Method for preparing aluminium oxide and phosphorus-containing fertilizer from methanol-to-olefin waste catalyst

A technology for methanol to olefins and waste catalysts, which is used in alumina/aluminum hydroxide, alumina/hydroxide preparation, fertilizer mixtures, etc., can solve problems such as unsuitability for recycling, and achieve stable, controllable and operable processes. Strong sex, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

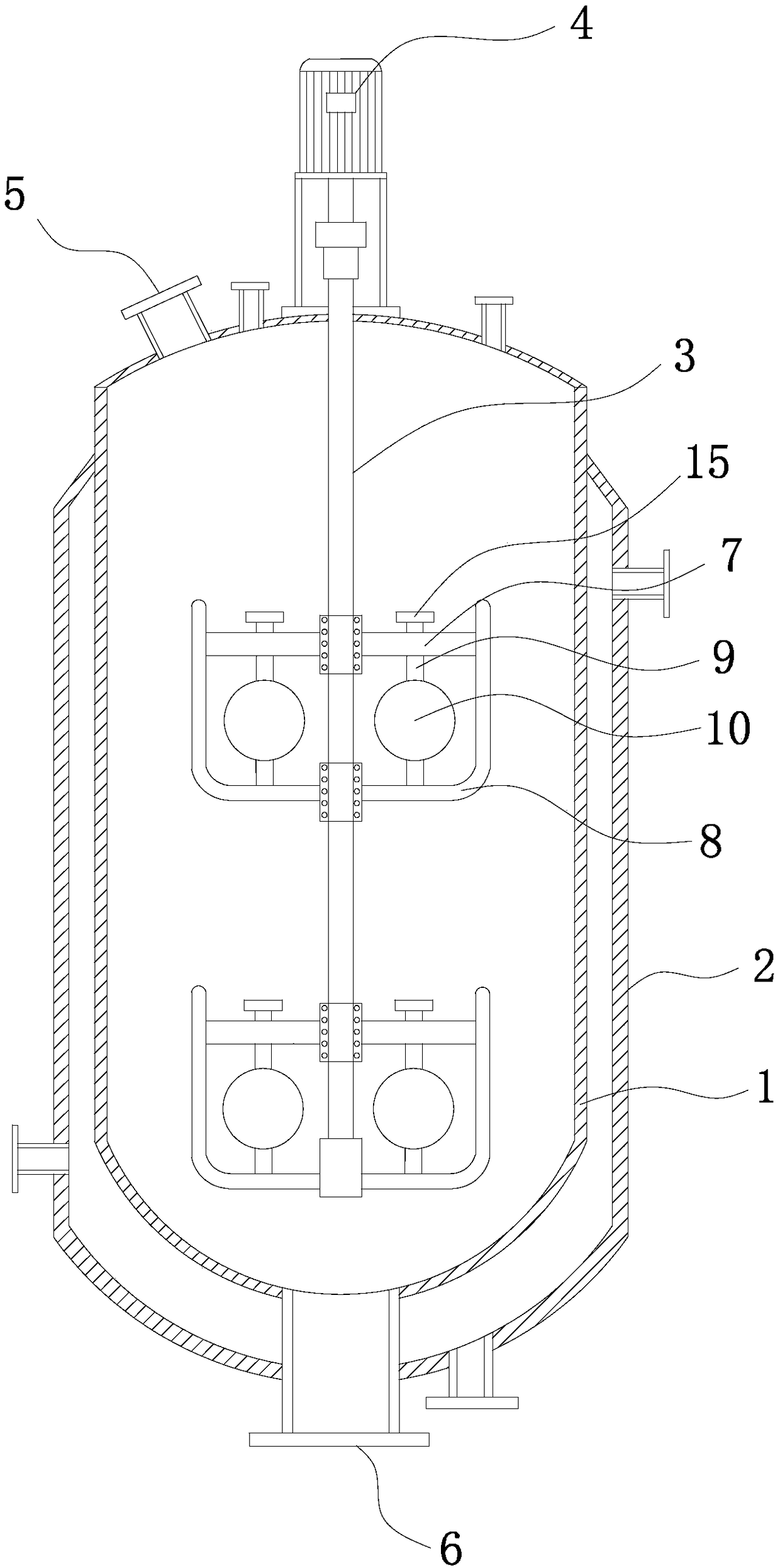

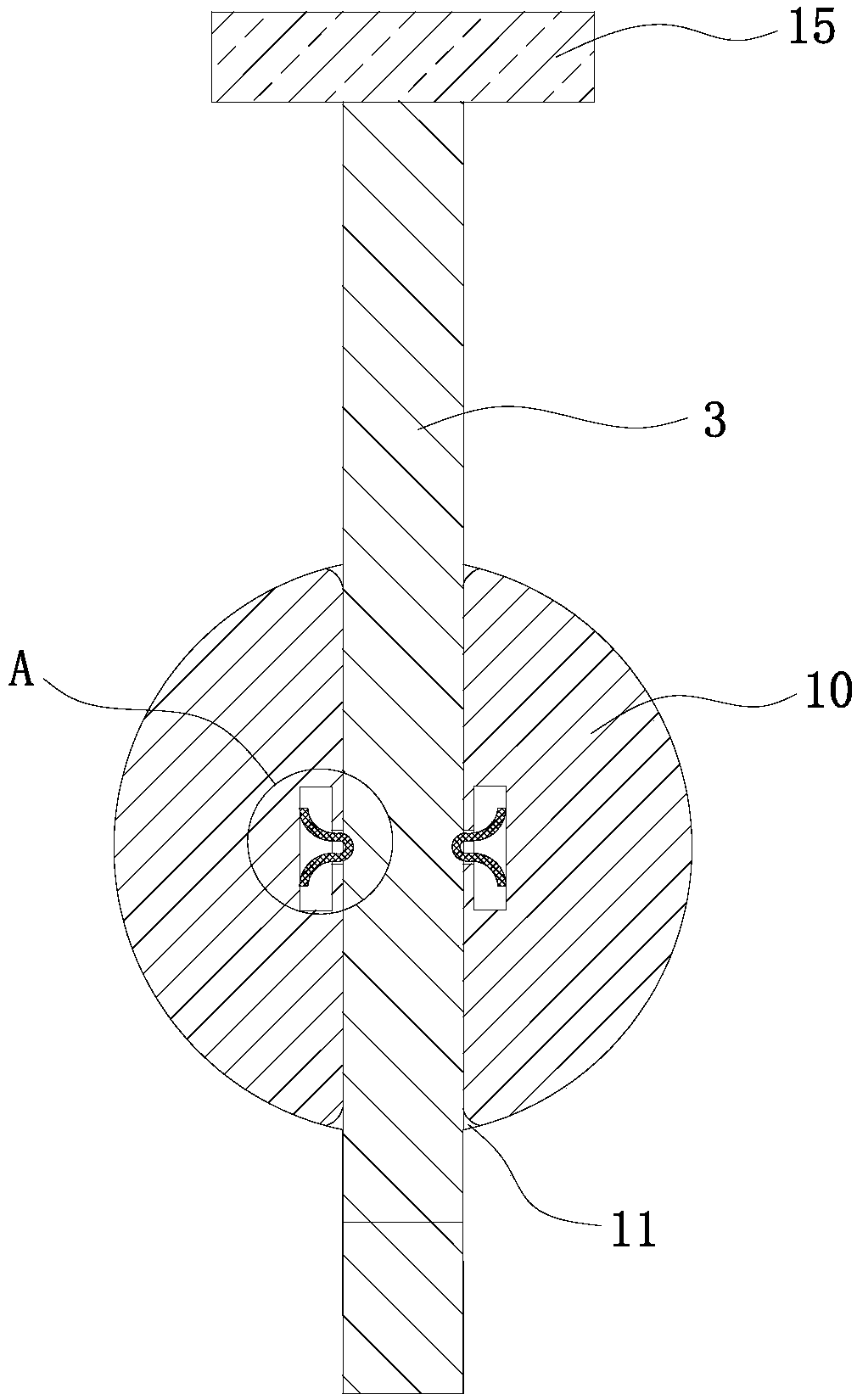

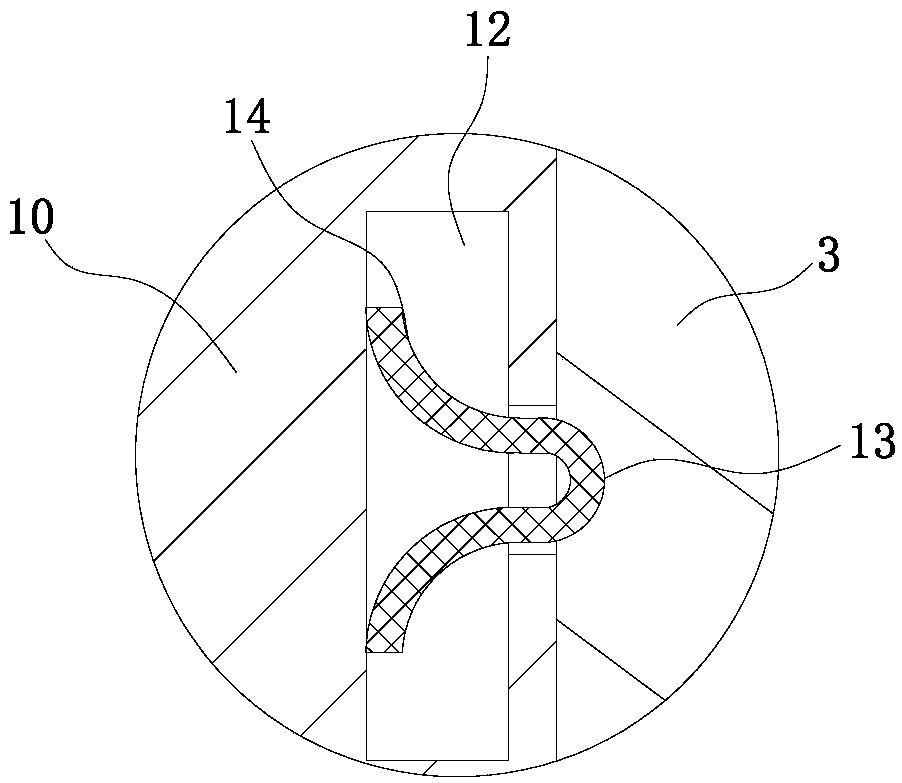

Image

Examples

Embodiment 1

[0033] (1) After the waste catalyst is mixed with the decomposition aid calcium peroxide, it is sent into the rotary kiln to be calcined once, cooled, and the primary calcined material is obtained. After the waste catalyst is mixed with the decomposition aid, the decomposition aid accounts for 3% of the total mass of the mixture. %, the calcination temperature for the first calcination is 500°C, the calcination time is 20min, and it is cooled to 75°C after calcination;

[0034] (2) Mix the primary calcined material with ammonium sulfate and send it into the disc tunnel kiln for secondary calcination, and cool to obtain the secondary calcined material. Mixing at a ratio of 1:7, the calcination temperature for the secondary calcination is 380°C, the calcination time is 160min, and cooled to 115°C after calcination;

[0035] (3) adding the secondary calcined material into the sulfuric acid solution with a mass concentration of 10% for leaching, cooling, and filtering to obtain th...

Embodiment 2

[0040] (1) After the waste catalyst is mixed with the decomposition aid calcium peroxide, it is sent into the rotary kiln to be calcined once, and cooled to obtain the primary calcined material. After the waste catalyst is mixed with the decomposition aid, the decomposition aid accounts for 5% of the total mass of the mixture. %, the calcination temperature of the primary calcination is 700°C, the calcination time is 10min, and cooled to 85°C after calcination;

[0041] (2) Mix the primary calcined material with ammonium sulfate and send it into the disc tunnel kiln for secondary calcination, and cool to obtain the secondary calcined material. Mixing at a ratio of 1:9, the calcination temperature for the secondary calcination is 420°C, the calcination time is 130min, and cooled to 125°C after calcination;

[0042] (3) adding the secondary calcined material into the sulfuric acid solution with a mass concentration of 10% for leaching, cooling, and filtering to obtain the filtra...

Embodiment 3

[0047] (1) After the waste catalyst is mixed with the decomposition aid calcium peroxide, it is sent into the rotary kiln to be calcined once, and cooled to obtain a primary calcined material. After the waste catalyst is mixed with the decomposition aid, the decomposition aid accounts for 4% of the total mass of the mixture. %, the calcination temperature for one calcination is 600°C, the calcination time is 15min, and it is cooled to 80°C after calcination;

[0048] (2) Mix the primary calcined material with ammonium sulfate and send it into the disc tunnel kiln for secondary calcination, and cool to obtain the secondary calcined material. Mixing at a ratio of 1:8, the calcination temperature for the secondary calcination is 400°C, the calcination time is 150min, and cooled to 120°C after calcination;

[0049] (3) adding the secondary calcined material into the sulfuric acid solution with a mass concentration of 10% for leaching, cooling, and filtering to obtain the filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com