an automatic feeding system

An automatic feeding and material box technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low efficiency of the feeding mechanism, save material reclaiming time, improve assembly quality, and quickly and accurately feed materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

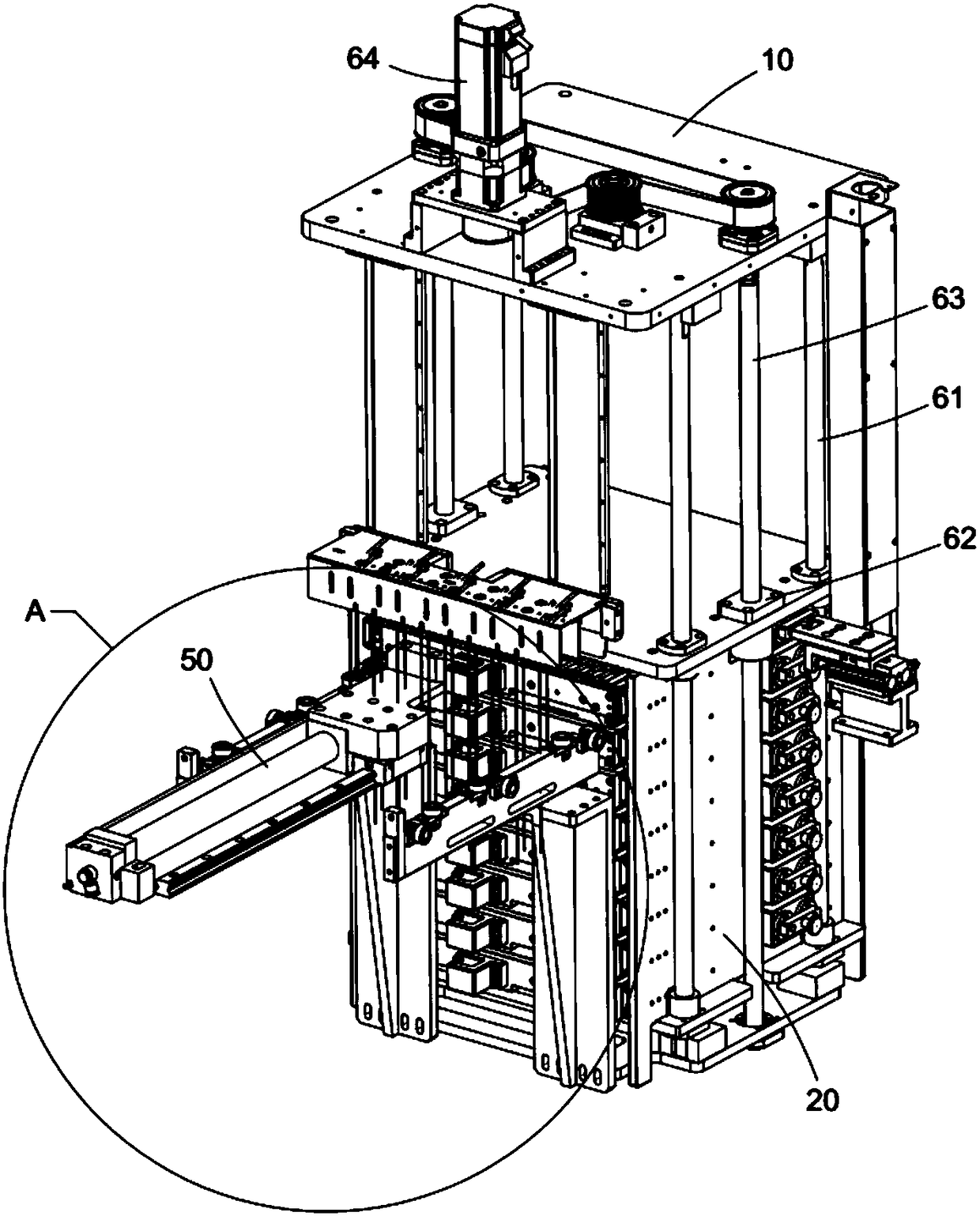

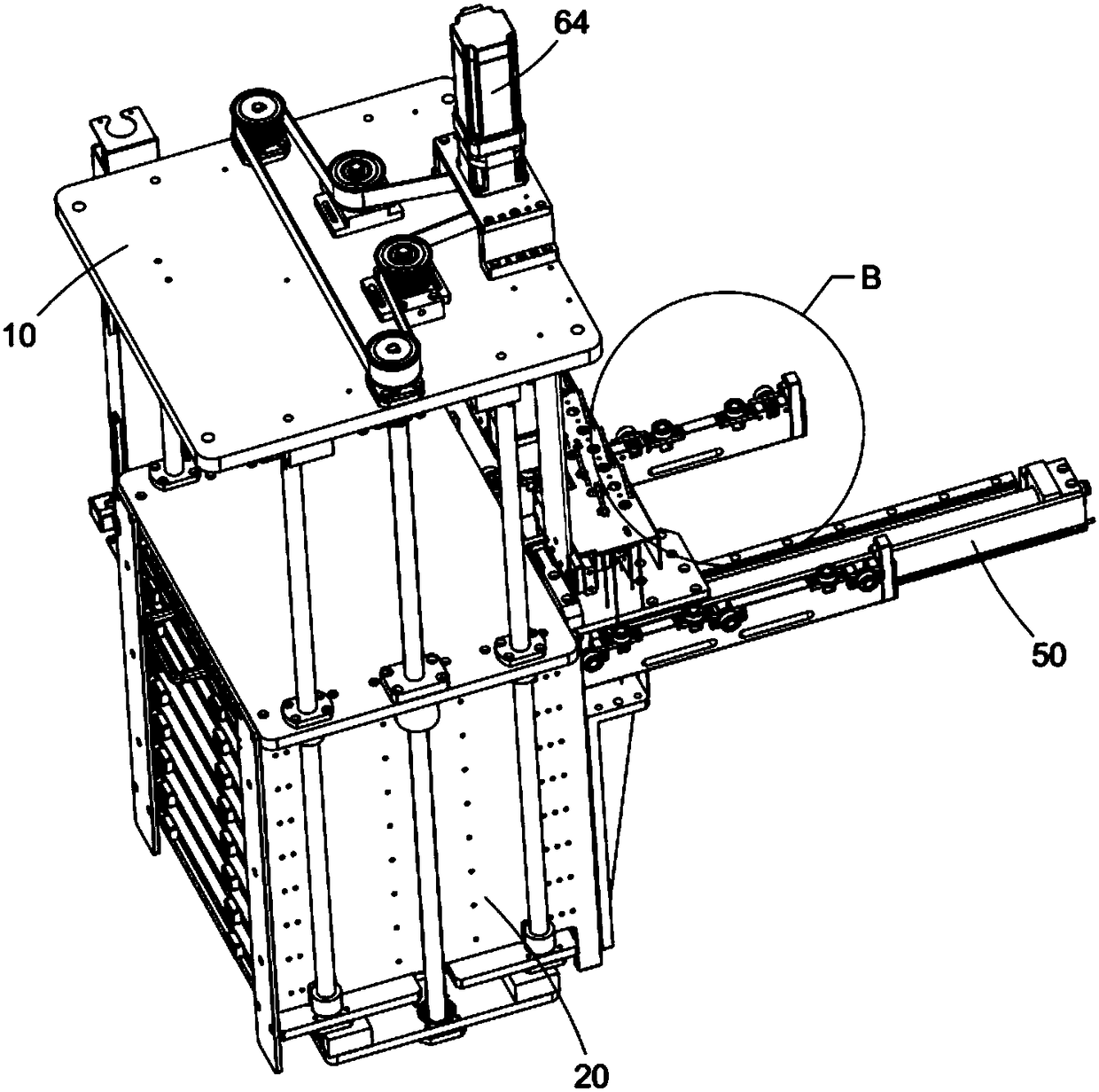

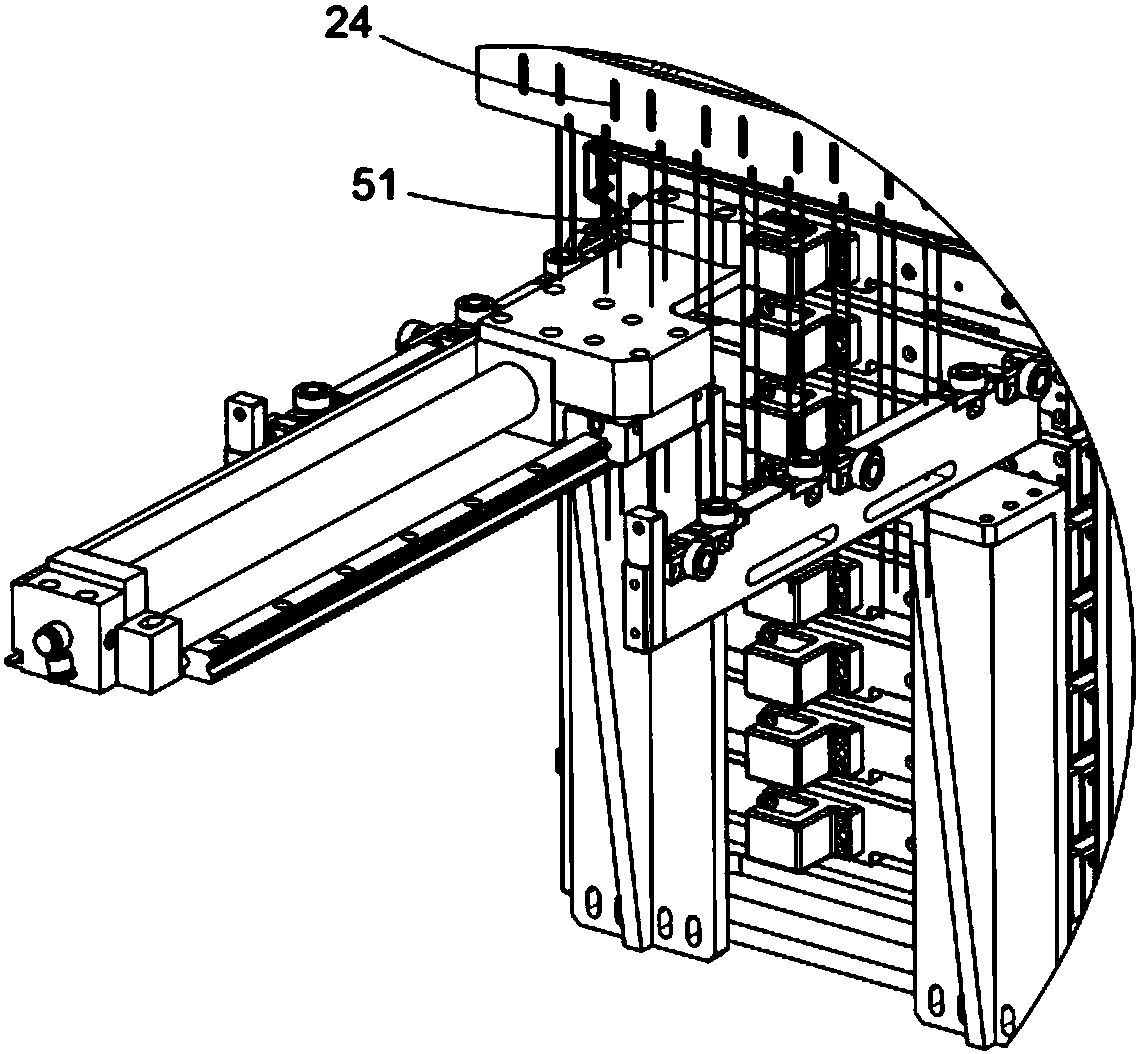

[0033] combine figure 1 , figure 2 , an automatic feeding system, including a lifting multi-layer silo 20, and a push-pull mechanism 50 located in front of the multi-layer silo.

[0034] The multi-layer feed bin 20 and the main frame 10 are all in the shape of a cuboid, the multi-layer feed bin is located in the main frame, and the lifting mechanism drives the multi-layer feed bin to lift in the main frame. The lifting mechanism includes an upright guide rod 61 fixed on the main frame and movably inserted in the top plate of the multi-layer silo, a screw slider 62 fixed on the top plate of the multi-layer silo, and a wire rod matched with the screw slider. Rod 63, the servomotor 64 that drives screw mandrel rotation and is installed on the top of main frame.

[0035] combine Figure 5 to Figure 7 Each layer of the multi-layer silo 20 is inserted with a material box 21, and a material tray 22 is loaded in the material box; a ball plunger 211 is provided on an inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com