Method for preparing oxidation-resistant active peptides from crab shells by double-enzyme multistep enzymolysis

A step-by-step enzymatic hydrolysis technology for antioxidant active peptides, which is applied to the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve problems such as pollution of resources and waste, and achieve stable and controllable processes, simple process steps, and increased The effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Raw material pretreatment: wash the crab shells with water, dry them in the air, and pulverize them with a pulverizer to obtain crab shell powder for later use;

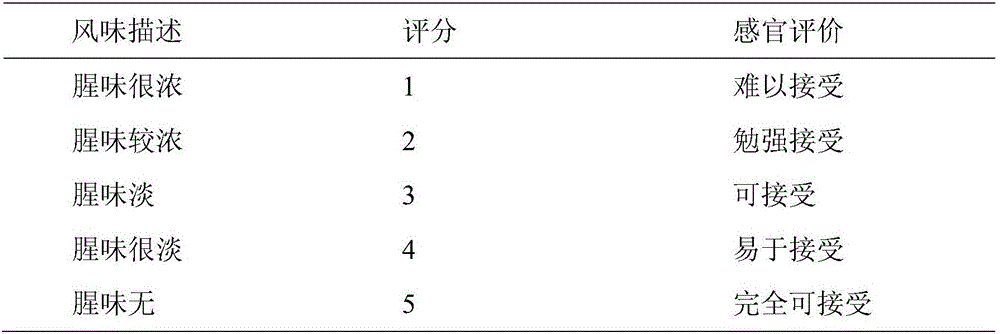

[0019] (2) Dual-enzyme enzymatic hydrolysis: mix crab shell powder and water at a mass ratio of 1:5, adjust the pH to 2.0, keep warm at 30°C for 10 minutes, add 0.1% of the mass of crab shell powder and 20,000 U / g of enzyme activity Acid protease, heat preservation enzymolysis for 6 hours under stirring condition, rise to 95°C to inactivate enzyme for 15min, cool to 50°C, adjust pH to 6.5, add flavor protease with 0.1% of crab shell powder mass and enzyme activity ≥30000U / g, in Under the condition of stirring, incubate the enzymatic hydrolysis at 50°C for 2 hours, then raise the temperature to 95°C to inactivate the enzyme for 10 minutes to obtain the enzymatic hydrolysis solution;

[0020] (3) Centrifugal separation: perform high-speed centrifugation on the enzymatic hydrolysis solution, and take the supe...

Embodiment 2

[0025] (1) Raw material pretreatment: wash the crab shells with water, dry them in the air, and pulverize them with a pulverizer to obtain crab shell powder for later use;

[0026] (2) Double-enzyme hydrolysis: mix crab shell powder and water at a mass ratio of 1:10, adjust the pH to 3.0, keep warm at 40°C for 20 minutes, add 0.3% crab shell powder mass and 50,000 U / g enzyme activity Acid protease, heat preservation enzymolysis for 8 hours under stirring conditions, rise to 100°C to inactivate enzyme for 20min, cool to 60°C, adjust pH to 7.5, add flavor protease with 0.3% of crab shell powder mass and enzyme activity ≥30000U / g, in Under the condition of stirring, incubate the enzymatic hydrolysis at 60°C for 4 hours, then raise the temperature to 100°C to inactivate the enzyme for 20 minutes to obtain the enzymatic hydrolysis solution;

[0027] (3) Centrifugal separation: perform high-speed centrifugation on the enzymatic hydrolysis solution, and take the supernatant to obtain...

Embodiment 3

[0032] (1) Raw material pretreatment: wash the crab shells with water, dry them in the air, and pulverize them with a pulverizer to obtain crab shell powder for later use;

[0033] (2) Double-enzyme enzymatic hydrolysis: mix crab shell powder and water at a mass ratio of 1:7, adjust the pH to 2.5, incubate at 35°C for 15 minutes, add 0.2% crab shell powder mass and 30,000 U / g enzyme activity Acid protease, heat preservation enzymolysis for 7 hours under stirring condition, rise to 98°C to inactivate enzyme for 17min, cool to 55°C, adjust pH to 7.2, add flavor protease with 0.2% of crab shell powder mass and enzyme activity ≥30000U / g, in Under the condition of stirring, incubate the enzymatic hydrolysis at 55°C for 3 hours, then raise the temperature to 97°C to inactivate the enzyme for 15 minutes to obtain the enzymatic hydrolysis solution;

[0034] (3) Centrifugal separation: perform high-speed centrifugation on the enzymatic hydrolysis solution, and take the supernatant to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com