Garment decoration modeling processing method for intelligent garment processing

A processing method and clothing technology, applied in the field of clothing processing, can solve the problems of low work efficiency and low degree of automation, and achieve the effects of high work efficiency, high degree of automation, and reduced torsional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

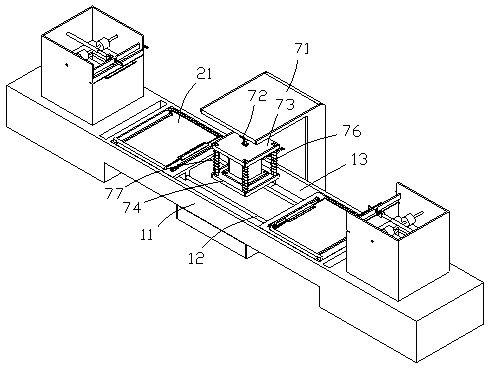

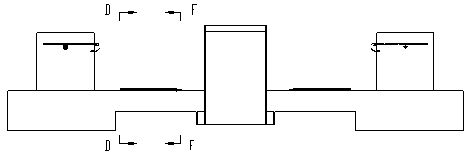

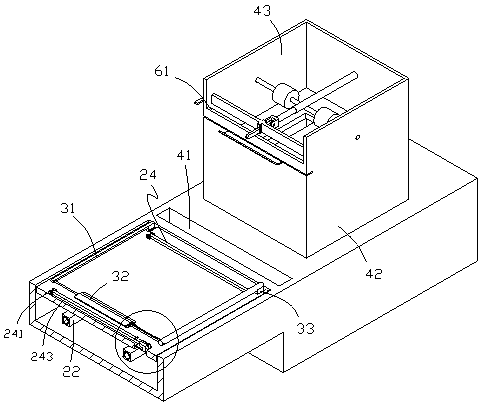

[0032] like Figure 1-11 As shown, a garment decoration molding processing method for intelligent processing of garments, the intelligent processing of garment decoration molding is carried out through an automatic drilling device. Rail 12, two groups of upper drilling stations that can move left and right along the slide rail, clamping devices that can be turned over on the upper drilling stations, heating devices on the machine base, and loading and unloading that match the upper drilling stations Device; Processing method comprises the following steps:

[0033] a. Place the garment to be drilled on one of the drilled stations, and fix it on the drilled station, and then install the crystal drill sticker on the drilled station through the clamping device, and the position is stacked Overlay on the garment to be drilled;

[0034] b. The start of the slide rail drives the upper drilling station to move to the position below the heating device, and the heating device heats th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com