Treatment process of high-concentration arsenic-containing waste acid

A treatment process and high-concentration technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the vulcanization process control method cannot fully meet the changing conditions and hazardous chemical conditions To solve problems such as shrinking production capacity and increased concentration of heavy metals, and achieve the effects of improving copper and arsenic removal efficiency, broadening processing capacity, and high sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

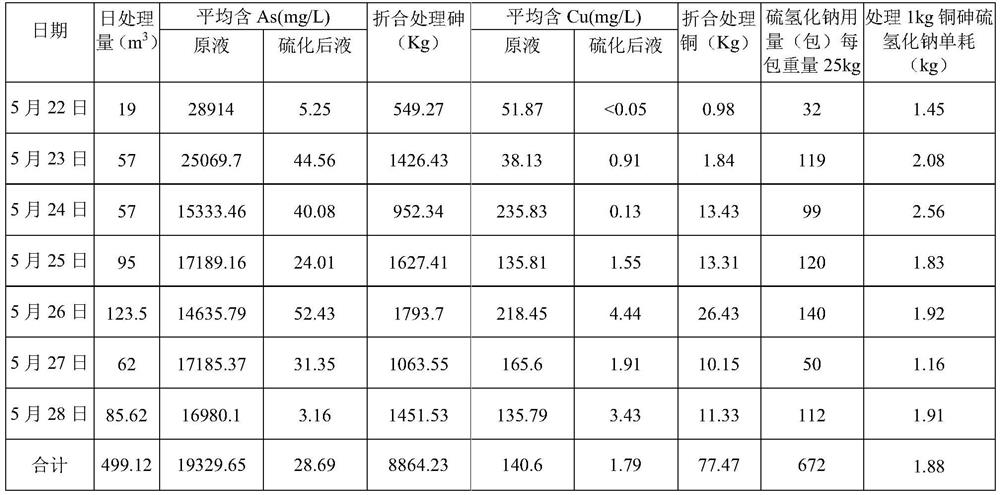

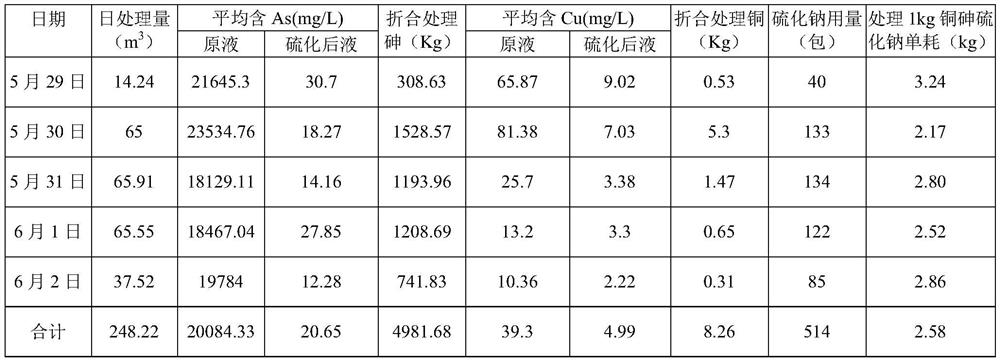

Examples

Embodiment 1

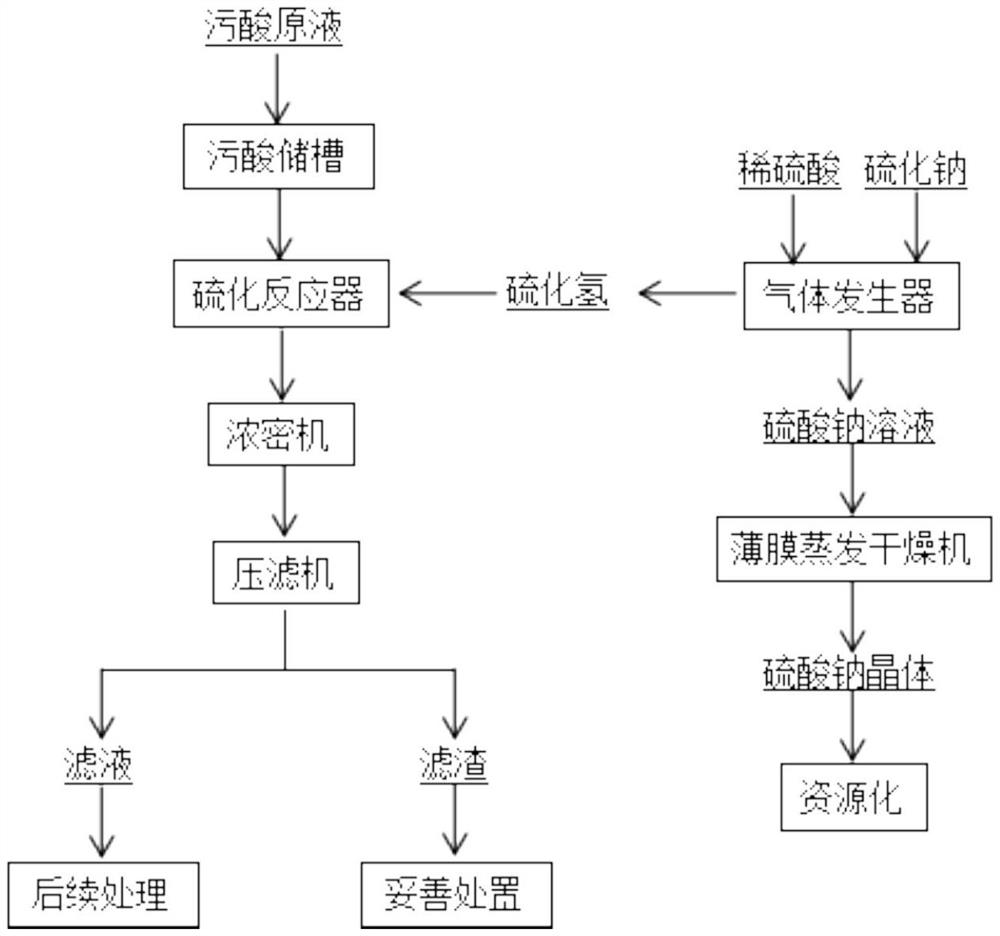

[0037] A treatment process for high-concentration arsenic-containing polluted acid, comprising the following steps:

[0038] Step S10, introducing the high-concentration dirty acid stock solution into the dirty acid storage tank after being filtered through a filter, stirring and mixing, and standing for 3 hours;

[0039] Step S20, sodium bisulfide is added to the hydrogen sulfide gas generator, and a dilute sulfuric acid solution with a concentration of 50% is added, and the sulfuric acid and sodium bisulfide react with gas to produce hydrogen sulfide gas and sodium sulfate; the preparation of dilute sulfuric acid includes: using The control mode of flowmeter and adding valve is interlocked. Add 98% concentrated sulfuric acid and fresh water to the sulfuric acid dilution tank to make a 50% dilute sulfuric acid solution. The heat generated by sulfuric acid dilution is taken away by the circulating water through the jacket of the dilution tank. The end point of the reaction is ...

Embodiment 2

[0043] A treatment process for high-concentration arsenic-containing polluted acid, comprising the following steps:

[0044] Step S10, introducing the high-concentration dirty acid stock solution into the dirty acid storage tank after being filtered through a filter, adding polyferric sulfate, stirring and mixing, and standing for 4 hours;

[0045] Step S20, adding sodium bisulfide to the hydrogen sulfide gas generator, adding a dilute sulfuric acid solution with a concentration of 50%, sulfuric acid reacts with sodium bisulfide to produce hydrogen sulfide gas and sodium sulfate; the preparation of the dilute sulfuric acid includes: Using the control method of flow meter and adding valve interlocking, add 98% concentrated sulfuric acid and fresh water into the sulfuric acid dilution tank to make a 50% dilute sulfuric acid solution. The heat generated by sulfuric acid dilution is taken away by the circulating water through the jacket of the dilution tank , the end point of the ...

Embodiment 3

[0049] A treatment process for high-concentration arsenic-containing polluted acid, comprising the following steps:

[0050] Step S10, introducing the high-concentration dirty acid stock solution into the dirty acid storage tank after being filtered through a filter, stirring and mixing, and standing for 2 hours;

[0051] Step S20, adding sodium bisulfide to the hydrogen sulfide gas generator, adding a dilute sulfuric acid solution with a concentration of 50%, sulfuric acid reacts with sodium bisulfide to produce hydrogen sulfide gas and sodium sulfate; the preparation of the dilute sulfuric acid includes: Using the control method of flow meter and adding valve interlocking, add 98% concentrated sulfuric acid and fresh water into the sulfuric acid dilution tank to make a 50% dilute sulfuric acid solution. The heat generated by sulfuric acid dilution is taken away by the circulating water through the jacket of the dilution tank , the end point of the reaction is judged by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com