Controlling method of automatic threaded sleeve assembling mechanism

An automatic assembly and control method technology, applied in computer control, program control, general control system, etc., can solve the problems of cumbersome recording of workpiece serial number assembly time, torque, depth, etc., difficult operation, and high labor cost. Achieve real-time information scanning code retrieval query, avoid recording and retrieval, and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

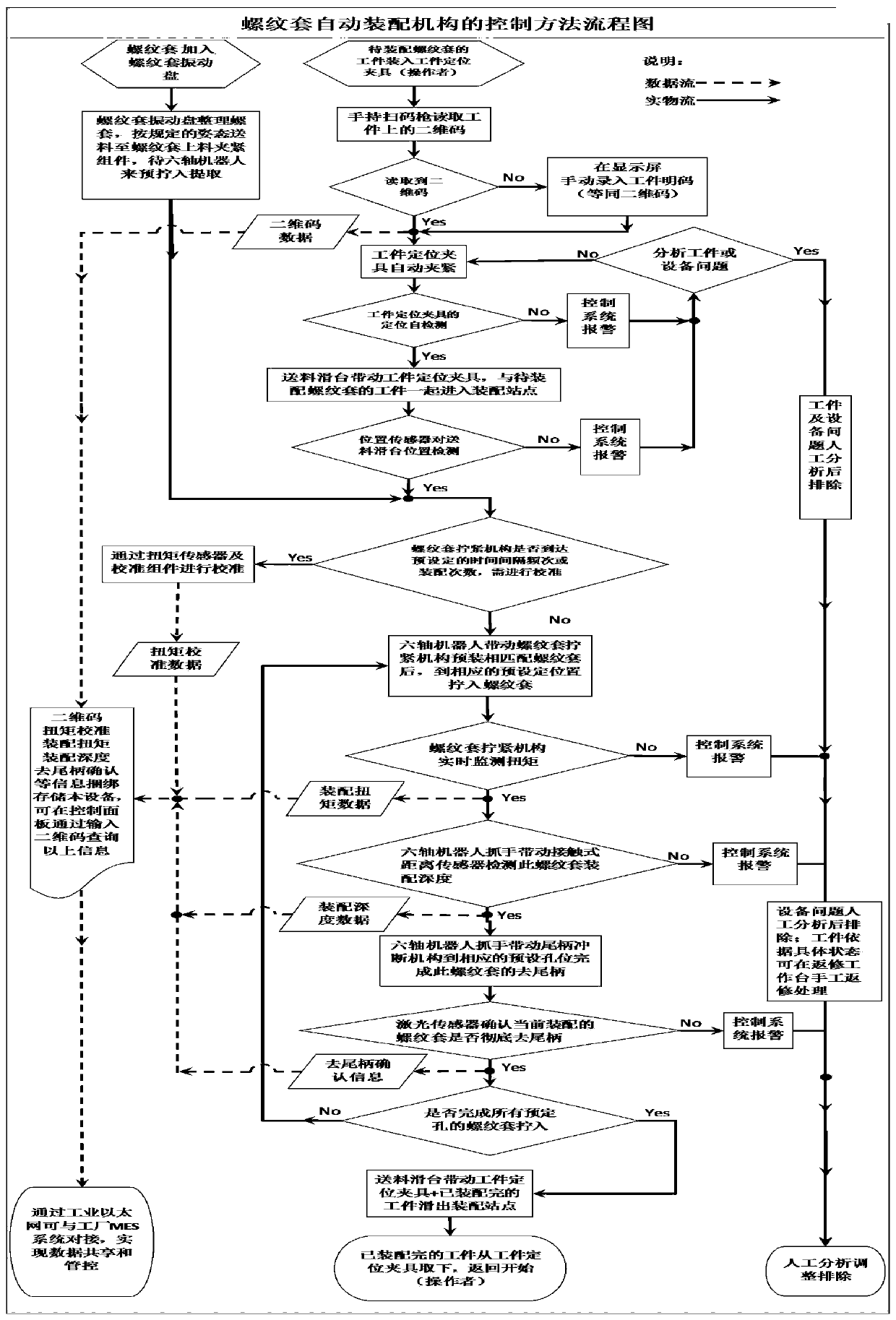

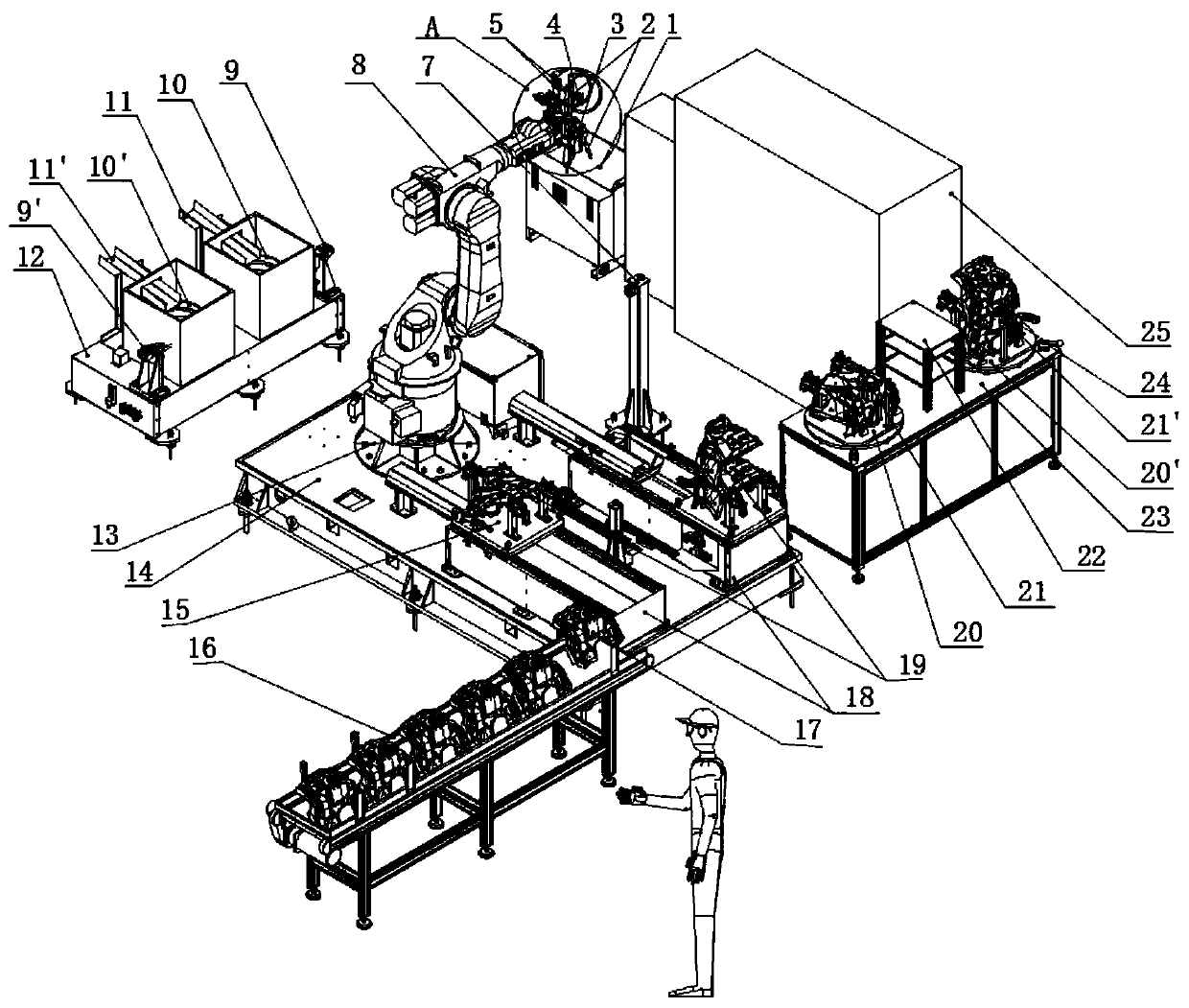

[0044] The present invention is described in detail below in conjunction with accompanying drawing:

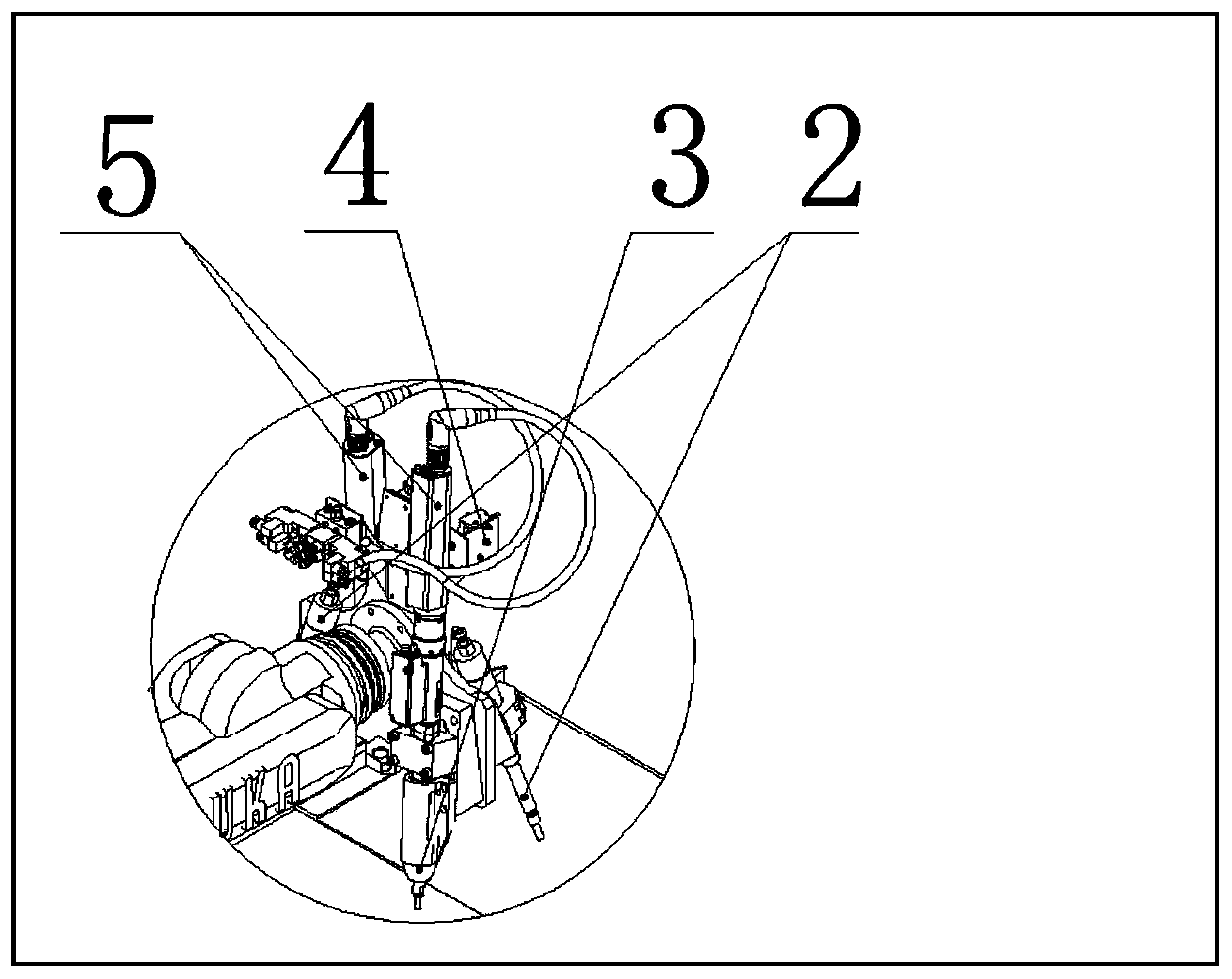

[0045] refer to figure 2 , image 3 , Figure 5 , the whole equipment is mainly composed of feeding slide 18, workpiece positioning fixture 15, hand-held code scanning gun 27, blanking line 16, six-axis robot 8, tail handle punching mechanism 2, threaded sleeve installation mandrel 3, laser sensor 4, thread Sleeve tightening mechanism 5, contact distance sensor 6, threaded sleeve vibration plate 10, threaded sleeve feeding and clamping assembly 12, torque sensor and calibration assembly 7, equipment base assembly 14, control system 25, touch display screen 26, repair work Major components such as Taiwan 23 are formed.

[0046] Through a six-axis robot 8, a threaded sleeve vibration plate 10, a threaded sleeve feeding and clamping assembly 9, a threaded sleeve tightening mechanism 5, a tail handle punching mechanism 2, a laser sensor 4, a contact distance sensor 6, and a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com