Method for preparing high-purity methyl acetate from low-purity methyl acetate

A low-purity methyl acetate technology, which is applied in the field of producing high-purity methyl acetate, can solve the problems of difficult extraction agent recovery, complex process, and high cost, and achieve low equipment investment, simple process flow, and low energy consumption in the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

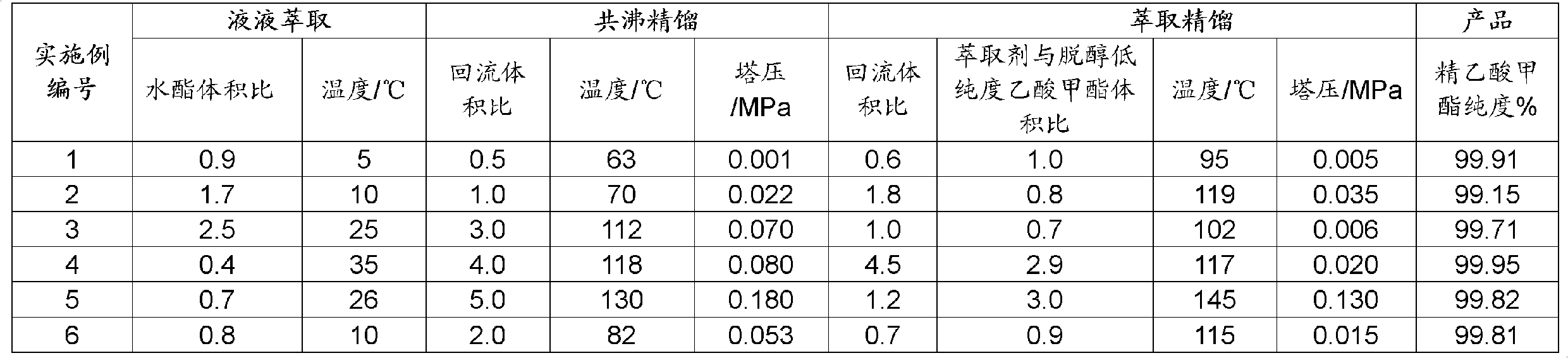

Embodiment 1

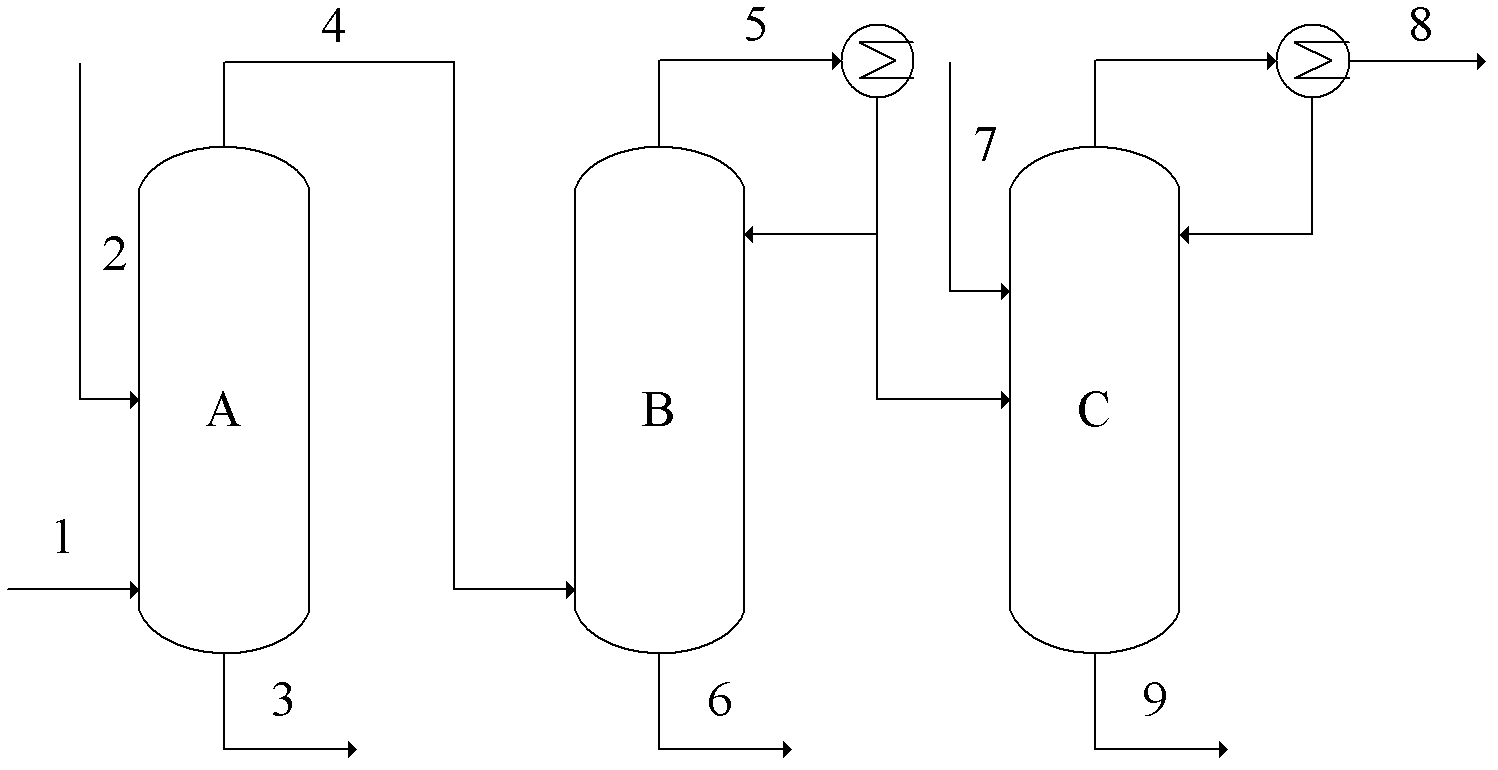

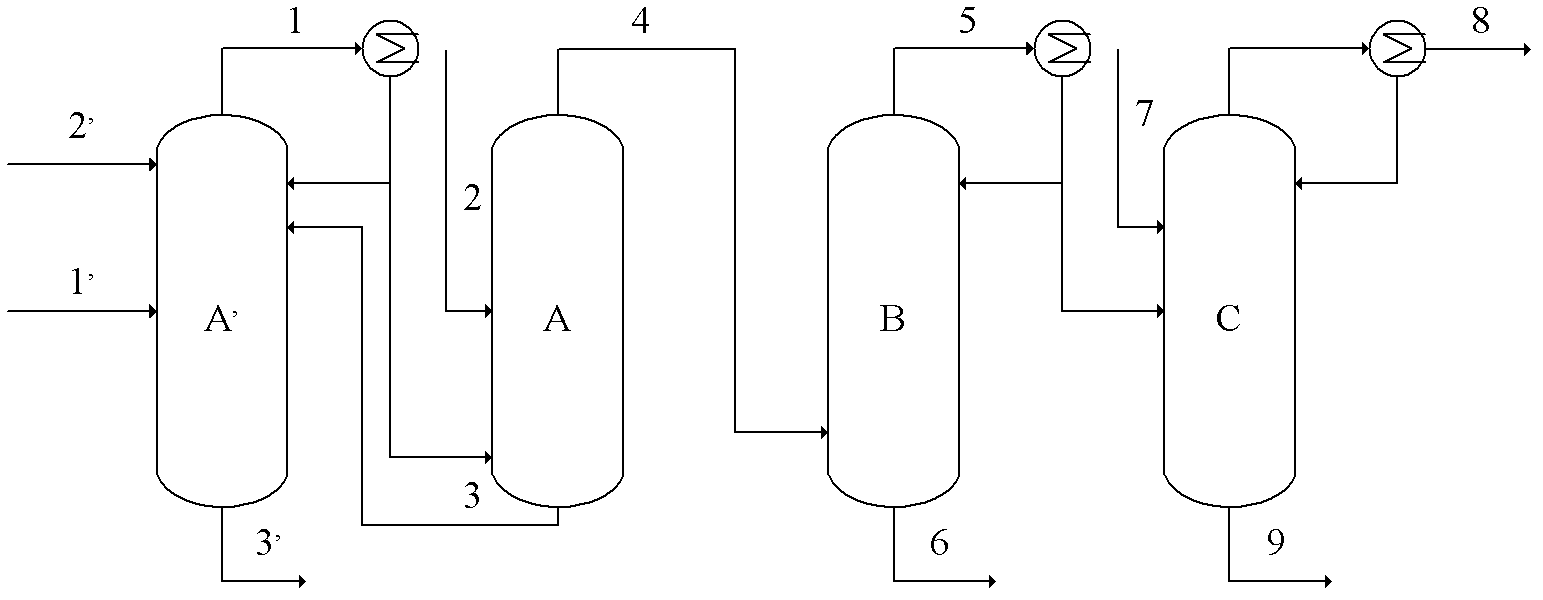

[0053] (a) refer to figure 1 As shown in the process flow, low-alcohol and low-purity methyl acetate 1 (wherein the mass fraction of methyl acetate is 91.3%, methanol is 0.9%, and the rest is water and other impurities) is added from the lower part of extraction tower A, and deionized water 2 is extracted from The middle part of tower A is added, and the low-alcohol and low-purity methyl acetate 1 is subjected to countercurrent extraction. The upper part of the extraction tower A obtains the raffinate 4 of methyl acetate, and its component mass fraction is methyl acetate 93.0% and methanol 0.053%. The extraction solution 3 containing methyl acetate and methanol in the tower kettle is subjected to rectification and purification to recover methyl acetate and methanol. Various control parameters of the liquid-liquid extraction: the volume ratio of the amount of deionized water 2 added to the low-alcohol low-purity methyl acetate is 0.9:1, and the extraction temperature is 5°C.

...

Embodiment 2

[0057] (a) refer to figure 1 As shown in the process flow, low-alcohol and low-purity methyl acetate 1 (wherein the mass fraction of methyl acetate is 87.5%, methanol is 1.95%, and the rest is water and other impurities) is added from the lower part of extraction tower A, and deionized water 2 is extracted from The middle part of tower A is added, and the low-alcohol and low-purity methyl acetate 1 is subjected to countercurrent extraction, and the raffinate 4 of methyl acetate is obtained in the upper part of the extraction tower A, and the mass fraction of its components is 92.5% of methyl acetate and 0.055% of methanol. The extraction solution 3 containing methyl acetate and methanol in the tower kettle carries out rectification and purification to reclaim methyl acetate and methanol. Various control parameters of liquid-liquid extraction: the volume ratio of deionized water 2 added to low-alcohol and low-purity methyl acetate is 1.7:1, and the extraction temperature is 10°...

Embodiment 3

[0061] (a) refer to figure 1As shown in the process flow, low-alcohol and low-purity methyl acetate 1 (wherein the mass fraction of methyl acetate is 72.8%, methanol is 4.95%, and the rest is water and other impurities) is added from the lower part of extraction tower A, and deionized water 2 is extracted from The middle part of tower A is added, and the low-alcohol and low-purity methyl acetate 1 is subjected to countercurrent extraction, and the raffinate 4 of methyl acetate is obtained in the upper part of the extraction tower A, and its component mass fraction is methyl acetate 91.5% and methanol 0.14%. The extraction solution 3 containing methyl acetate and methanol in the tower kettle is subjected to rectification and purification to recover methyl acetate and methanol. The control parameters of the liquid-liquid extraction: the volume ratio of the amount of deionized water 2 added to the low-alcohol low-purity methyl acetate is 2.5:1, and the extraction temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com