Preparation method for biomass charcoal adsorbent loaded with chitosan magnetic nanoparticles

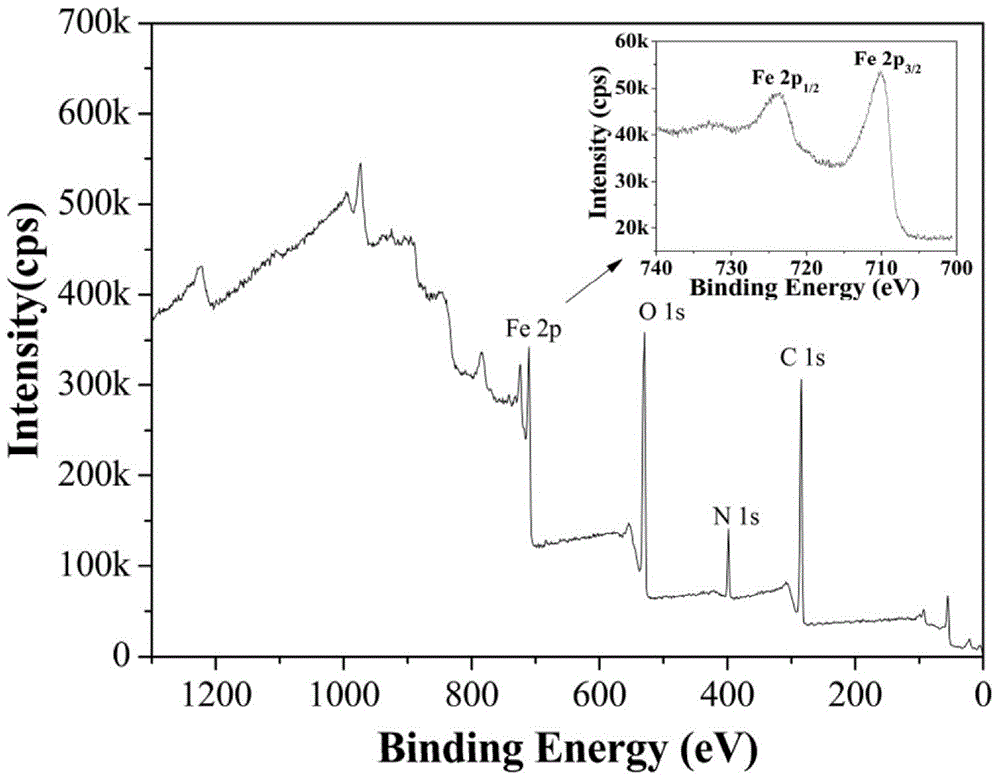

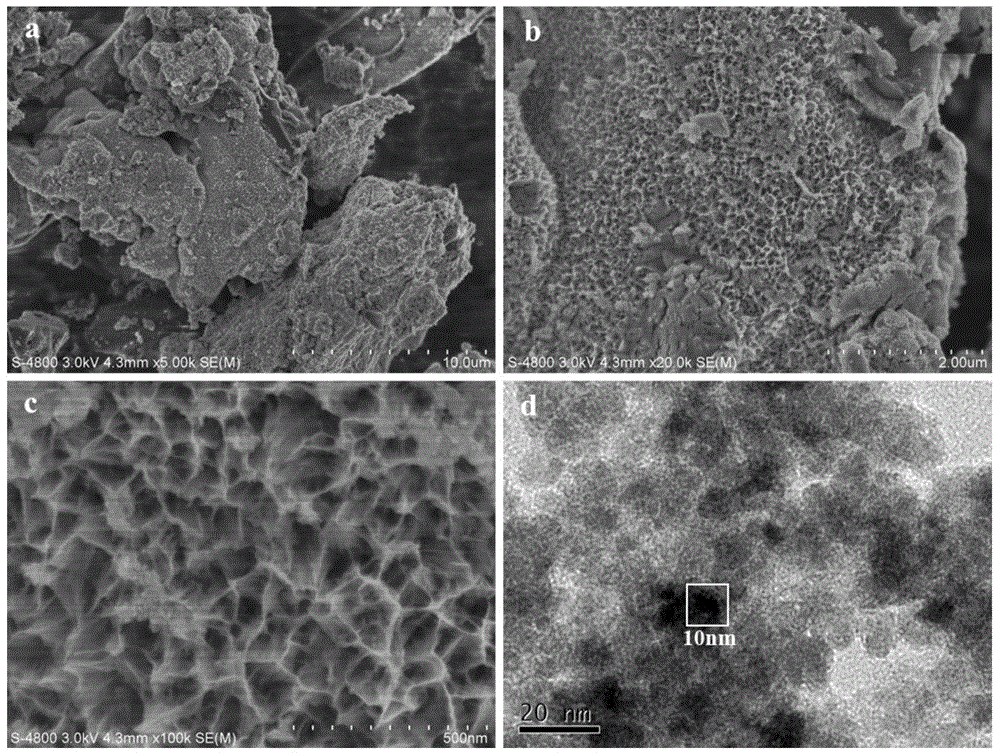

A magnetic nanoparticle, chitosan-loaded technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve the effect of reducing loss, stable quality, and large saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

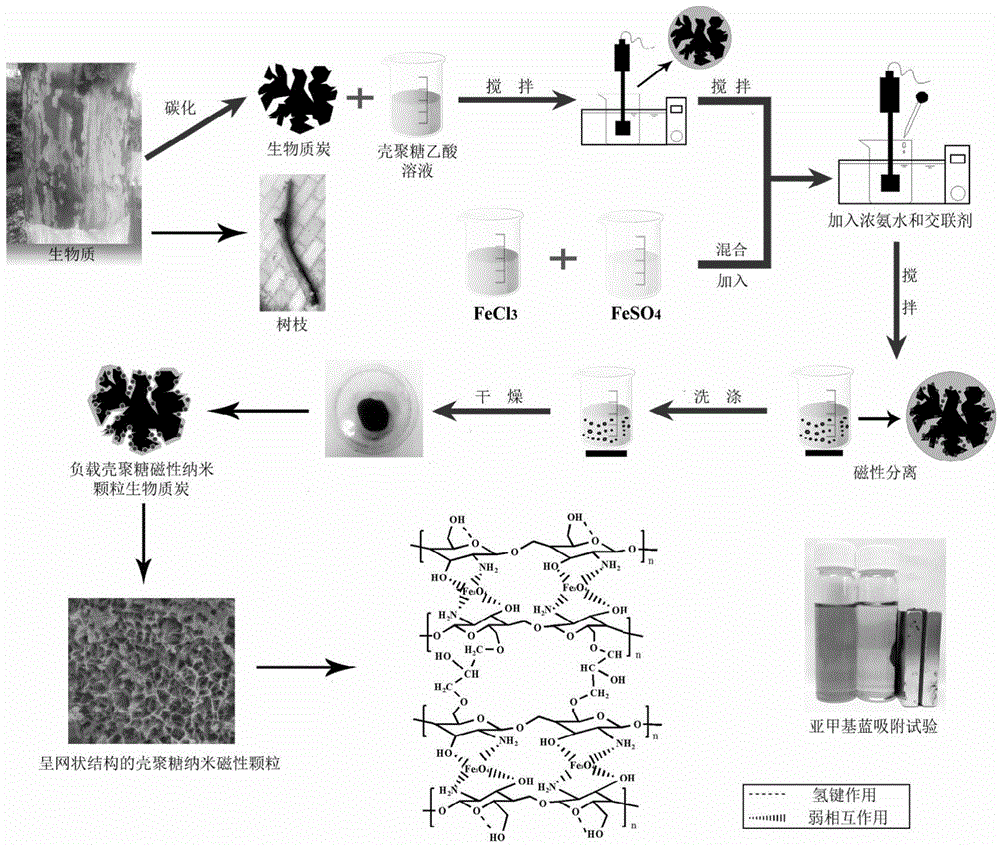

[0027] Load chitosan magnetic nanoparticle biochar adsorbent, its preparation process is as follows:

[0028] (1) Preparation of biochar: dry the biomass (wood, agricultural waste, activated sludge sludge cake, etc.) After the temperature is stable, maintain it for 1 hour, take out the powder after cooling, and obtain powdery biochar;

[0029] (2) The configuration of chitosan-acetic acid solution: mix glacial acetic acid, chitosan and water, the dosage ratio of glacial acetic acid, chitosan and water is 2.5mL: 2.5g: 500mL, let it stand still, and the shell Polysaccharide-acetic acid solution;

[0030] (3) Preparation of iron solution: dissolve ferric chloride and ferrous sulfate in a small amount of water, the molar ratio of ferric chloride and ferrous sulfate is 2:1, and the solution is prepared and used immediately.

[0031] (4) Preparation of biochar adsorbent loaded with chitosan magnetic nanoparticles: mix a certain mass of powdered biochar with chitosan-acetic acid so...

Embodiment 2

[0040] Load chitosan magnetic nanoparticle biochar adsorbent, its preparation process is as follows:

[0041] (1) Preparation of biochar: dry the biomass (wood, agricultural waste, activated sludge sludge cake, etc.) After the temperature is stable, keep it for 0.5h, take out the powder after cooling, and then get the powdery biochar;

[0042] (2) Configuration of chitosan-acetic acid solution: mix glacial acetic acid, chitosan and water evenly, the dosage ratio of glacial acetic acid, chitosan and water is 5.0mL: 5.0g: 500mL, let it stand still to obtain shell Polysaccharide-acetic acid solution;

[0043] (3) Preparation of iron solution: Dissolve ferric chloride and ferrous sulfate in a small amount of water, the molar ratio of ferric chloride and ferrous sulfate is 3:1, and the solution is prepared and used immediately.

[0044](4) Preparation of biochar adsorbent loaded with chitosan magnetic nanoparticles: mix a certain mass of powdered biochar with chitosan-acetic acid...

Embodiment 3

[0048] Load chitosan magnetic nanoparticle biochar adsorbent, its preparation process is as follows:

[0049] (1) Preparation of biochar: dry the biomass (wood, agricultural waste, activated sludge sludge cake, etc.) After the temperature is stable, maintain it for 2.0 hours, take out the powder after cooling, and obtain powdery biochar;

[0050] (2) The configuration of chitosan-acetic acid solution: mix glacial acetic acid, chitosan and water, the dosage ratio of glacial acetic acid, chitosan and water is 1.0mL: 2.0g: 500mL, let it stand still, and the shell Polysaccharide-acetic acid solution;

[0051] (3) Preparation of iron solution: dissolve ferric chloride and ferrous sulfate in a small amount of water, the molar ratio of ferric chloride and ferrous sulfate is 1:1, and the solution is prepared and used immediately.

[0052] (4) Preparation of biochar adsorbent loaded with chitosan magnetic nanoparticles: mix a certain mass of powdered biochar with chitosan-acetic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com