Material heat exchange system and method for fermentation reaction

A technology of heat exchange system and fermented material, which is applied in the field of material heat exchange system, can solve the problems of small space, high operating cost of circulating water, and difficult maintenance of heat exchange structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] Example 1: Heat Exchange System

[0145] The present embodiment provides a heat exchange system for fermentation reaction, which specifically includes:

[0146] A total of 40 meters of latex tubes of DN15 are connected from the bottom of the fermentation reactor, of which 30 meters are formed into a circle with a diameter of 25cm and hovered in a 40L stainless steel container. The stainless steel container is filled with running tap water to keep the temperature low. Place spring water stop clips on the latex tube. The latex tubing was fed into a stainless steel container by a peristaltic pump at the 1 m position. After the latex tube came out of the stainless steel container, it was connected to the fermentation reactor through the feed port at the top of the fermentation reactor.

Embodiment 2

[0147] Example 2: Heat Exchange System

[0148] The present embodiment provides a heat exchange system for fermentation reaction, which specifically includes:

[0149] This embodiment provides a heat exchange system for fermentation reaction. A total of 40 meters of stainless steel hoses of DN15 are connected from the bottom of the fermentation reactor, of which 30 meters are formed into a circle with a diameter of 25cm and are coiled in a stainless steel container of a 100L chiller. . The stainless steel container is filled with ice water to keep the temperature low. Stainless steel hoses use sanitary ball valves to control material flow. The stainless steel hose pipeline enters the stainless steel container through a sanitary centrifugal pump at a position of 1 meter. After the stainless steel pipe comes out of the stainless steel container, it is connected to the fermentation reactor through the feed port on the upper part of the fermentation reactor.

Embodiment 3

[0150] Example 3: Heat Exchange System

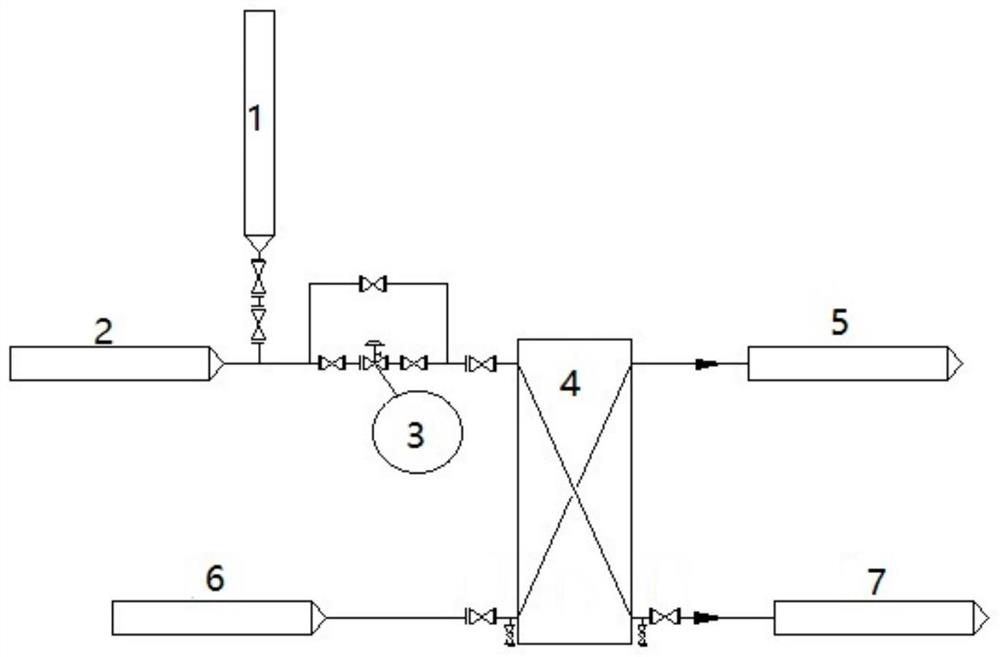

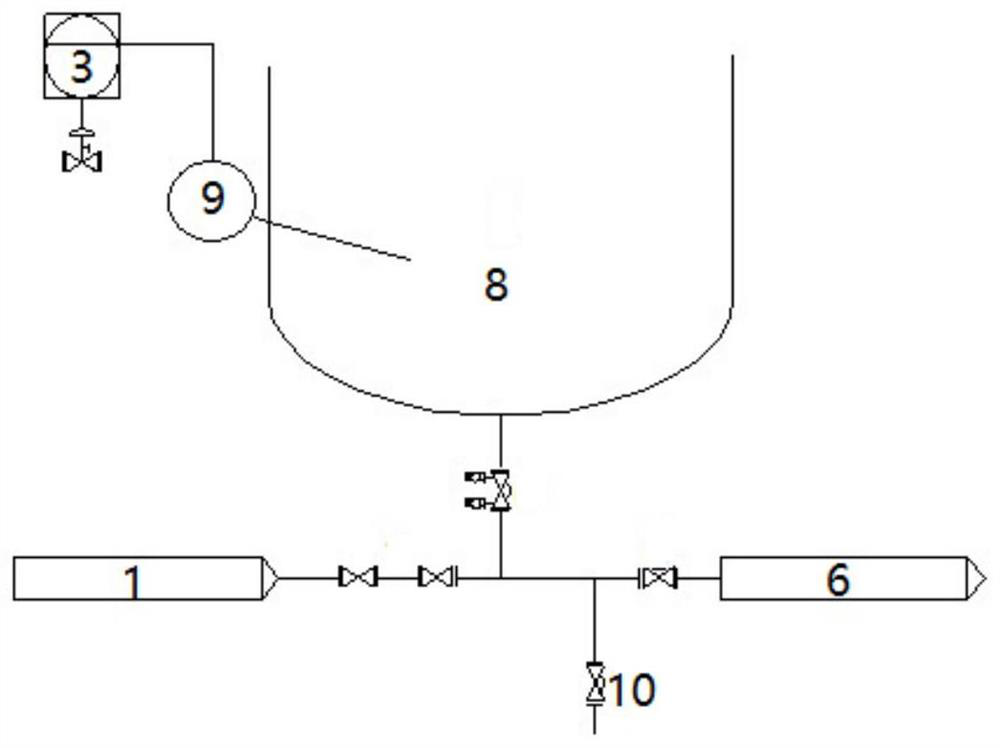

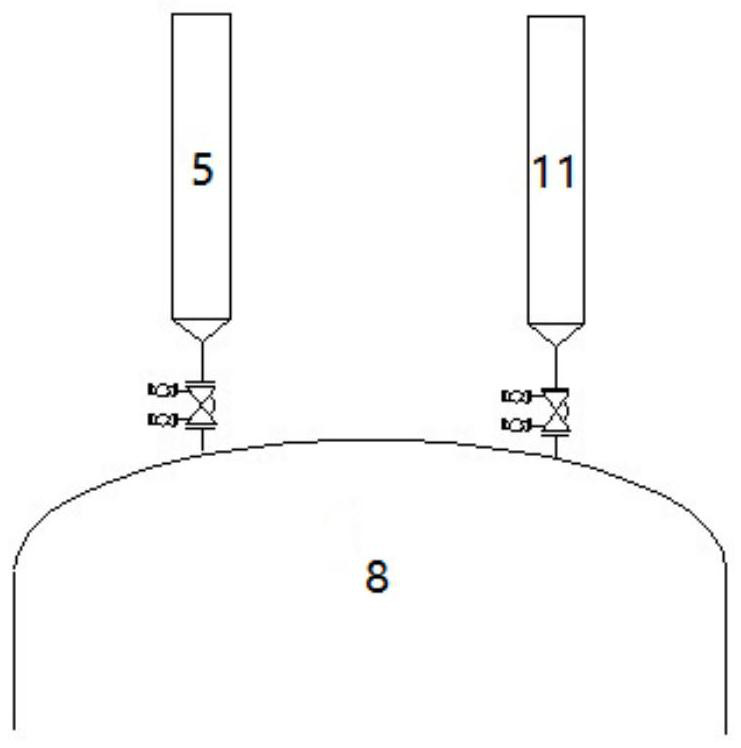

[0151] This embodiment provides a heat exchange system for fermentation reaction, which specifically includes a fermentation material outflow pipe 6, a fermentation material heat exchange pipe, and a fermentation material inflow pipe 5 connected in sequence; the heat exchange pipe passes through a plate heat exchanger 4. Fully exchange heat between the fermentation material in the pipeline and the cold and hot medium / substance introduced into the plate heat exchanger 4 (the cold and hot medium is input through the cold and hot medium source pipe 2, and is output through the cold and hot medium return pipe 7) to achieve Heat exchange of fermentation material (e.g. figure 1 shown); the inlet of the fermented material outflow pipeline 6 is connected with the discharge port at the bottom of the fermentation reactor 8, and the bottom of the fermentation reactor is also provided with a filter device and a blowdown valve 10 (such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com