Long and thin cutter support device

A technology for supporting devices and cutting tools, which is used in manufacturing tools, grinding workpiece supports, and other manufacturing equipment/tools, etc., can solve the problems of low tool processing yield, tool bar breakage, and tool bar deformation under compression. , to achieve the effect of improving tool processing quality and yield, reducing the number of feeding times, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

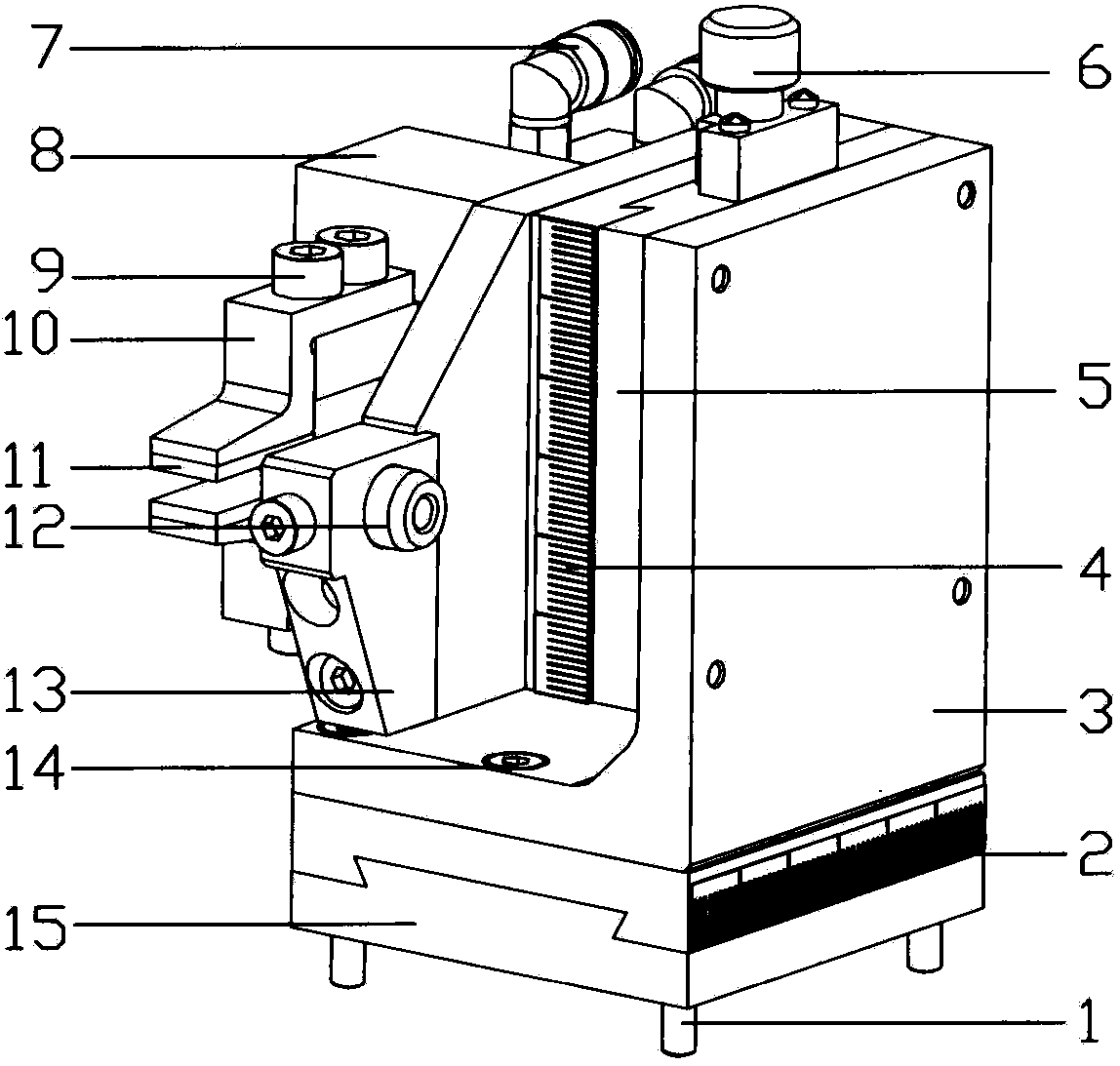

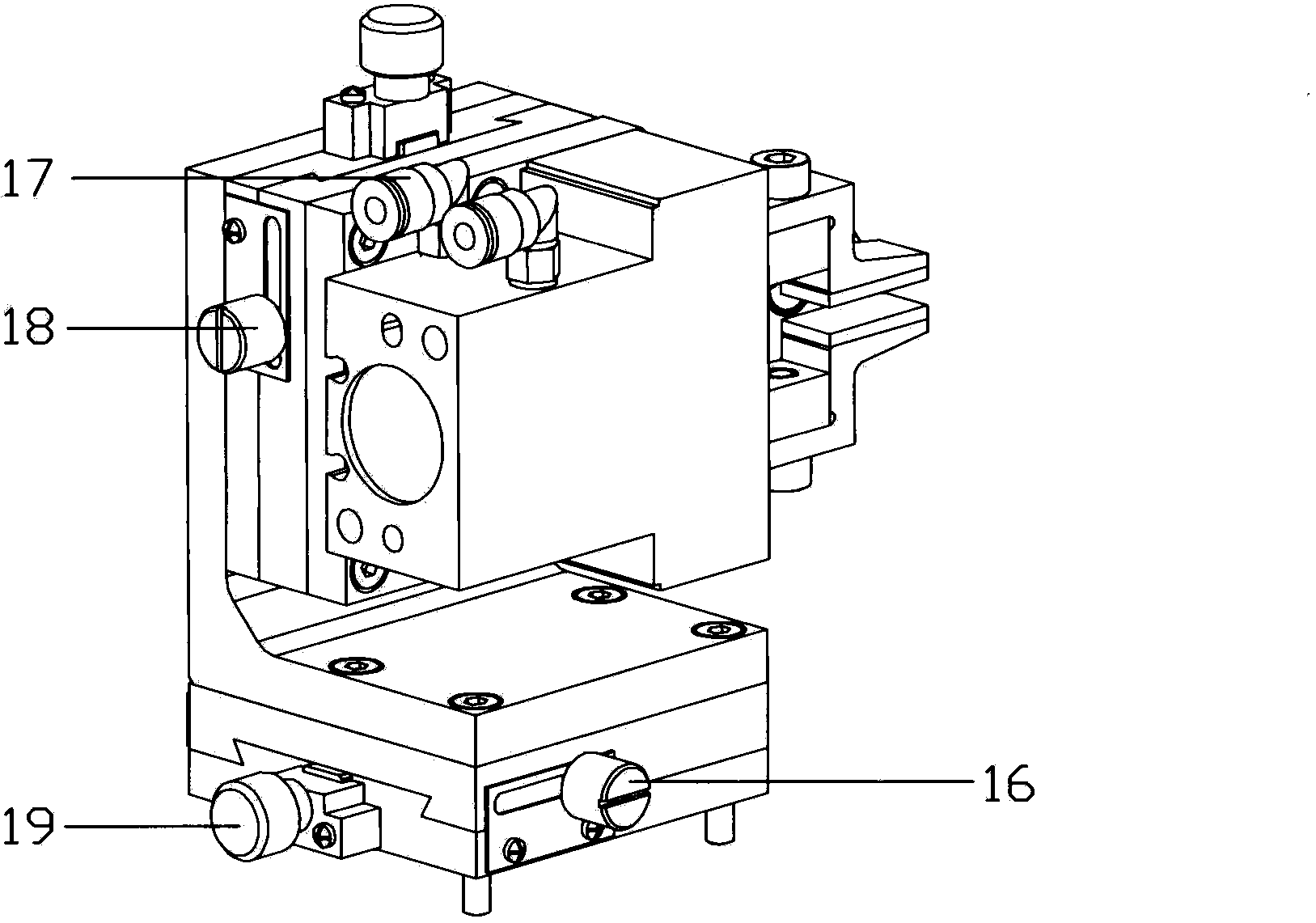

[0009] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a manual Y-axis fixing screw 1, a manual Y-axis scale 2, a manual Z-axis mount 3, a manual Z-axis scale 4, a manual Z-axis 5, a manual Z-axis adjustment knob 6, The first cylinder air pipe joint 7, cylinder 8, parallel two-finger clamp fixing screw 9, parallel two-finger clamp 10, rubber pad 11, bushing 12, bushing mounting seat 13, manual Z-axis mounting seat fixing screw 14, manual Y-axis 15, manual Y-axis set screw 16, second cylinder air pipe joint 17, manual Z-axis set screw 18 and manual Y-axis adjustment knob 19, manual Y-axis set screws are arranged below the four corners of manual Y-axis 15 1. A manual Y-axis scale 2 is provided on the side of the manual Y-axis 15, and a manual Y-axis set screw 16 is provided on the opposite side of the manual Y-axis scale 2. On the side adjacent to the manual Y-axis set screw 16 A manual Y-axis adjustment knob 19 is provided, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com