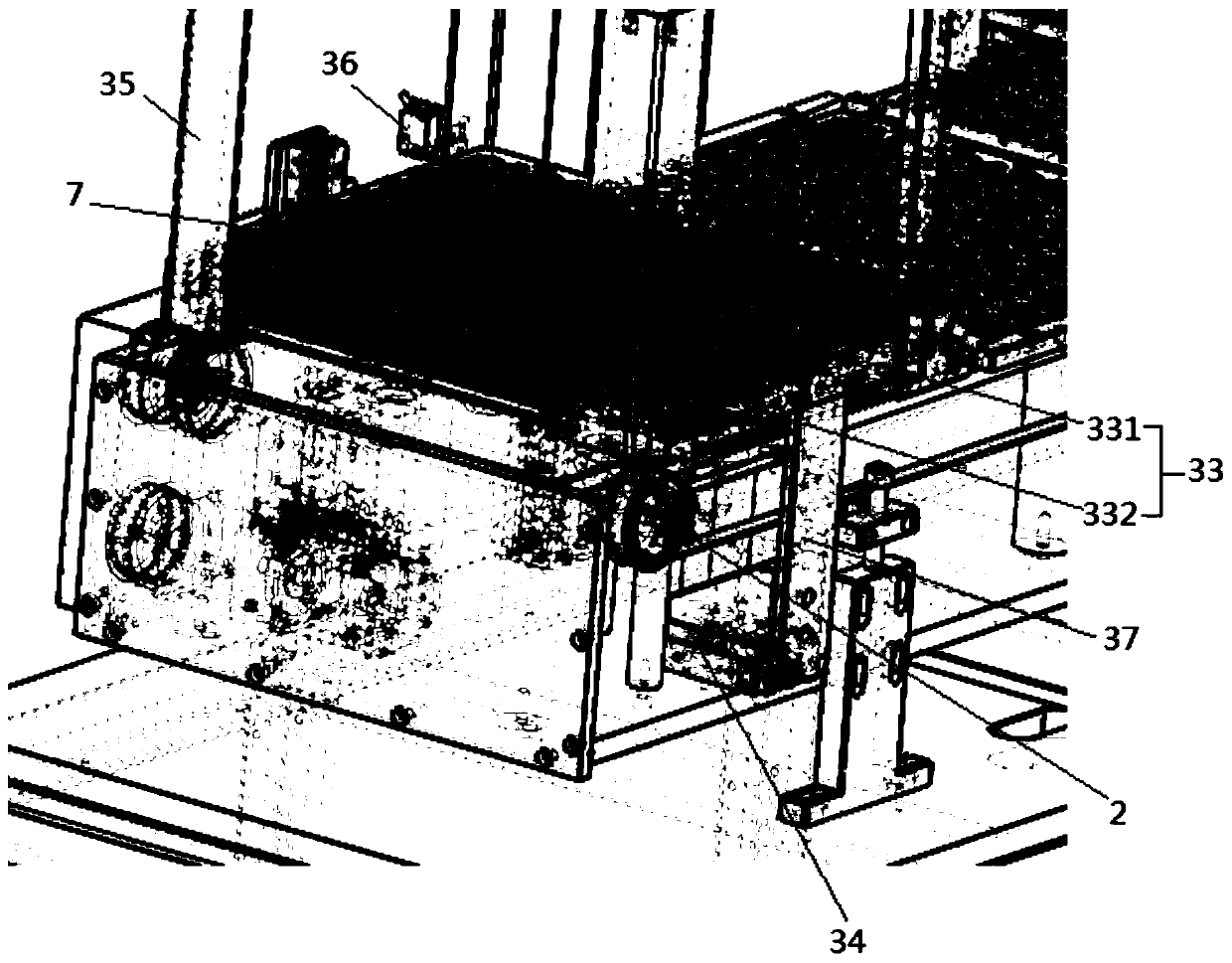

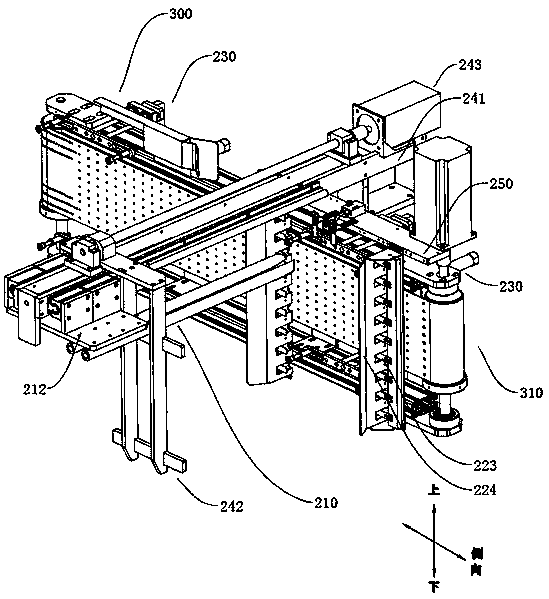

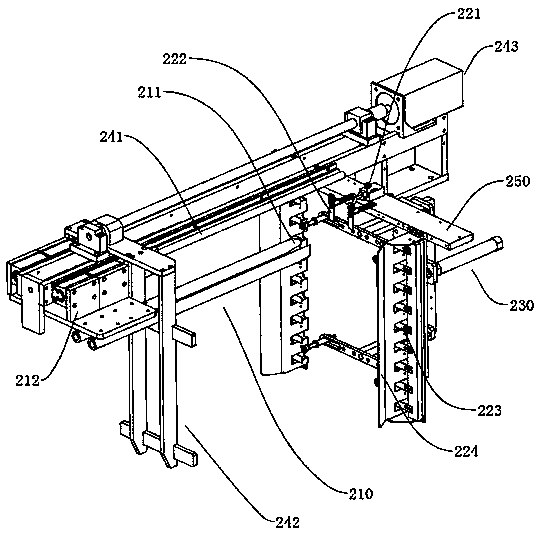

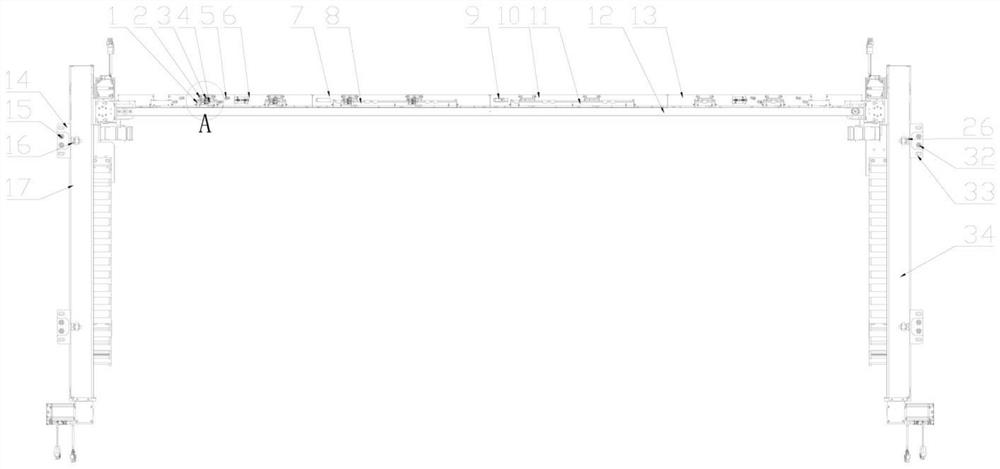

Spiral stirrup continuous synchronous processing machine and processing method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

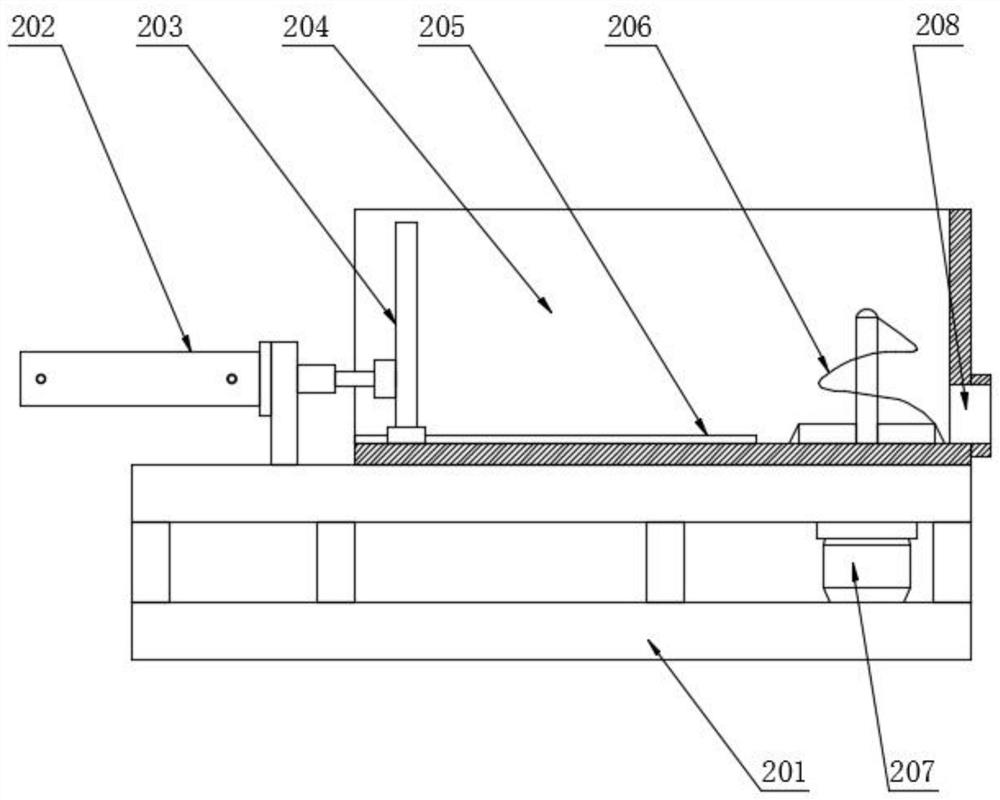

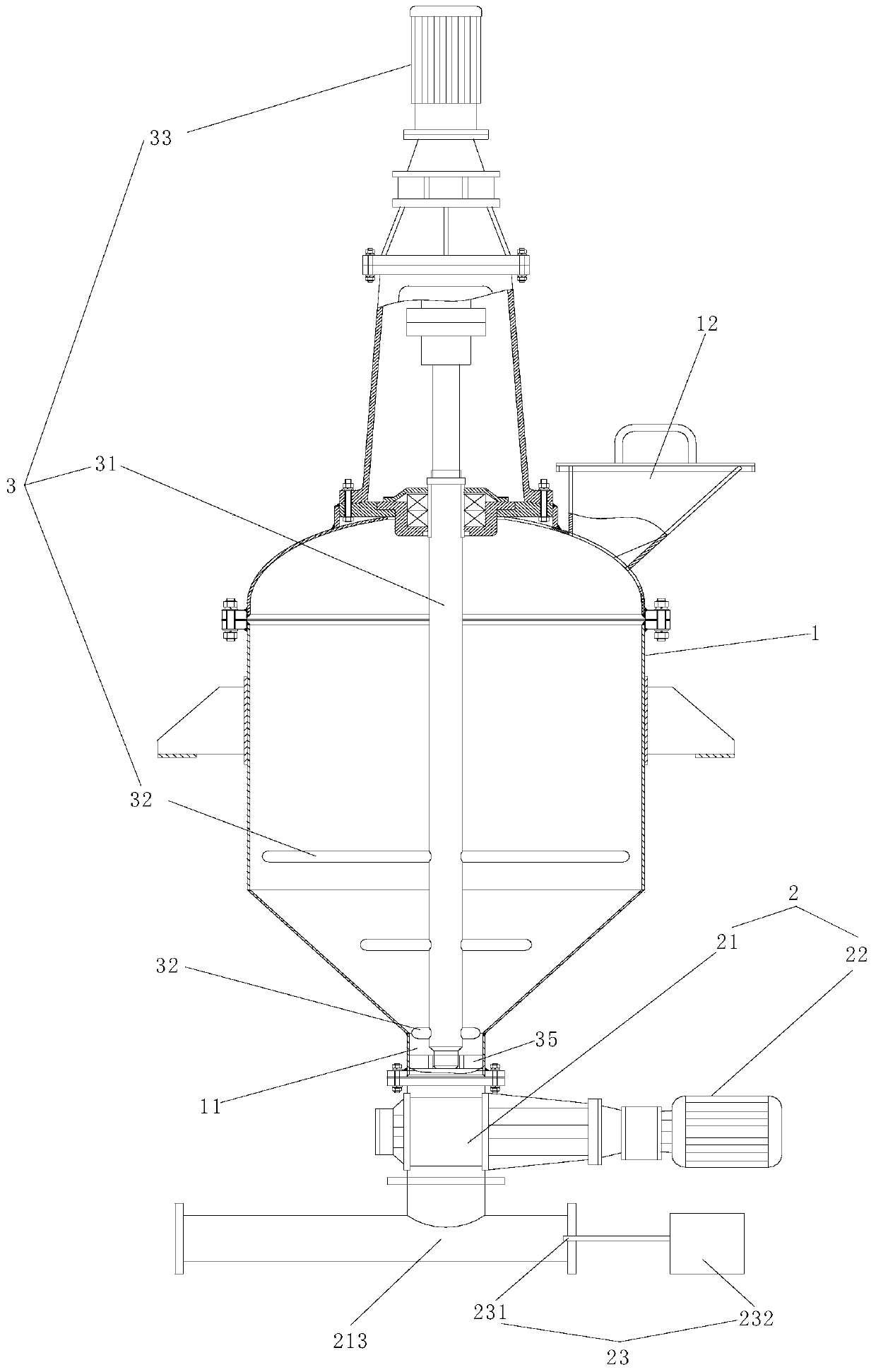

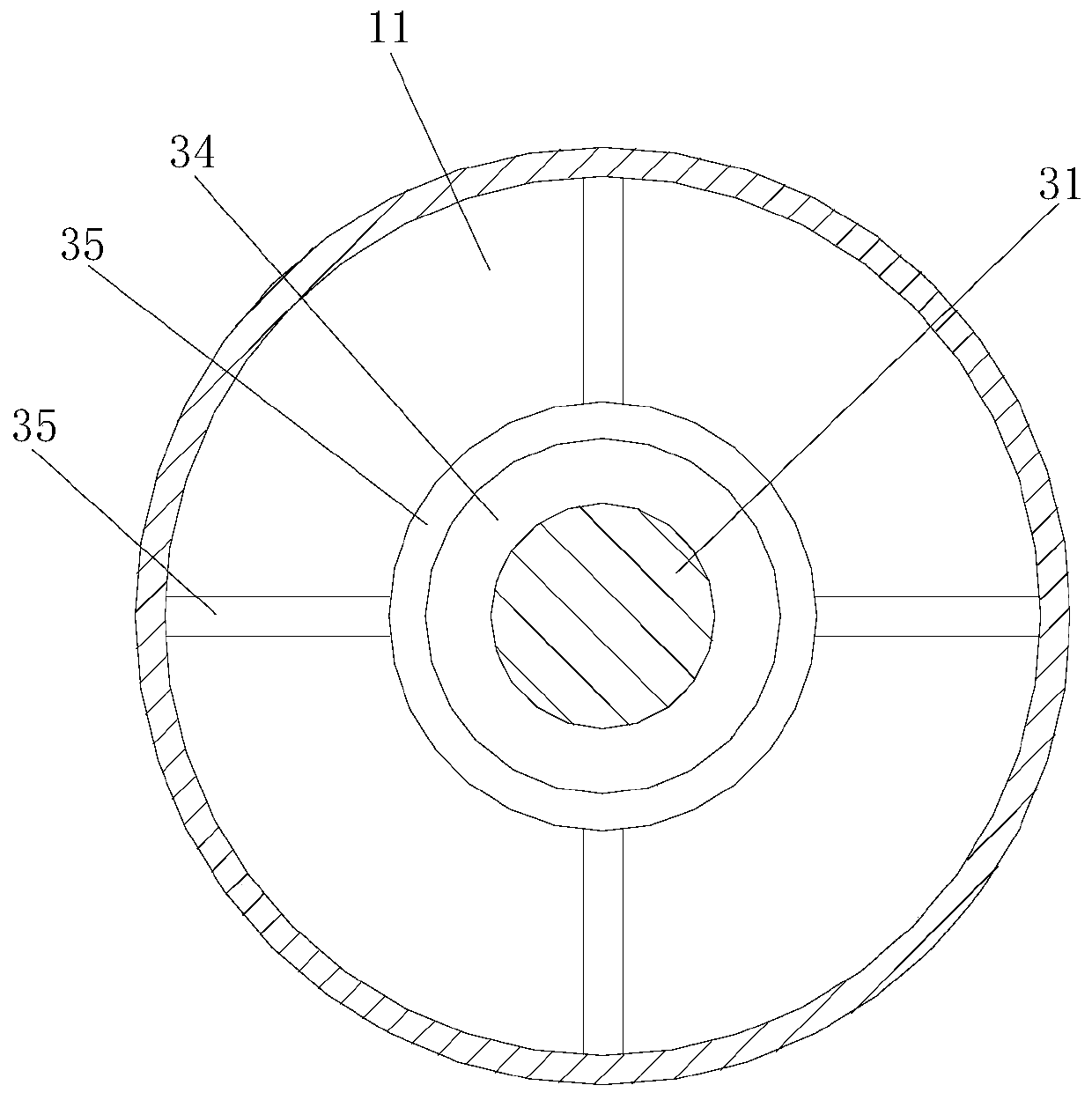

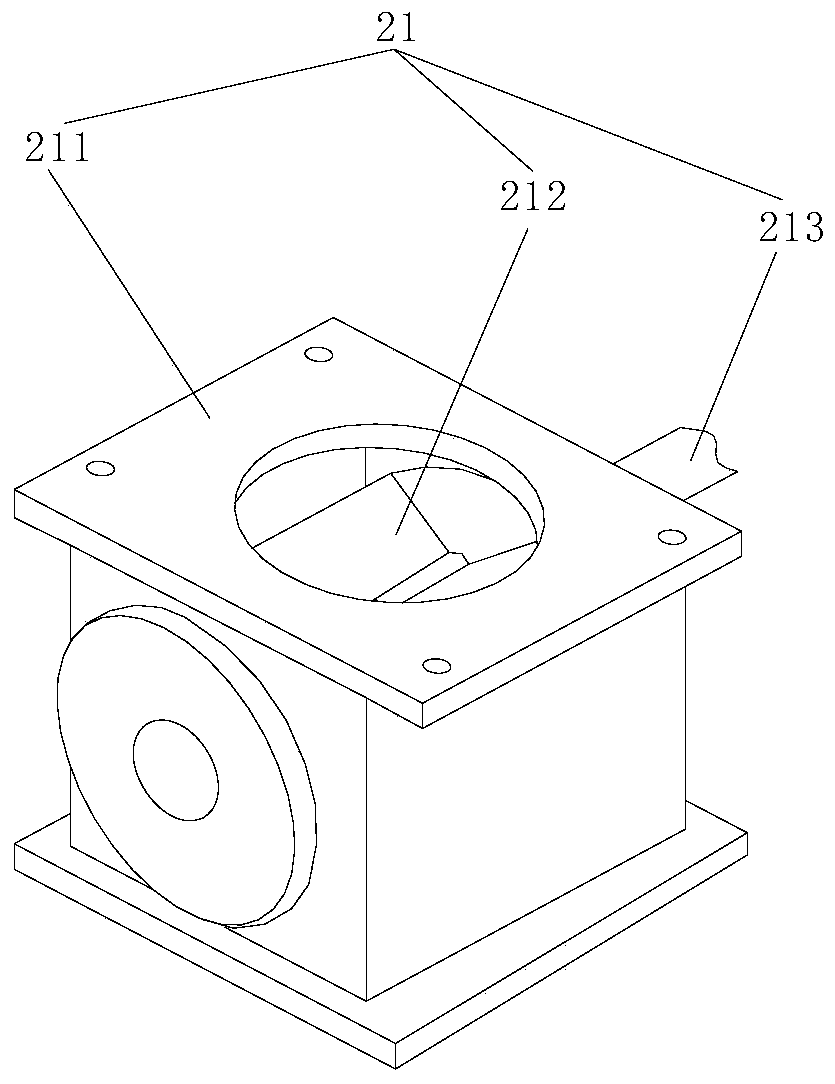

Feeding device

PendingCN109911435ALarge capacityReduce feeding timesLarge containersTank wagonsEngineeringStorage tank

The invention provides a feeding device, and relates to the technical field of material conveying devices. The technical problem that in the prior art, materials are caked, and the feeding device is blocked is mainly solved. The feeding device comprises a storage tank, a feeding structure and a stirring structure. The feeding structure is connected with a discharging opening of the storage tank sothat materials in the storage tank can be output through the feeding structure. The stirring structure is located in the storage tank so that the stirring structure can stir the materials stored in the storage tank. According to the feeding device, by arranging the stirring structure, the materials can be stirred when the feeding device supplies the materials, and therefore the materials are prevented from caked entering the feeding structure, and then the aim of preventing the materials from blocking the feeding device is achieved.

Owner:LANGFANG DEV ZONE FANHUA PETRIFACTION MACHINERY EQUIP

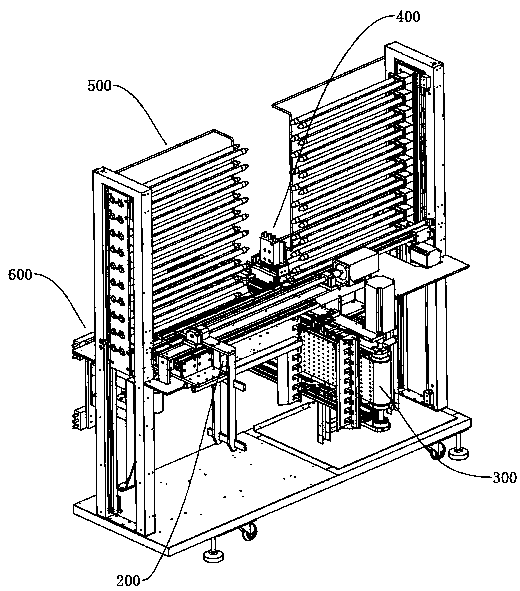

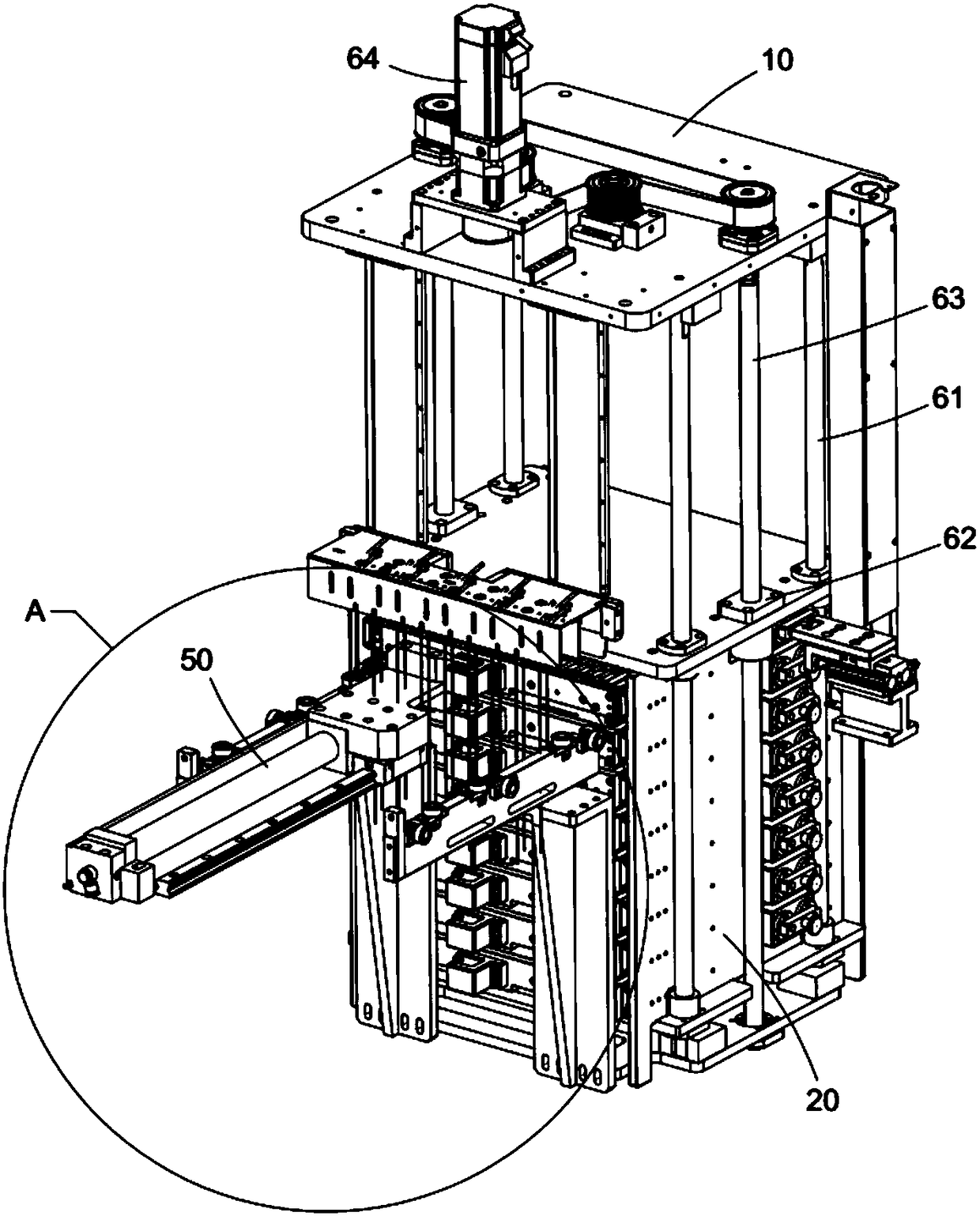

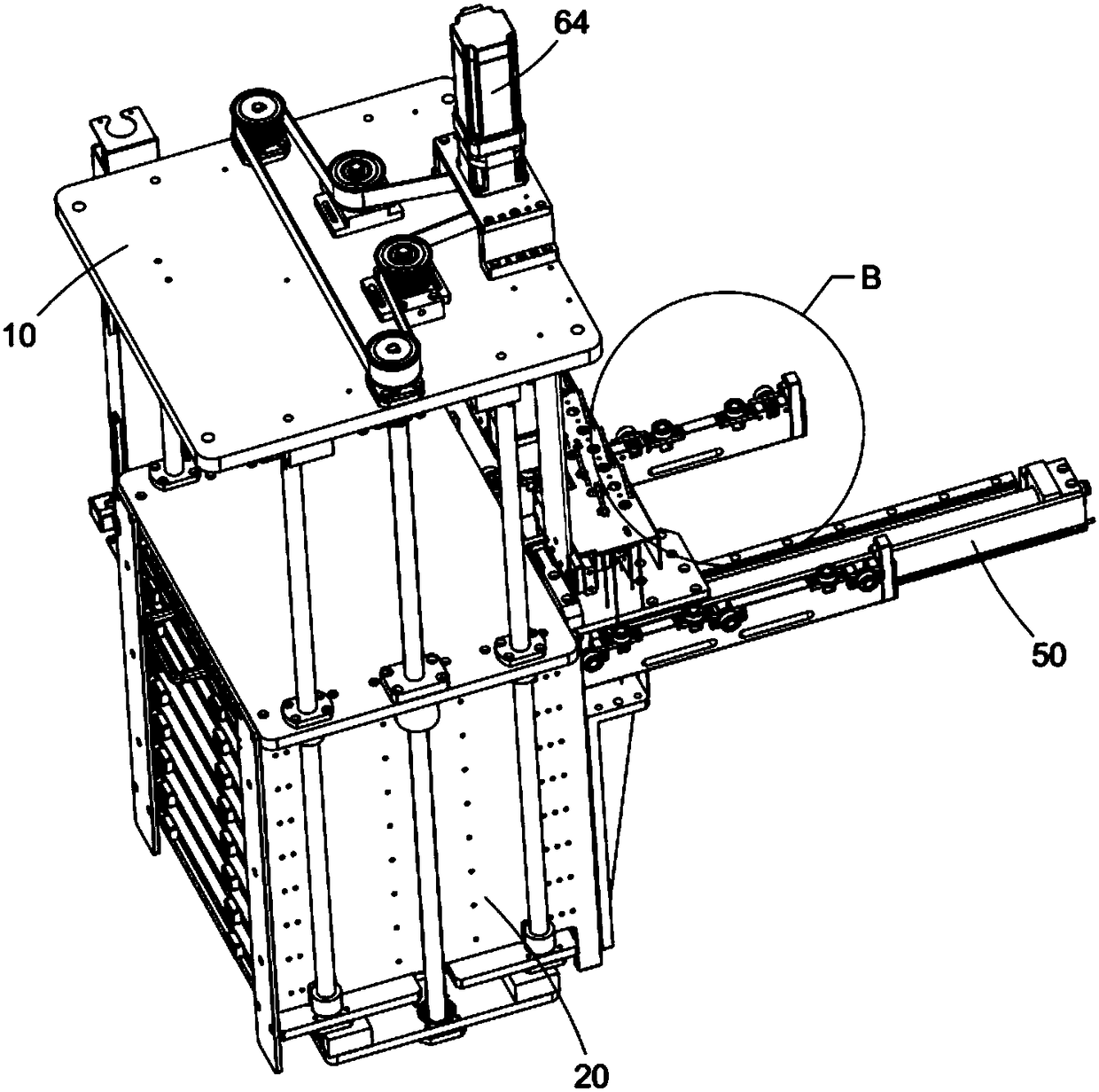

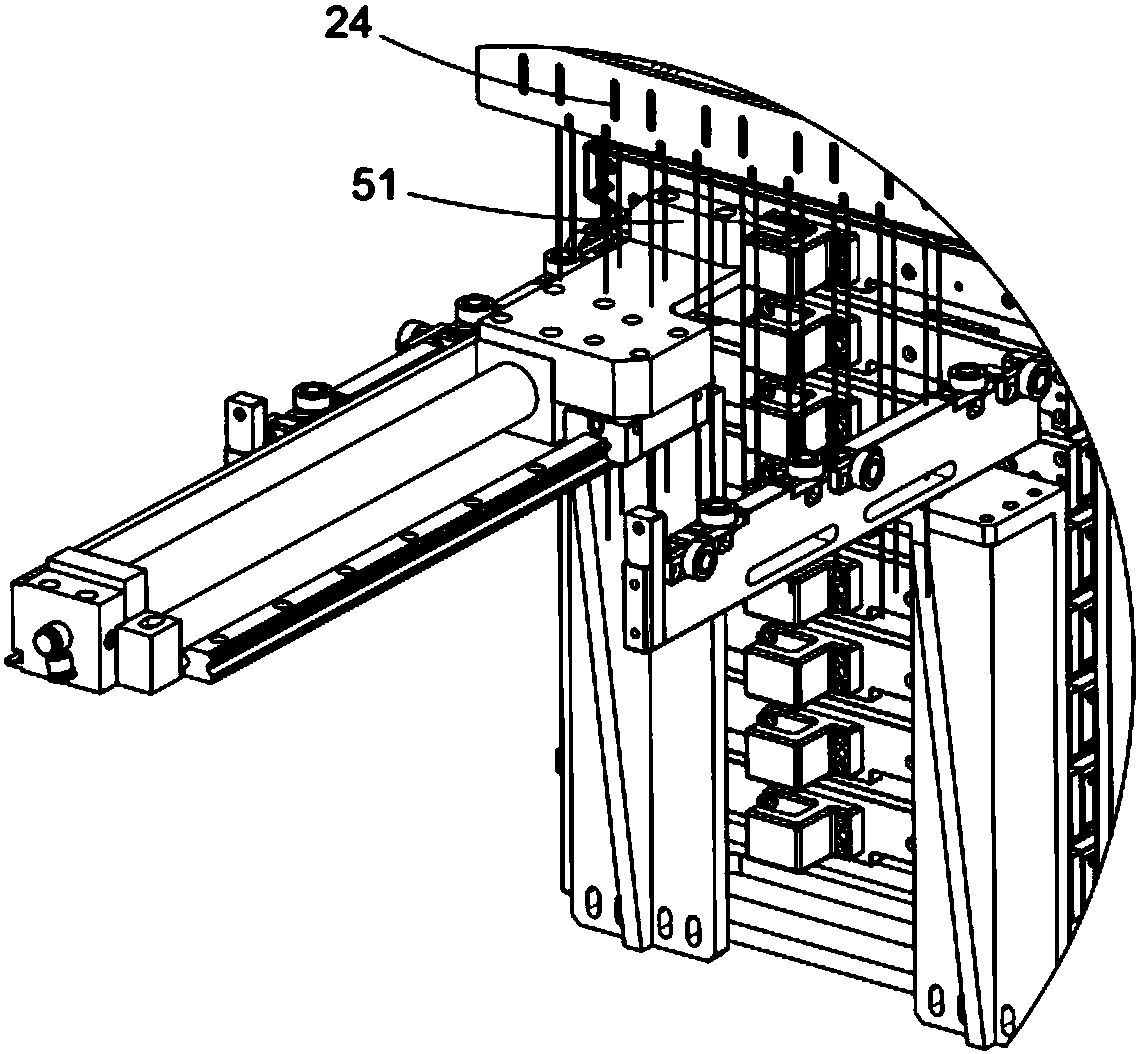

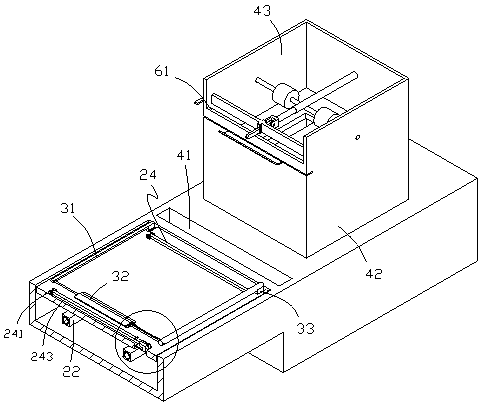

Full-automatic feeding and discharging equipment of blow molding plate

PendingCN110697427AAvoid downtimeIncrease usageControl devices for conveyorsStacking articlesBlow moldingElectric machinery

The invention relates to a full-automatic feeding and discharging equipment of a blow molding plate. The full-automatic feeding and discharging equipment comprises a conveying line, a blow molding plate mounting station, a working position and a blow molding plate taking station. During work, a first motor drives a first supporting plate to rise, an air cylinder drives a second supporting plate toopen outwards, and the blow molding plate is dropped on the first supporting plate; the air cylinder drives the second supporting plate to retract inwards, the second supporting plate supports the second blow molding plate at the bottom, and the first blow molding plate at the bottom is located on the first supporting plate; the first motor drives the first supporting plate to descend, the bottomfirst blow molding plate is placed on the conveying line to be conveyed to the working position through the conveying line, the conveying line conveys the blow molding plate at the working position to the blow molding plate station, and the second motor drives the blow molding plate on a top plate to rise until the blow molding plate penetrates through two one-way opening-closing supporting plates to reach a location above the two one-way opening-closing supporting plates, the second motor drives the top plate to descend, and the blow molding plate is left on the two one-way opening-closing supporting plate. The full-automatic feeding and discharging equipment solves the technical problem that shutdown is required during feeding and discharging of the blow molding plate in the prior art.

Owner:安费诺永亿(海盐)通讯电子有限公司

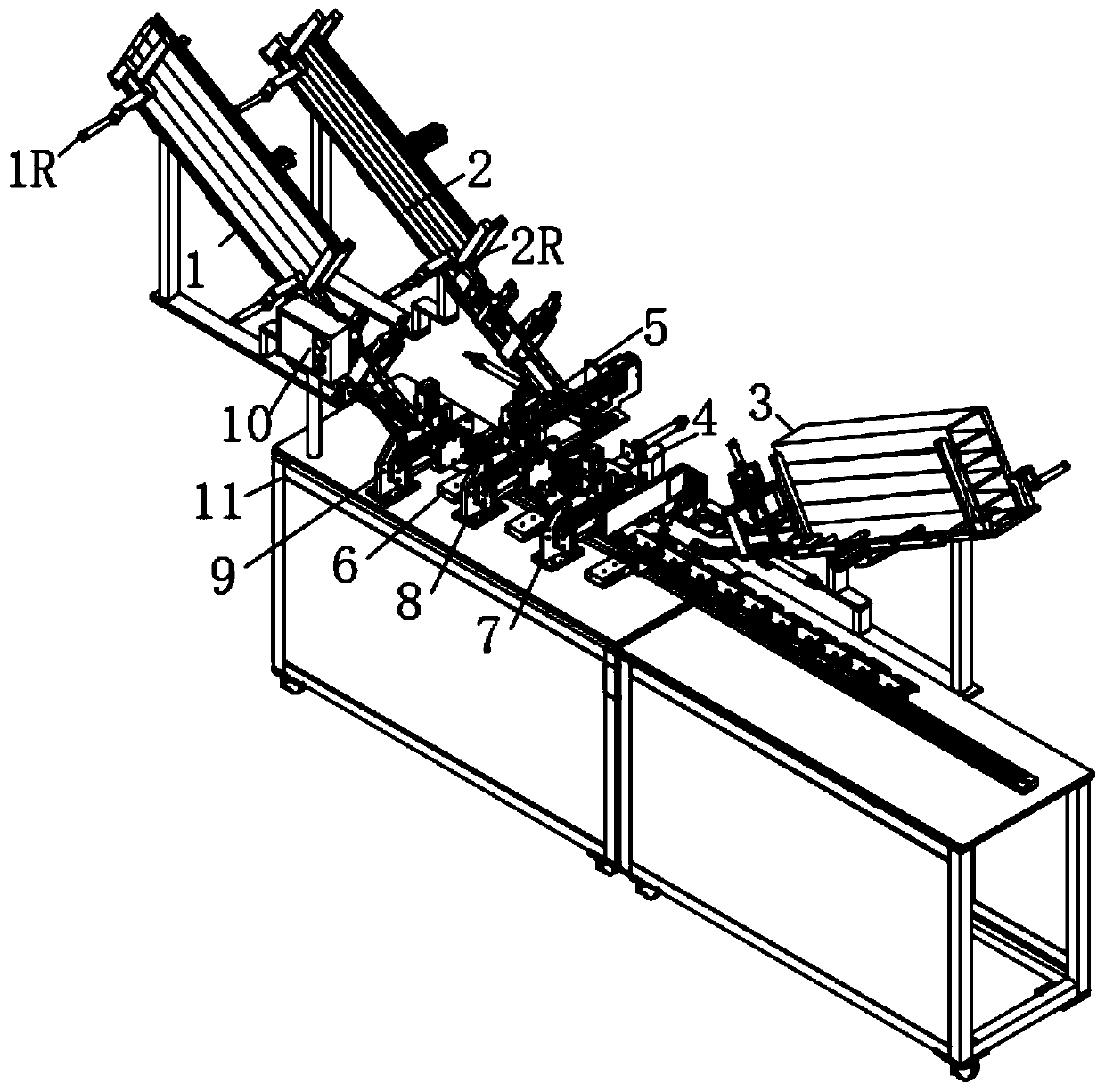

Full-automatic handle press fitting machine

PendingCN111546700AReduce feeding timesIncrease productivityBag making operationsPaper-makingSoftware engineeringMachine

The invention discloses a full-automatic handle press fitting machine which comprises a bag conveying mechanism, a handle conveying system and a handle press-fitting mechanism. The bag conveying mechanism can convey bags to the handle press-fitting mechanism. The handle conveying system can convey handles to the handle press-fitting mechanism. The handle press-fitting mechanism can perform press fitting on the handles onto the bags. The handle conveying system comprises a handle conveying channel assembly and a handle storing mechanism. The handle conveying channel assembly comprises handle press-fitting and conveying channels for conveying the handles, and a handle send-out mechanism. The handle storing mechanism comprises a plurality of handle storing assemblies capable of stacking the handles. The handle storing assemblies can be placed into the handle press-fitting and conveying channels correspondingly. The handle send-out mechanism can send out the handles placed on the handle storing assemblies of the handle press-fitting and conveying channel, many handles can be stored through the plurality of handle storing assemblies, the feeding frequency is reduced, and the bag and handle press-fitting production efficiency is improved.

Owner:日力智能科技(中山)有限公司

A swinging fast fertilizer applicator for agriculture

ActiveCN107864728BReduce feeding timesEvenly distributedFertiliser distributersAgricultural engineeringAgriculture

The invention discloses an agricultural swing type rapid fertilizing machine. The agricultural swing type rapid fertilizing machine comprises a base, a storage box, a first motor, a feeding hopper anda second motor, wherein an inclined guiding plate is arranged at the bottom in the storage box, and a discharge port is formed in the side wall, corresponding to the lower end of the guiding plate, of the storage box; a receiving seat is fixed on the base corresponding to the outer end of the discharge port, and a downward recessed receiving groove is formed in the upper surface of the receivingseat; a horizontal guiding roller is mounted in the receiving groove; a swing mechanism is arranged on the outer side of the receiving seat. According to the agricultural swing type rapid fertilizingmachine, more fertilizer can be stored by the storage box, and feeding times of the fertilizing machine are reduced; fertilizer in the receiving groove fly out through the guiding roller, the fertilizer fly out uniformly and is spread to the surrounding, and uniform distribution of the fertilizer is facilitated; the flying-out fertilizer falls on a horizontal plate and an inclined plate, the horizontal plate and the inclined plate can swing under the action of the motors to knock out the fertilizer horizontally, so that the fertilizer moves horizontally, and action range of fertilization is expanded.

Owner:龙南天宇生态农业有限公司

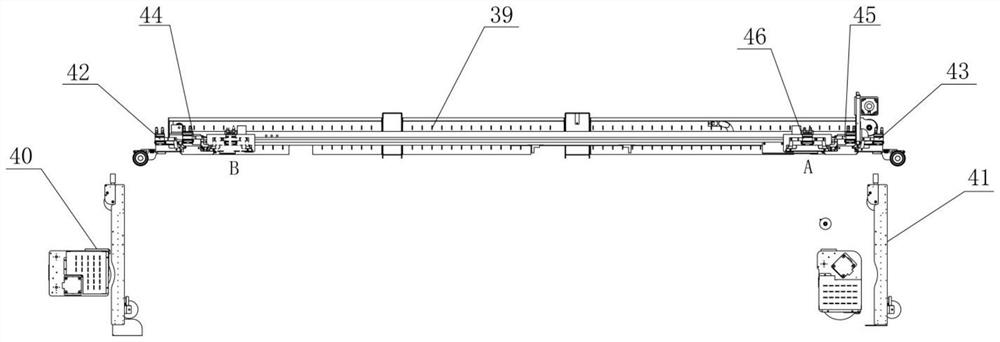

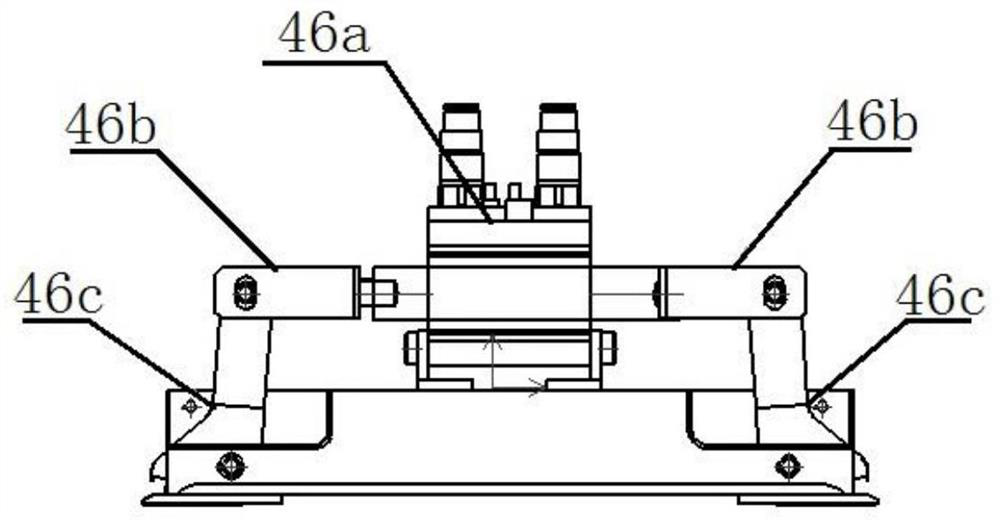

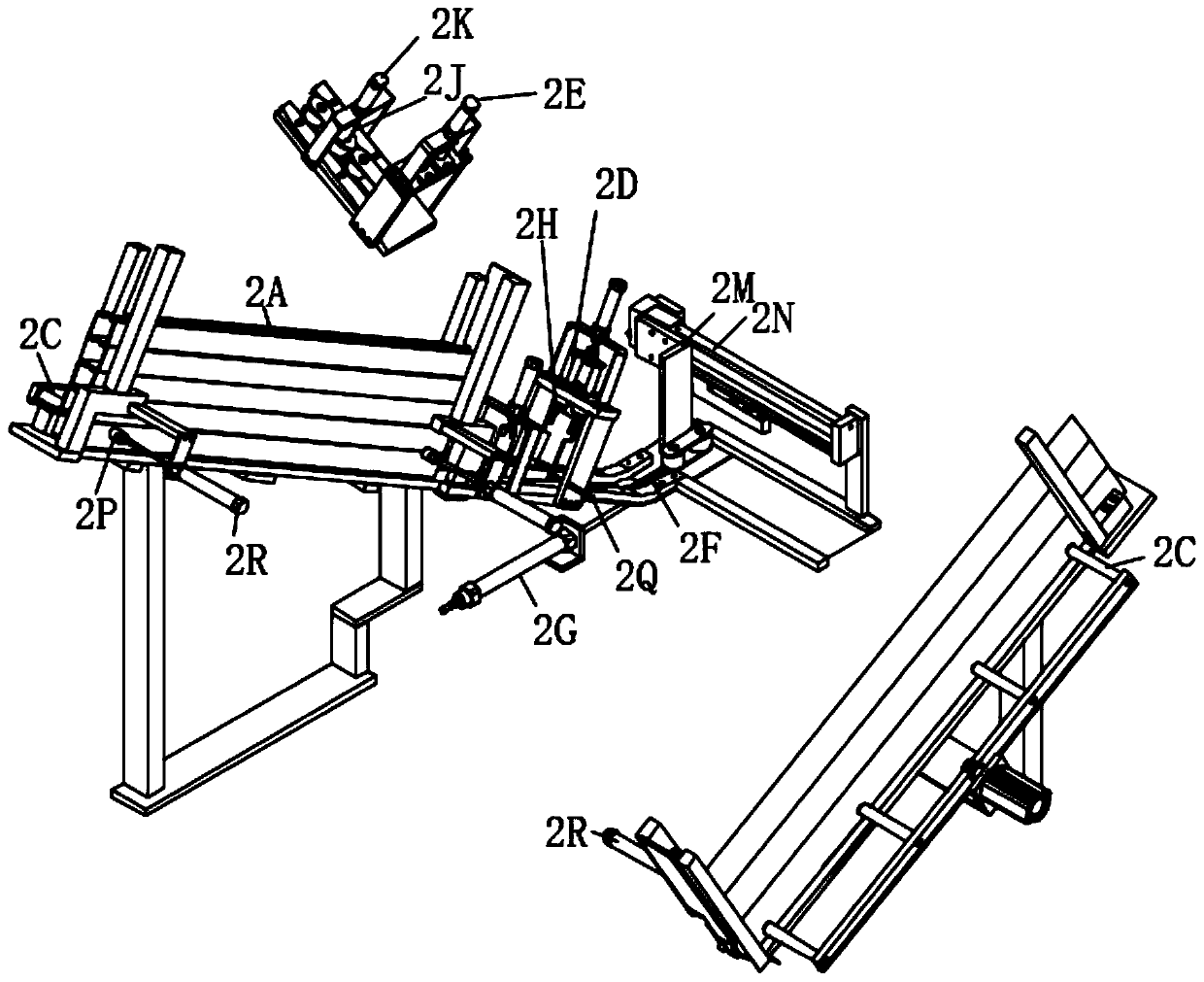

Bypass bus bar manufacturing mechanism, bus bar supply mechanism and method for machining bus bar through stitch welding machine

ActiveCN112846591AReduced return pull actionReduce feeding timesFinal product manufactureWelding/cutting auxillary devicesStructural engineeringMechanical engineering

The invention discloses a bypass bus bar manufacturing mechanism, a bus bar supply mechanism and a method for machining a bus bar by a stitch welding machine. The bypass bus bar manufacturing mechanism comprises a displacement mechanism, a first bus bar supply mechanism, a second bus bar supply mechanism, a first fixed clamp hand, a second fixed clamp hand, a first cutter mechanism, a second cutter mechanism and a bus bar pulling mechanism; the bypass bus bar supply mechanism comprises a bus bar guiding and correcting mechanism, a bus bar horizontal carrying mechanism and a bus bar vertical carrying mechanism, the bus bar guiding and correcting mechanism comprises a cross beam provided with a first end positioning mechanism, a second end positioning mechanism and a middle positioning mechanism, and the bus bar horizontal carrying mechanism comprises a left servo module and a right servo module; and the bus bar vertical carrying mechanism comprises left and right Z-direction servo modules connected with the left and right servo modules, and the left Z-direction servo module and the right Z-direction servo module are connected with the cross beam in a floating mode. The embodiment of the invention further provides a method for machining the bus bar through the stitch welding machine.

Owner:无锡市联鹏新能源装备有限公司

Cooking heating furnace by using biomass fuel

InactiveCN102384490BBurn fullyFierce firepowerLighting and heating apparatusStove/ranges for heating waterPush and pullCombustion chamber

The invention relates to a cooking heating furnace by using biomass fuel. The cooking heating furnace comprises a heating water jacket, a charging box, a cooking body, a heating and cooking regulating push-and-pull device, a pipe frame type water cooled wall and a ventilating ash dropping chamber, wherein the charging box and the heating water jacket are arranged in parallel right and left; the cooking body is positioned in front of the charging box and the heating water jacket; the heating and cooking regulating push-and-pull device runs through the cooking body longitudinally and is connected with the inner wall of the heating water jacket; the pipe frame type water cooled wall is arranged at the periphery of the inner wall of the cooking body and is connected with the heating water jacket; and the ventilating ash dropping chamber is formed in the middles of lower sides of the charging box, the heating water jacket and the cooking body. In the cooking heating furnace, the capacity of the charging box is high, a few charging times is required, and the fire sealing time is long; smoke discharge and fire running are smooth during cooking; a smoke discharge push-and-pull material puller is arranged, so that smoke stored in the charging box can be discharged in time before charging, and fire in a combustion chamber is not cut off during the cooking; the combustion of the fuel is full, heat power is high, and the cooking heating furnace has obvious energy-saving and environment-friendly effects.

Owner:高文申 +1

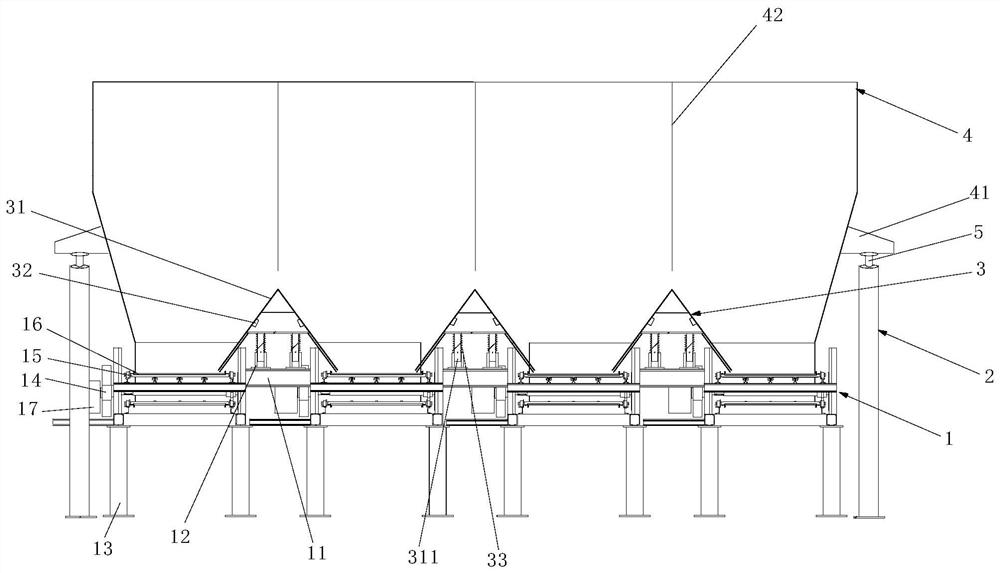

Ceramic raw material feeding equipment and feeding method thereof

PendingCN113772355AReduce feeding timesImprove work efficiencyCleaningControl devices for conveyorsLeather beltManufacturing engineering

The invention relates to ceramic raw material feeding equipment and a feeding method thereof. The feeding equipment comprises at least two conveying belt assemblies, a support, vibration triangular plate assemblies and a shell, wherein the two sides of each conveying belt assembly extend outwards to form bosses, fixing grooves are formed in the bosses, each vibration triangular plate assembly comprises a triangular plate and an electric vibrator, two fixing bolts are arranged on the bottom face of each triangular plate in a protruding mode, the electric vibrators are fixed to the inner side walls of the triangular plates, the triangular plates connect the two adjacent conveying belt assemblies through cooperation of fixing bolts and the fixing grooves, the shell is installed on the support and covers the upper portion of the conveying belt assemblies after connection is completed, and weighing sensors are arranged between convex shoulders and the support. According to the ceramic raw material feeding equipment and the feeding method thereof, the raw material loading capacity of a feeding machine can be improved, the manual feeding frequency is reduced, the feeding efficiency is improved, and the simple and efficient feeding process is realized.

Owner:JIANGXI WONDERFUL CERAMICS CO LTD

an automatic feeding system

Owner:BOZHON PRECISION IND TECH CO LTD

A photovoltaic module packaging line

ActiveCN111559549BReduce labor intensitySimple structurePackaging automatic controlPackaging machinesMechanical engineeringElectrical and Electronics engineering

The invention relates to a photovoltaic module packaging line, which includes a stacking and conveying station, a shaping station is arranged on one side of the stacking and conveying station, a packing station is arranged on one side of the shaping station, and a bottom cover outer pulling mechanism and corner guards are arranged at the four corners of the packing station. The installation station, the side panel installation station is set around the packaging station, and the top cover installation station is arranged on the side of the packaging station. The invention has a simple structure, adopts multiple sets of feed bins, reduces the times of feeding, saves operation time, reduces labor intensity of workers, and improves production efficiency.

Owner:无锡市航空地面设备有限公司

Clip chain assembling machine

ActiveCN111498475APrevent artifacts from being mixedReduce the frequency of loadingConveyor partsMetal chainsManufacturing engineeringIndustrial engineering

The invention discloses a clip chain assembling machine. The clip chain assembling machine comprises a rack, a base stock bin discharging mechanism and an intermediate stock bin discharging mechanismare installed on one side of the upper end of the rack, the base stock bin discharging mechanism is located on the front face of the intermediate stock bin discharging mechanism, an electric control screen is fixedly connected to one side of the upper end of the rack through a supporting rod, the electric control screen is located on the front face of the base stock bin discharging mechanism, a top cover stock bin discharging mechanism is installed on the other side of the upper end of the rack, and a middle base plate grabbing mechanism is installed in the middle of the upper end of the rack.The clip chain assembling machine achieves the beneficial effects that an intermediate material box, a base material box, a top cover material box and a middle base plate material box are customizedaccording to the boundary dimension of workpieces, the workpieces can be prevented from being mixed for use, multiple sets of material bins are adopted, the feeding frequency is reduced, the operationtime is saved, due to the fact that automatic feeding and discharging are achieved in the working process, the labor intensity of workers is relieved, the production efficiency is improved, and all parameters in an assembly machine can be monitored in real time and data backup can be conducted.

Owner:无锡安鑫卓越智能科技有限公司

Garment decoration modeling processing method for intelligent garment processing

ActiveCN110916280AHigh degree of automationImprove work efficiencyClothes making applicancesProcess engineeringWaste material

The invention discloses a garment decoration modeling processing method for intelligent garment processing. The processing method comprises the following steps that a, a garment to be subjected to rhinestone feeding is placed on one of the rhinestone feeding stations and fixed to the rhinestone feeding station, and then the crystal diamond sticker is installed on the rhinestone feeding station through the clamping device and overlaps the garment to be subjected to rhinestone feeding; b, the sliding rail is started to drive the rhinestone feeding station to move to the position below a heatingdevice, the heating device heats the crystal rhinestone sticker on the rhinestone feeding station, and the crystal rhinestone sticker on the crystal rhinestone sticker is attached to the garment; andc, the sliding rail drives the rhinestone feeding station to move to the side position of the feeding and discharging device, the clamping device turns over upwards relative to the rhinestone feedingstation, and the bottom sticker of the crystal rhinestone sticker is torn off from the garment. The whole process is high in automation degree, short in consumed time and high in working efficiency; the clamping device can directly achieve discharging of waste materials and feeding of new materials in the overturning process, and the machining efficiency is high.

Owner:河南阿尔本制衣有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com