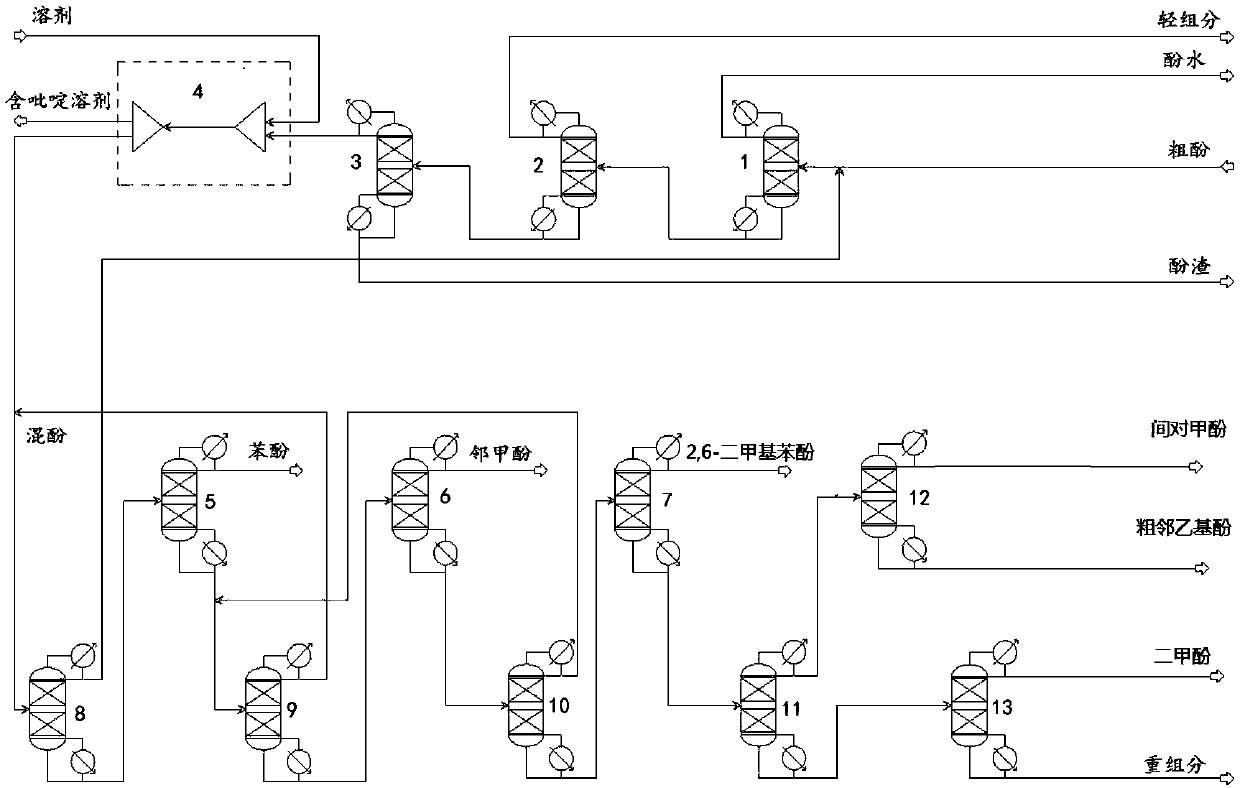

Method and device for separating various phenols from middle-low-temperature coal tar crude phenols

A technology for low-temperature coal tar and crude phenol, applied in the field of coal chemical industry, can solve problems such as inability to separate, and achieve the effect of improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The crude phenol refining method of medium and low temperature coal tar crude phenol provided in this example is as follows: the crude phenol raw material obtained from medium and low temperature coal tar includes the following components: 9.71wt% of water, 3.18wt% of pyridine compounds, 17.60wt% of phenol, ortho Cresol 12.39wt%, m-p-cresol 31.86wt%, xylenol 15.91wt%, tricresol 0.30wt%, phenol residue, high boiling point phenol and tar 9.05%. According to the medium and low temperature coal tar crude phenol refining method provided by the present invention, the above-mentioned crude phenol raw material is sent to the dehydration tower 1, the operating pressure at the top of the tower is 30KPa, the operating pressure at the bottom of the tower is 55KPa, the temperature at the top of the tower is 60°C, and the temperature at the bottom of the tower is Under the conditions of 140°C, a reflux ratio of 2, and a plate number of 65, the top of the dehydration tower 1 is separat...

Embodiment 2

[0033]The crude phenol refining method of medium and low temperature coal tar crude phenol provided in this example is as follows: the crude phenol raw material obtained from medium and low temperature coal tar includes the following components: water 12.31wt%, pyridine compounds 2.70wt%, phenol 18.30wt%, ortho Cresol 10.29wt%, m-p-cresol 34.48wt%, xylenol 12.64wt%, tricresol 0.16wt%, phenol residue, high boiling point phenol and tar 9.12%. According to the medium and low temperature coal tar crude phenol refining method provided by the present invention, the above-mentioned crude phenol raw material is sent to the dehydration tower 1, the operating pressure at the top of the tower is 40KPa, the operating pressure at the bottom of the tower is 64kPa, the temperature at the top of the tower is 71 ° C, and the temperature at the bottom of the tower is Under the conditions of 145°C, a reflux ratio of 3, and a plate number of 65, the top of the dehydration tower 1 is separated to o...

Embodiment 3

[0035] The crude phenol refining method of medium and low temperature coal tar crude phenol provided in this example is as follows: the crude phenol raw material obtained from medium and low temperature coal tar includes the following components: 9.71wt% of water, 3.18wt% of pyridine compounds, 17.60wt% of phenol, ortho Cresol 12.39wt%, m-p-cresol 31.86wt%, xylenol 15.91wt%, tricresol 0.30wt%, phenol residue, high boiling point phenol and tar 9.05%. According to the medium and low temperature coal tar crude phenol refining method provided by the present invention, the above-mentioned crude phenol raw material is sent to the dehydration tower 1, the operating pressure at the top of the tower is 30KPa, the operating pressure at the bottom of the tower is 55KPa, the temperature at the top of the tower is 60°C, and the temperature at the bottom of the tower is Under the conditions of 140°C, a reflux ratio of 2, and a plate number of 65, the top of the dehydration tower 1 is separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com