Method for producing glutaric acid by double-cell adhesion coupling method

A technology of glutaric acid and cells, which is applied in the field of double-cell adhesion coupling method to produce glutaric acid, which can solve the problems of poor catalytic effect and low mass transfer efficiency, so as to improve permeability, improve catalytic efficiency and reduce use cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Construction and cultivation process of embodiment 1 bacterial strain [1]

[0038] 1.1 Construction of strains

[0039] The preparation process of E.coli BL21 (DE3) competent refers to the operation of the E. coli competent preparation kit of Baori Medical Biotechnology Company;

[0040] Recombinant plasmids pET22b-DavAB and pACYC-GabTD were provided by our laboratory, and the plasmids were extracted using the plasmid mini-extraction kit from TIANGEN Company;

[0041] The recombinant plasmid pET22b-DavAB was introduced into the competence of E.coli BL21(DE3), and the recombinant strain E.coli BL-22AB overexpressing DavAB was obtained;

[0042] The recombinant plasmid pACYC-GabDT was introduced into the competence of E.coli BL21(DE3), and the recombinant strain E.coli BL-YDT overexpressing GabDT was obtained.

[0043] 1.2 Medium

[0044] LB medium: tryptone 10g / L, yeast extract 5g / L, sodium chloride 5g / L, solvent is water, pH 7.0.

Embodiment 2

[0054] Example 2 Preparation process of double-cell adhesion coupling

[0055] 2.1 Permeability modification of recombinant strain E.coli BL-22AB

[0056] Resuspend the recombinant bacterial strain E.coli BL-22AB bacterium sludge obtained in Example 1 with PBS buffer at pH 7.0 to obtain OD 600 =5 concentration of the recombinant bacterial strain E.coli BL-22AB cell solution, add 0.5% (volume concentration) TritonX-100 surfactant in the solution, stir 3 hours under the condition of 200r / min, 37 ℃, promptly obtain pass Cell solution of recombinant strain E.coli BL-22AB with increased permeability.

[0057] 2.2 Preparation of adhesive coating on the surface of recombinant strain E.coli BL-22AB after permeability modification

[0058] Take 10mL of the recombinant bacterial strain E.coli BL-22AB cell solution with increased permeability obtained in 2.1, mix it with 10mL of 2g / L dopamine solution in pH 7.5 Tris-HCl buffer, and mix it under the conditions of 200r / min and 18℃ After...

Embodiment 3

[0063] Embodiment 3 analytical method

[0064] 3.1 Catalytic method

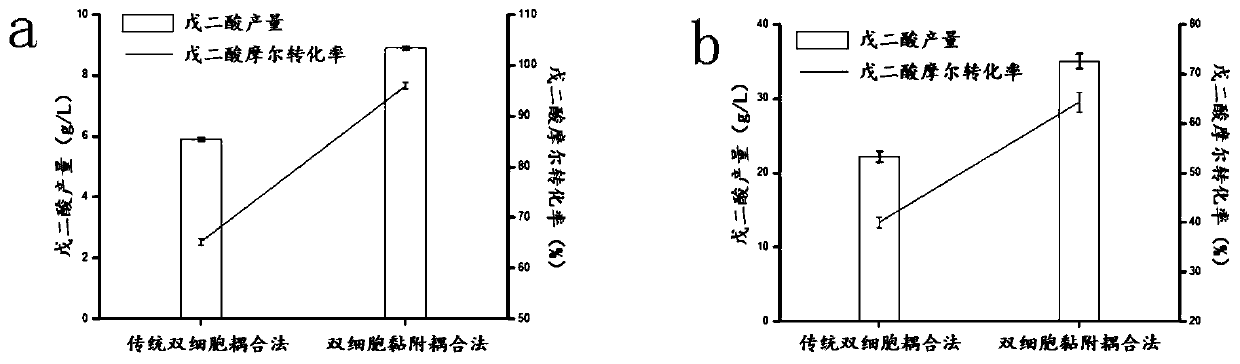

[0065] (1) Traditional two-cell coupling method: resuspend the microbial cells collected in Example 1 with PBS at pH 7.0 to the cell solution concentration OD of E.coli BL-22AB and E.coli BL-YDT in the system 600 =5, and add the prepared L-lysine mother liquor and α-ketoglutaric acid mother liquor with pH 7.0, so that the final concentrations of L-lysine and α-ketoglutaric acid in the system are both 10g / L , catalyzed at 37°C for 30 hours. After the reaction, the microbial cell pellet was removed by centrifugation, and the supernatant was taken for liquid phase detection.

[0066] (2) Two-cell adhesion coupling method: Resuspend the coupling adhesion sludge C collected in Example 2 with PBS of pH 7.0 to the cell solution concentration OD of E.coli BL-22AB and E.coli BL-YDT in the system 600 =5, and add the prepared L-lysine mother liquor and α-ketoglutaric acid mother liquor with pH 7.0, so that the final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com