A photovoltaic module packaging line

A photovoltaic module and packaging line technology, applied in the field of packaging, can solve problems such as workpiece confusion, affecting packaging efficiency, and high labor intensity of workers, and achieve the effects of reducing the number of feeding times, simple structure, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

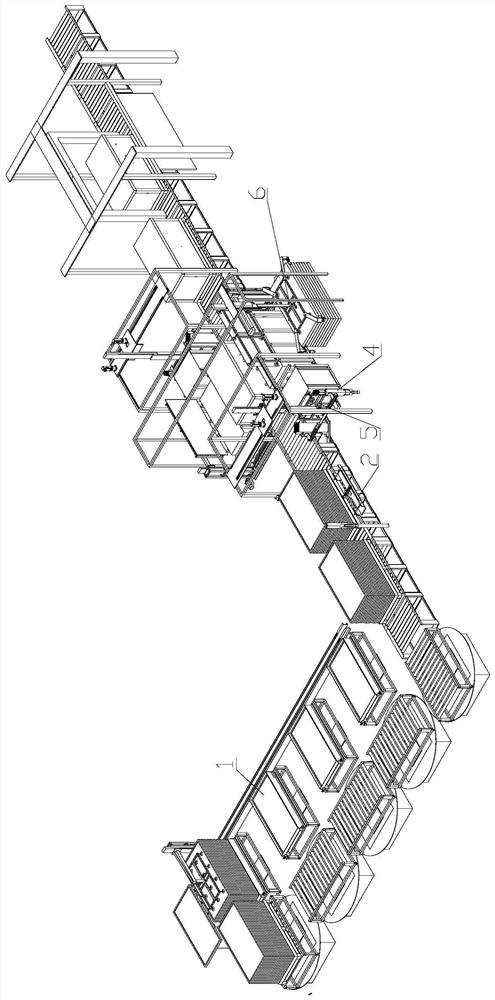

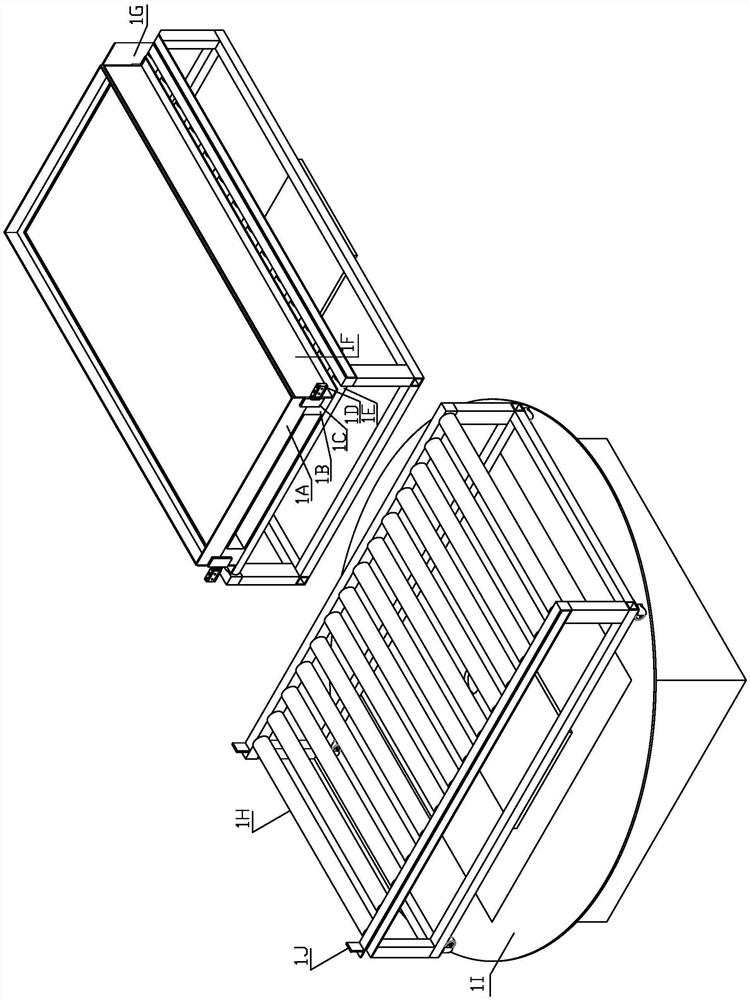

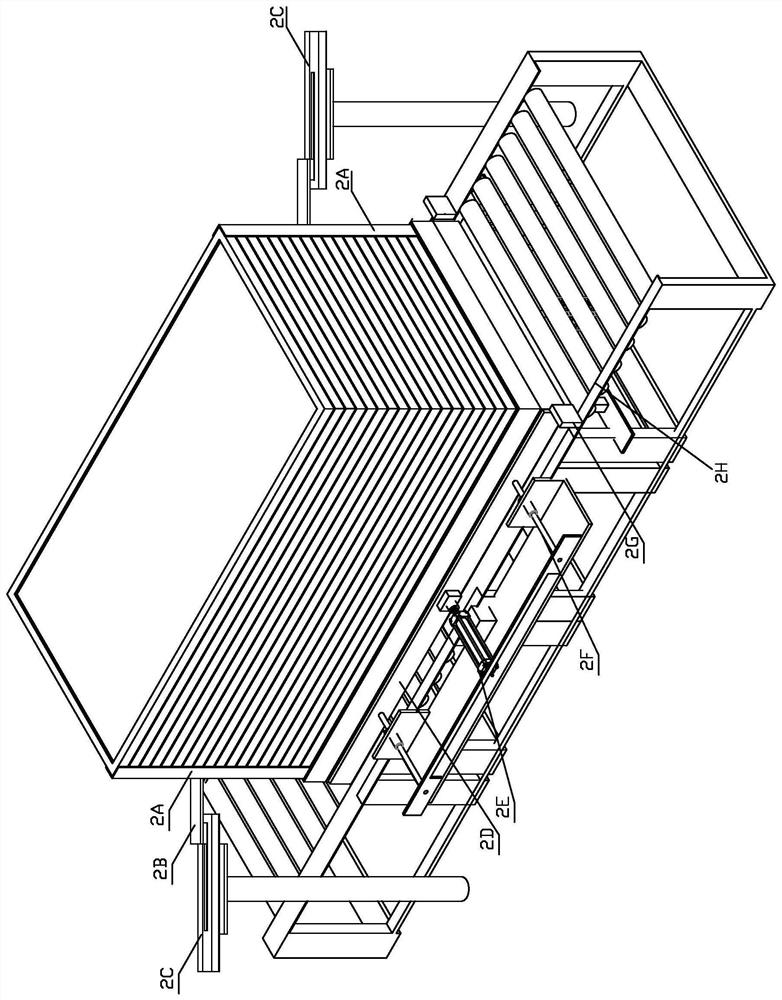

[0024] Figure 1-7 Including stacking conveying station 1, paper bottom cover 1A, wooden bottom support 1B, stacking conveying blocking plate 1C, stacking conveying opening and closing cylinder 1D, first electric roller conveying line 1E, stacking side baffle 1F , Stacking rear baffle 1G, second electric roller conveyor line 1H, electrical proximity switch 1J, electric rotary platform 1I, shaping station 2, shaping push plate 2B, shaping linear moving device 2C, shaping positioning plate 2D, shaping cylinder 2E , Reshaping guide column 2F, Reshaping electric proximity switch 2G, The third electric drum conveying line 2H, Bottom cover pull out moving cylinder 3A, First bottom cover pull out cylinder 3B, Second bottom cover pull out cylinder 3C, First bottom cover Pull-out vacuum suction cup 3D, second bottom cover pull-out vacuum suction cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com