Method for prevention of generation of power oscillation in main stop valve full-stroke test of steam turbine

A power oscillation and steam turbine technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as excessive valve closing speed, tripping of machines and furnaces, parameter fluctuations, etc., to prevent power fluctuations And the effect of power oscillation, preventing power oscillation, and reducing the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

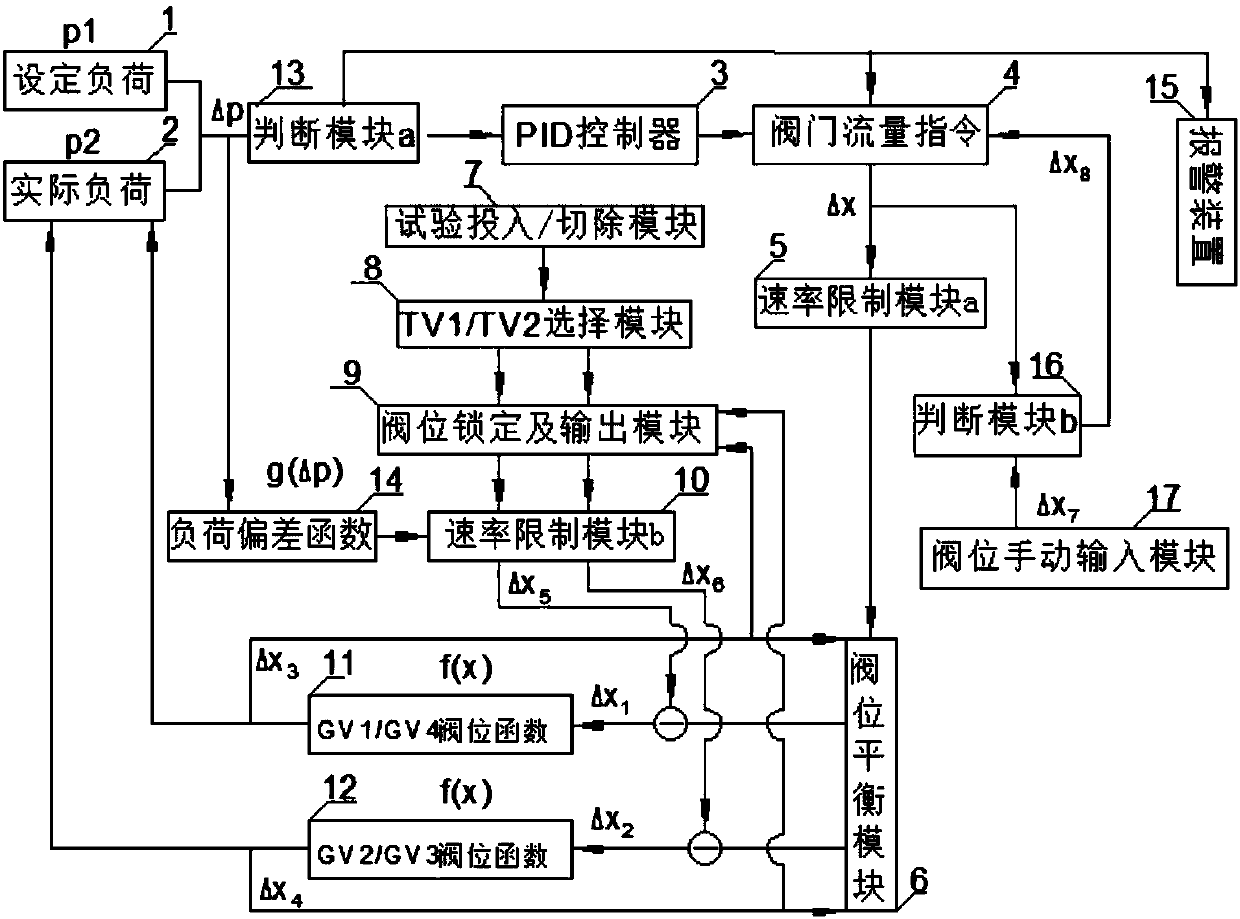

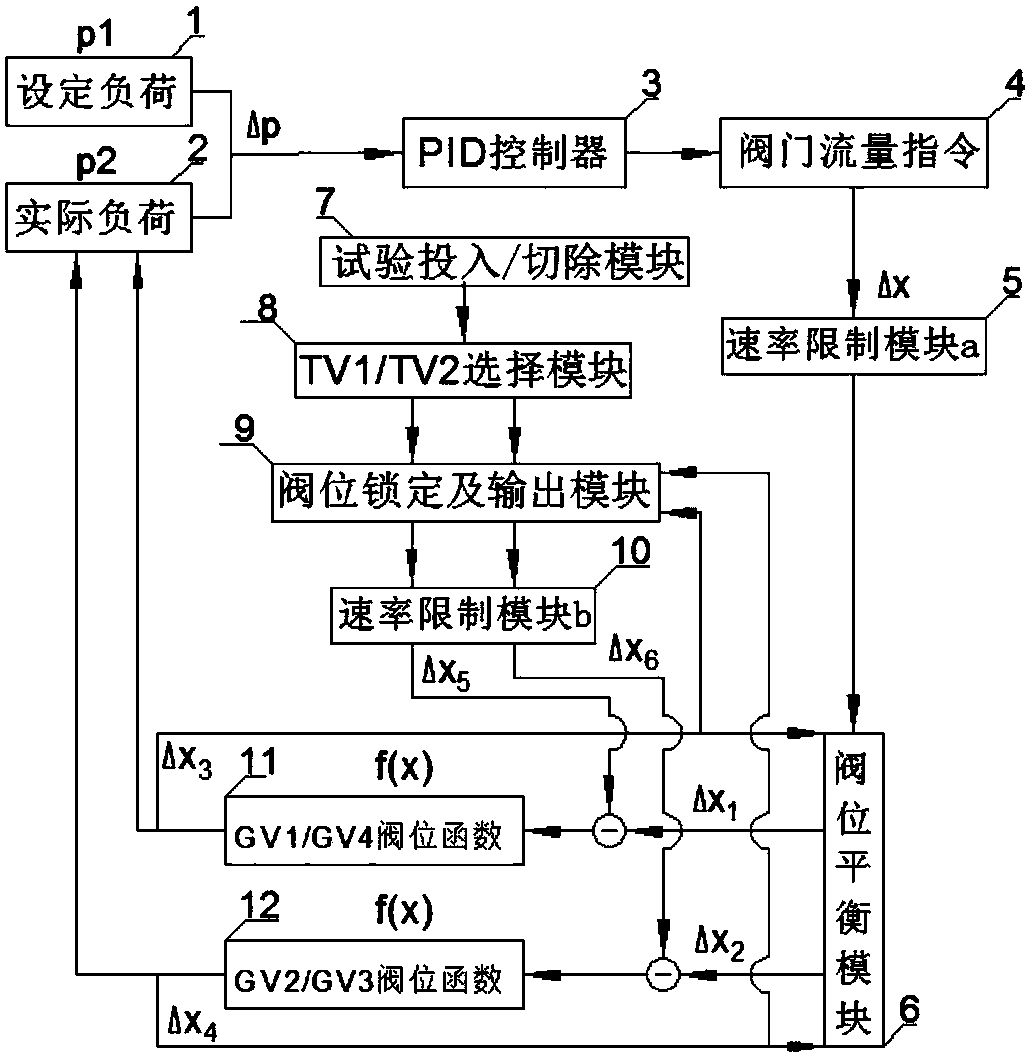

[0032] The technical scheme of the invention is described in detail below in conjunction with the accompanying drawings. Taking the main steam valve 1 of the steam turbine unit, that is, the full stroke activity test of TV1, as an example, the steam turbine load is below 70% of the rated value, and the AGC is cut off, coordinated control, and primary frequency regulation. The steam turbine runs at Single valve, power control loop mode.

[0033] (1) When |Δp|

[0034] a) The load deviation value Δp is input to the PID controller 3 module after being judged by the judgment module a13, and then sequentially passes through the valve flow command module 4, the rate lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com