Colloid storage battery electrolyte and preparation method thereof

A colloidal battery and electrolyte technology, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of small capacity and large internal resistance, and achieve stable and controllable process, low cost and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

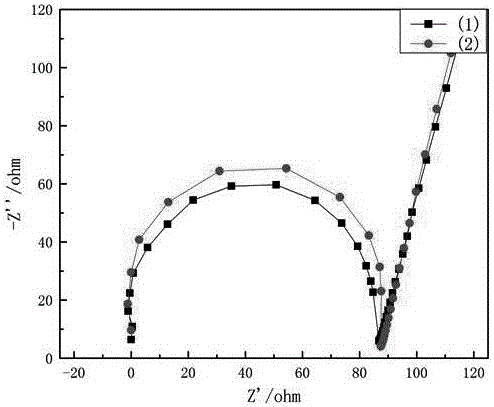

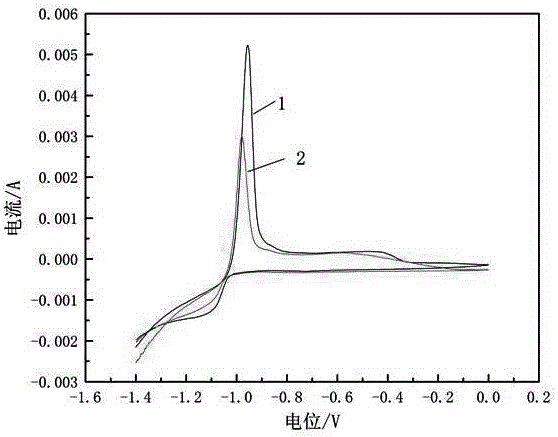

Image

Examples

Embodiment 1

[0021] Weigh 12.48mL of water into a 50mL small beaker, and weigh 1.8791g of fumed silica into the small beaker to make a fumed silica hydrosol (ultrasound if necessary). Dilute 98% concentrated sulfuric acid with deionized water into an aqueous solution of sulfuric acid with a specific gravity of 1.37, let it stand to cool to room temperature and perform freezing treatment. Add 20mL of sulfuric acid aqueous solution with a specific gravity of 1.37 into the fumed silica hydrosol and mix thoroughly. Weigh polyvinylpyrrolidone accounting for 0.04% of the total mass of the gel battery electrolyte, add it to the above mixed solution, stir and mix thoroughly, and make the gel battery electrolyte.

Embodiment 2

[0023] Weigh 12.48mL of water into a 50mL small beaker, and weigh 1.8791g of fumed silica into the small beaker to make a fumed silica hydrosol (ultrasound if necessary). Dilute 98% concentrated sulfuric acid with deionized water into an aqueous solution of sulfuric acid with a specific gravity of 1.37, let it stand to cool to room temperature and perform freezing treatment. Add 20mL of sulfuric acid aqueous solution with a specific gravity of 1.37 into the fumed silica hydrosol and mix thoroughly. Weigh polyvinylpyrrolidone accounting for 0.08% of the total mass of the gel battery electrolyte, add it to the above mixed solution, stir and mix thoroughly, and make the gel battery electrolyte.

Embodiment 3

[0025] Weigh 12.48ml of water into a 50ml small beaker, and weigh 1.8791g of fumed silica into the small beaker to make a fumed silica hydrosol (ultrasound if necessary). Dilute 98% concentrated sulfuric acid with deionized water into an aqueous solution of sulfuric acid with a specific gravity of 1.37, let it stand to cool to room temperature and perform freezing treatment. Add 20ml of sulfuric acid aqueous solution with a specific gravity of 1.37 into the fumed silica hydrosol and mix thoroughly. Weigh polyvinylpyrrolidone accounting for 0.12% of the total mass of the electrolyte of the colloidal battery, add it to the above mixed solution, stir and mix thoroughly to prepare the electrolyte of the colloidal battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com