Clamp used for supporting long and thin tools

A tool and fixture technology, applied in the field of fixtures supporting slender tools, can solve the problems of low yield rate of tool processing, inability to automatically feed materials, long length of tool clamped by the chuck, etc., to improve tool processing quality and yield , Improve tool processing quality, reduce the effect of feeding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

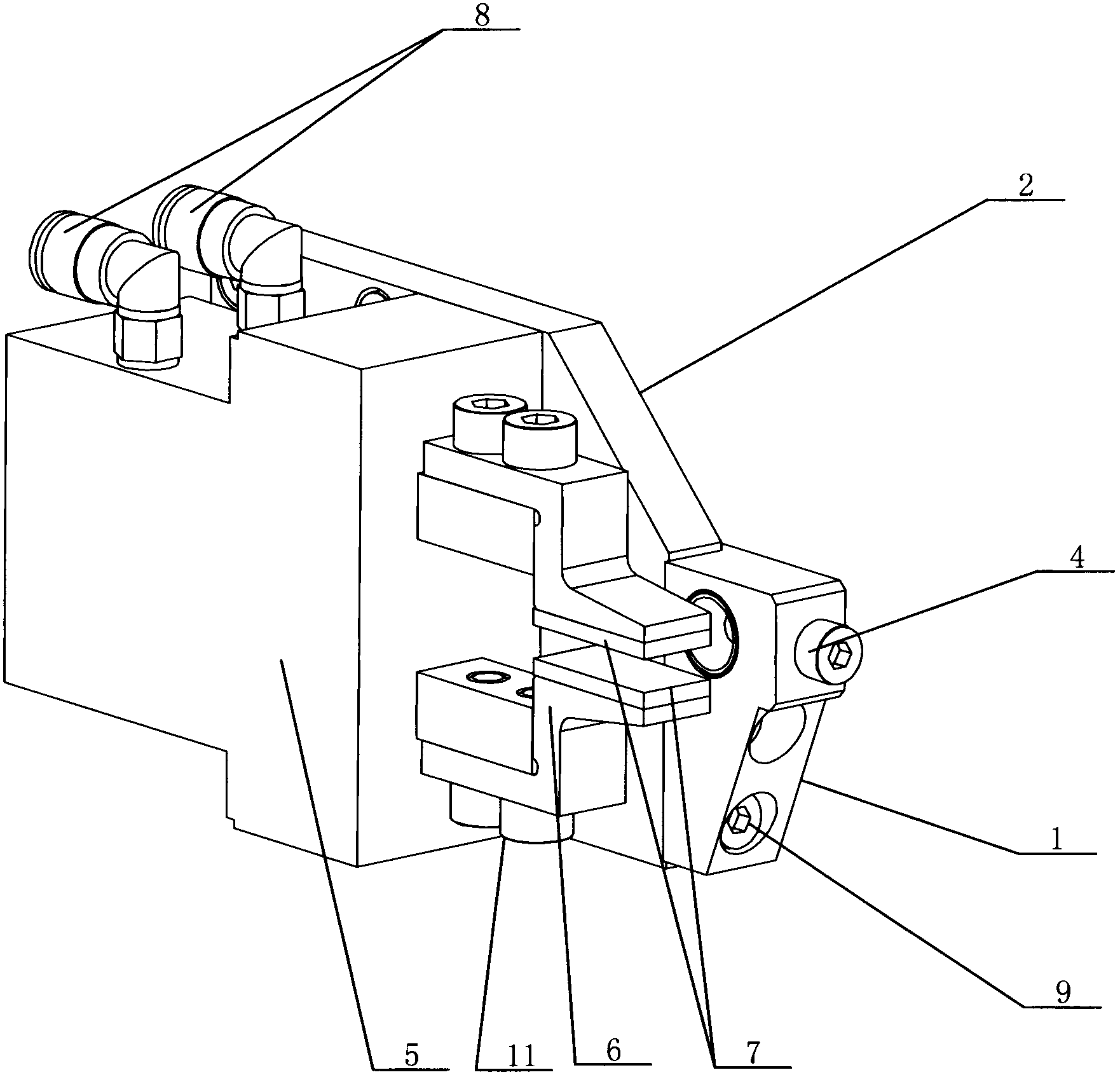

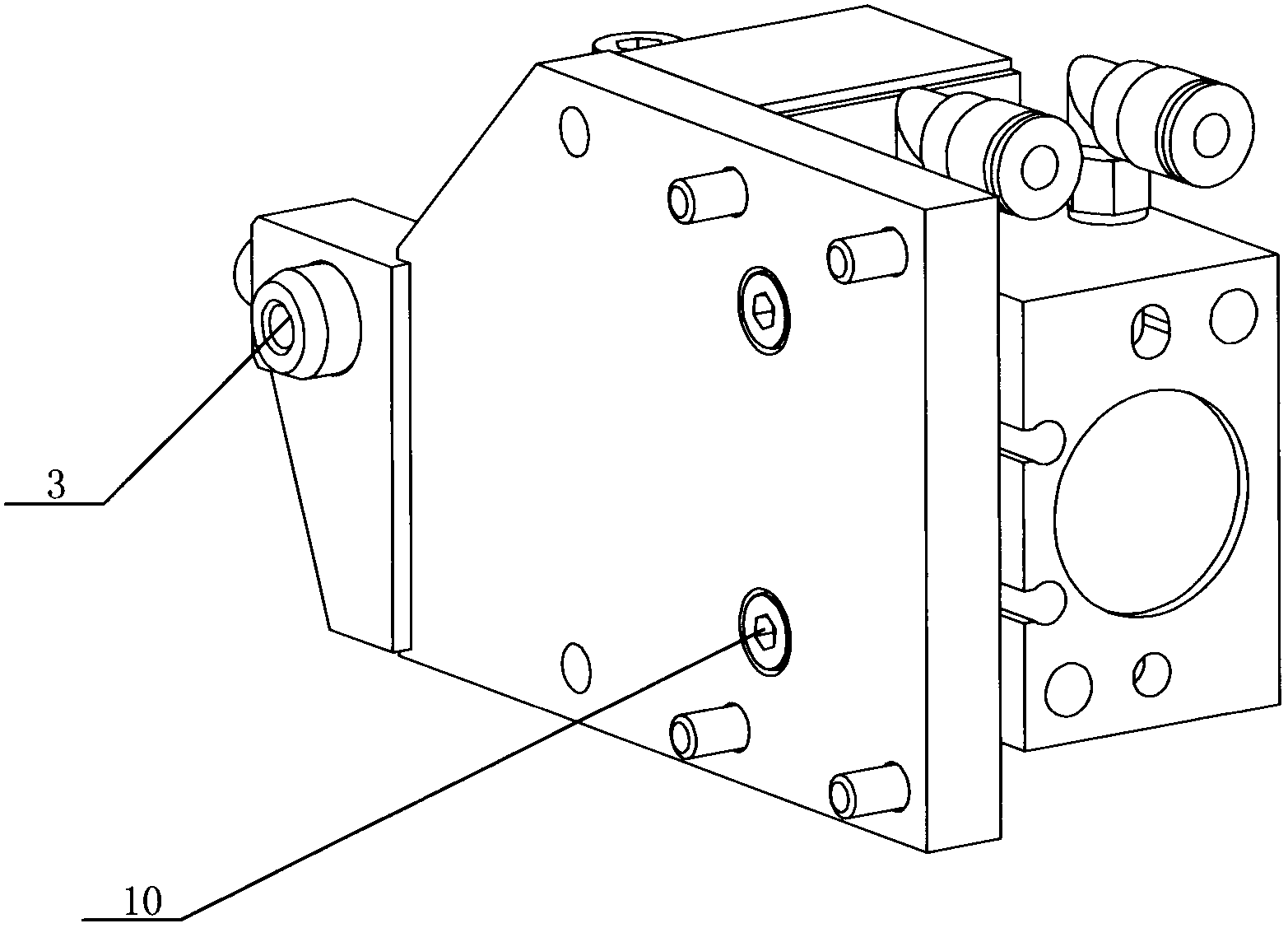

[0016] refer to figure 1 and figure 2 , the specific implementation adopts the following technical solutions: it includes a shaft sleeve mounting seat 1, a shaft sleeve mounting seat connecting plate 2, a shaft sleeve 3, a shaft sleeve jacking screw 4, a cylinder 5, a parallel two-finger clamp 6, a shock pad 7 and Air pipe joint 8; shaft sleeve mounting seat 1 is connected with shaft sleeve mounting seat connecting plate 2 through shaft sleeve mounting seat fixing screw 9, shaft sleeve 3 is set on shaft sleeve mounting seat 1, and shaft sleeve jacking screw 4 is set on shaft sleeve 3 On the outside, the cylinder 5 is connected to the connecting plate 2 of the sleeve mounting seat through the cylinder fixing screw 10, the parallel two-finger clamp 6 is connected to the right side wall of the cylinder 5 through the parallel two-finger clamp fixing screw 11, and the parallel two-finger clamp 6 The inner walls of the upper and lower jaws are provided with shock pads 7, and two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com