Cooking heating furnace by using biomass fuel

A biomass fuel and heating stove technology, applied in the field of stoves, can solve the problems of difficult control of fire escape and smoke exhaust path, large additional investment, short fire sealing time, etc., achieve strong heating independence, reduce labor intensity, and long fire sealing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

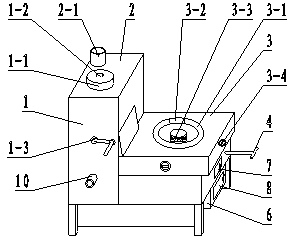

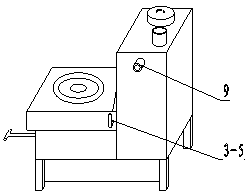

[0022] Referring to Fig. 1 and Fig. 2, the present invention comprises a heating water jacket 2, a feeding box 1, a stove body 3, a heating and cooking adjustment push-pull device 4, a pipe rack type water wall 5 and a ventilation ash chamber 6, the charging box 1 and the heating water jacket 2 are arranged side by side. The stove body 3 is located in front of the feeding box 1 and the heating water jacket 2. The heating and cooking adjustment push-pull device 4 runs through the stove body longitudinally and is connected with the inner wall of the heating water jacket 2. The pipe rack type water cooling wall 5 is arranged on the peripheral area of the inner wall of the stove body 3 and is connected with the heating water jacket 2 , and the ventilation ash chamber 6 is arranged in the middle part of the charging box 1 , the heating water jacket 2 and the lower side of the stove body 3 .

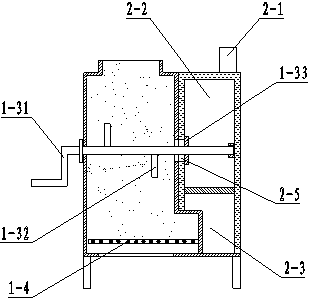

[0023] see image 3 , the heating water jacket 2 in the composition of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com