Patents

Literature

63results about How to "Stable and easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

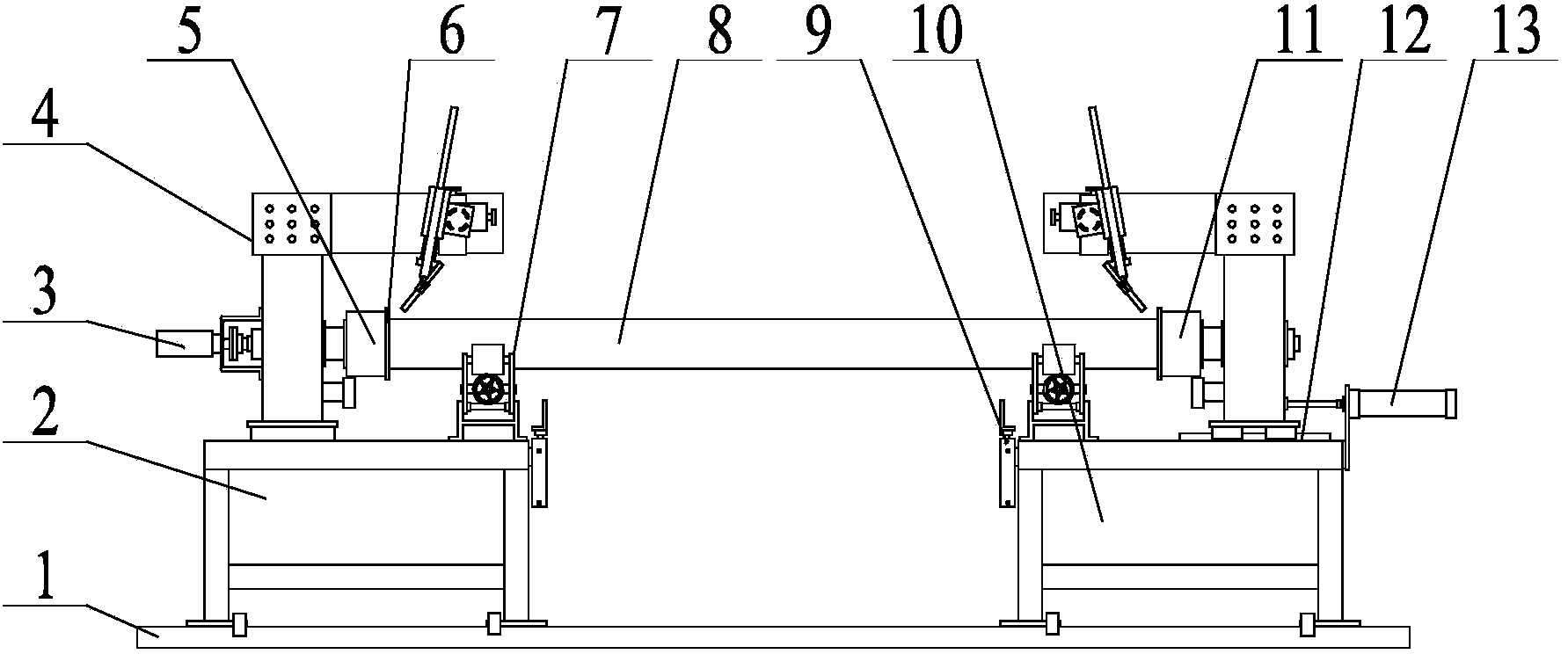

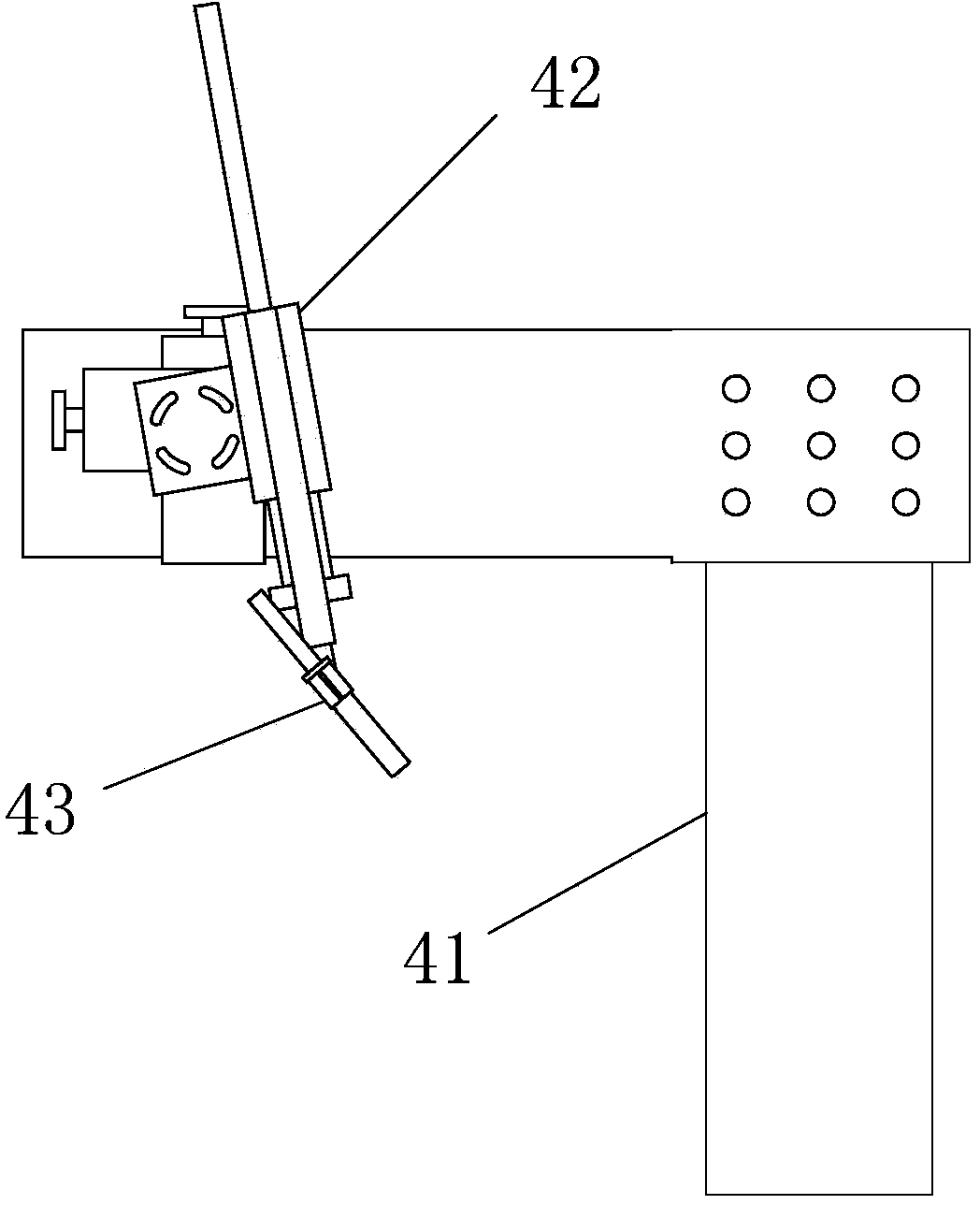

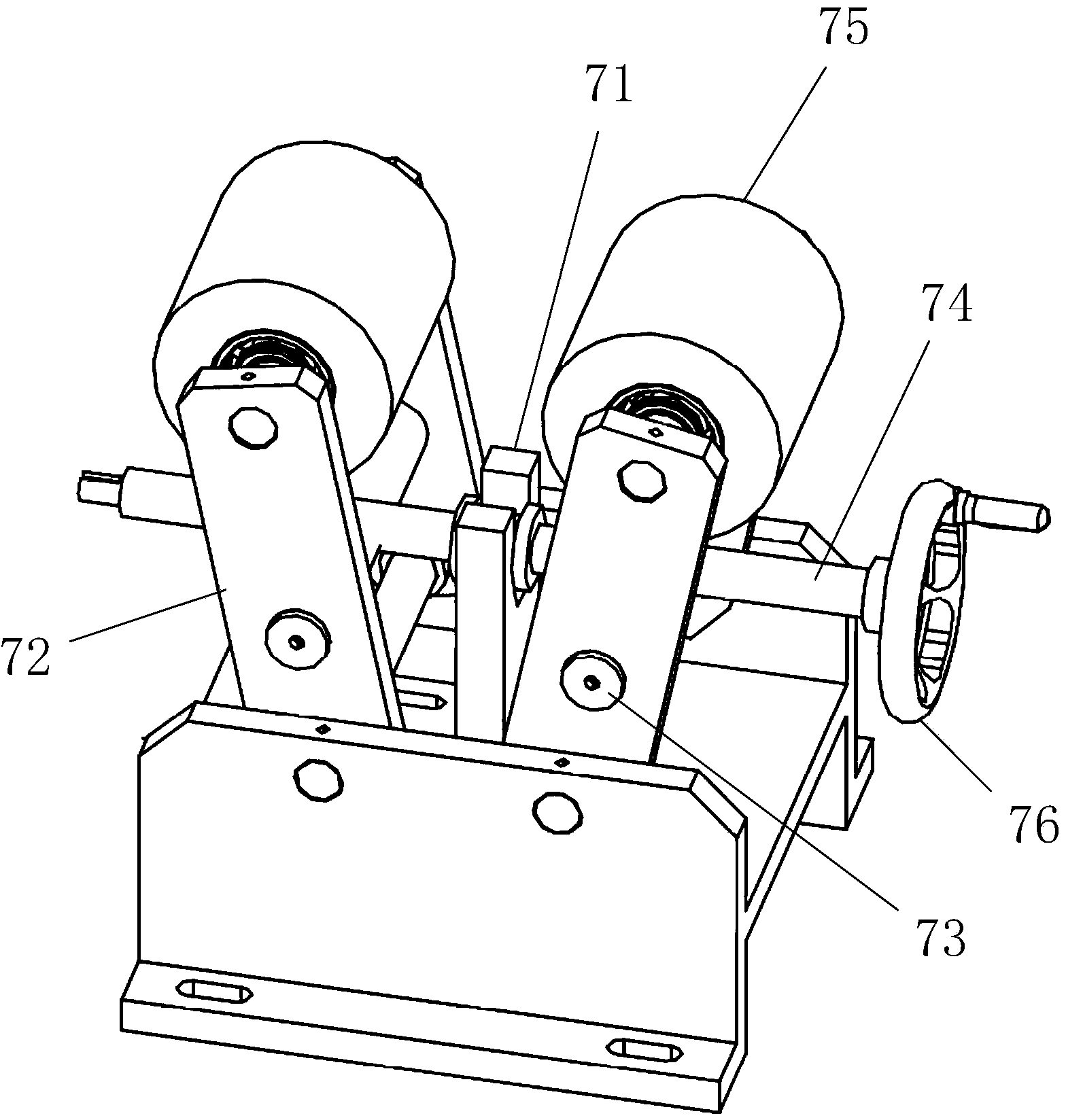

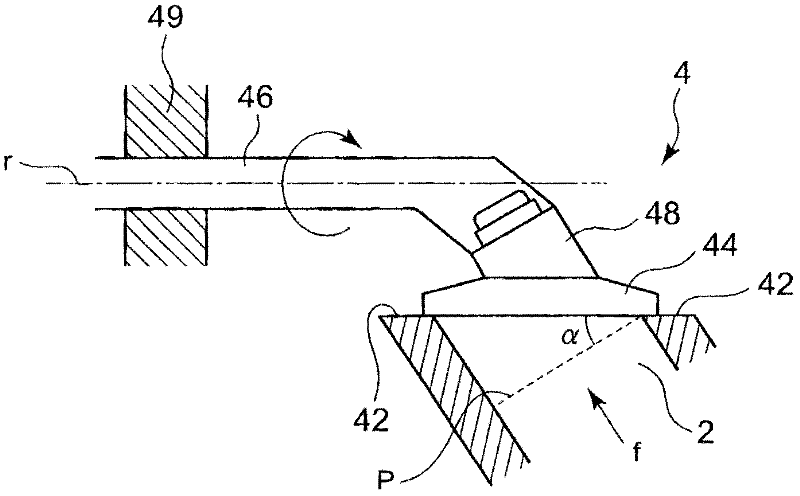

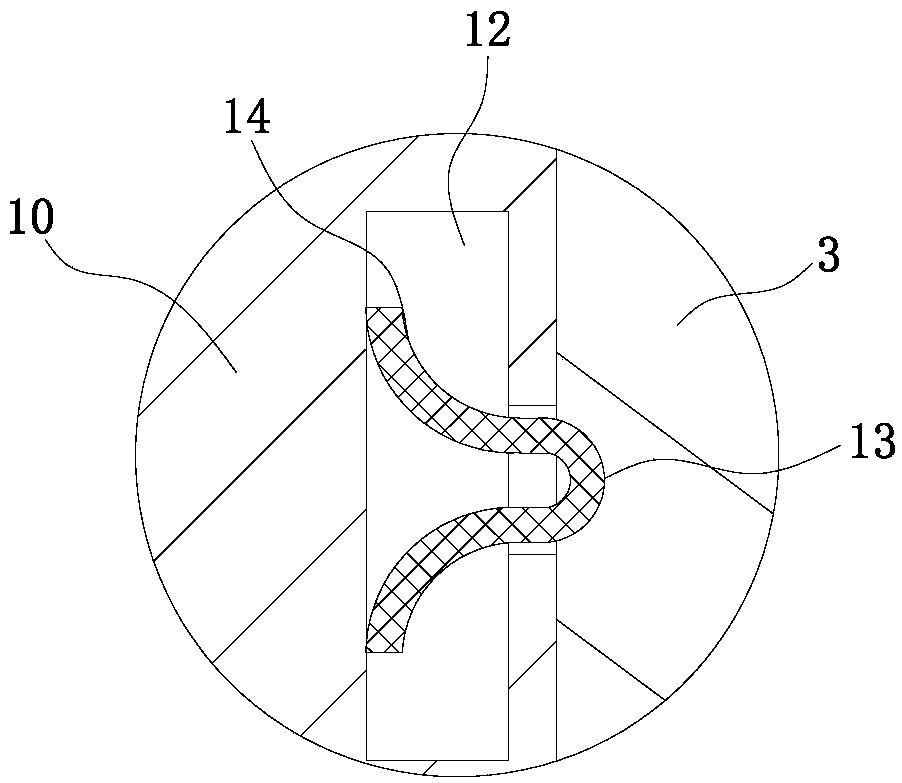

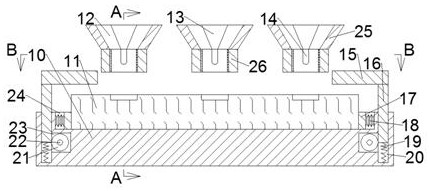

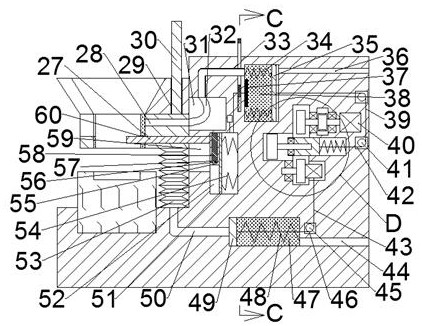

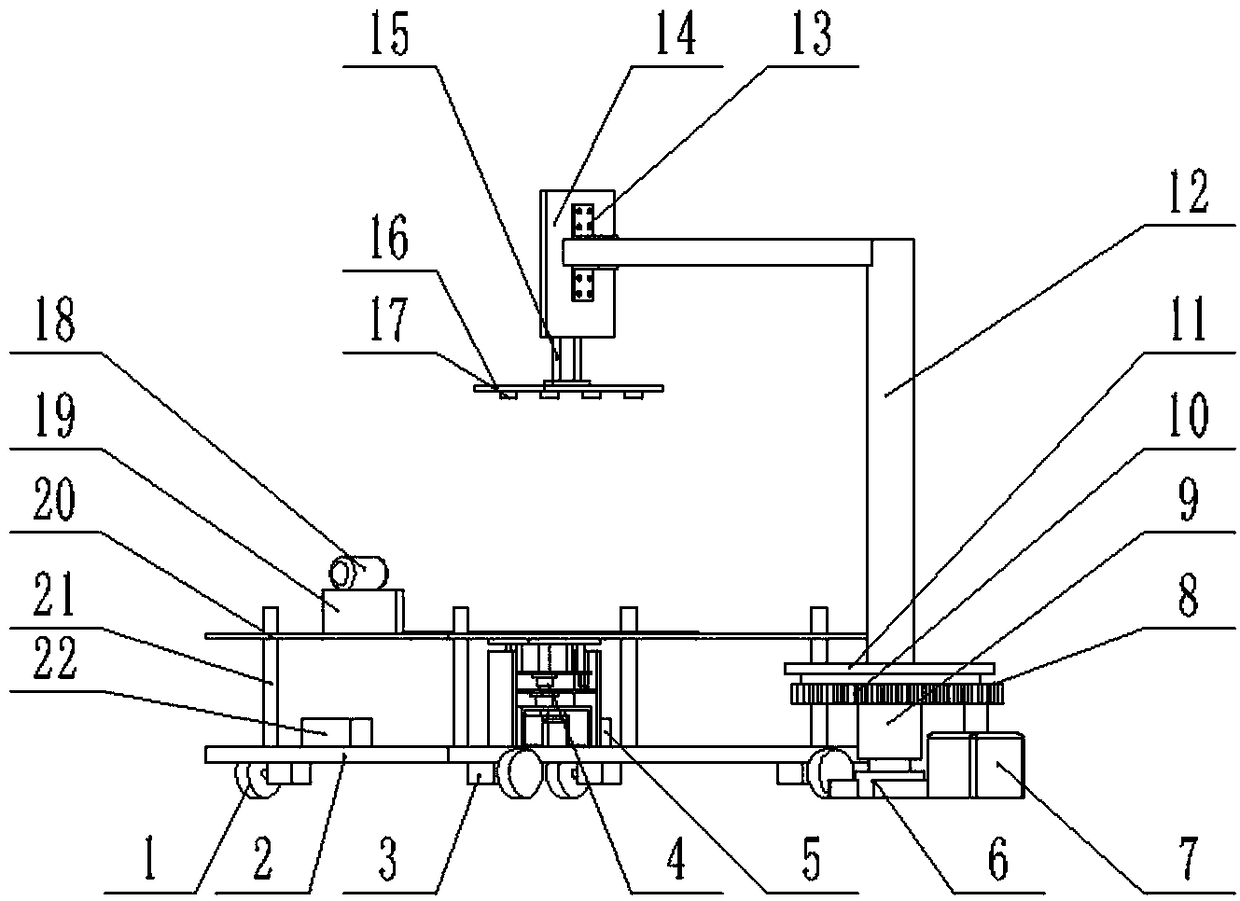

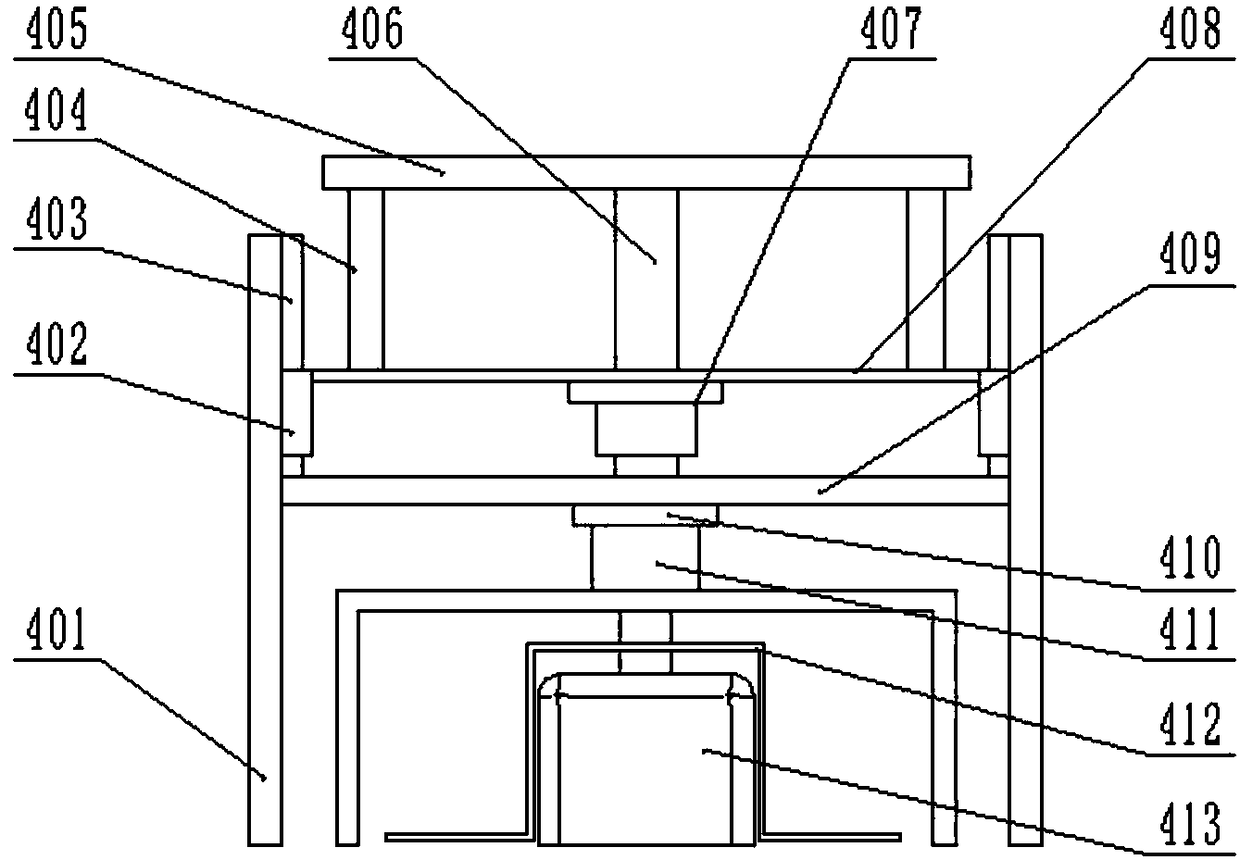

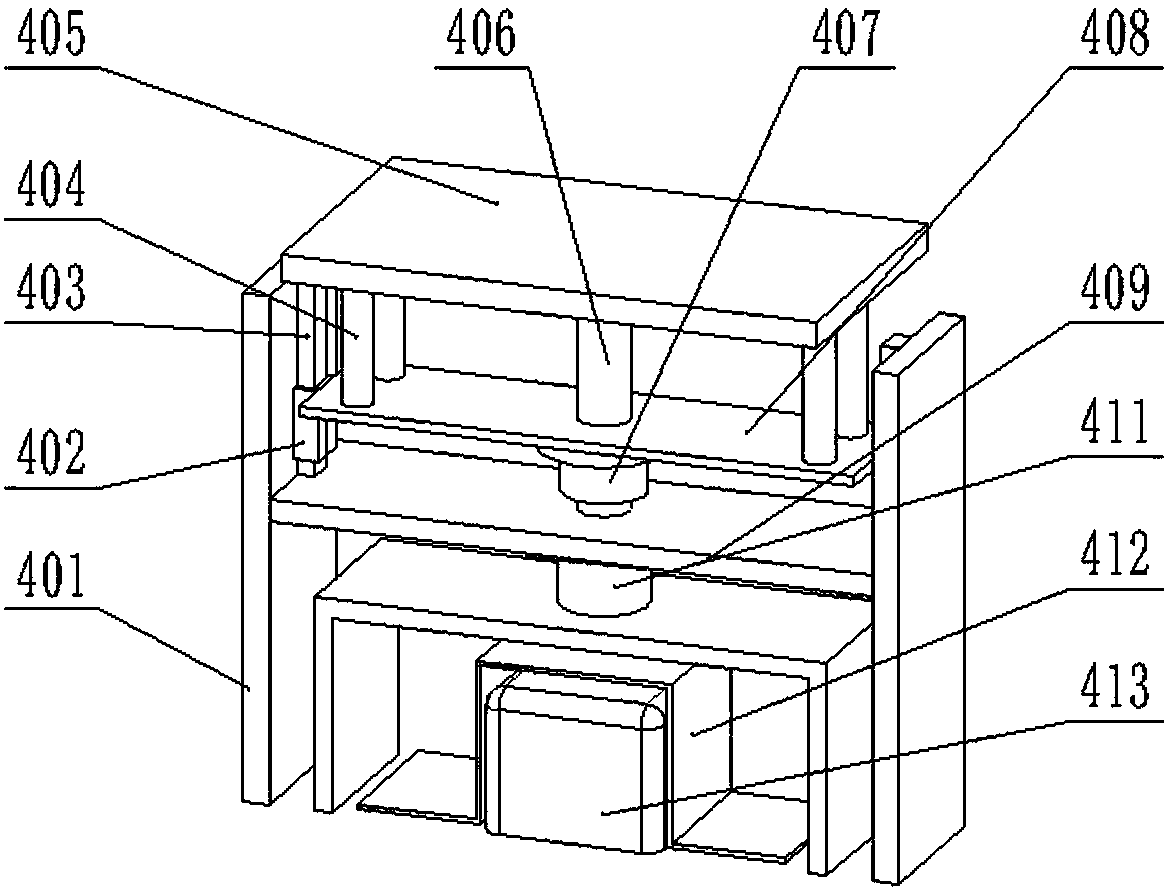

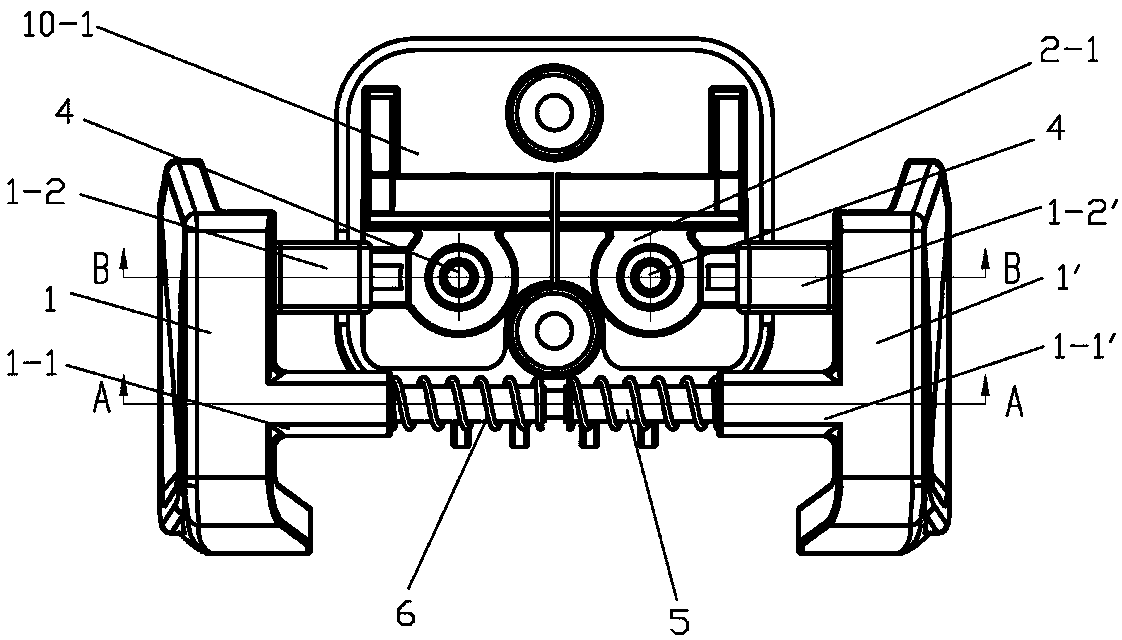

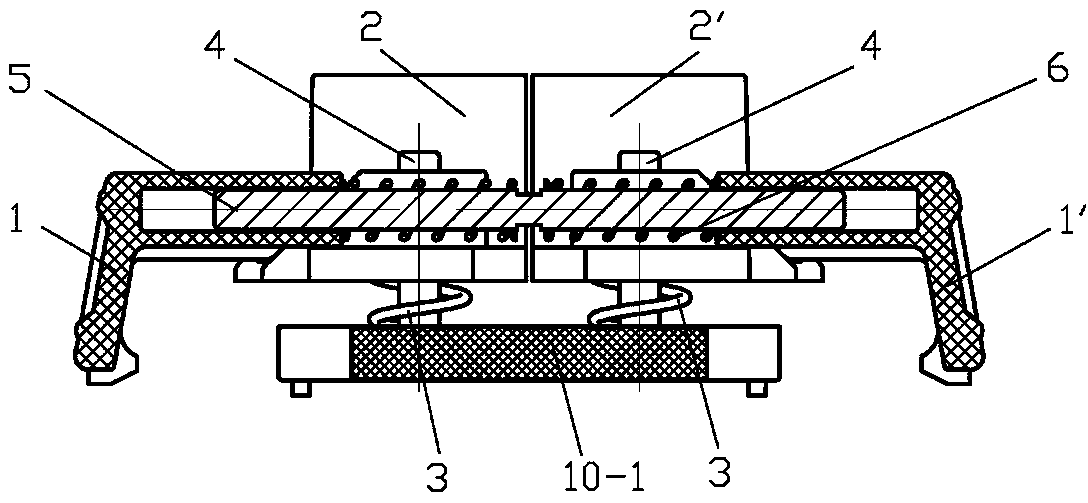

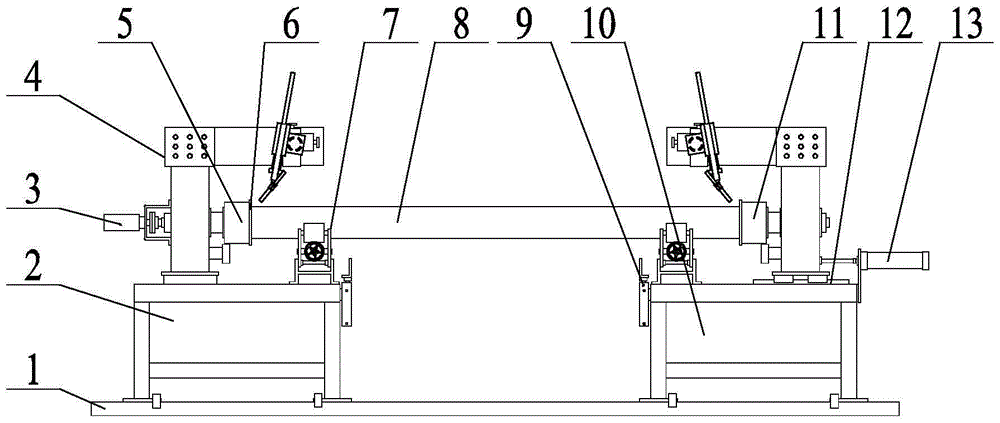

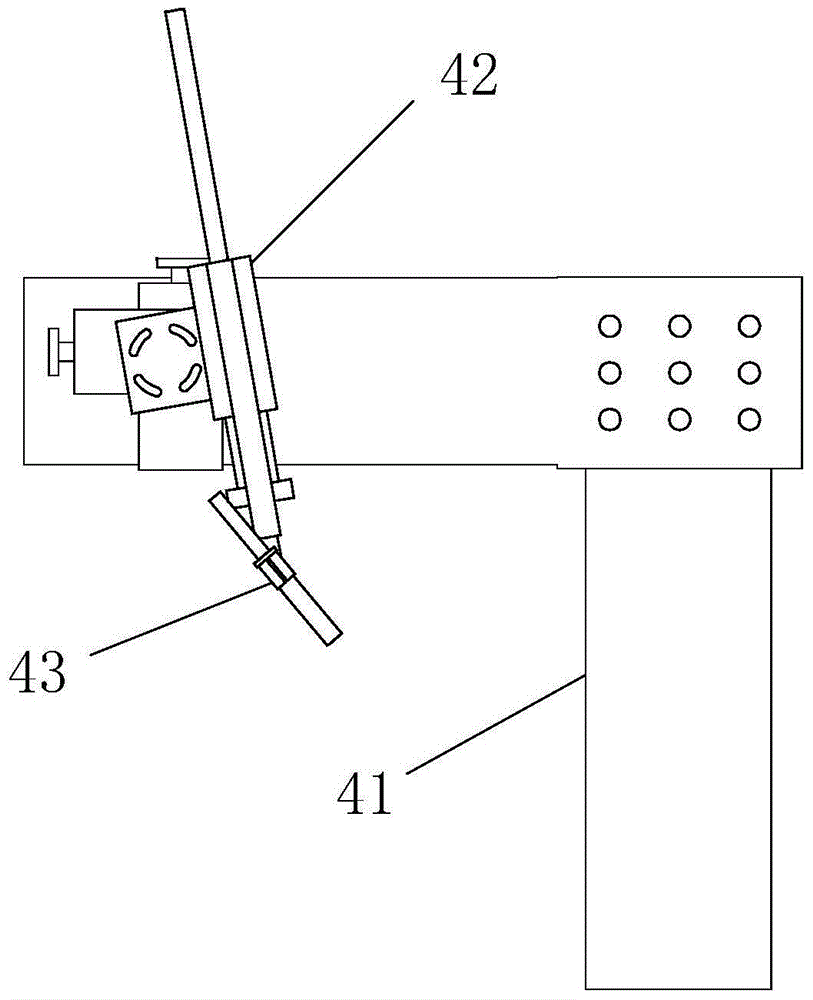

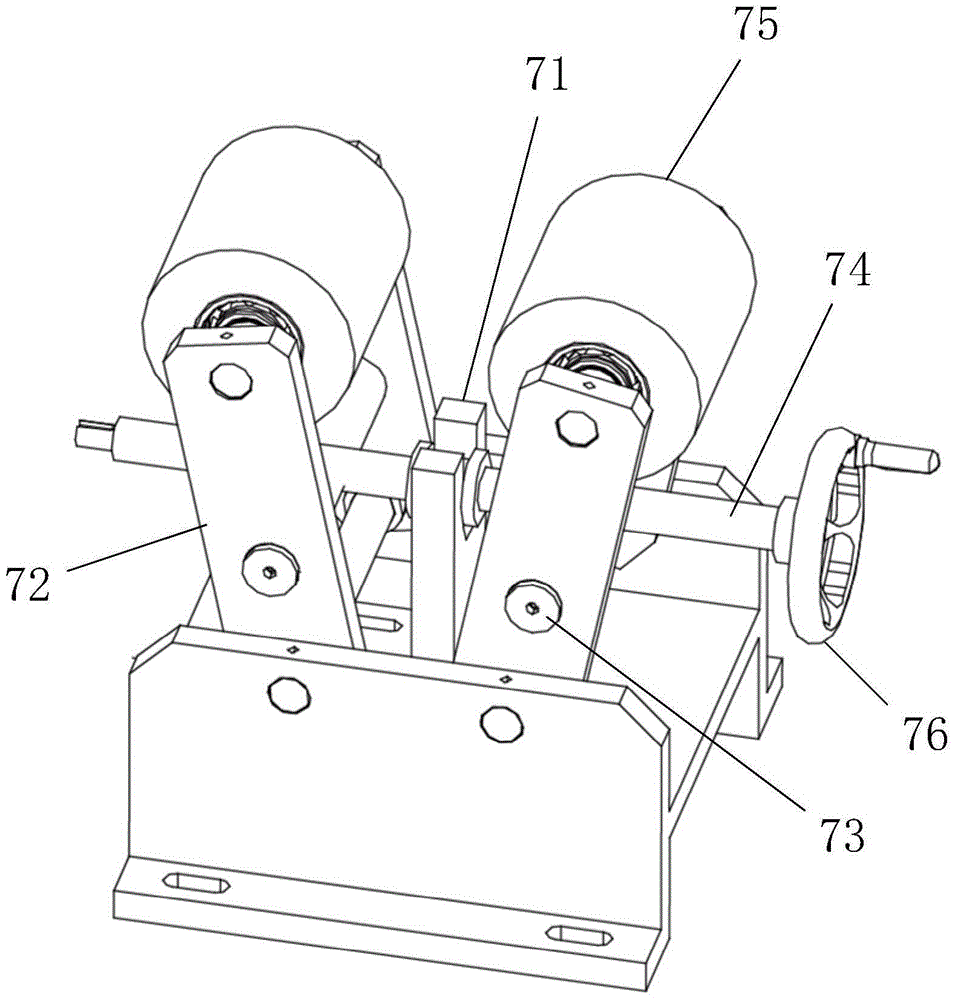

Steel pipe flange welding and positioning device

ActiveCN104014954ARealize dockingStable and easy to controlWelding/cutting auxillary devicesPipeline systemsSteel tubeFlange

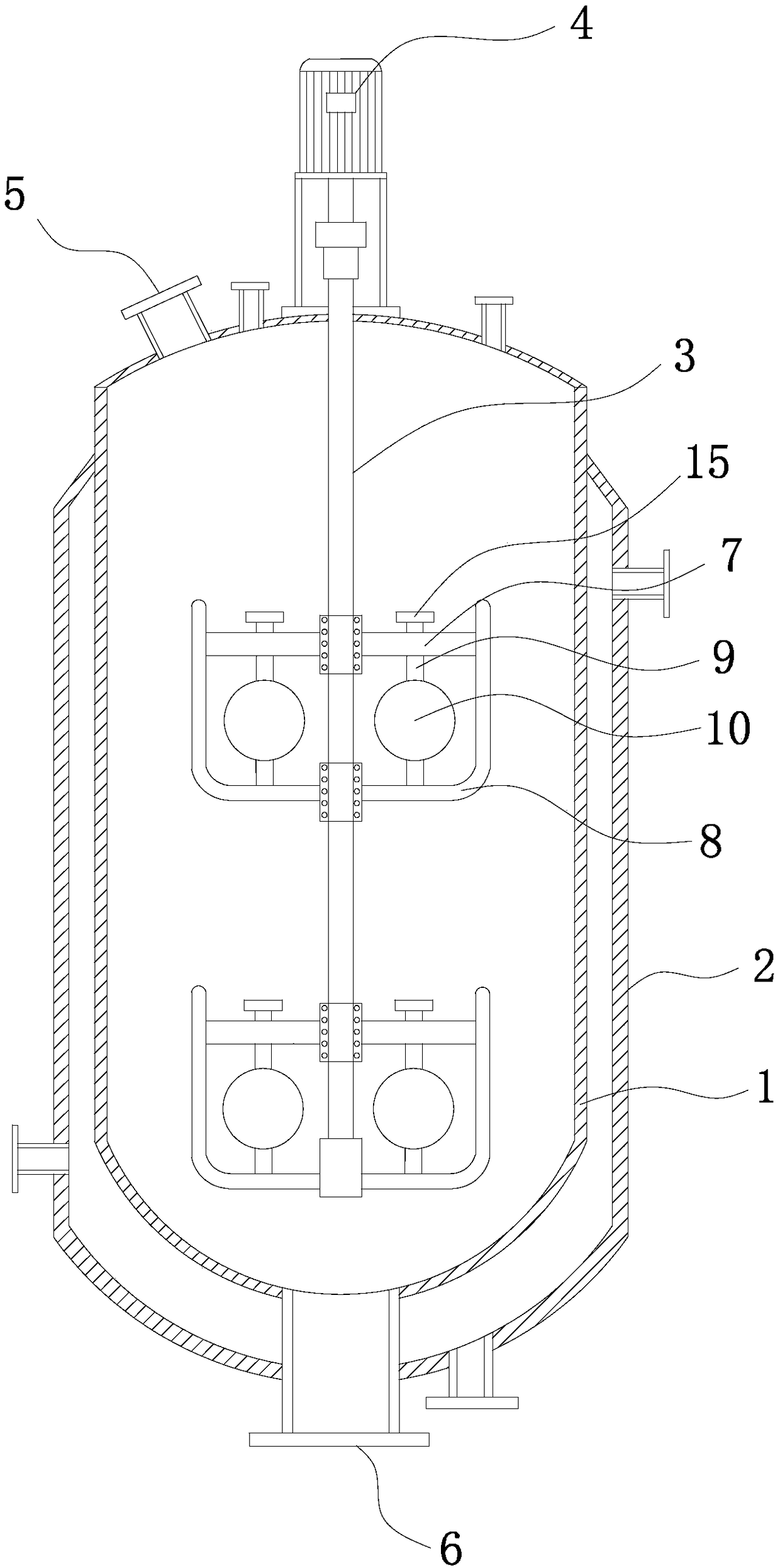

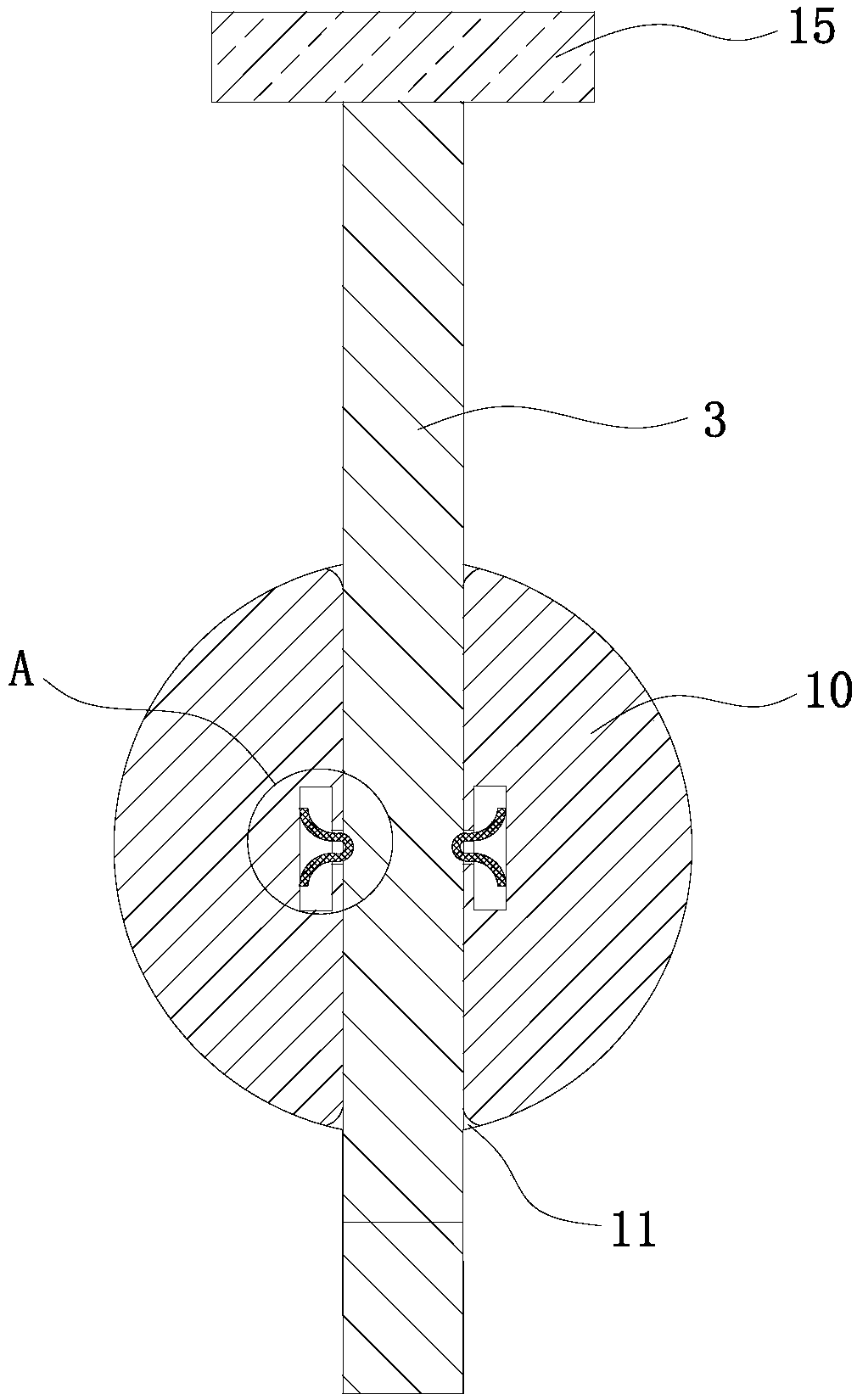

The invention relates to the technical field of welding, and provides a steel pipe flange welding and positioning device. The steel pipe flange welding and positioning device comprises a first sliding rail, a first platform and a second platform, wherein the first platform and the second platform are arranged on the first sliding rail in a sliding mode. Limiting devices are arranged between the first platform and the first sliding rail and between the second platform and the first sliding rail. A first fixing jaw and a second fixing jaw which are used for positioning flanges are connected to the first platform and the second platform in a relatively rotating mode, and at least one of the first fixing jaw and the second fixing jaw is driven by a power device to rotate. Roller carriers used for holding steel pipes are arranged at the positions, between the first fixing jaw and the second fixing jaw, of the first platform and the second platform, and the height of the roller carriers is adjustable. The device is ingenious in structural design, is particularly suitable for positioning of steel pipes of various diameters and flanges of various diameters, and can achieve stable welding and guarantee the welding quantity; the steel pipes and the flanges can be positioned conveniently. In addition, the device is simple in structure, low in cost and easy to popularize.

Owner:HEBEI FLEXTRONICS ELECTRICAL TECH

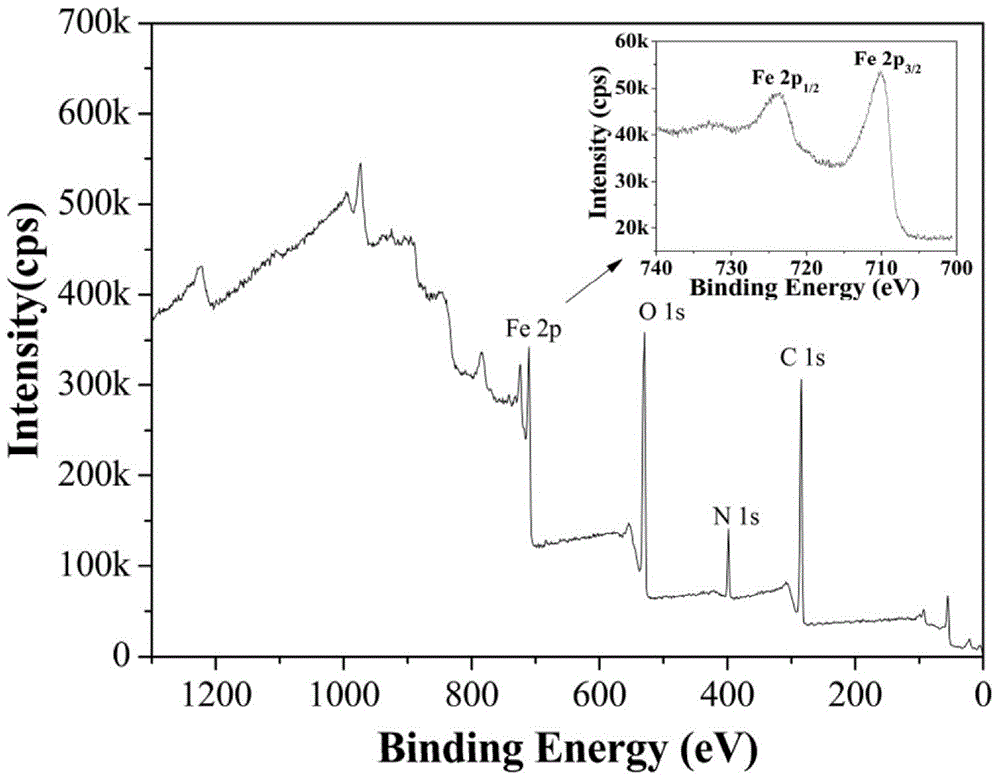

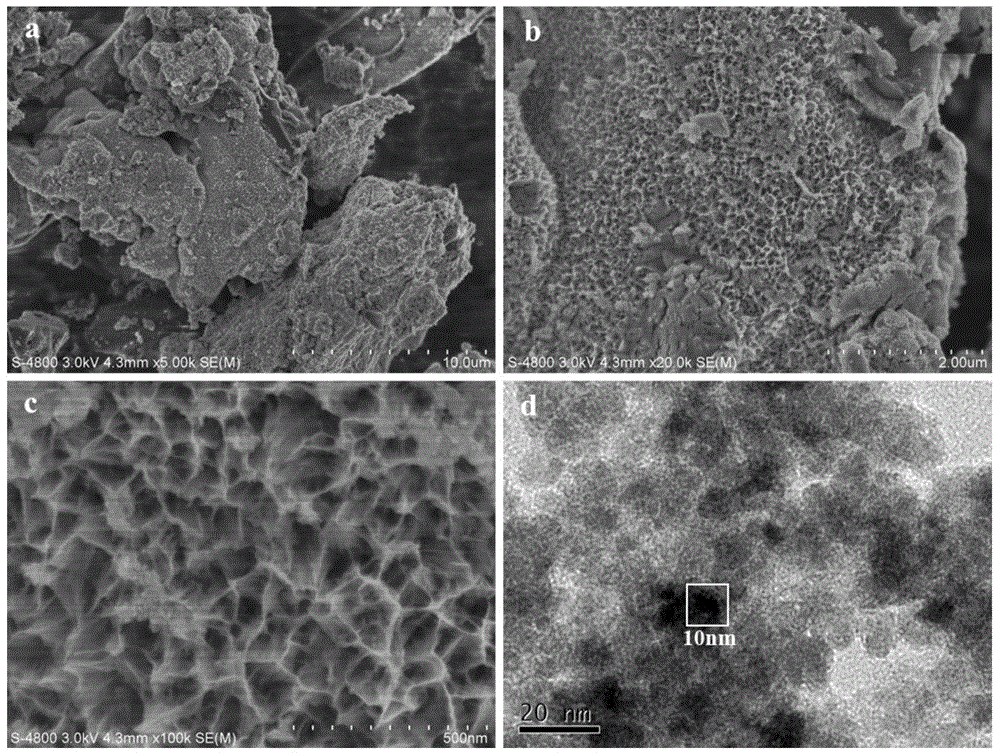

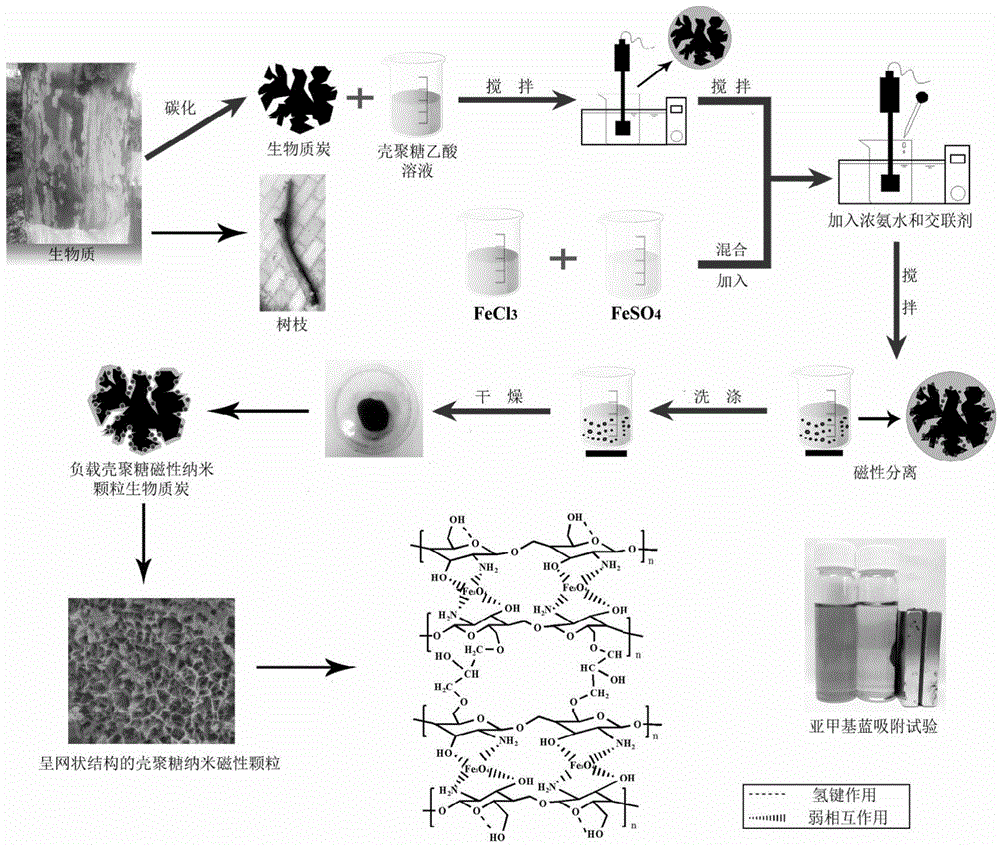

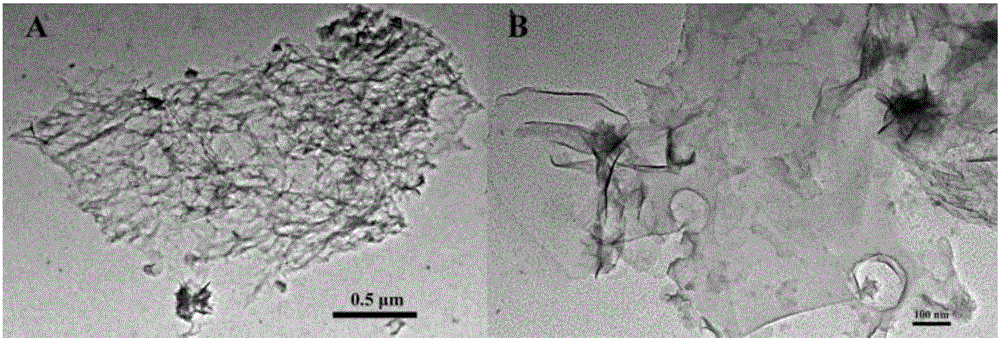

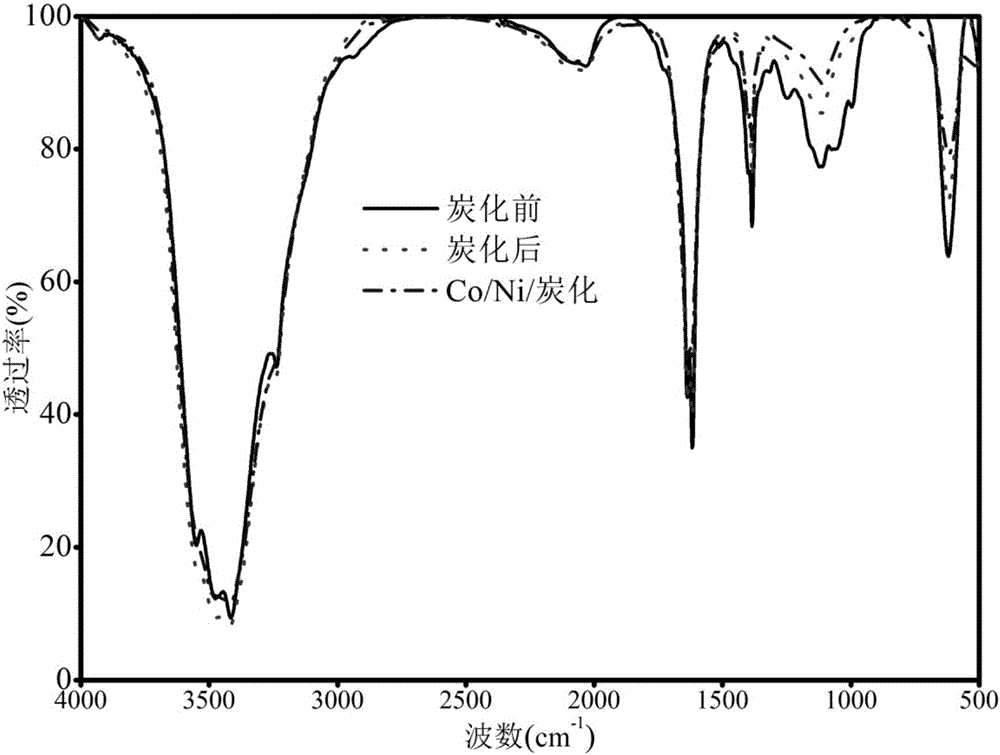

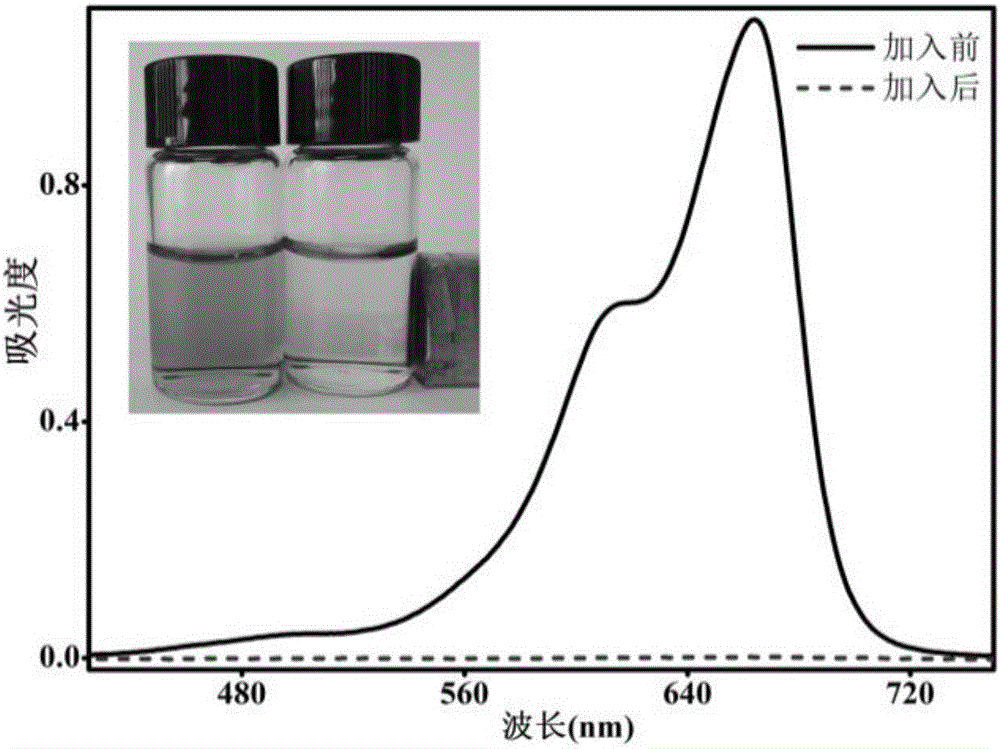

Preparation method for biomass charcoal adsorbent loaded with chitosan magnetic nanoparticles

InactiveCN104801280AImprove adsorption capacityEfficient removalOther chemical processesWater/sewage treatment by sorptionSorbentMagnetite Nanoparticles

The invention provides a preparation method for a biomass charcoal adsorbent loaded with chitosan magnetic nanoparticles. The preparation method comprises the following steps: preparing biomass charcoal, preparing a chitosan-acetic acid solution, preparing an iron solution and preparing biomass charcoal loaded with the chitosan magnetic nanoparticles. The invention further provides the biomass charcoal adsorbent loaded with the chitosan magnetic nanoparticles. According to the adsorbent, the biomass charcoal is used as a base material and the surface of the adsorbent is loaded with the chitosan magnetic nanoparticles. The adsorbent prepared through the preparation method can adsorb heavy metal, dye and partial anions, and has the advantages of high adsorption capacity, strong magnetism, stable property and high mechanical performance.

Owner:HOHAI UNIV

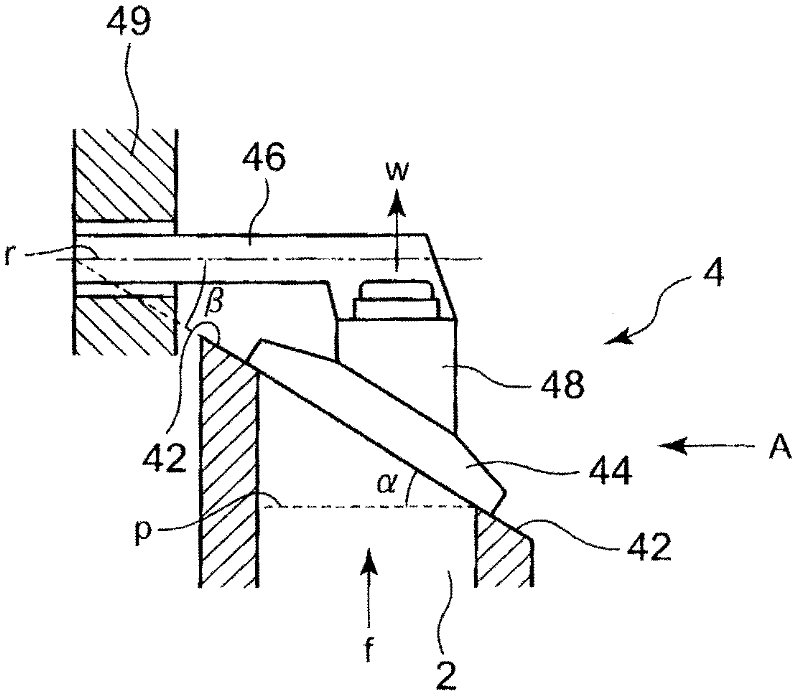

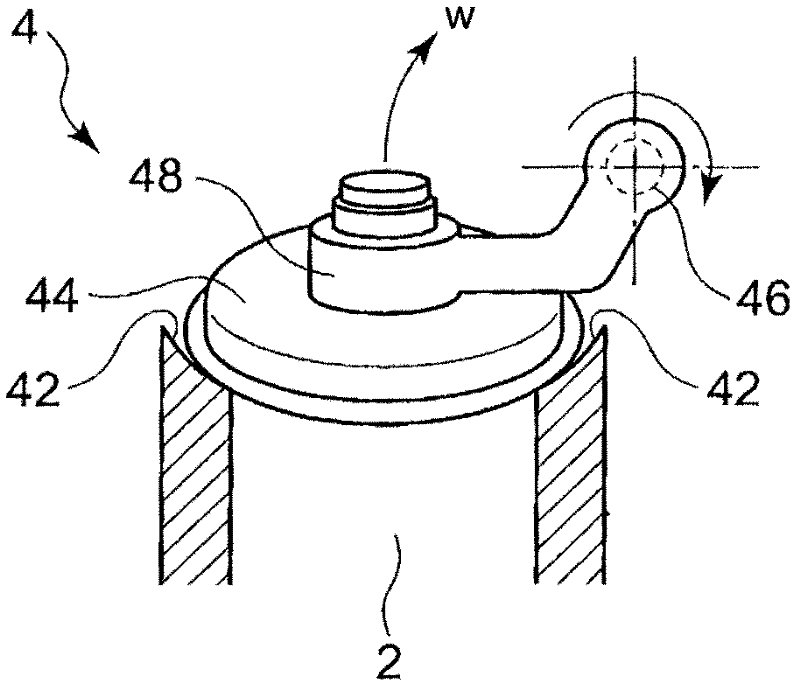

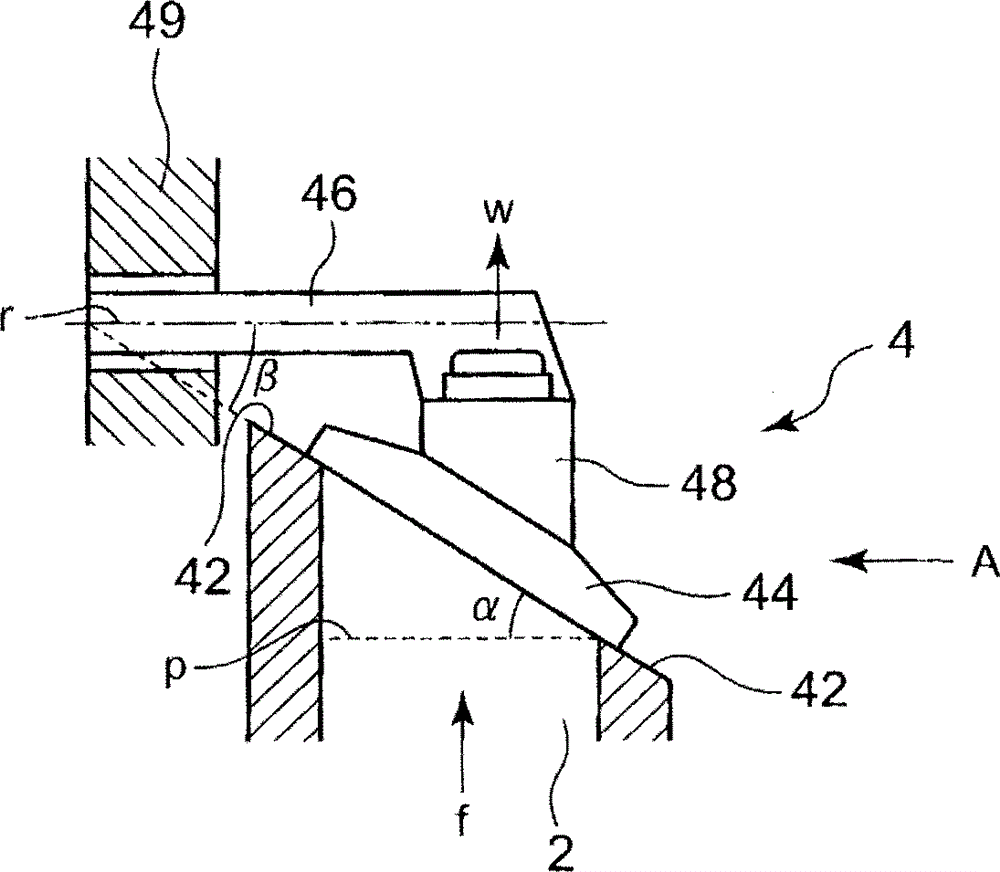

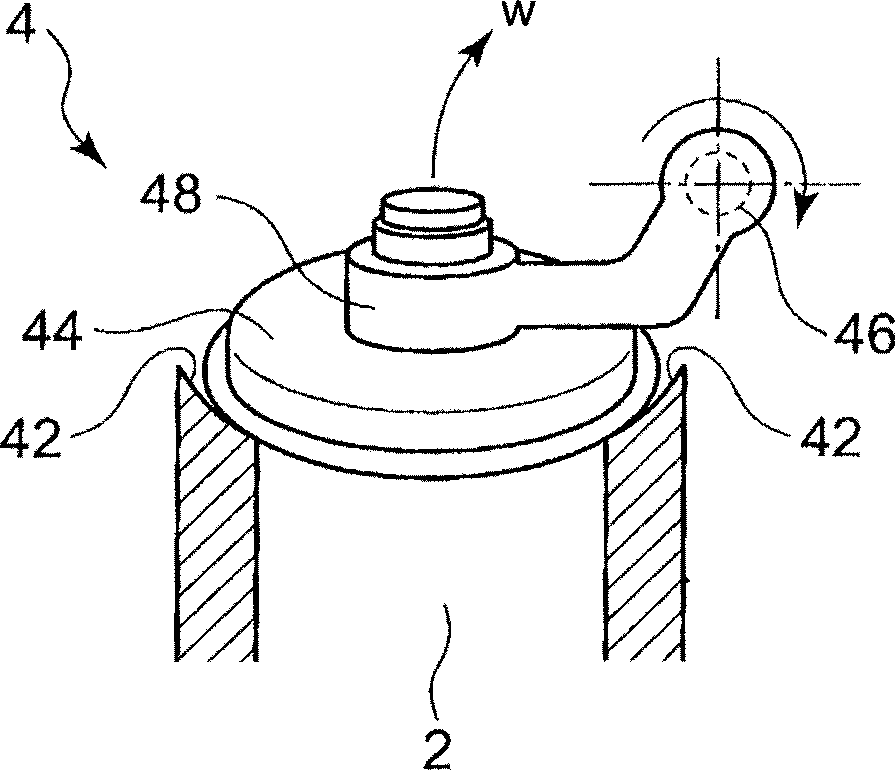

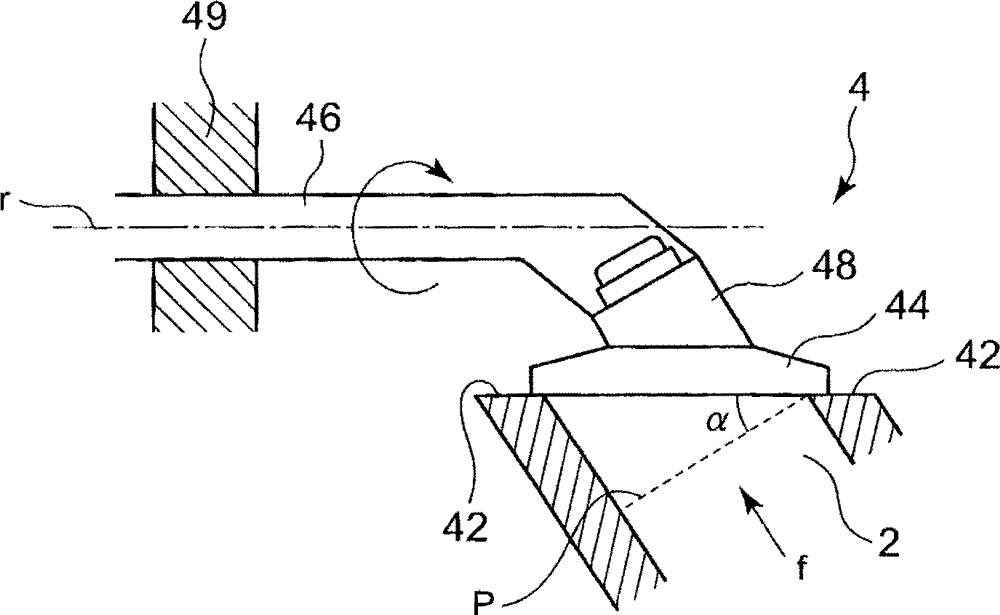

Waste gate valve

InactiveCN102472160AStable and easy to controlInternal combustion piston enginesEngine manufactureTurbochargerEngineering

A waste gate valve is provided in a bypass path for bypassing the turbine of the turbocharger provided in the exhaust gas path of the engine and opens and closes the bypass path. The waste gate valve comprises, in the bypass path: a valve seat formed on a surface which is perpendicular or tilted at an angle to the axial direction of the bypass path; and a valve element which can pivot about a rotation axis tilted at an angle (Beta) in the range of 0 DEG < Beta < 90 DEG relative to a plane including the valve seat, and which, as the valve element pivots, makes contact with and separates from the valve seat to close and open the valve.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

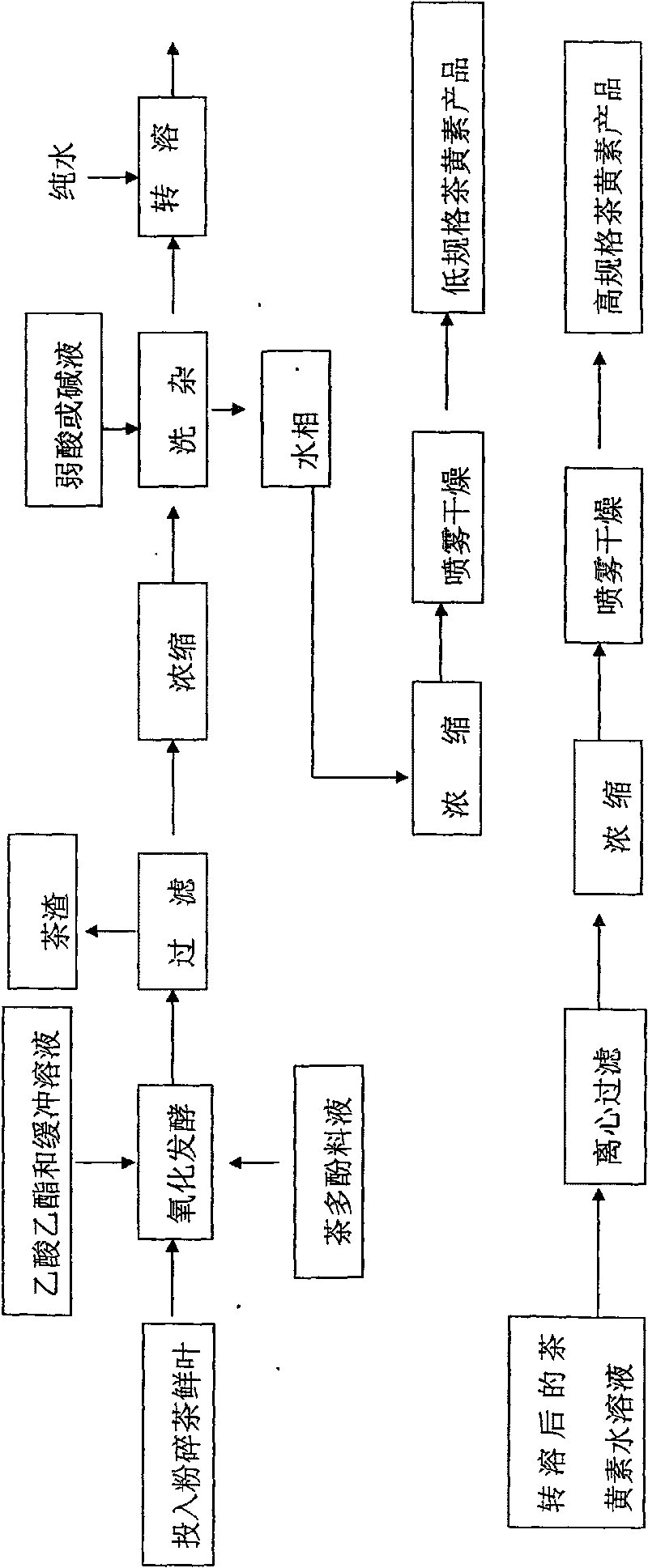

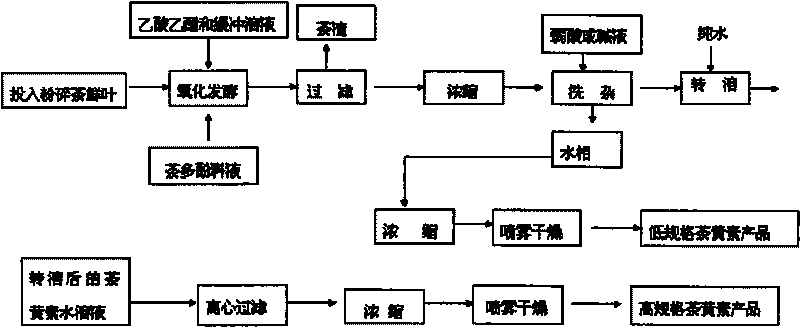

Industrial preparation method of theaflavin

InactiveCN101691591AReduce generationEnsure gentlenessOrganic chemistryFermentationAcetic acidTheaflavin

The invention relates to an industrial preparation method of theaflavin, which comprises the following steps: (1) preparing an ethyl acetate solution containing rich tea polyphenol; (2) respectively adding pulverized fresh tea leaves and the ethyl acetate solution into a oxidation-fermentation tank, orderly adding ethyl acetate and a buffering solution, introducing air at normal temperature, and stirring, oxidizing and fermenting to obtain the theaflavin ester-phase solution; (3) filtering the theaflavin ester-phase solution, concentrating and washing to remove impurities; (4) concentrating the water-phase solution, and spray-drying to obtain low-specification dry theaflavin powder; (5) concentrating the ester-phase solution to recycle ethyl acetate, and adding water so that the theaflavin is dissolved in the water; (6) centrifugally filtering the theaflavin water solution to obtain a pure theaflavin solution; (7) and concentrating the theaflavin solution, and spray-drying to obtain the dry theaflavin powder. The method of the invention simultaneously enhances the yield and the quality of the theaflavin, saves the energy and the man hours and reduces the emission of waste water.

Owner:ZHEJIANG PAINUO BIO TECH

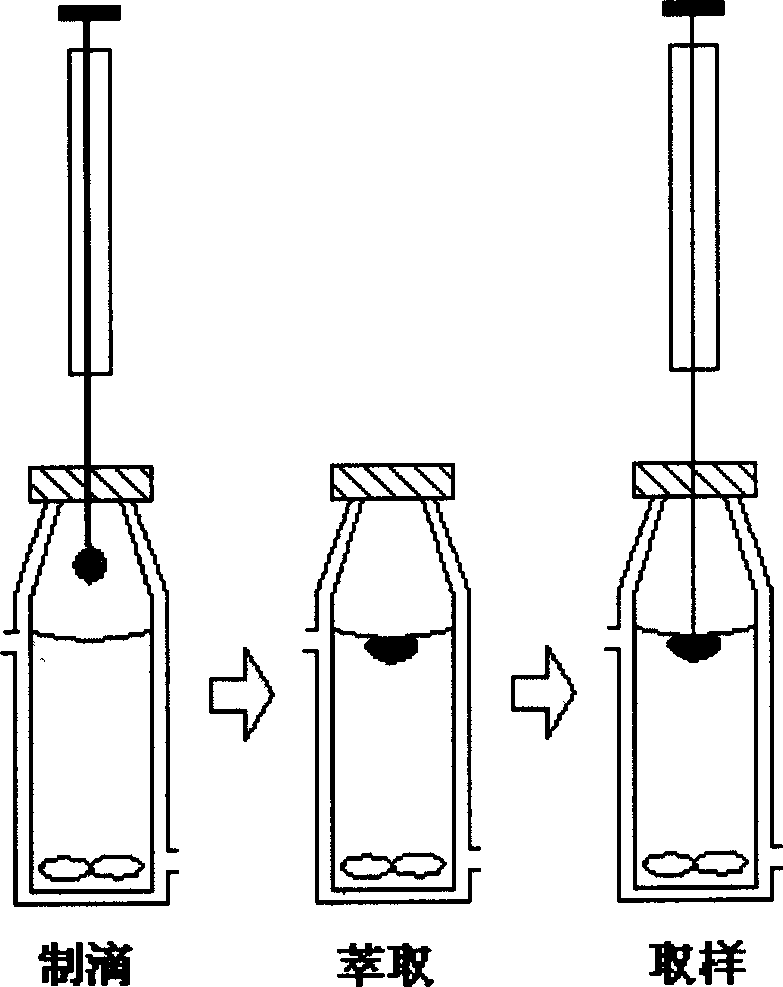

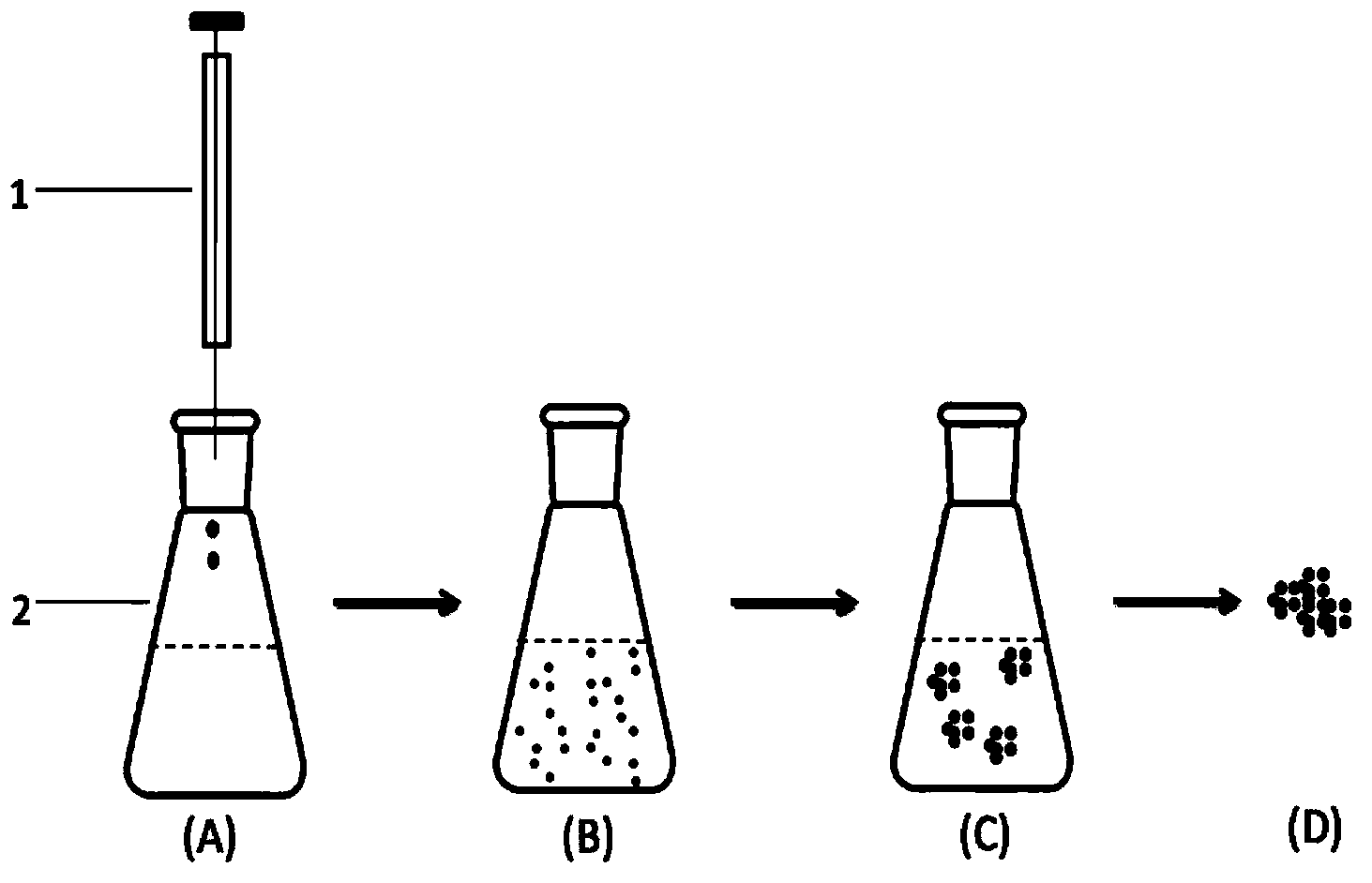

Hanging drop type liquid-liquid micro-extraction method

InactiveCN1663662AReduce demandEffectively eliminate interferencePreparing sample for investigationLiquid solutions solvent extractionBottleAmbient monitoring

The invention discloses a pendent drop liquid-liquid extraction method, which adds un-analyzed liquid sample in the extraction bottle with agitating, and quantitatively abstract extraction agent and drop it on the sample liquid. When the time is up to the setting time, use sampler to absorb the extraction agent, and use the analyzing instrument to detect. The method of the invention needs little amount of sample and can effectively exclude the interference of co-existing components of the compled samples to realize high multiplying factor gathering and to lower the analyzing limit and cost. It is very convenient for the invention to unite all kinds of chromatogram, spectrum and electro-chemical analyzing method. The invention can be utilized to food safety detection, environmental monitoring, natural resources extraction and the analyzing procedure of medicine and chemicals' manufacturing. The invention has strong technological priority and wide utilization foreground.

Owner:TSINGHUA UNIV

Method for preparing aluminium oxide and phosphorus-containing fertilizer from methanol-to-olefin waste catalyst

ActiveCN109455747AAchieve recyclingReduce pollutionAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminum ammonium sulfateALUMINUM PHOSPHATE

The invention relates to the technical field of silicon-aluminum-phosphate molecular sieve recycling, and particularly discloses a method for preparing aluminium oxide and phosphorus-containing fertilizer from a methanol-to-olefin waste catalyst. The method comprises the following steps: calcining and decomposing the waste catalyst, and then recovering by adopting an aluminum ammonium sulfate decomposing method to obtain the high-purity aluminium oxide, and performing acidolysis and curing to obtain a silicon-phosphorus-nitrogen compound fertilizer. The method disclosed by the invention is simple in processing steps, is stable and controllable in process, is high in operability, can prepare high-purity Al2O3 of which the purity is higher than 99% and the silicon-phosphorus-nitrogen compound fertilizer of which the content of effective nutrients is larger than 30% synchronously, realizes the recycling of the methanol-to-olefin waste catalyst, reduces the pollution of the waste catalystto the environment, and has great significance for developing coal chemical industry in China.

Owner:陕西好一化工科技有限公司

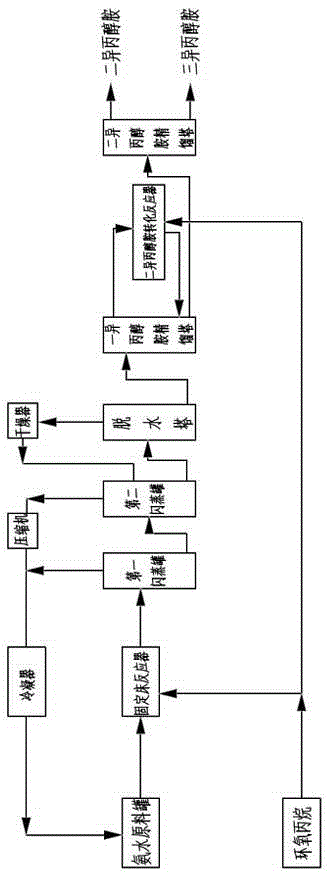

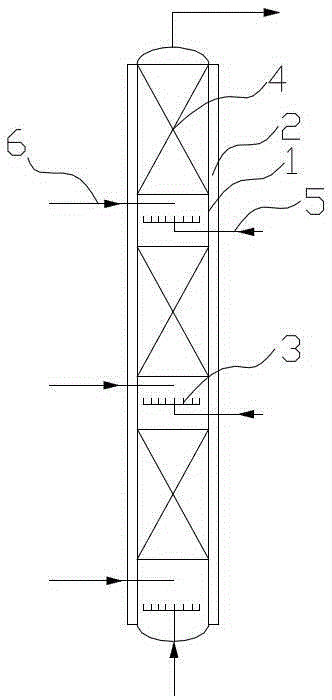

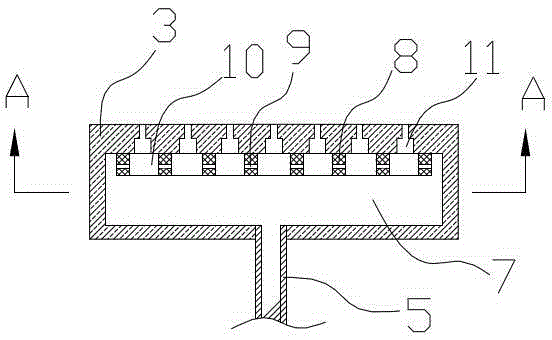

Method for producing isopropanolamine by using fixed bed tubular reactor

ActiveCN105348118AIncrease one-time synthesis rateAvoid side effectsOrganic compound preparationAmino-hyroxy compound preparationSide productChemistry

The present invention discloses a method for producing isopropanolamine by using a fixed bed tubular reactor. The method comprises: by using water as a catalyst, putting ammonia and epoxy propane with a molar ratio of (3.5-15):1 into a fixed bed reactor to perform a reaction, wherein the operation pressure of the reactor is 8-25 MPa, and the operation temperature is 160-220 DEG C; pumping a reaction product sequentially into a first flash evaporation tank and a second flash evaporation tank, performing two-stage flash evaporation and ammonia removal on the reaction product, and then introducing the processed reaction product into a dehydration tower for primary dehydration; introducing dehydration materials at the bottom of the dehydration tower into a monoisopropanolamine rectification tower, introducing discharged materials at the top of the monoisopropanolamine rectification tower into a monoisopropanolamine conversion reactor, and returning the materials to the bottom of the monoisopropanolamine rectification tower after reaction; introducing discharged materials at the top of the monoisopropanolamine rectification tower into a diisopropanolamine rectification tower, and after low pressure rectification, obtaining diisopropanolamine at the top of the diisopropanolamine rectification tower, and obtaining triisopropanolamine at the bottom of the diisopropanolamine rectification tower. The method provided by the present invention is capable of reducing the energy consumption of the whole process, effectively avoids reaction and side product generation, and improves the product purity.

Owner:ZHEJIANG JINGGONG NEW MATERIAL TECH

Heavy metal modified bioadsorbent and preparation method thereof as well as application of heavy metal modified bioadsorbent in tungsten-containing waste water treatment

InactiveCN103170313AWide adaptabilityAdaptableOther chemical processesWater contaminantsWastewaterAlgae

The invention discloses a heavy metal modified bioadsorbent and a preparation method thereof as well as an application of the heavy metal modified bioadsorbent in tungsten-containing waste water treatment. The heavy metal modified bioadsorbent is formed by alga or fruit residue sequentially subjected to saponification, saponification crosslinking, graft copolymerization, sulfenyl complexation and xanthation modification treatment. The preparation method of the heavy metal modified bioadsorbent takes certain amount of fruit residue waste or algae as a raw material and comprises the following steps of: cleaning, drying, levigating and sieving, sequentially carrying out saponification, saponification crosslinking, graft copolymerization, sulfenyl complexation and xanthation modification treatment, and then adding active groups adsorbing metal ions into orange peel, so that the aim of improving adsorption capacity of the heavy metal modified bioadsorbent is achieved. The invention also correspondingly provides a method for treating the tungsten-containing waste water by utilizing the heavy metal modified bioadsorbent. The heavy metal modified bioadsorbent has good adsorption effect and is simple to operate, easy to implement, low in cost and high in efficiency.

Owner:赣州世瑞钨业股份有限公司

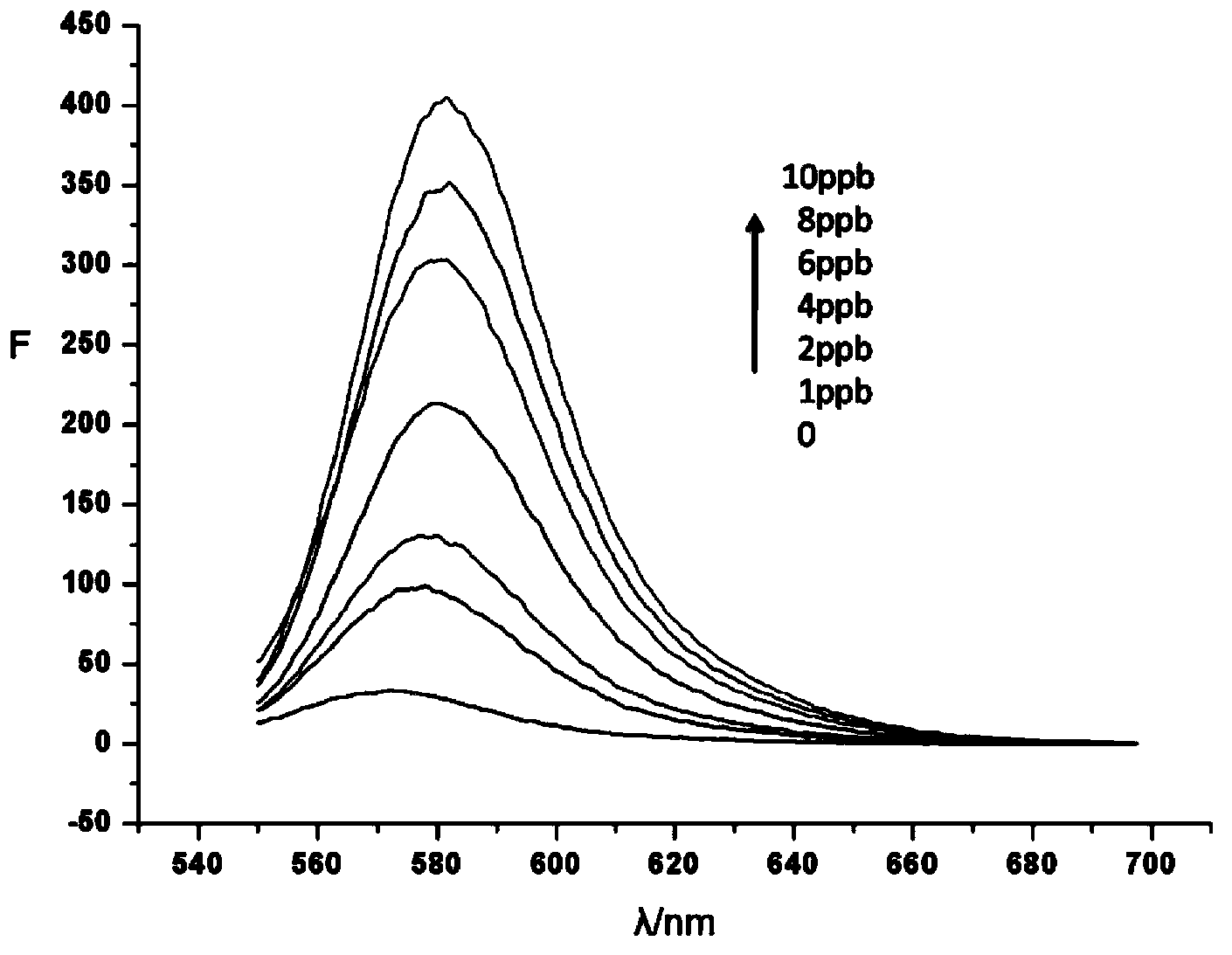

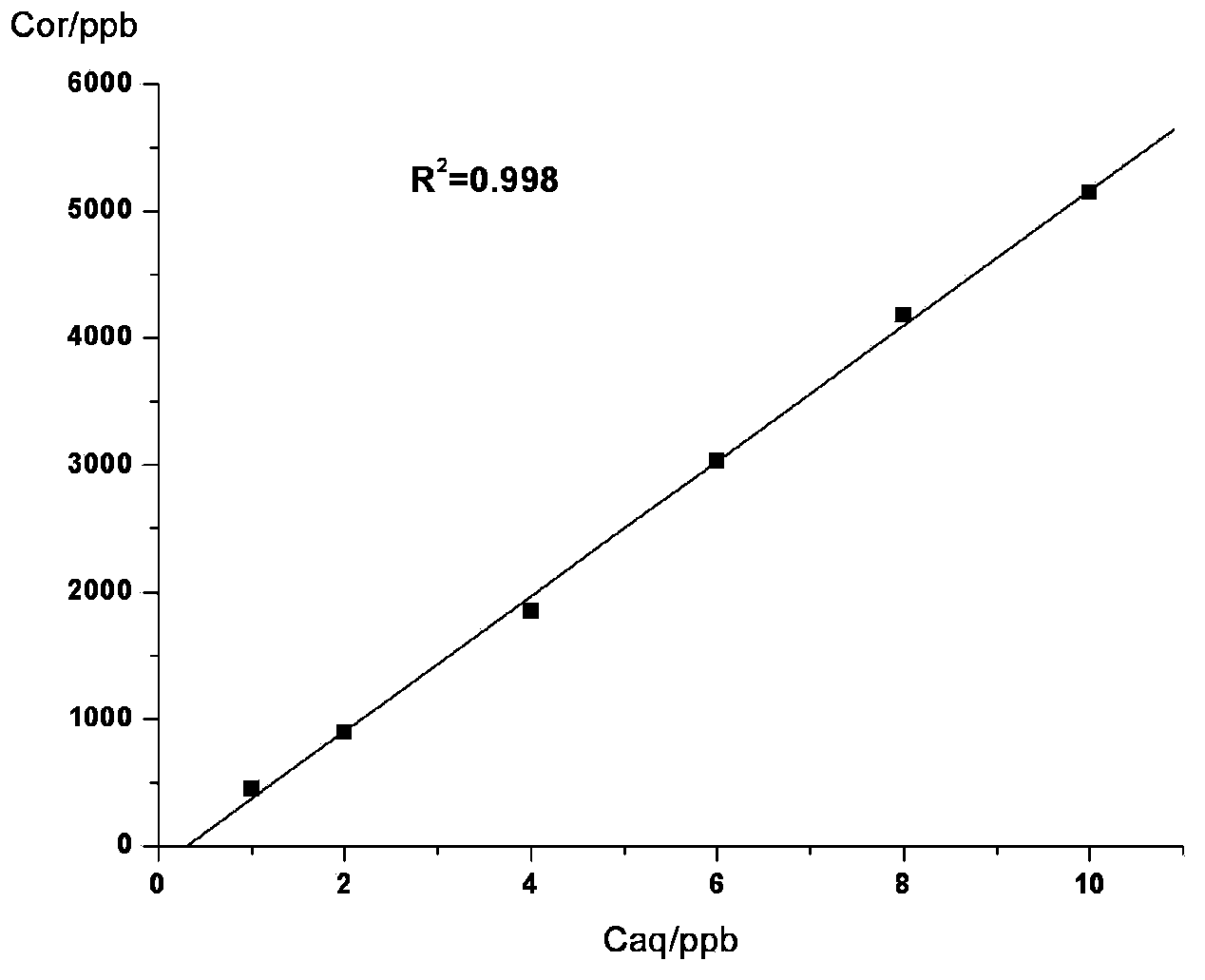

Dispersive liquid-liquid microextraction method of heavy metal ions by using alkyl carboxylic acid as extracting agent

InactiveCN103566623AReduce consumptionQuick analysisPreparing sample for investigationLiquid solutions solvent extractionSolid-phase microextractionCarboxylic acid

The invention provides a dispersive liquid-liquid microextraction method of heavy metal ions by using an alkyl carboxylic acid as an extracting agent. The method comprises steps of heating a sample making the temperature of the sample higher than the melt point of the alkyl carboxylic acid; mixing the alkyl carboxylic acid extracting agent and a dispersant; adding the mixture of the extracting agent and the dispersant into the sample to form an emulsion; cooling to solidify the extracting agent; and separating the solidified extracting agent for detection. The alkyl carboxylic acid in the method is used as a complexing agent and the extracting agent simultaneously. The method has less organic solvent types, small using amount of the organic solvents, short extraction time, high enrichment capability and simple operation. An elution step in solid-state microextraction, and a centrifugal separation step in traditional liquid-liquid microextraction are omitted. The method provided by the invention is a low-cost, simple and efficient sample pretreatment technology, and can extract the heavy metal ions in a water sample rapidly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

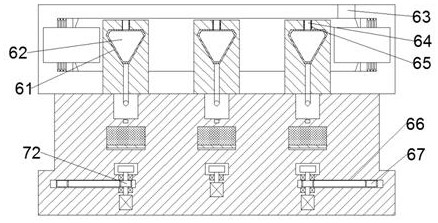

Socket device for mechanically assisting in plugging and unplugging plug

InactiveCN111817080AStable and easy to controlImprove securityCoupling device detailsAirbagElectric wire

The invention discloses a socket device for mechanically assisting in plugging and unplugging a plug. The socket device comprises a box body, wherein a socket fixing mechanism is arranged at a rear end of the box body, three upper supporting blocks are evenly arranged on a rear end surface of a top end of the box left and right, an expansion bucket groove with an upward opening is formed in a topsurface of a rear end of the upper supporting block, an upper through groove with a backward opening is formed in a rear end wall of the expansion bucket groove, a guide groove communicating up and down is formed in a front end of the upper supporting block, a guide rod is slidably connected into the guide groove, a lifting plugging block is fixedly arranged on a bottom surface of the guide rod, plug slots which are communicated up and down are formed in rear ends of the lifting plugging blocks, telescopic airbags are fixedly arranged on side walls of the plug slots, an inner through groove with an upward opening is formed in a rear end of the telescopic airbag, a rear end surface of the lifting plugging block is provided with a plug wire groove which is located at the rear side of the inner through groove and is provided with an upward opening, and a side wall of the plug wire groove is fixedly provided with a protection pad. The socket device is advantaged in that the position of theplug is automatically adjusted, the plug is automatically pressed into the socket through mechanical operation, and the socket is automatically pressed to pull out the plug.

Owner:杭州建德睿夕电子科技有限公司

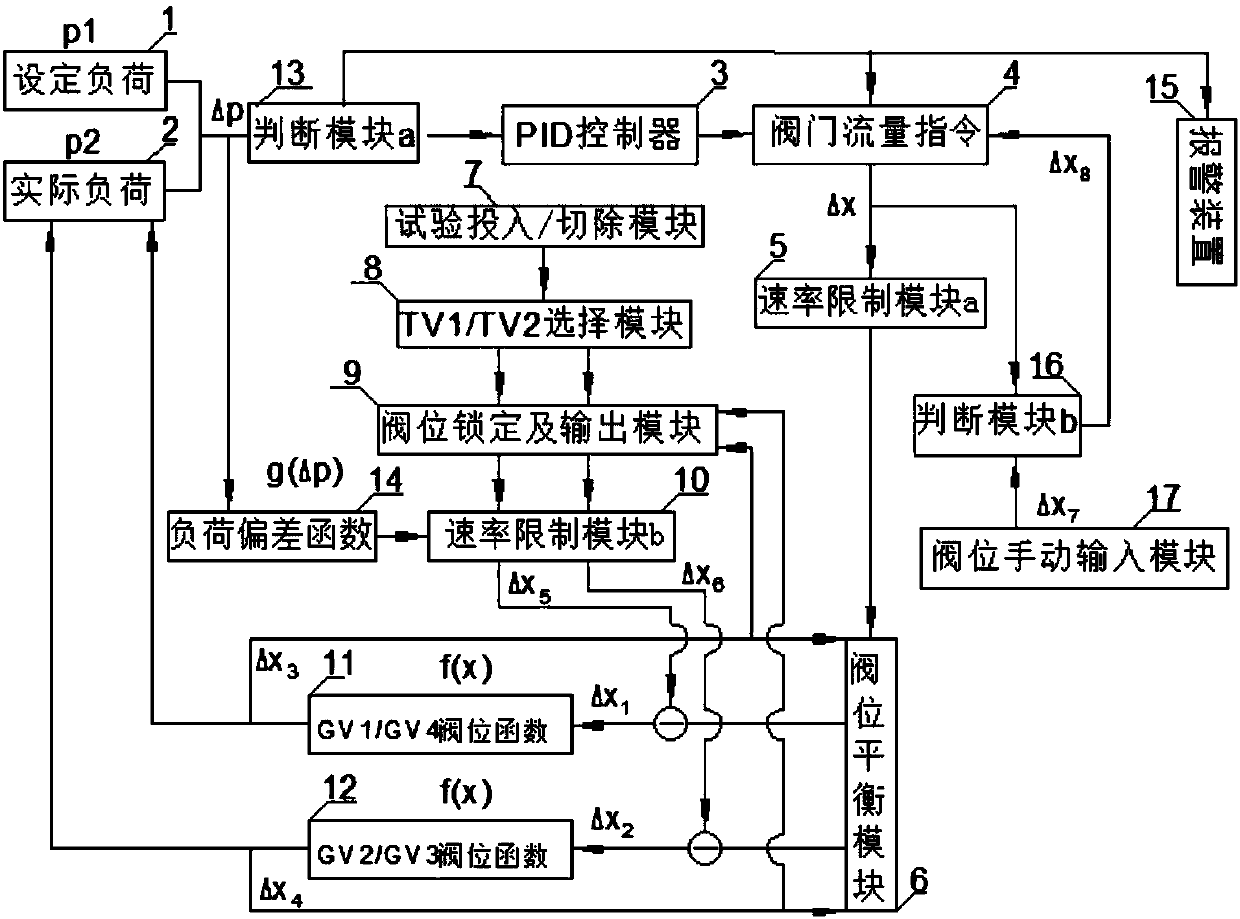

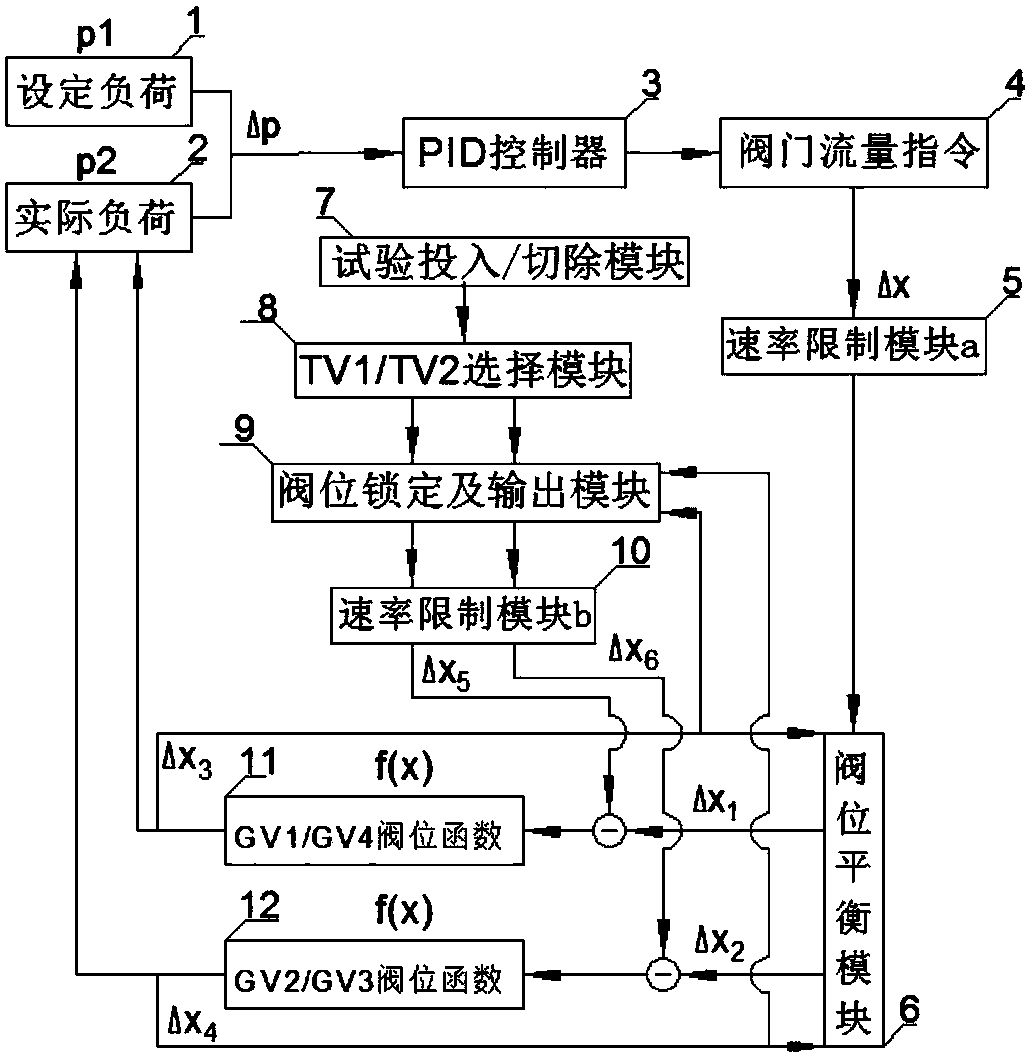

Method for prevention of generation of power oscillation in main stop valve full-stroke test of steam turbine

The present invention discloses a method for prevention of generation of power oscillation in a process of a main stop valve full-stroke test of a steam-turbine generation steam turbine. On the basisof the prior art, a determination module a and an alarm device are added to achieve removal of a power control loop, effectively prevent a unit from generating power fluctuation and power oscillationad emit an acousto-optic alarm after a steam turbine set is large in load deviation; a load deviation function is added to achieve that a high-pressure control valve can be switched on and off at variable speeds and reduce a small steam turbine load fluctuation amplitude; and a determination module b and a valve location manual input module are added to achieve a unit valve location maintenance function and a manual input valve location value function and effectively prevent the unit to generate power fluctuation and power oscillation. The method for prevention of generation of power oscillation in a main stop valve full-stroke test of a steam turbine provides a great guarantee for normal and smooth performing of the main stop valve full-stroke test of the steam turbine, and effectively reduces operators' burden.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

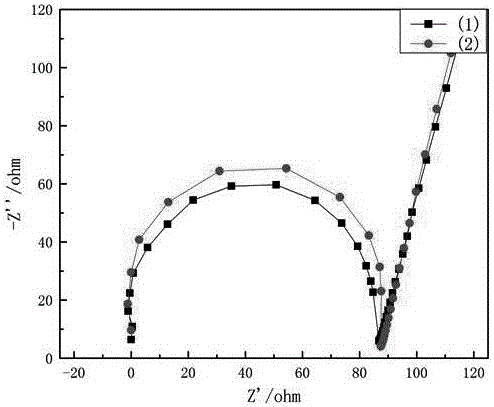

Biochar-supported magnetic substance composite adsorption material, and preparation method and application method thereof

ActiveCN106799208AGuaranteed stabilityQuality improvementOther chemical processesWater contaminantsNickel saltCobalt salt

The invention discloses a biochar-supported magnetic substance composite adsorption material, and a preparation method and application method thereof, and belongs to the field of water treatment. The biochar-supported magnetic substance composite adsorption material is prepared by the following steps: mixing and uniformly grinding a biomass, a cobalt salt and a nickel salt to obtain a mixture, calcining the obtained mixture under the protection of inert gas, and performing cooling. The preparation scheme requires few steps, is environment-friendly, and has broad industrial production prospect, and the biochar-supported magnetic substance composite adsorption material prepared by the preparation method has a good adsorption effect.

Owner:HUANGHUAI UNIV +1

Colloid storage battery electrolyte and preparation method thereof

InactiveCN106410288ALower internal resistanceLarge capacityFinal product manufactureLead-acid accumulators constructionLithium sulphateInternal resistance

The invention provides a colloid storage battery electrolyte and a preparation method thereof, and belongs to the technical field of colloid storage batteries. Polyvinylpyrrolidone is taken as a colloid stabilizer, lithium sulfate is taken as an additive and a phosphoric acid is taken as an auxiliary electrolyte; and performance test is carried out on the electrolyte by changing the content of various components to find out the most appropriate proportions: the polyvinylpyrrolidone accounts for 0.12% of total mass of the colloid storage battery electrolyte, the lithium sulfate accounts for 0.8% of total mass of the colloid storage battery electrolyte and the phosphoric acid accounts for 0.9% of total mass of the colloid storage battery electrolyte. The disadvantage of relatively high internal resistance of the colloid battery is improved, the capacity of the battery is improved and the service life of the battery is prolonged.

Owner:YANGZHOU UNIV

Method for preparing oxidation-resistant active peptides from crab shells by double-enzyme multistep enzymolysis

InactiveCN106801079AHigh economic valueThe process steps are simpleChemical industryPeptide preparation methodsFreeze-dryingOxidation resistant

The invention discloses a method for preparing oxidation-resistant active peptides from crab shells by double-enzyme multistep enzymolysis. The method comprises the following steps: (1) raw material pretreatment; (2) double-enzyme enzymolysis; (3) centrifugal separation; (4) membrane separation; and (5) vacuum freeze drying. By using the crab shells as the raw material, the crab shells are pulverized, and subjected to double-enzyme multistep enzymolysis, centrifugal separation, membrane separation and vacuum freeze drying to obtain the solid crab shell oxidation-resistant peptides. The method has the advantages of simple technical steps, stable and controllable process, energy saving, high efficiency and environment friendliness, implements comprehensive utilization on crab processing waste resources, enhances the application value of the crabs, and effectively increases the economic value of the crabs.

Owner:ZHEJIANG OCEAN UNIV

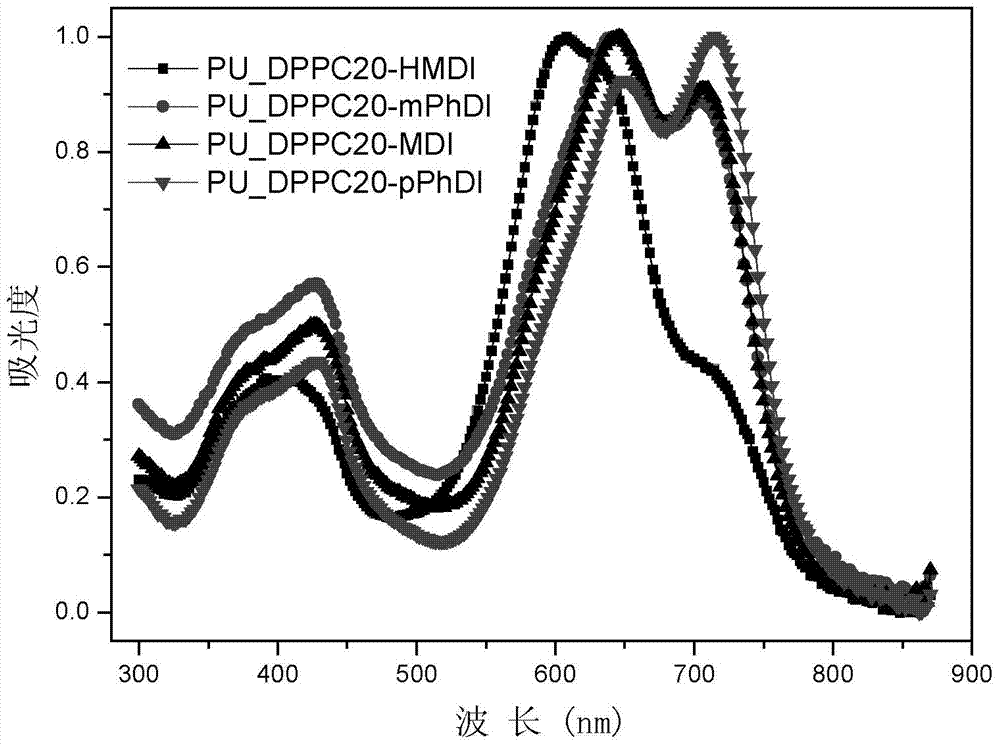

Polymer material containing multiple conjugated chain sections as well as preparation method and application of polymer material

InactiveCN104744666AStable and easy to controlGood film formingOrganic chemistrySolid-state devicesPolymer scienceDegree of polymerization

The invention provides a polymer material containing multiple conjugated chain sections as well as a preparation method and application of the polymer material. Particularly, the invention provides a polymer having photoelectrical activity. The polymer has multiple conjugated chain sections and non-conjugated chain sections arranged between every two conjugated chain sections and used for connecting the conjugated chain sections, wherein the conjugated chain sections are of full conjugated structures. The polymer disclosed by the invention can be used as photoelectrical material and has excellent film-forming property while the photoelectrical activity is not limited by polymerization degree and the activity is stable.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation method of silicon dioxide aerogel material

InactiveCN108147415AStable and easy to controlLow densityLiquid repellent fibresSilicon compoundsSilica gelSilicon tetrachloride

The invention belongs to the field of chemical materials, and particularly relates to a preparation method of a silicon dioxide aerogel material. The method comprises the following steps: mixing silicon tetrachloride with alcohol and carrying out alcoholysis reaction to obtain reaction liquid; carrying out mixing reaction on the reaction liquid and water to obtain silica sol; successively carryingout gelation and ageing on the silica sol to obtain wet gel; mixing the wet gel with a hydrophobic modifier and carrying out hydrophobic modification to obtain hydrophobic wet gel; and drying the hydrophobic wet gel to obtain silicon dioxide aerogel. After the silica soil is obtained, a felt pad is soaked with the silica soil to prepare a silicon dioxide aerogel felt pad. The method is stable andcontrollable when the silica sol is prepared, the problems that precipitates are generated due to local over heating in a reacting process due to the fact that silicon tetrachloride directly reacts with water, and uniform and stable silica soil cannot be formed are solved, and the performance of the finally prepared silicon dioxide aerogel material is improved.

Owner:UNIV OF SCI & TECH OF CHINA

Method for preparing ultraviolet-proof energy-saving glass

The invention belongs to the technical field of functional building materials, relates to ultraviolet-proof energy-saving glass and mainly provides nano powder with dual effects of ultraviolet proofing and photochromism and a preparation method thereof. The photochromic composite nanoparticle with the ultraviolet proofing effect is mainly formed by molybdenum trioxide (MoO3), titanium dioxide (TiO2), zinc oxide (ZnO), cerium dioxide (CeO2), cobalt oxide (CoO) and silicon dioxide (SiO2). By adopting glass as a matrix, a composite film is formed by coating the inorganic composite nano powder onthe glass through a wet coating method to prepare the ultraviolet-proof energy-saving glass. The photochromic composite nano powder provided by the invention has excellent dispersibility, oxidation resistance and light transmittance; the preparation method is simple in process, stable and controllable in process, high in color change response speed, low in equipment and raw material costs, easy tooperate, free of toxicity or pollution and convenient for industrial mass production.

Owner:山西普思盈创科技有限公司

Device for carrying up and down wheelchair at station

InactiveCN108423573AStable handlingStable and easy to controlCranesWheelchair userElectric machinery

The invention discloses a device for carrying up and down a wheelchair at a station and belongs to the field of transportation auxiliary equipment. The device comprises wheels, a chassis, a stepping motor, a lifting mechanism, a power source, a bearing base, a rotary motor, a first gear, a rotary shaft, a second gear, a rotary connecting disc, a rotary upright, a second connecting plate, a cylinder attaching plate, a cylinder, an electromagnetism sucker attaching plate, an electromagnetism sucker, a camera, a camera support, a man bearing table, a support unthreaded column and a controller. Through the device, overall stable carrying of a wheelchair user at a bus platform can be achieved.

Owner:曾美枝

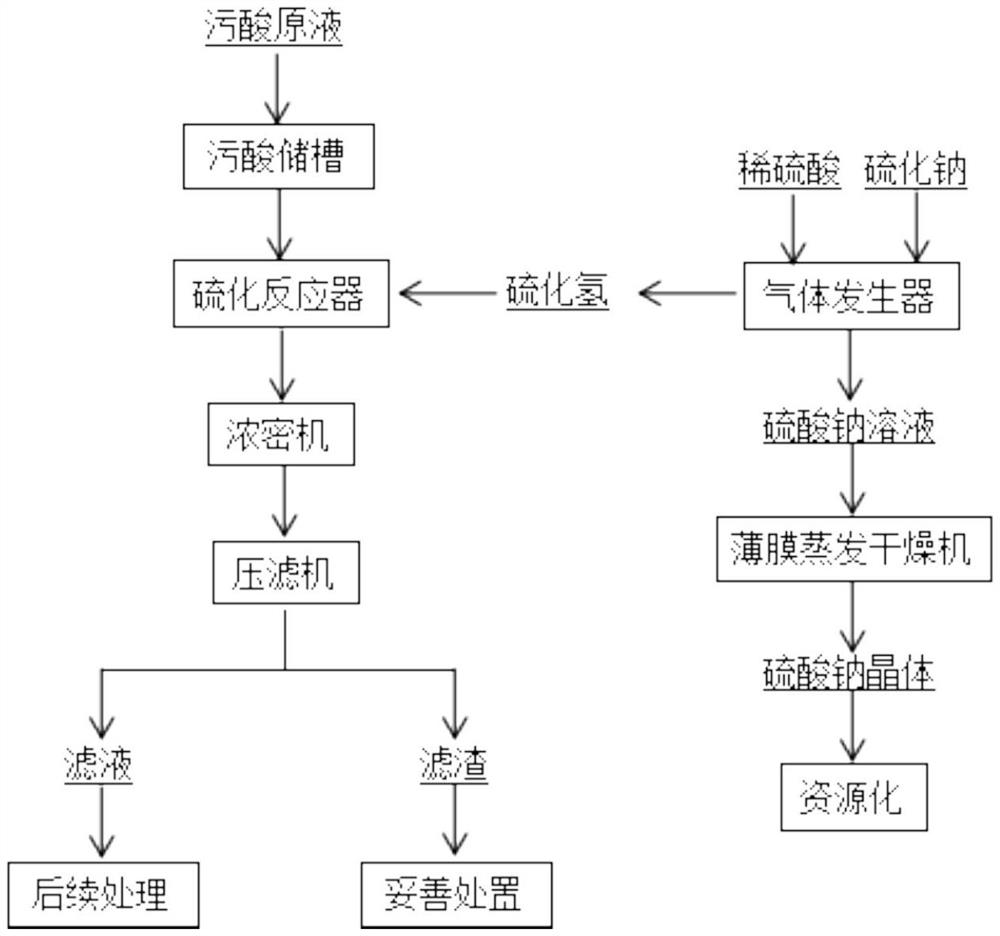

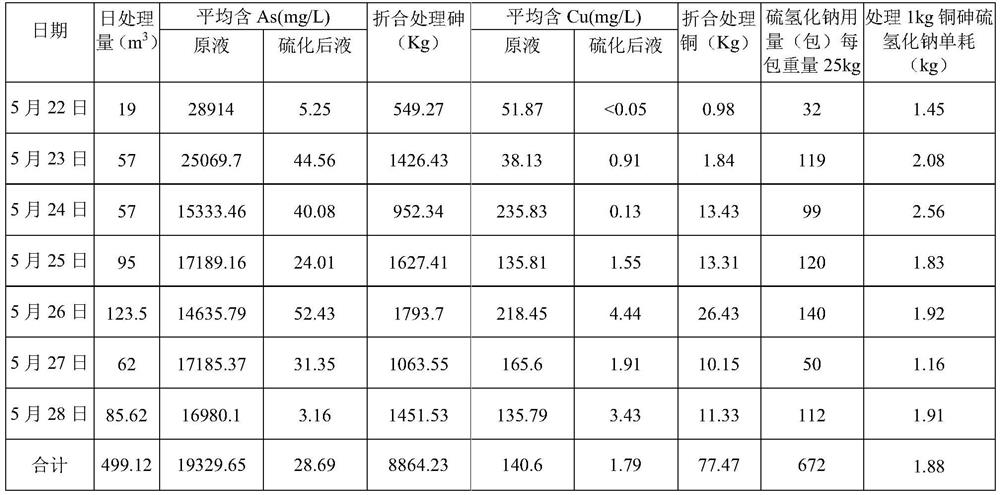

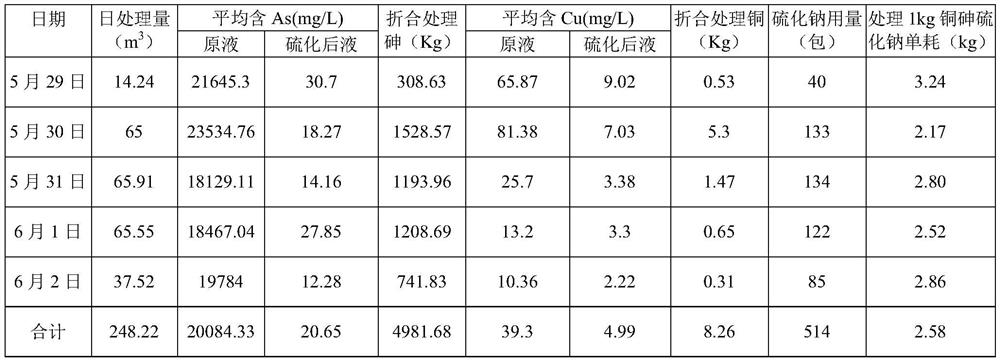

Treatment process of high-concentration arsenic-containing waste acid

PendingCN113233646ALow costLow running costWater/sewage treatment by centrifugal separationWater contaminantsSodium hydrosulfideSodium hydride

The invention discloses a treatment process of high-concentration arsenic-containing waste acid. The treatment process comprises the following steps: filtering the high-concentration waste acid by a filter, and introducing the filtered high-concentration waste acid into a waste acid storage tank; adding sodium hydrosulfide into a hydrogen sulfide gas generator, and adding a dilute sulfuric acid solution to obtain hydrogen sulfide gas; after sedimentation and solid-liquid separation, liquid in a waste acid storage tank is introduced into a vulcanization reactor through a centrifugal pump, then hydrogen sulfide gas is added, and high-concentration arsenic-containing waste acid is subjected to internal circulation through an internal circulation pump of the reactor, so that the hydrogen sulfide gas reacts with heavy metals in the liquid, and precipitates are produced; the precipitates are pumped into a thickening tank through a liquid discharge pump and is treated by a filter press, so that solid-liquid separation is realized, and standard discharge of the waste acid is realized. According to the process, comprehensive contrastive analysis is carried out from the aspects of a medicament adding mode and vulcanizing agent selection, the operation cost of a high-concentration waste acid treatment system is greatly reduced by upgrading and transforming vulcanizing agent dissolution and completing process system optimization, and meanwhile, the copper and arsenic removal efficiency is improved to reach the highest level of the copper smelting waste acid treatment process.

Owner:紫金铜业有限公司

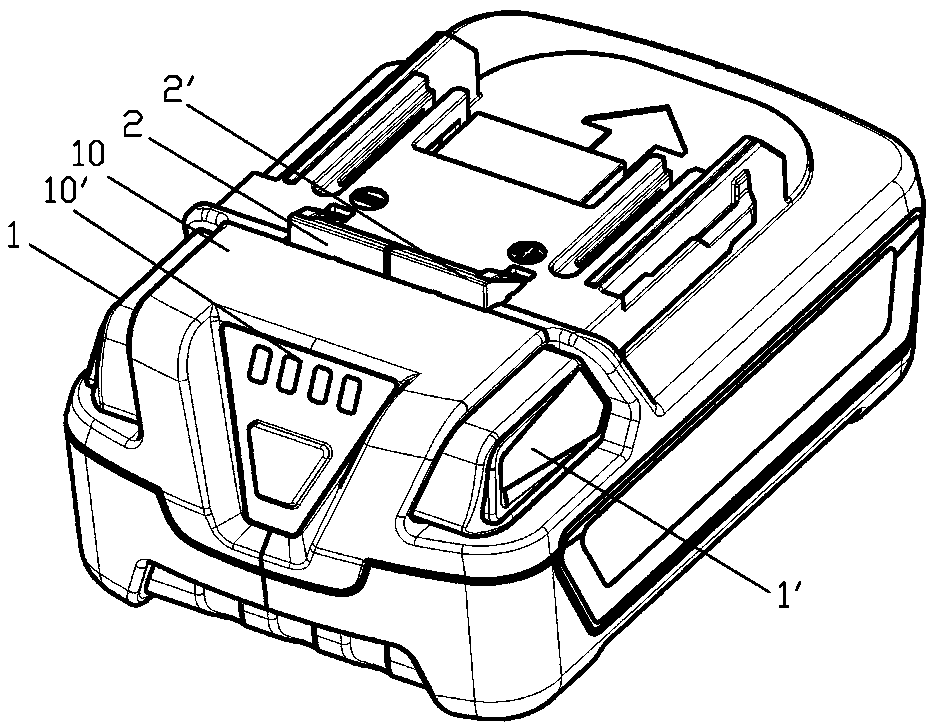

Battery pack horizontal button unlocking mechanism and battery pack adopting mechanism

PendingCN108389990ASolve the adaptation problemStable and easy to controlPortable power-driven toolsCell component detailsElectrical batteryEngineering

The invention relates to a battery pack horizontal button unlocking mechanism, belonging to the technical field of battery power supplying power device. The mechanism comprises a shell in which a battery pack is arranged, a plunger latch with a lower part arranged inside the shell and tending to rise up to lock as well as a left unlocking button and a right unlocking button which stretch out of two sides of the shell, the left unlocking button and the right unlocking button respectively form a horizontal movement pair with the shell, two sides of the plunger latch are respectively in contact with the inner sides of the left unlocking button and the right unlocking button so as to form an inclined plane pair which is used for changing the horizontal displacement of the unlocking button intoa vertical displacement of the plunger latch. During unlocking, the left unlocking button and the right unlocking button are oppositely pinched, and the rising trend of the plunger latch can be overcome through the inclined plane pair which is always in fit to enable the plunger latch to drop and unlock. In the process, the inclined plane pair can always be used for keeping the horizontal displacement of the unlocking button and the lifting displacement of the plunger latch in a linear relation, so that the operation and control are stable and flexible. Especially, by adopting the structure of the invention, the battery pack horizontal button unlocking mechanism can be maintained to adapt to original various main engines, so that the adaptive problem that a battery pack after remodeling is difficult to adapt to a product in the market, is properly solved.

Owner:NANJING JIUCHI ELECTROMECHANICAL IND

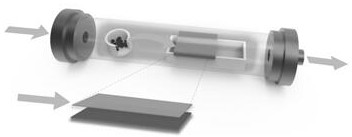

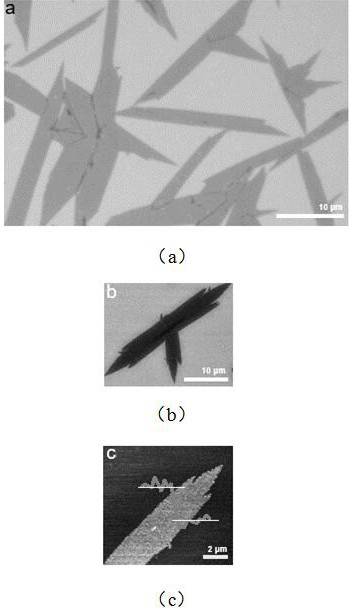

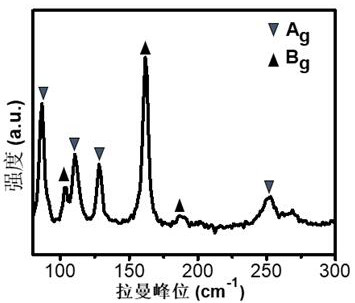

Confinement chemical vapor deposition preparation method of two-dimensional molybdenum ditelluride nano material

ActiveCN113428845AAvoid Spatial InhomogeneityLarge compositing windowNanotechnologyMetal selenides/telluridesMicron scaleSodium molybdate

The invention generally relates to the technical field of two-dimensional material preparation, and provides a confinement chemical vapor deposition preparation method of a two-dimensional molybdenum ditelluride (MoTe2) nano material, which comprises the following steps of: (1) preparing two substrates, and marking the substrates as a substrate A and a substrate B; and carrying out plasma surface treatment on the polished surface of the substrate A; (2) coating the surface of the treated substrate A with a sodium molybdate solution to form a sodium molybdate coating; (3) constructing a confinement growth environment: overlapping the sodium molybdate coating surface of the substrate A and the polished surface of the substrate B in a face-to-face manner, with the substrate B being on the top, to form a laminated substrate with a micron-order slit (1-30 microns); (4) enabling the tellurium powder to be firstly heated into tellurium steam through arrangement of the placement position, and then enabling the tellurium steam and a molybdenum source, rapidly introduced into the heating area, in the laminated substrate to react in a confinement and grow; and (5) sampling: after a quartz tube is cooled to room temperature, taking out the laminated substrate, and obtaining two-dimensional MoTe2 on the surface of the substrate B.

Owner:NAT UNIV OF DEFENSE TECH

Waste gate valve

InactiveCN102472160BStable and easy to controlEngine manufactureInternal combustion piston enginesTurbochargerEngineering

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Water-resistant ceramic-like internal wall decorative paint and preparation method thereof

The invention discloses a water-resistant ceramic-like internal wall decorative paint which is prepared from the following components in parts by weight: 30-40 parts of silicone acrylic emulsion, 5-10 parts of urea-formaldehyde resin, 3-5 parts of VAE (vinyl acetate-ethylene) redispersible latex powder, 5-10 parts of nano kaolin, 1-5 parts of magnesium oxide, 1-5 parts of magnesium chloride, 3-5 parts of tea saponin, 15-20 parts of wollastonite powder, 5-10 parts of heavy calcium carbonate powder, 3-5 parts of sodium silicate, 1-1.5 parts of sodium hexametaphosphate, 0.5-1 part of hydroxyethyl cellulose, 1-2 parts of Texanol ester alcohol, 1-3 parts of sodium hydroxide, 10-15 parts of quicklime and 20-25 parts of water. The water-resistant ceramic-like internal wall decorative paint has the advantages of reasonable and scientific formula design, low cost, no toxicity, high safety, favorable smoothness, excellent water resistance and no sag after scratching. The invention also discloses a preparation method of the water-resistant ceramic-like internal wall decorative paint. The method has the advantages of simple processing steps and stable and controllable process, and is easy to implement and suitable for industrial production.

Owner:ZHEJIANG COLLEGE OF CONSTR

Polyalkylene oxide catalyst with medium-low molecular weight and preparation method thereof

ActiveCN102030896BHigh low temperature activityStable and easy to controlAlkaline earth metalActive agent

The invention relates to a polyalkylene oxide catalyst with medium-low molecular weight and a preparation method thereof. The catalyst is characterized by being an organic compound of metal calcium, metal strontium and metal barium in a weight ratio of 1 to (0.01-1.7) to (0.01-2) and being prepared by making alkaline earth metal with high purity, anhydrous liquid ammonia, an active agent and a dispersant react in a liquid-phase environment. Compared with the prior art, the catalyst prepared by the method has the advantages of a plurality of activity centers, high low-temperature activity, high aggregation efficiency, stable and controllable aggregation process and short aggregation time. The catalyst of the invention is utilized to prepare a polyethylene glycol oxide product with a medium-low molecular weight at a 0.2-1 million stage and can adjust the molecular weight according to a catalyst prescription. The catalyst of the invention has easily obtained raw materials, simple and convenient preparation, low cost and safe transportation and storage without aging.

Owner:上海豪胜化工科技有限公司 +1

Liquid nitrogen flash freezing method for swimming crabs

ActiveCN109349331AIncrease roughnessGood adhesionMeat/fish preservation by freezing/coolingAquatic productOperability

The invention relates to the technical field of freezing and refreshing of aquatic products, in particular to a liquid nitrogen flash freezing method for swimming crabs. The method comprises the following steps of 1, cleaning; 2, pore formation; 3, immersion; 4, ice glazing; 5, average-temperature liquid nitrogen flash freezing; 6, vacuum packaging. The technical steps are easy, the process is stable and controllable, the operability is high, the frozen cracking rate of the frozen swimming crabs obtained by using the method is low, the ice is uniform in thickness and not likely to peel off, and the frozen swimming crabs are good in appearance quality.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

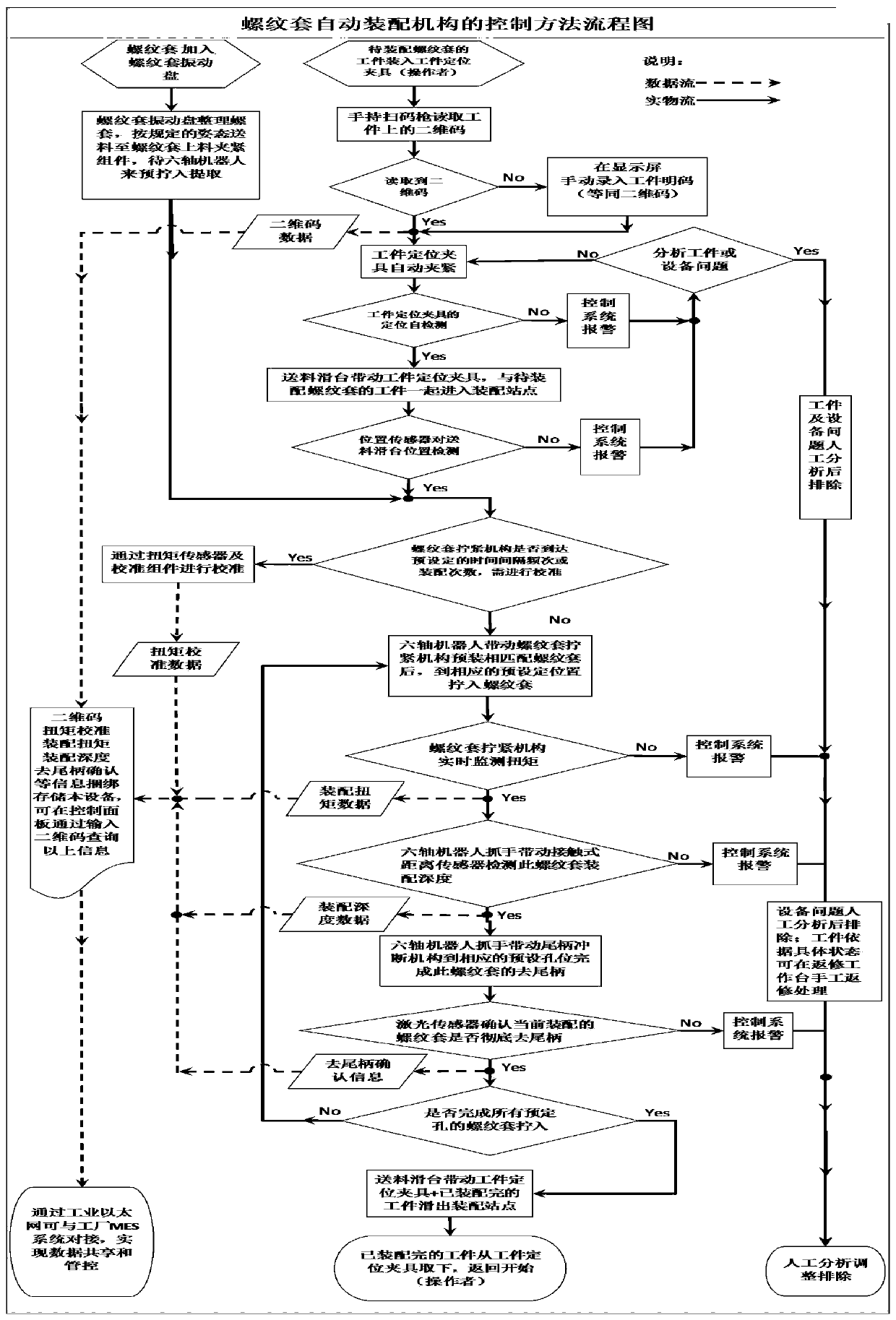

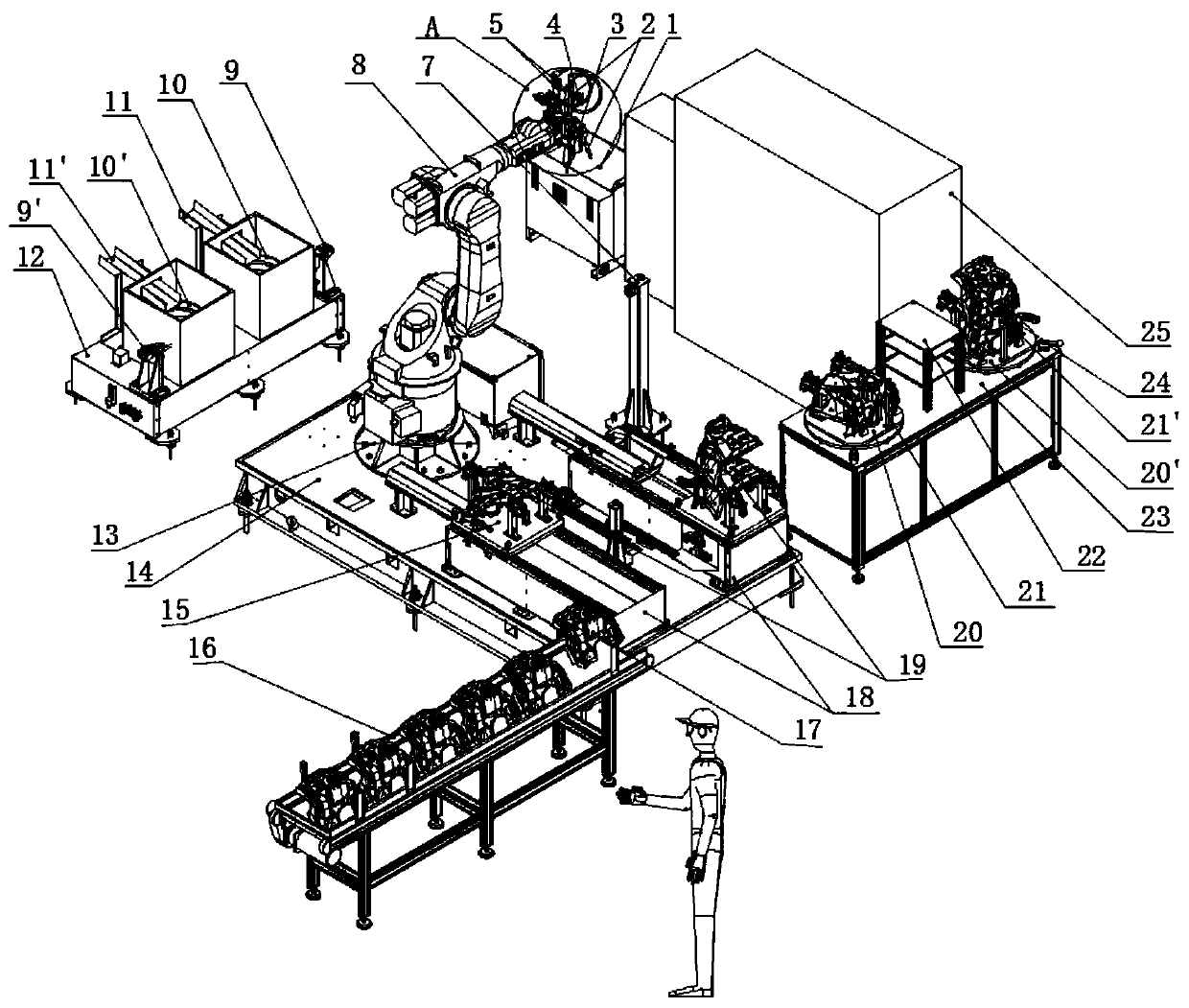

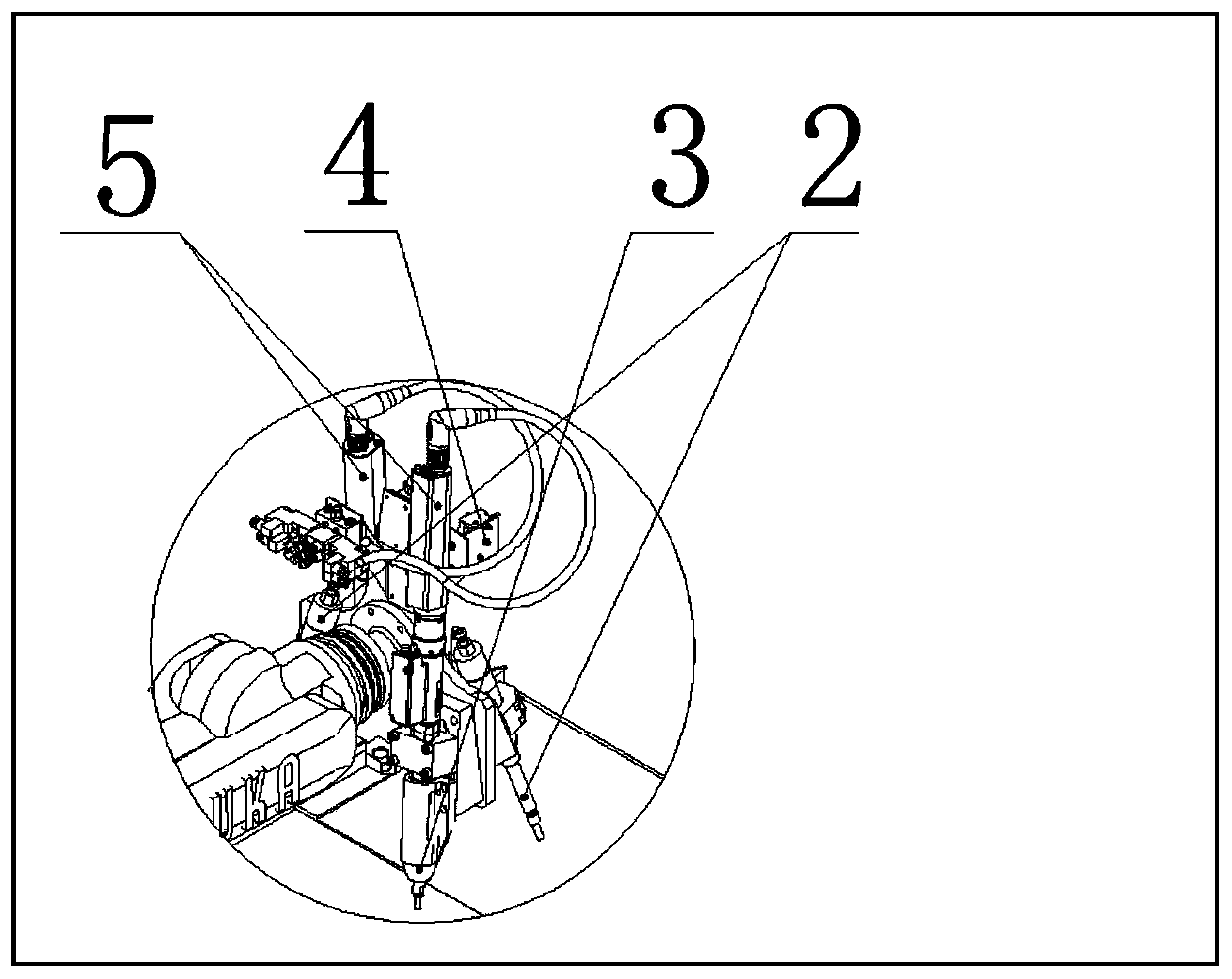

Controlling method of automatic threaded sleeve assembling mechanism

ActiveCN110977419AAvoid damageReduce labor intensityProgramme controlComputer controlControl systemControl engineering

The invention belongs to the technical field of threaded sleeve assembling, and relates to a controlling method of an automatic threaded sleeve assembling mechanism. The controlling method comprises the following steps that 1, a workpiece to be assembled with a threaded sleeve is installed on a workpiece positioning clamp; 2, the threaded sleeve is automatically arranged and fed, and a two-dimensional code of the workpiece is read by an operator holding a code scanning gun; 3, a workpiece positioning clamp is automatically positioned and clamped and positioning detection is carried out, 4, a transfer in-place signal is fed back to a controlling system by a position sensor, and the condition that a current tightening mechanism is calibrated effectively is confirmed by the controlling system; 5, automatic threaded sleeve screwing is carried out, and a threaded sleeve screwing mechanism outputs current hole assembly torque data to the controlling system; 6, a contact type distance sensoris driven to conduct threaded sleeve depth measurement; 7, a tail handle of the threaded sleeve is removed; and 8, a laser sensor is driven to perform tail handle removing confirmation detection. According to the controlling method, high-positioning and repeated-positioning precision including space angles can be achieved, damage to the threaded sleeve and a workpiece assembly bottom hole is avoided, and automatic assembly reduces labor intensity and greatly improves production efficiency.

Owner:CHINA FIRST AUTOMOBILE +1

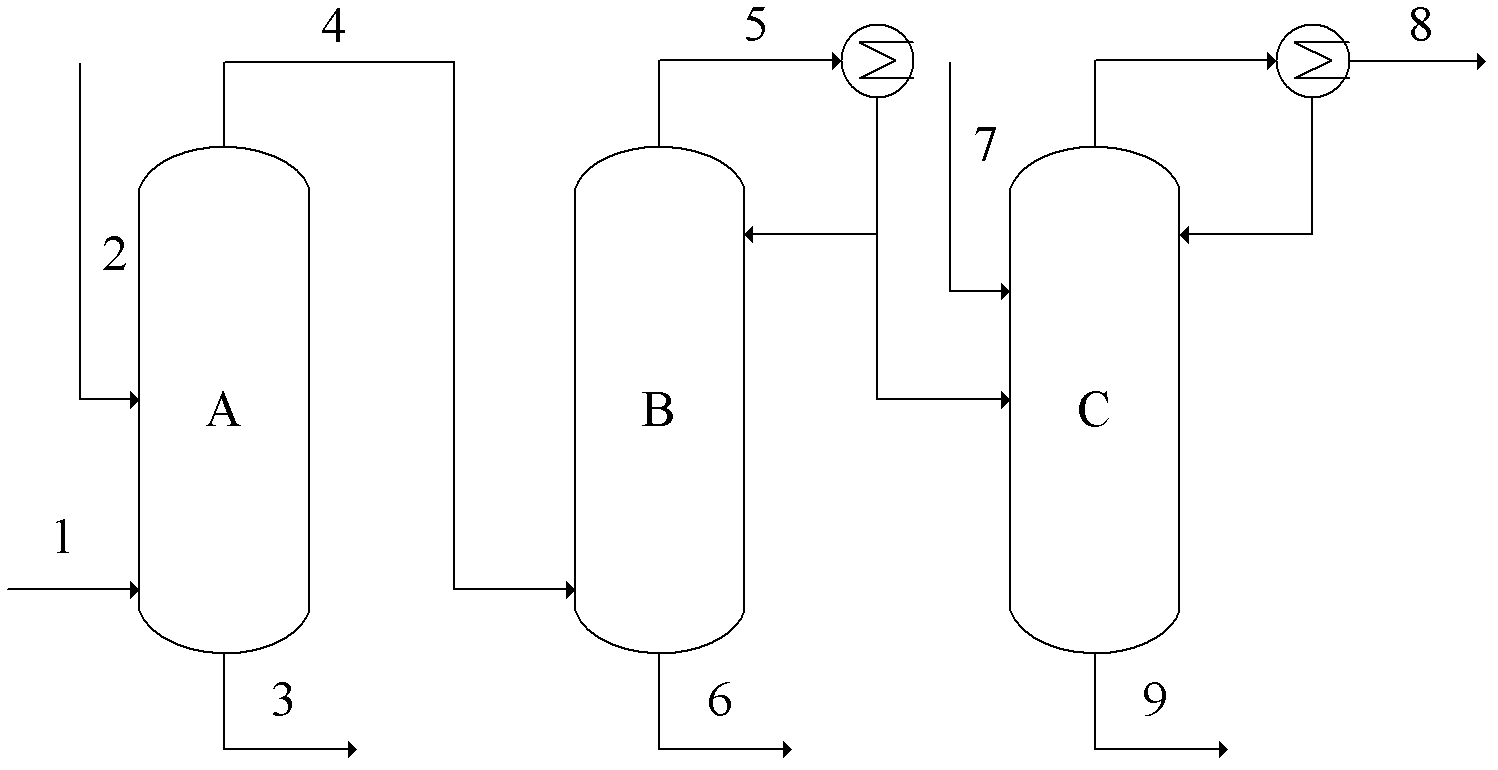

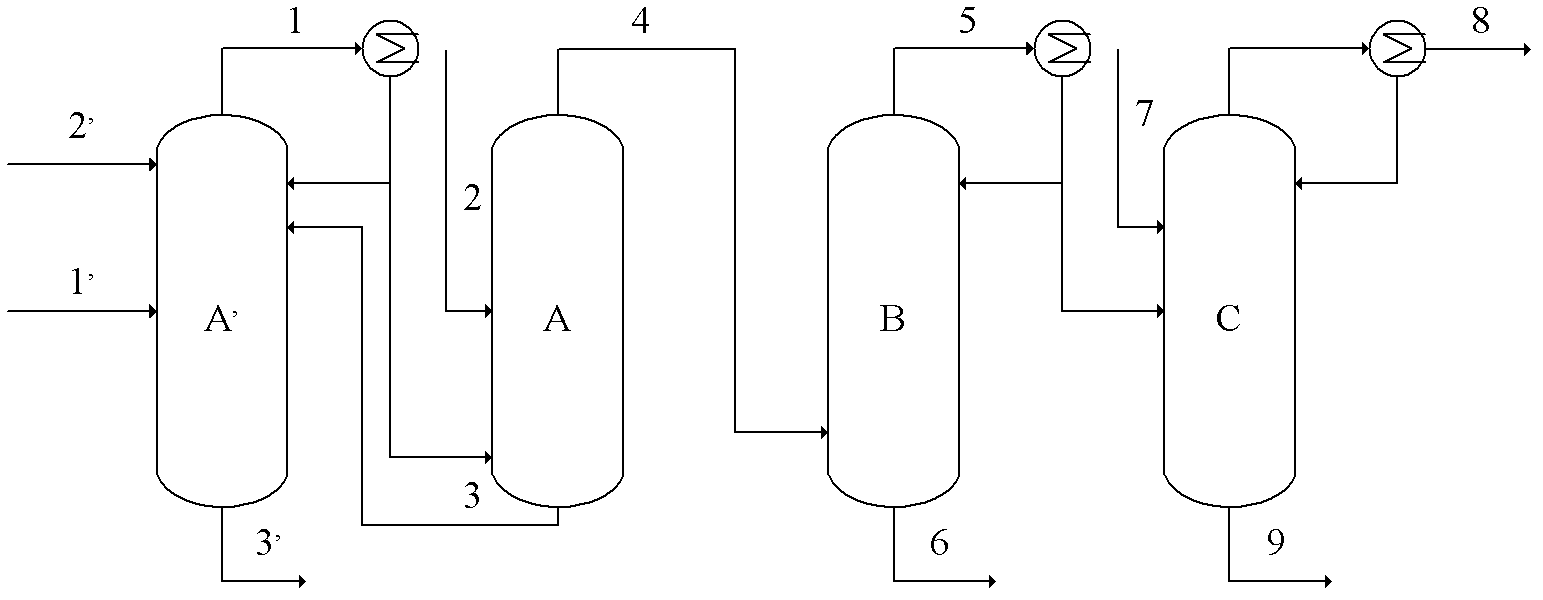

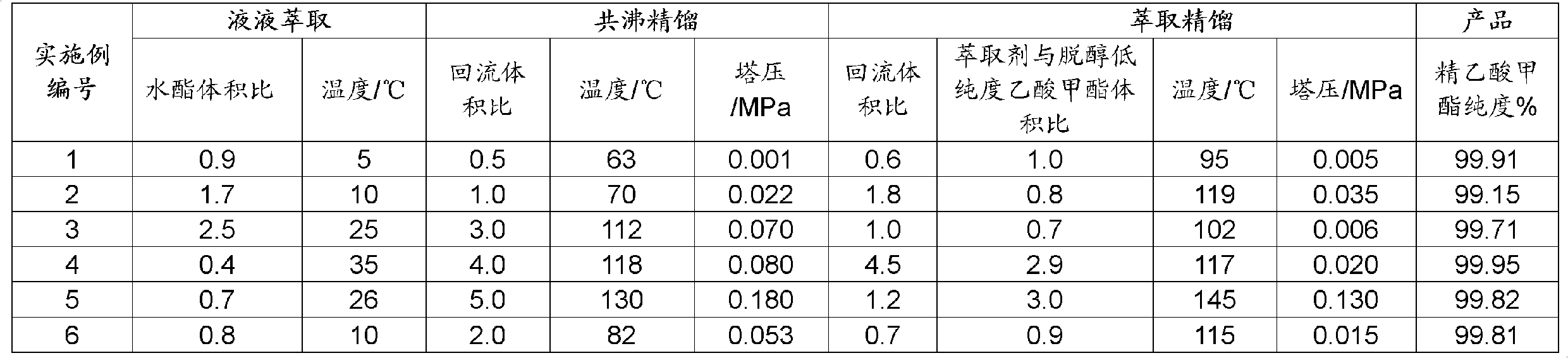

Method for preparing high-purity methyl acetate from low-purity methyl acetate

ActiveCN103183610AHigh removal rateReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationPolyvinyl alcoholExtractive distillation

The present invention provides a method for preparing high-purity methyl acetate from low-purity methyl acetate, comprising the steps of liquid-liquid extraction, azeotropic distillation and extractive distillation, wherein water is the extractant for methyl acetate / methanol, and acetic acid is the extractant for water. Further, for the high alcohol low-purity methyl acetate, such as waste liquid (or waste gas) from the production of polyvinyl alcohol can be roughly distilled and then purified by the method. The method has the advantages of simple technological processes, small investment in equipment, stable operation and easy control, low energy consumption, and preparing high purity methyl acetate and stable quality.

Owner:HUNAN XIANGWEI

Zirconia-based refractory materials and preparation method thereof

The invention belongs to the field of refractory materials, and particularly discloses a zirconia-based refractory material and a preparation method thereof. The refractory material based on zirconiumoxide comprises zirconium oxide, silicon oxide, aluminum oxide, a stabilizing agent, a binding agent and other raw materials, and is mainly prepared and formed through a three-step method of materialmixing, blank forming and sintering forming. Compared with the prior art, the refractory material based on zirconium oxide has the advantages of excellent heat resistance, low apparent porosity, thesmall apparent pore diameter, the high compressive strength, the high corrosion resistance and the low cost. The preparation method of the refractory materials based on zirconium oxide is simple and safe to operate and stable and controllable in process.

Owner:TAICANG HONGDA JUNMENG NEW MATERIAL

Steel pipe flange welding positioning device

ActiveCN104014954BRealize dockingStable and easy to controlWelding/cutting auxillary devicesPipeline systemsPipe weldingFlange

The invention relates to the technical field of welding, and provides a steel pipe flange welding and positioning device. The steel pipe flange welding and positioning device comprises a first sliding rail, a first platform and a second platform, wherein the first platform and the second platform are arranged on the first sliding rail in a sliding mode. Limiting devices are arranged between the first platform and the first sliding rail and between the second platform and the first sliding rail. A first fixing jaw and a second fixing jaw which are used for positioning flanges are connected to the first platform and the second platform in a relatively rotating mode, and at least one of the first fixing jaw and the second fixing jaw is driven by a power device to rotate. Roller carriers used for holding steel pipes are arranged at the positions, between the first fixing jaw and the second fixing jaw, of the first platform and the second platform, and the height of the roller carriers is adjustable. The device is ingenious in structural design, is particularly suitable for positioning of steel pipes of various diameters and flanges of various diameters, and can achieve stable welding and guarantee the welding quantity; the steel pipes and the flanges can be positioned conveniently. In addition, the device is simple in structure, low in cost and easy to popularize.

Owner:HEBEI FLEXTRONICS ELECTRICAL TECH

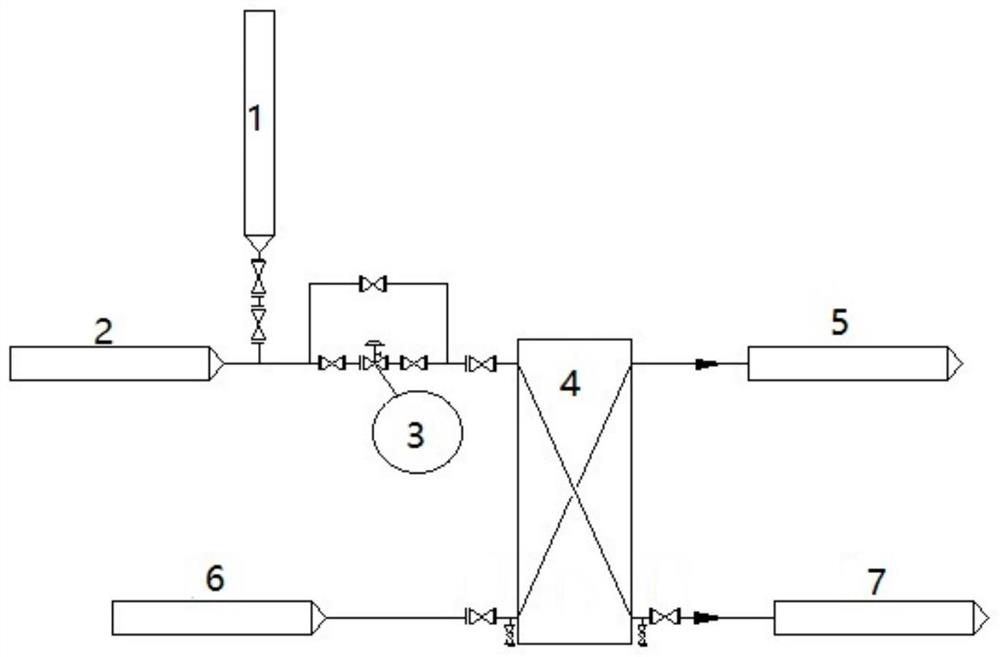

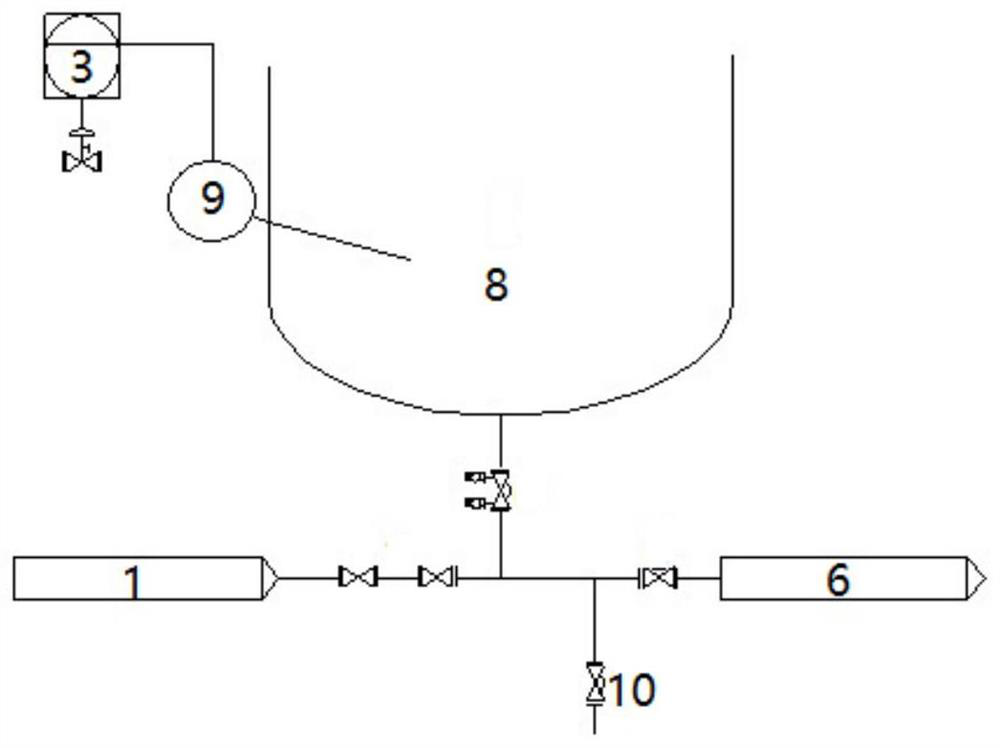

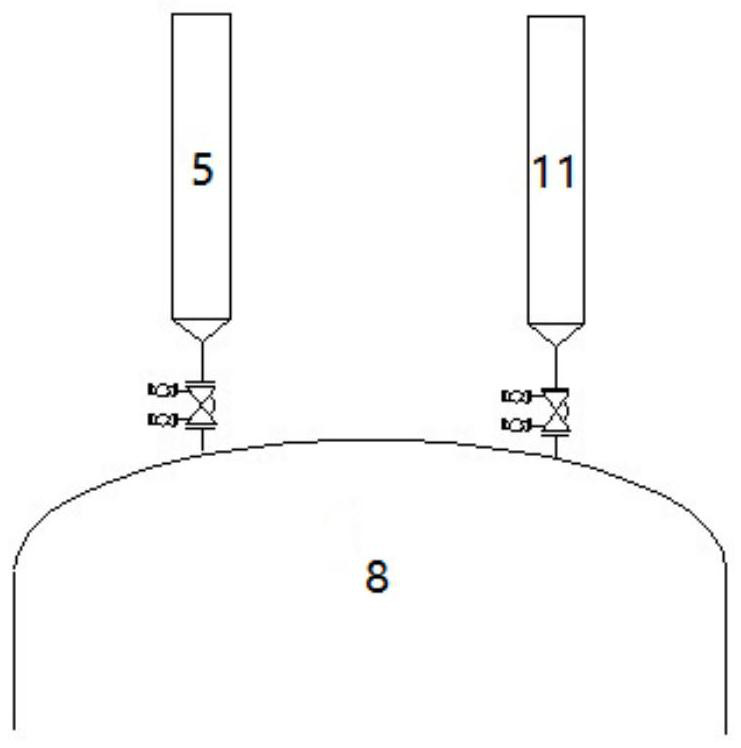

Material heat exchange system and method for fermentation reaction

InactiveCN112608833ASave spaceReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringFermentation

The invention relates to a material heat exchange system for fermentation reaction. The material heat exchange system comprises a fermentation material outflow pipeline, a fermentation material heat exchange pipeline and a fermentation material inflow pipeline which are connected in sequence; an inlet of the fermentation material outflow pipeline is connected with a discharge port in the bottom of the fermentation reactor, an outlet of the fermentation material inflow pipeline is connected with a feed port in the top of the fermentation reactor, and no heat exchange structure exists in the fermentation reactor. The heat exchange system provided by the invention is simple in structure, the used pipelines and equipment are arranged outside the fermentation reactor, the internal space of the fermentation reactor is not occupied, the manufacturing period and the manufacturing cost of the fermentation reactor are greatly reduced, the transformation and maintenance are simple and convenient, the working safety is high, and the system provided by the invention can reduce the bacterial contamination risk in the fermentation reaction. The auxiliary period time of fermentation culture is shortened, the utilization rate of a fermentation reactor is increased, the heat exchange efficiency is improved, and high application and popularization value is achieved.

Owner:ANHUI BBCA BIOCHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com