Butyl acetate high-conversion-rate preparation method and preparation system

A butyl acetate, high conversion technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the difficulty of preparing high-purity butyl acetate, the complex composition of the product refining system, and the separation process. The problems such as complicated process, to achieve the effect of simplifying the separation process settings, reducing the energy consumption of preparation, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

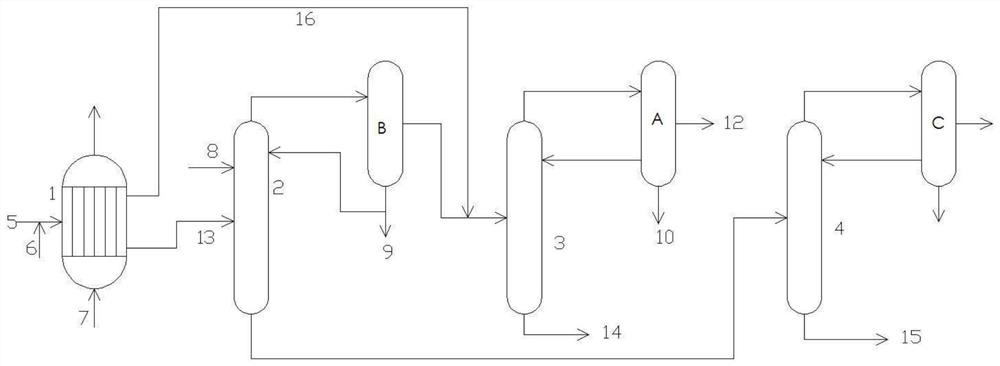

[0014] The preparation system for realizing the high conversion rate preparation method of butyl acetate disclosed in this patent application, the basic composition of the system includes a tube reactor 1, and a solid catalyst is filled in the tube reactor 1, and the solid catalyst can be a cationic resin catalyst , heteropolyacid catalyst or molecular sieve catalyst, preferably sulfonic acid series macroporous cation exchange resin catalyst.

[0015] Acetic acid and butanol are mixed by pipelines 5 and 6 at a molar ratio of 1 to 2:1 respectively, and then enter tube reactor 1. Heat transfer oil pipeline 7 controls the temperature and reaction conditions of tube reactor 1 in the range of 90-110°C. At normal pressure and space velocity 1.0~10h -1 reaction. The tube reactor 1 is provided with uniform heat supply reaction conditions by the heat conduction oil. In addition to butyl acetate, the reaction product also includes water and a small amount of butanol. At a lower tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com