Open water area sludge treatment pyrolysis reactor and sludge treatment method

A pyrolysis reactor and sludge treatment technology, which is applied in the field of resources and environment, can solve the problems of increased difficulty in sludge oil production, and achieve the effects of reduced energy consumption, strong adsorption, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Sludge source: sludge from the bottom of Suzhou Changyang Lake

[0066] (2) Determination of sludge pyrolysis reaction temperature and reaction time

[0067] ①The pyrolysis reaction temperature is determined by thermogravimetric analysis. The specific operation method and results are as follows:

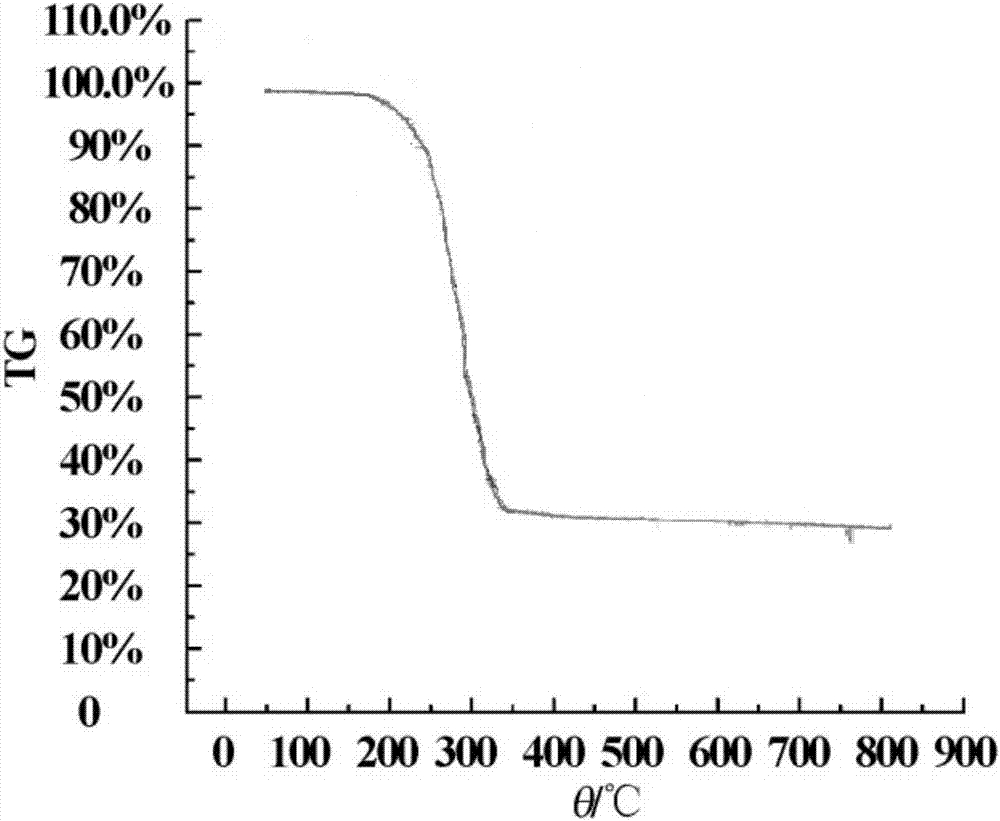

[0068] After the sludge was naturally dried for 7 days, it was placed in a constant temperature box, dried at 100 °C for 3 h, passed through a 150-mesh sieve after grinding, and analyzed by thermogravimetric analysis (temperature range: 50 °C~800 °C, pressure: normal pressure , heating rate: 5°C / min, carrier gas: nitrogen, purity >99.9%, flow rate: 60 mL / min) to analyze the dried sludge samples, the specific results are attached image 3 shown.

[0069] It can be concluded from the figure that the sludge quality changes significantly in the range of reaction temperature from 150°C to 320°C, but when the reaction temperature is higher than 320°C, the sludge quality does n...

Embodiment 2

[0099] (1) Sludge source: Bottom sludge of Baiyangdian Lake, Baoding City, Hebei Province

[0100] (2) Determination of sludge pyrolysis reaction temperature and reaction time

[0101] ①The pyrolysis reaction temperature is determined by thermogravimetric analysis. The specific operation method and results are as follows:

[0102] After the sludge was naturally dried for 7 days, it was placed in a constant temperature box, dried at 100 °C for 3 h, passed through a 150-mesh sieve after grinding, and analyzed by thermogravimetric analysis (temperature range: 50 °C~800 °C, pressure: normal pressure , heating rate: 5°C / min, carrier gas: nitrogen, purity >99.9%, flow rate: 60 mL / min) to analyze the dried sludge samples, the specific results are attached Figure 4 shown.

[0103] It can be concluded from the figure that the quality of sludge changes significantly in the range of reaction temperature from 150°C to 330°C, but when the reaction temperature is higher than 330°C, the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com