Patents

Literature

54results about How to "Save time for retrieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

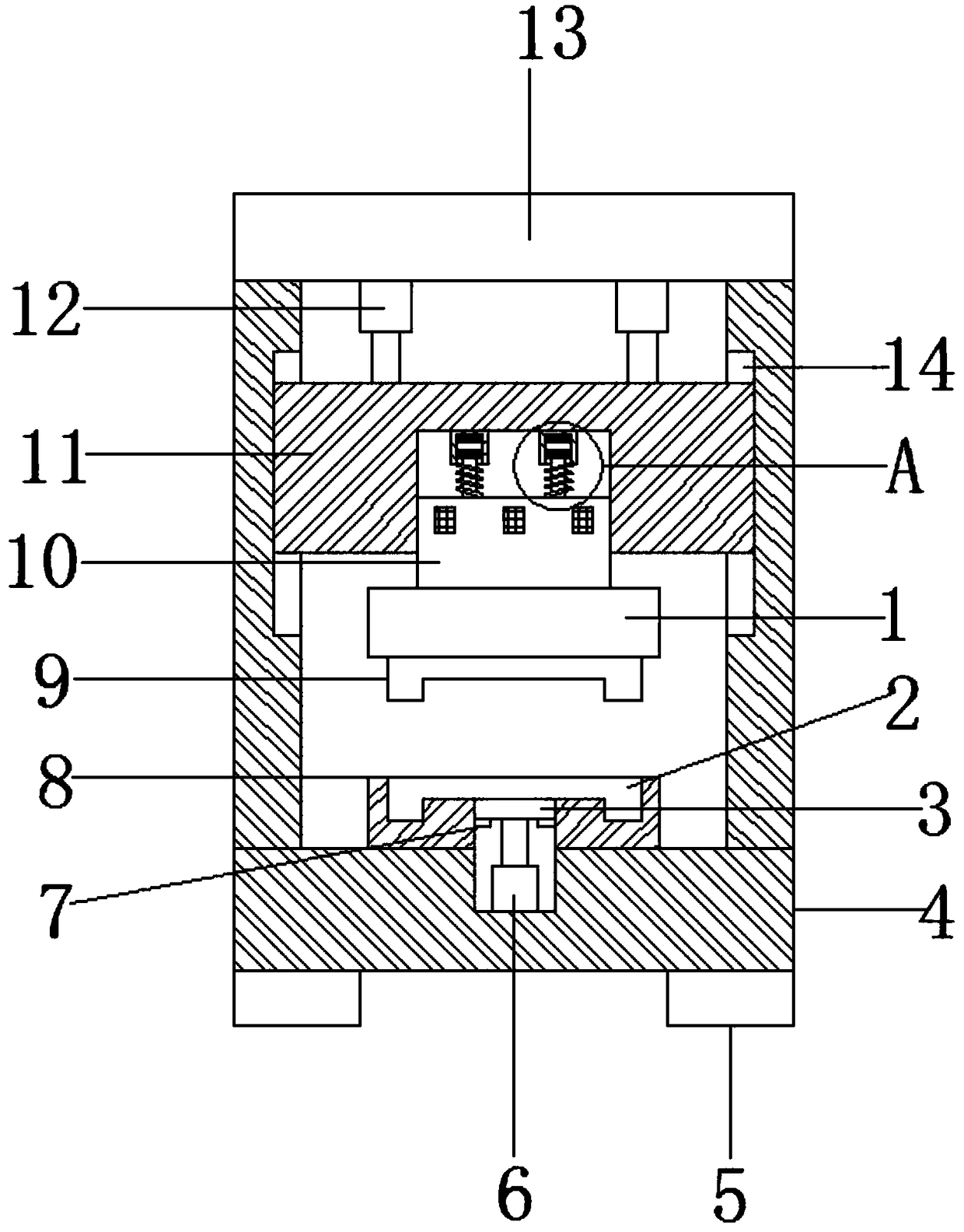

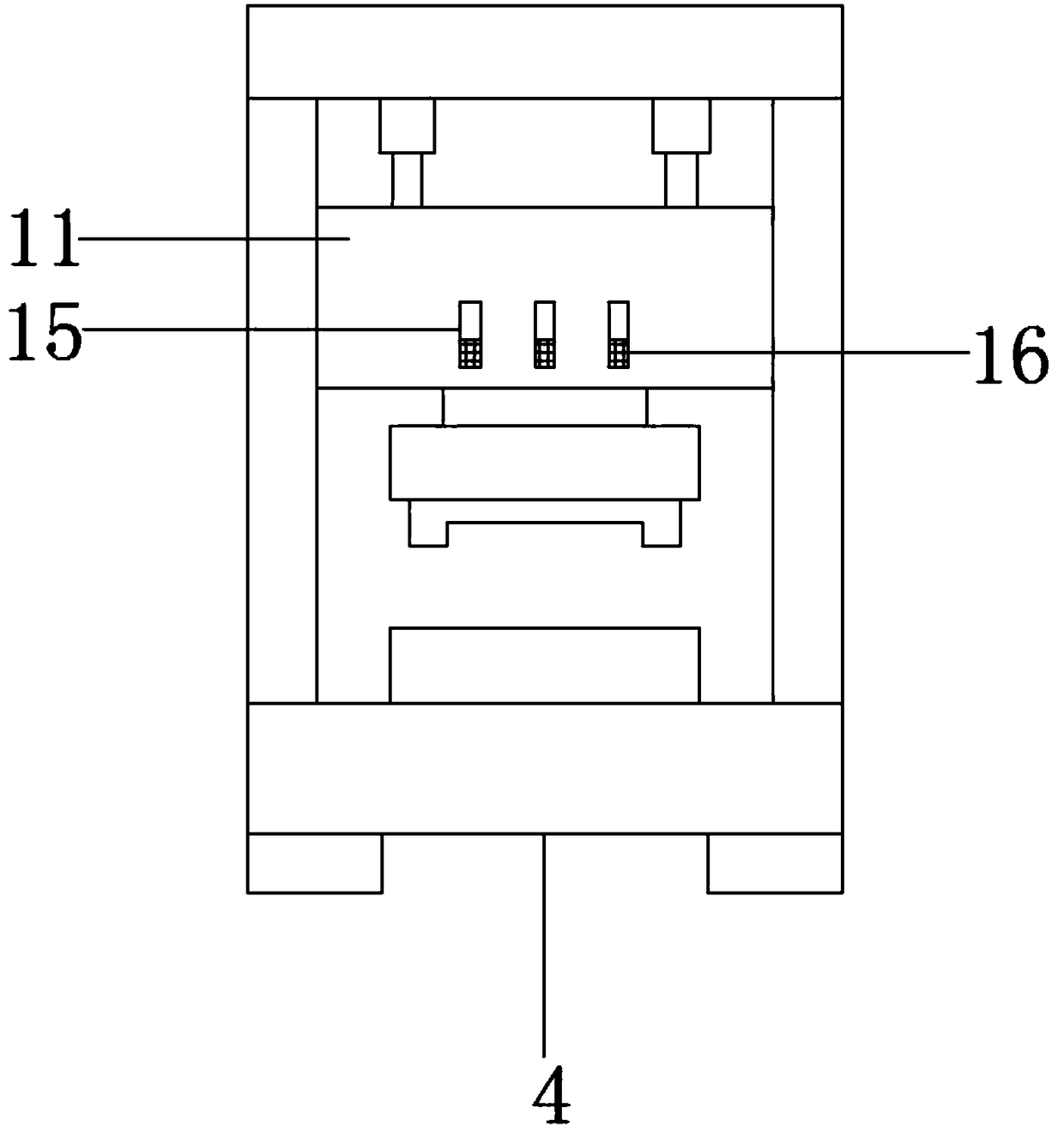

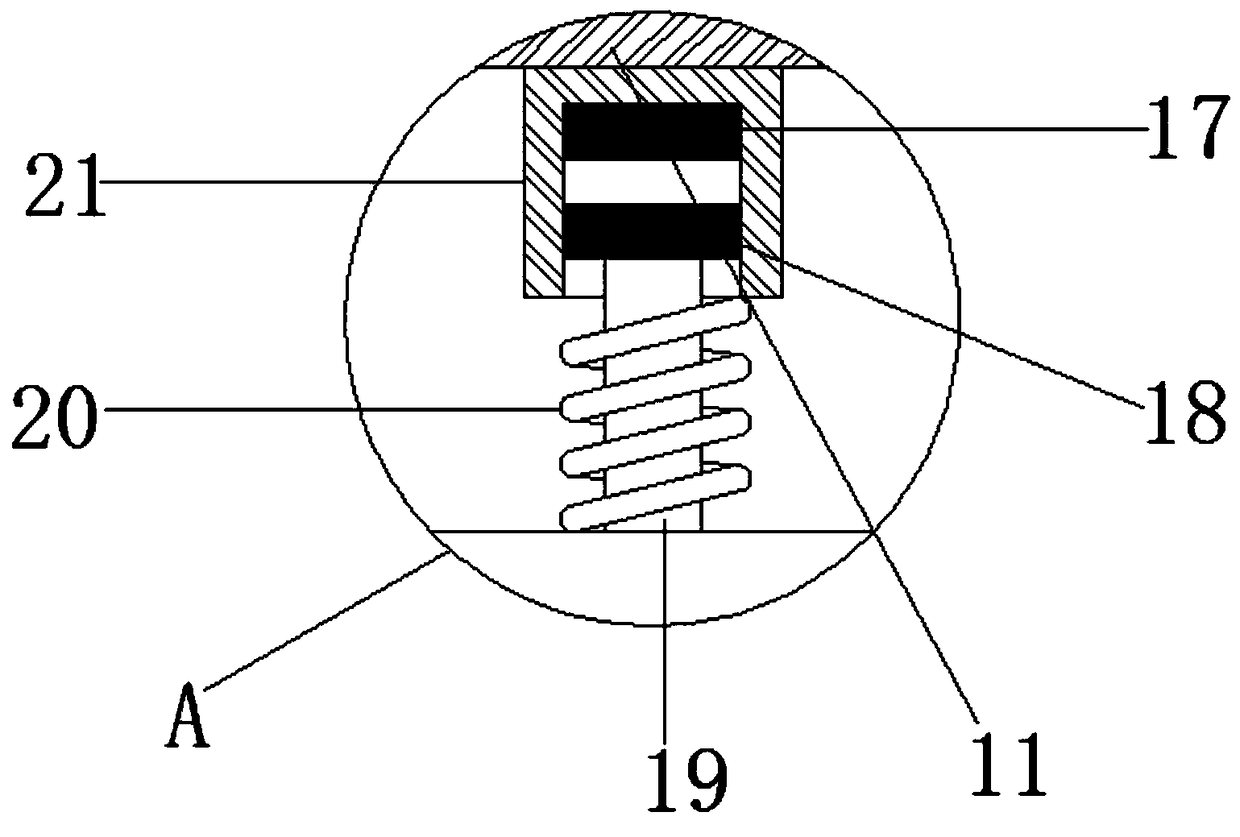

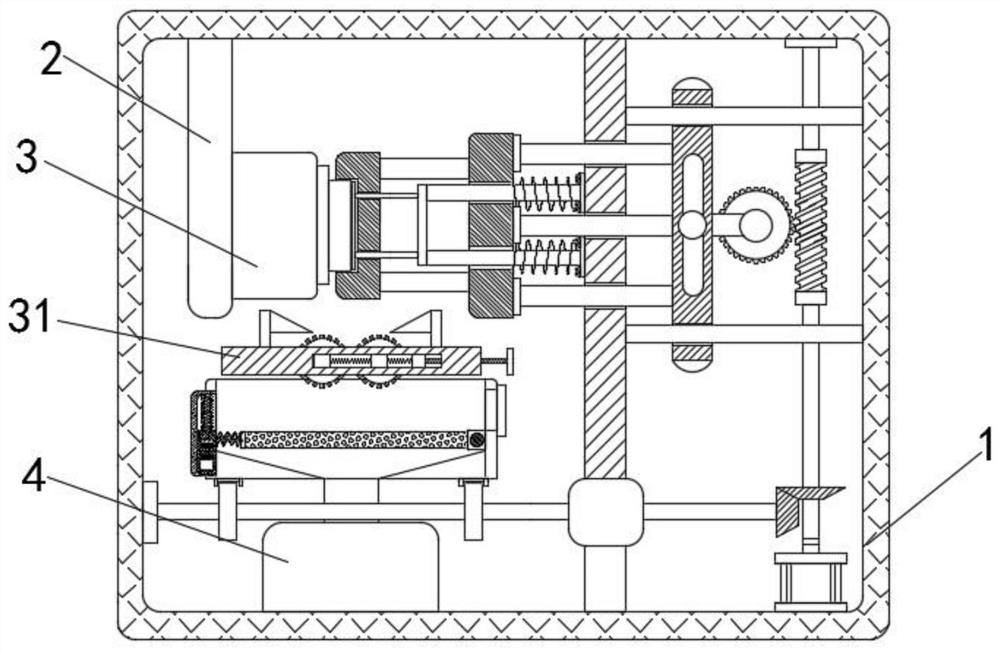

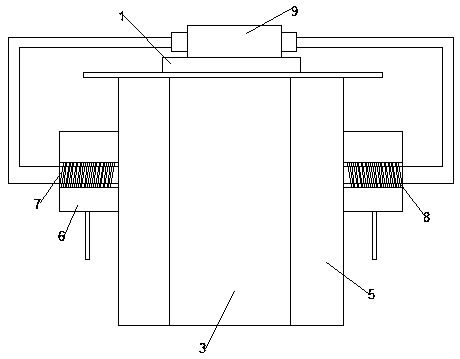

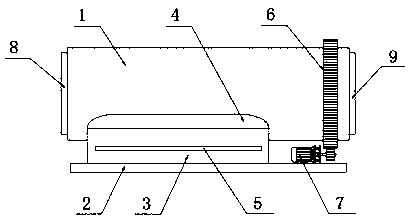

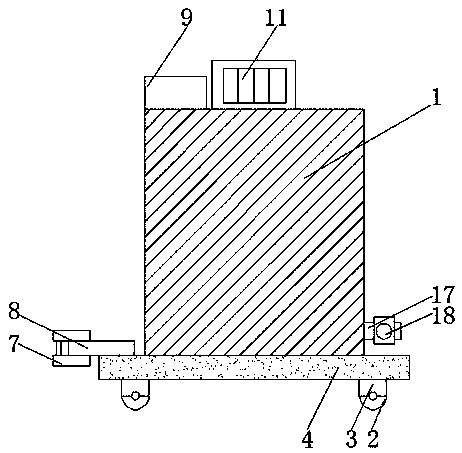

Bush press-in machine

InactiveCN103586677AIncrease the frequency of pressingGuaranteed verticalityMetal working apparatusHydraulic cylinderEngineering

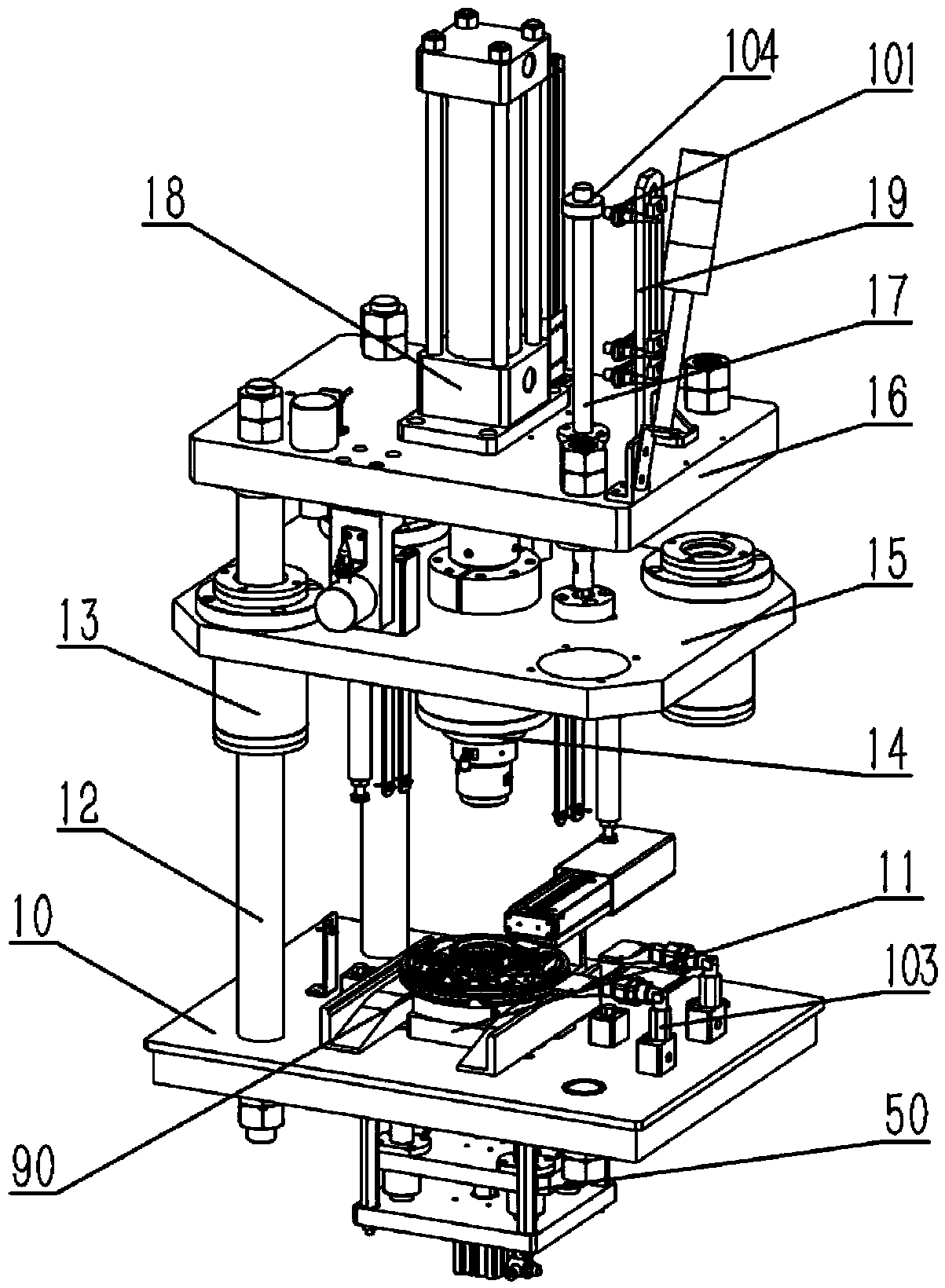

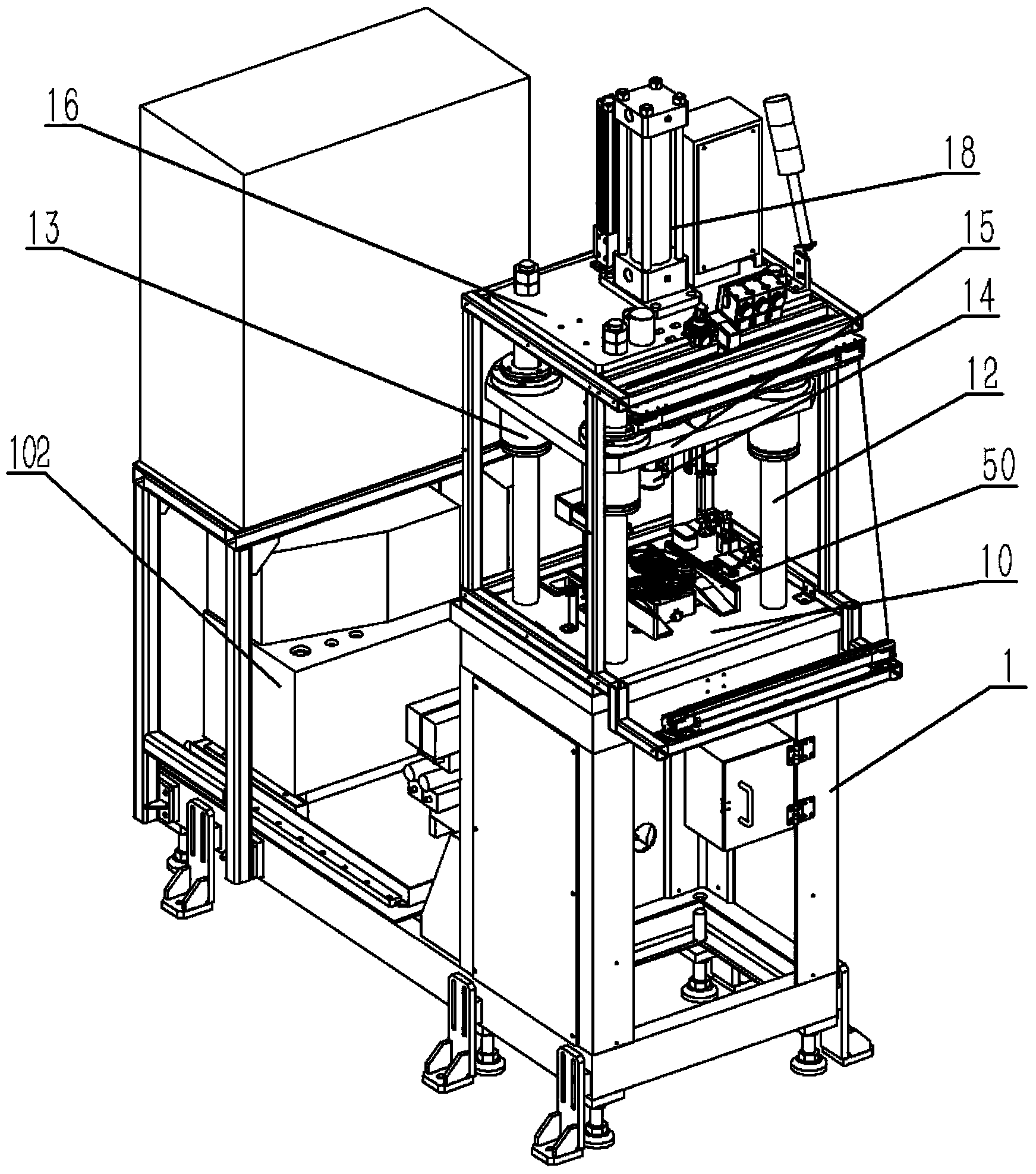

The invention discloses a bush press-in machine. A workbench is fixed to a machine frame of the bush press-in machine. A workpiece installation table is fixed to the workbench. A first guide shaft is fixed to the workbench. The upper end of the first guide shaft is fixed to a top board. The first guide shaft is sleeved with a first linear shaft and the first linear shaft is fixed to a middle board. A stamping head is fixed to the lower end face of the middle board. A piston rod of a hydraulic cylinder is fixed to the upper end face of the middle board. The hydraulic cylinder is fixed to the top board. A discharging mechanism is arranged below the workbench and located under the stamping head. According to the bush press-in machine, a bush is taken in a mechanical mode in bush press-in operation, so that the potential safety hazard caused by the fact that the bush is manually taken is avoided, and compared with manual bush taking operation, mechanical bush taking operation conducted after the bush is pressed in has the advantages that the bush taking time is shortened and the bush press-in frequency and the production efficiency are improved.

Owner:XIONG HUA MACHINERY SUZHOU CO LTD

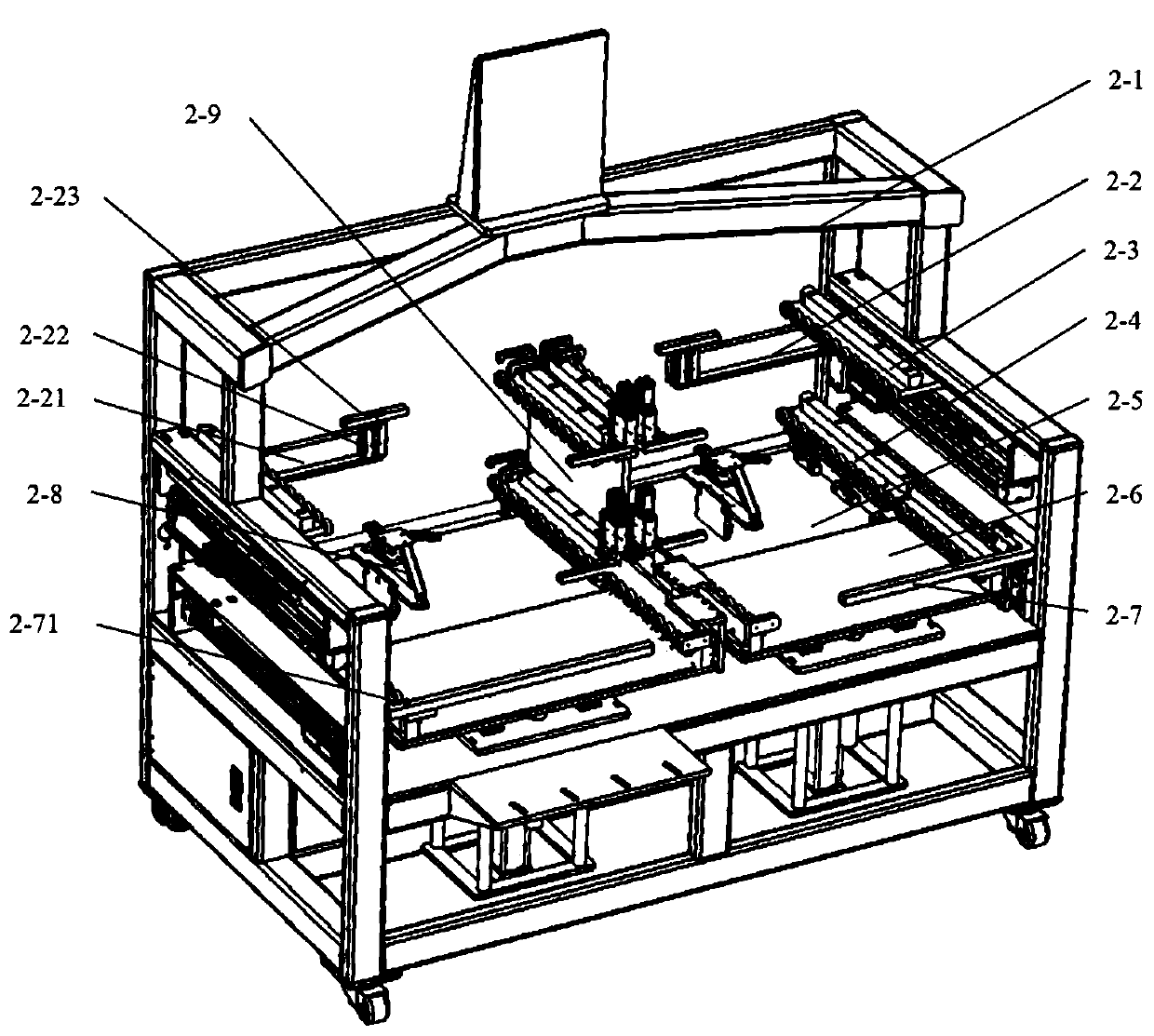

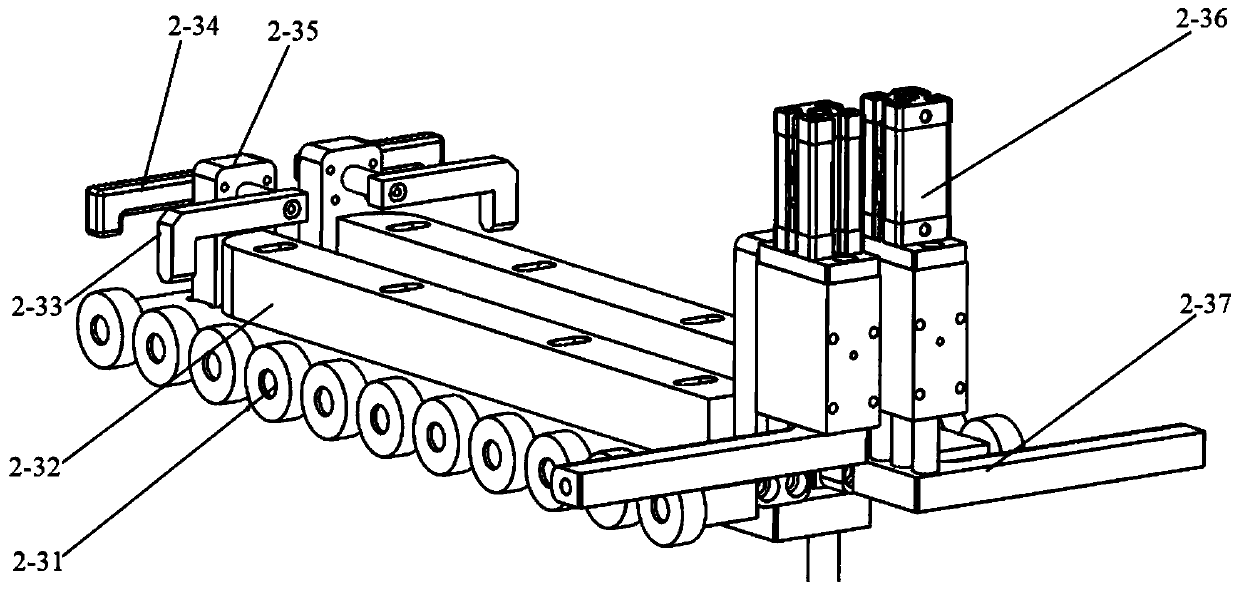

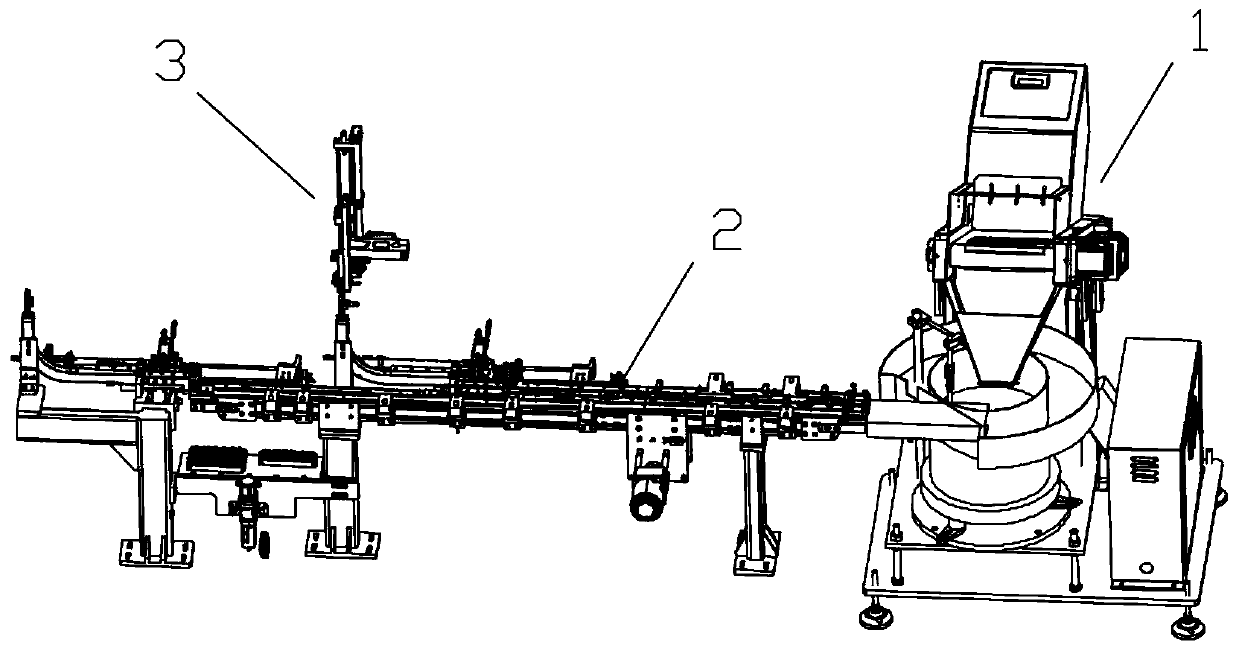

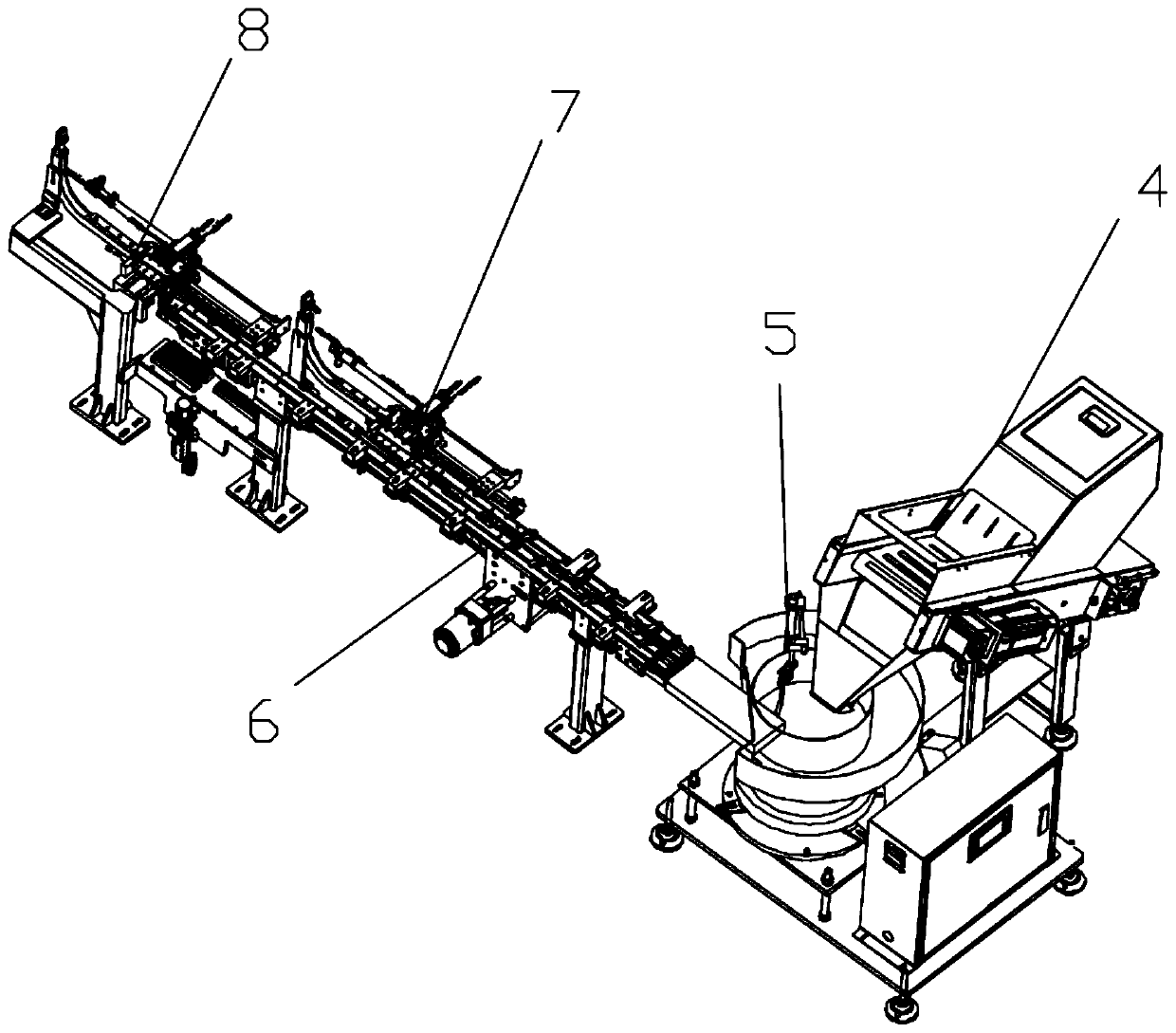

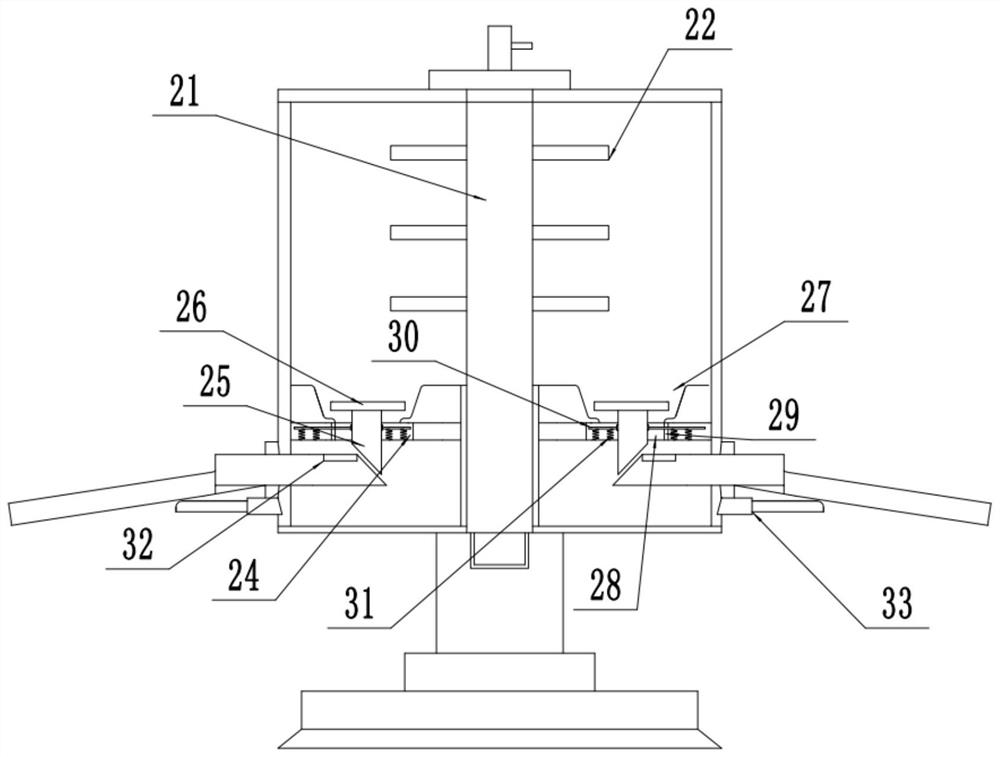

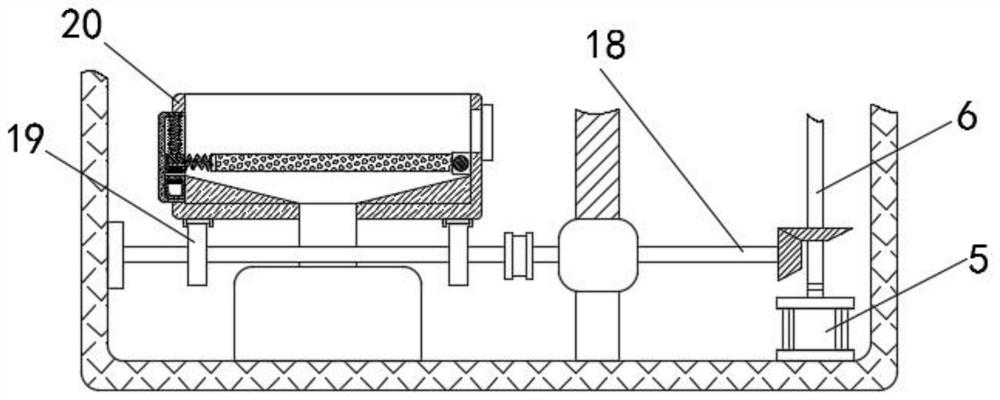

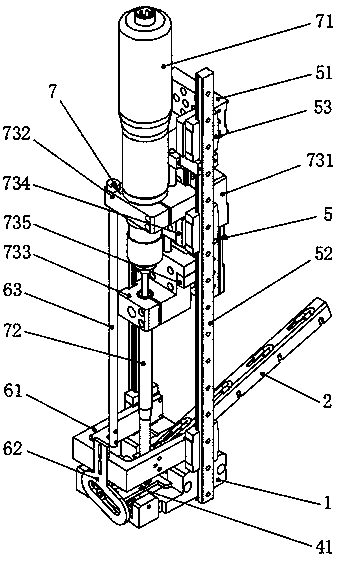

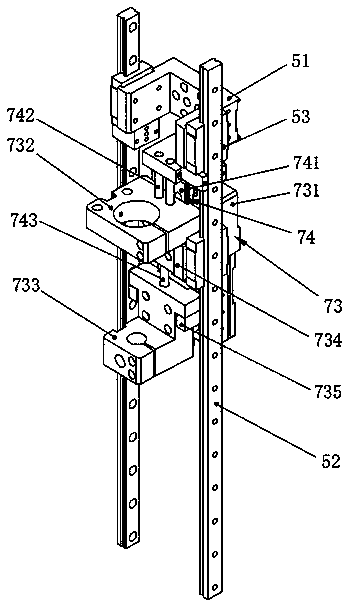

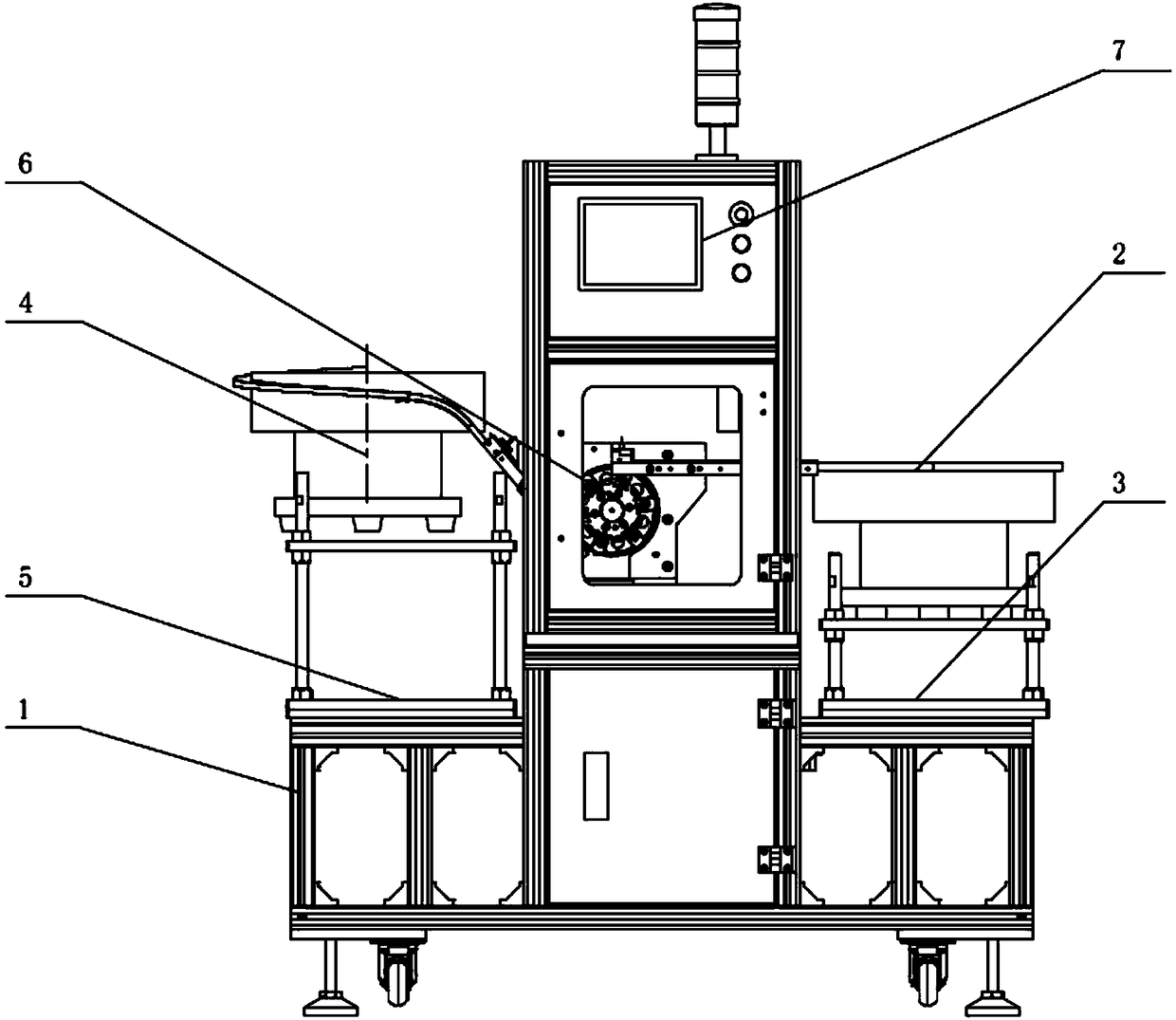

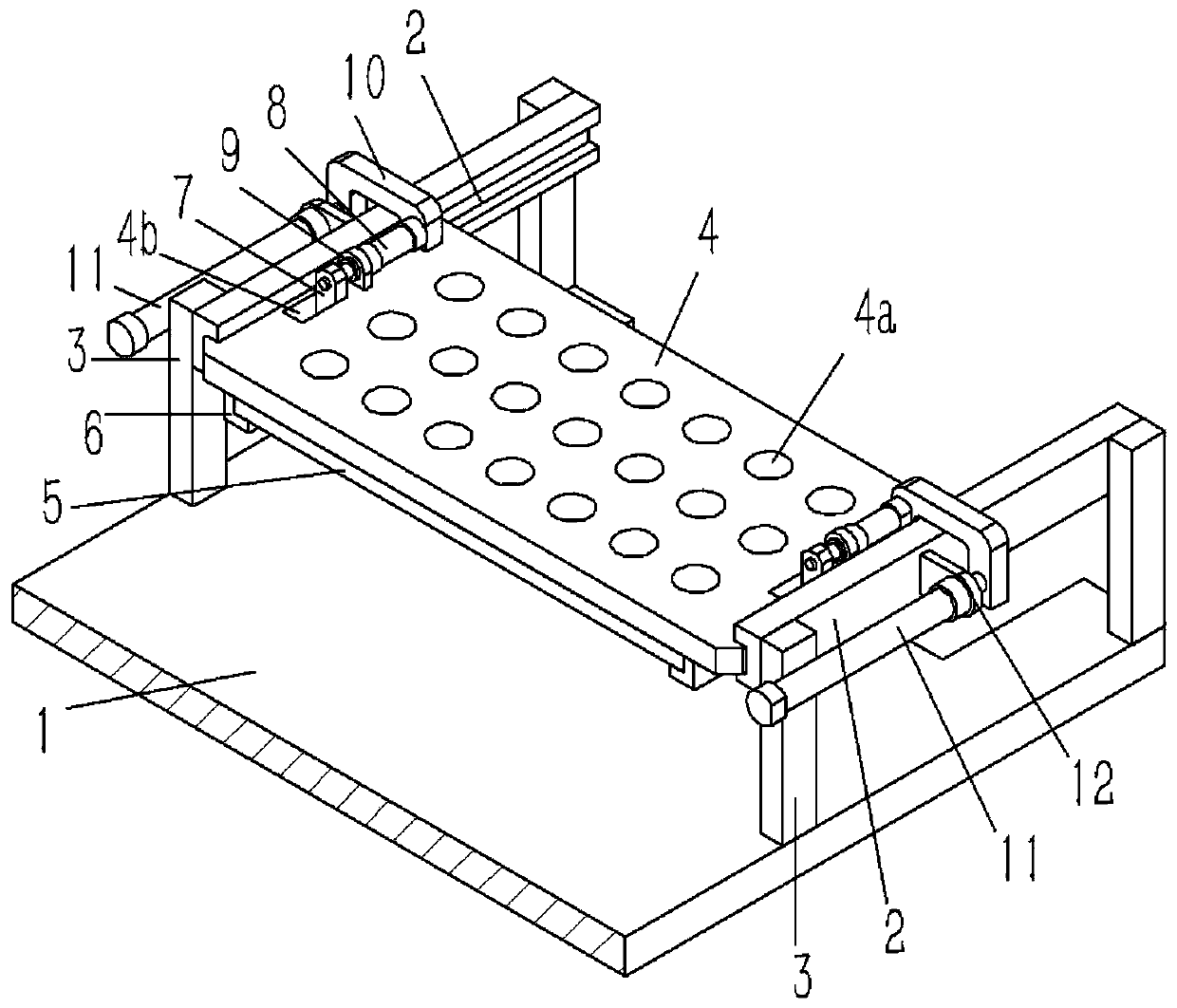

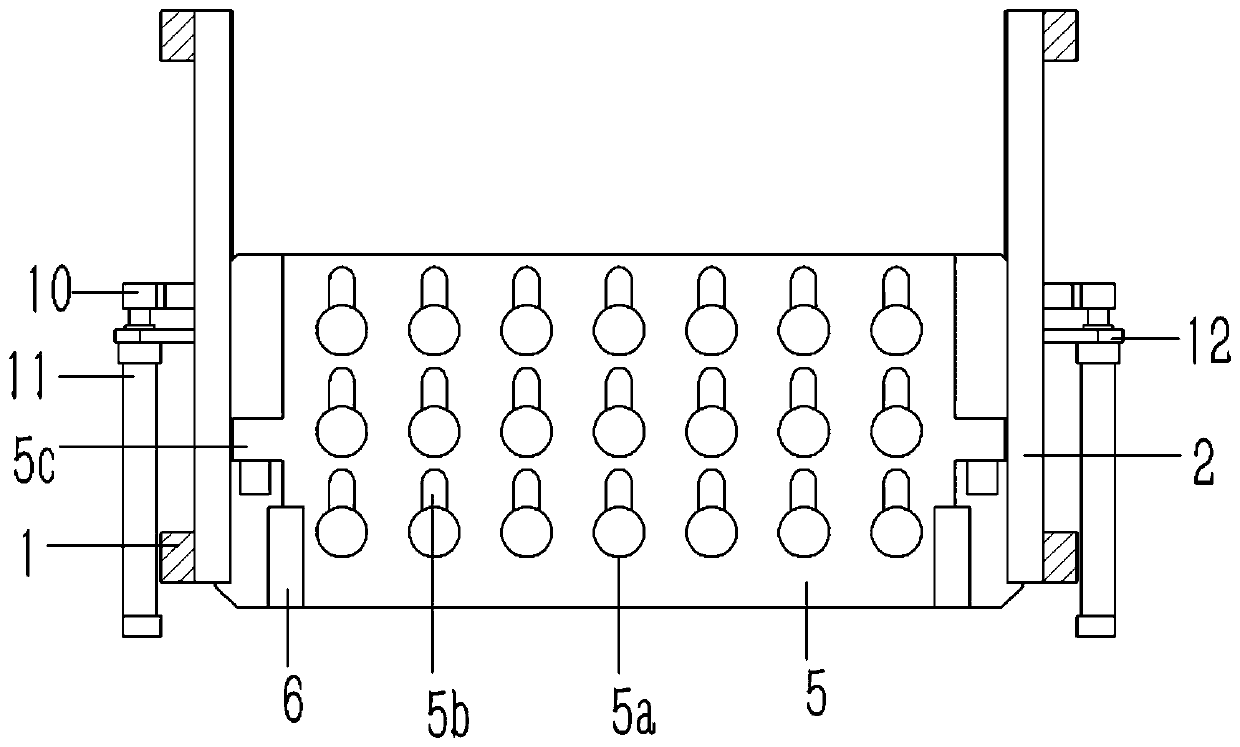

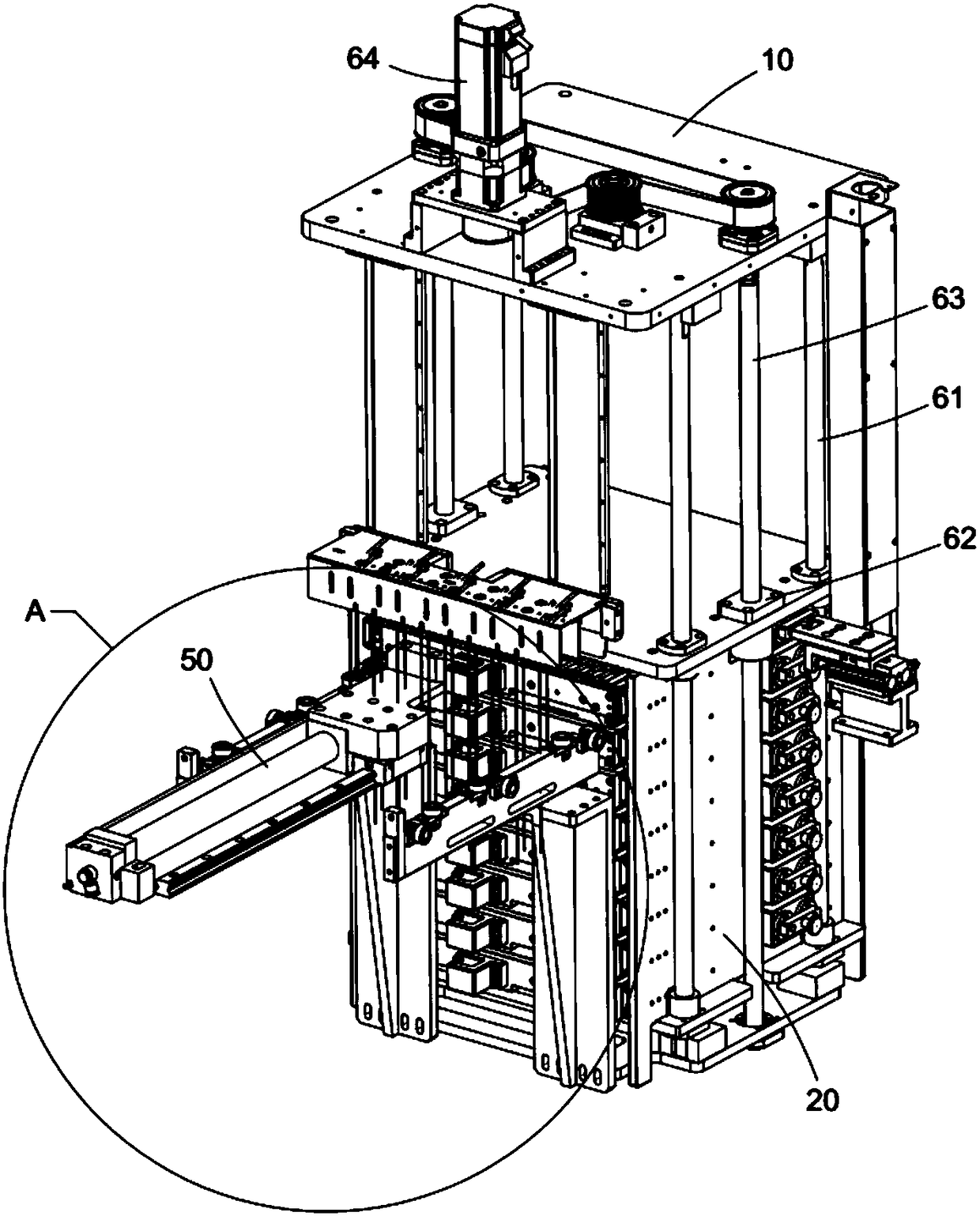

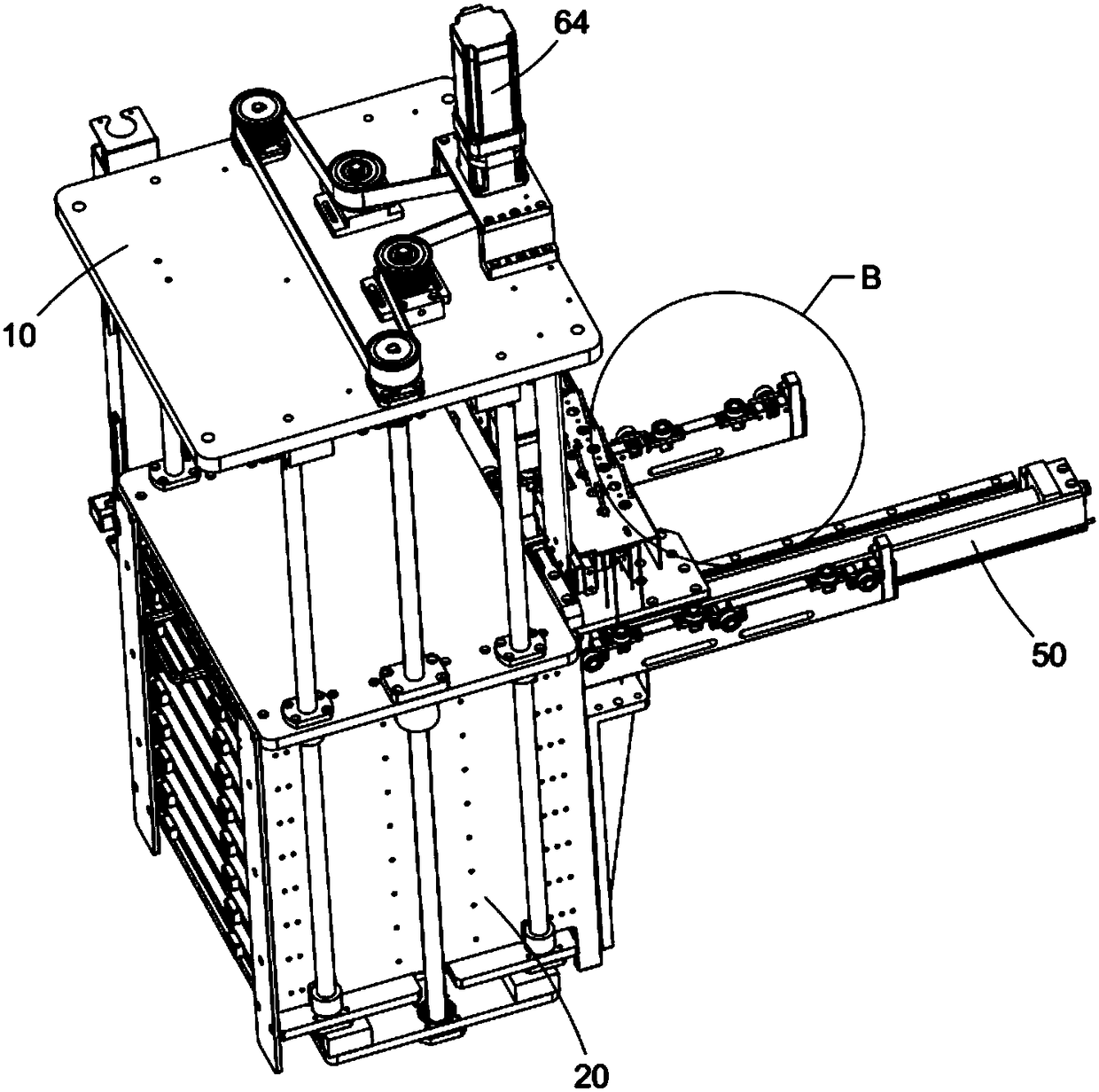

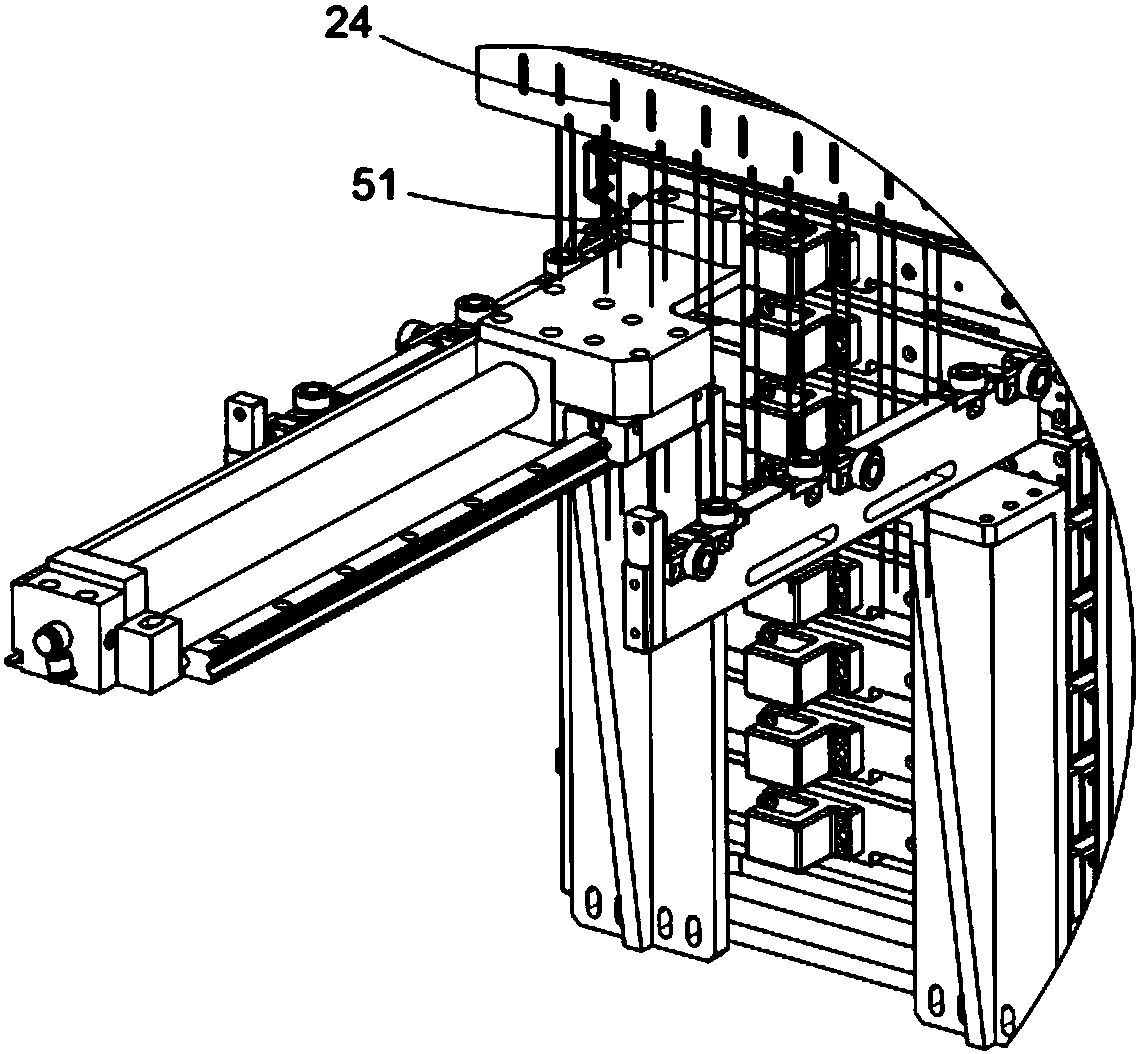

Automatic feeding and discharging device for perforating bullet assembly and assembling process thereof

ActiveCN110375597AMaximize production potentialIncrease productivityAmmunitionPunchingVertical plane

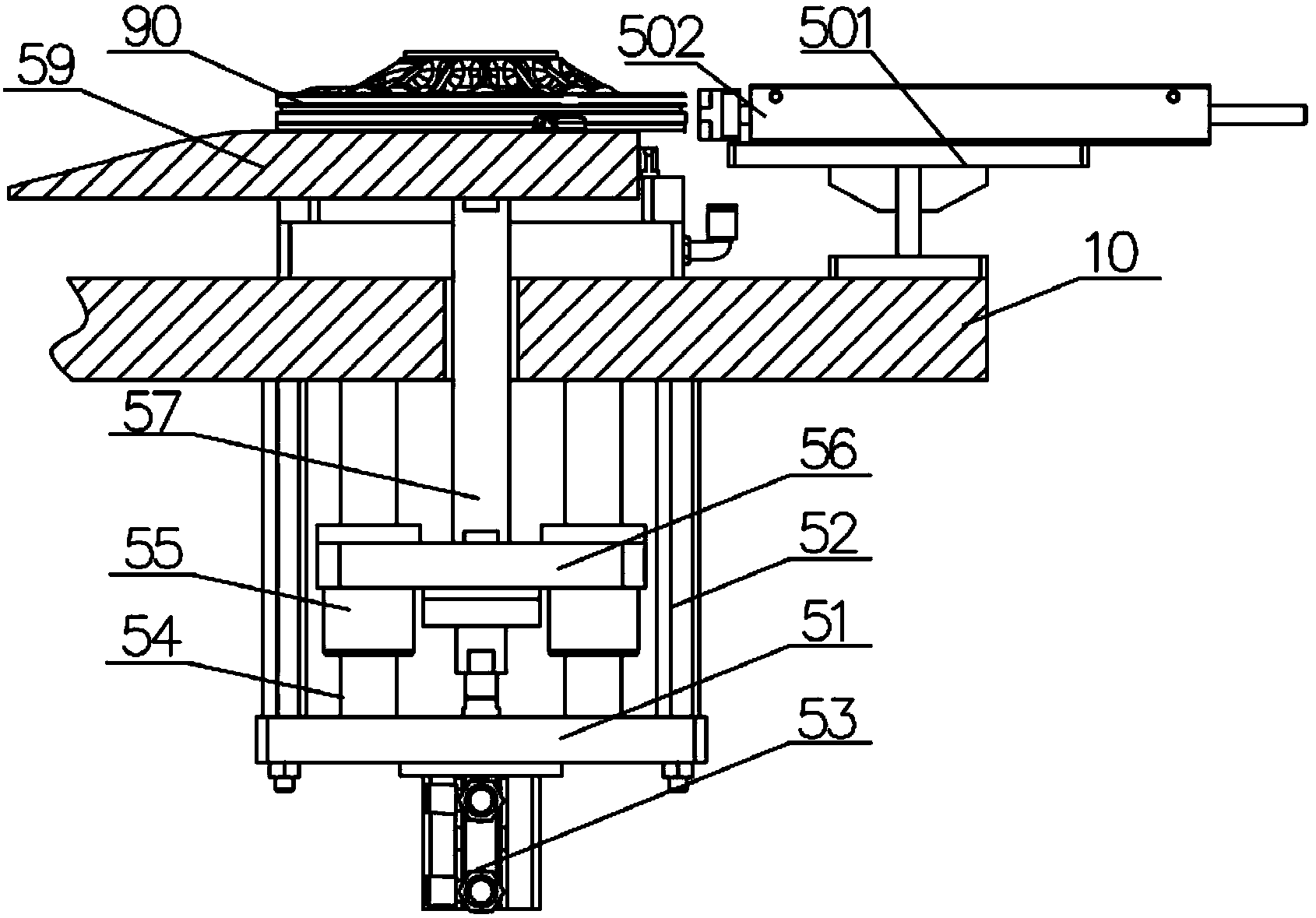

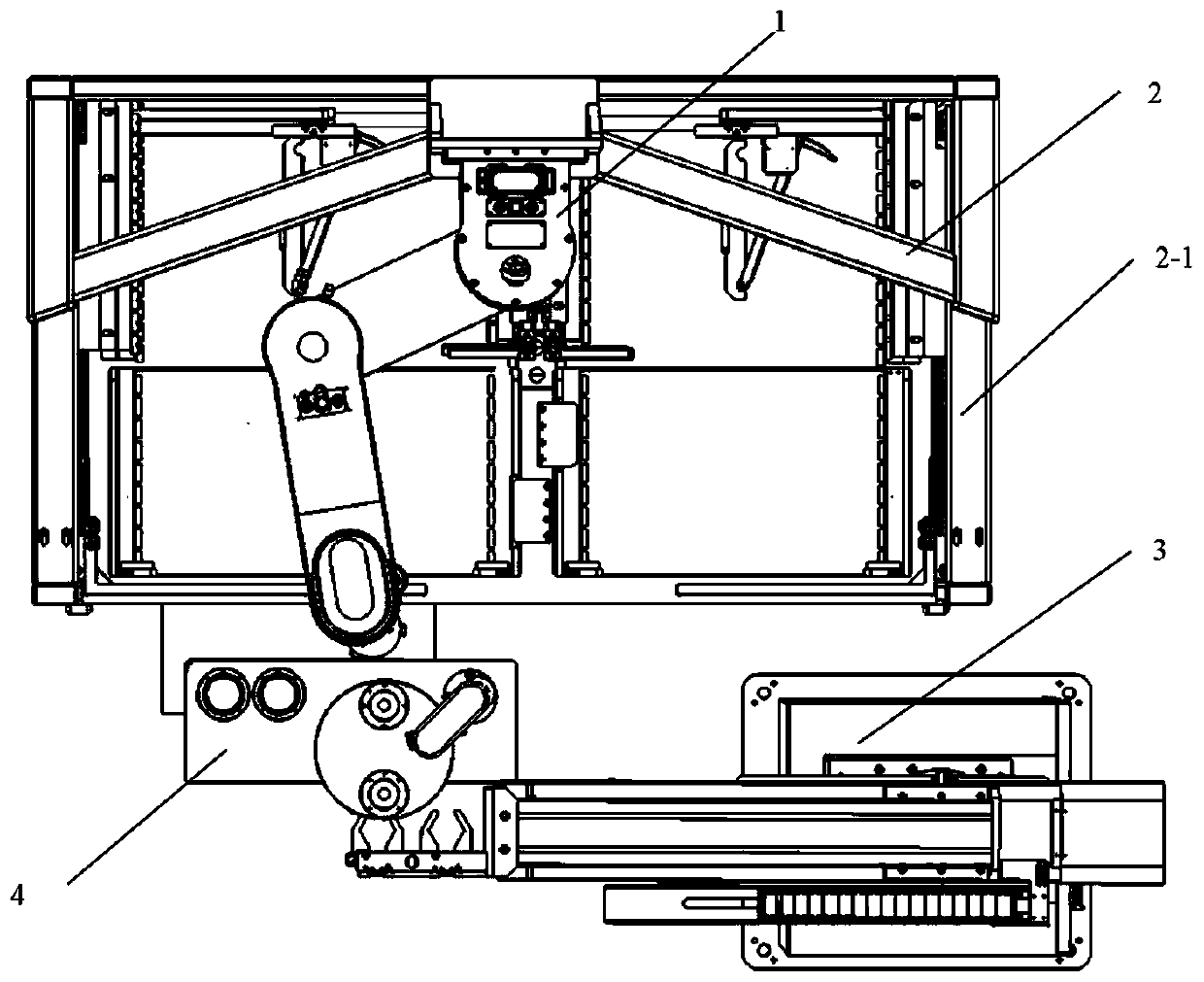

The invention discloses an automatic feeding and discharging device for perforating bullet assembly and an assembling process thereof. A carrying robot is arranged on a main frame of the feeding and discharging mechanism, an assembling transferring platform is fixed on the main frame through a mounting platform, the assembling transferring platform is used for assembling and storing an elastic body and a cover ring, and materials of a feeding mechanism are conveyed into a discharging mechanism through a lifting mechanism and a horizontal moving mechanism, the discharging mechanism is providedwith a locking mechanism, the discharging mechanism can slide along the movement direction of the horizontal moving mechanism, the lifting mechanism is used for vertically moving a tray; the carryingrobot is used for carrying the elastic body and the cover ring between the lifting mechanism and the assembling transferring platform, a stamping robot is fixed on the main frame, and has two degreesof freedom and a degree of freedom for rotating around the Z axis in a vertical plane; and the stamping robot is used for carrying the assembled elastic body and the cover ring between the assemblingtransferring platform and a hydraulic machine. The automatic feeding and discharging device has the advantages that the equipment safety is improved, the occupied area is reduced, the structure is simple, the control is easy, and the high-efficiency assembling and punching of the perforating bullet can be realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

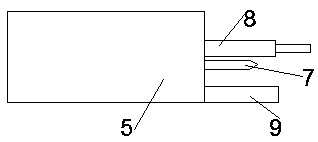

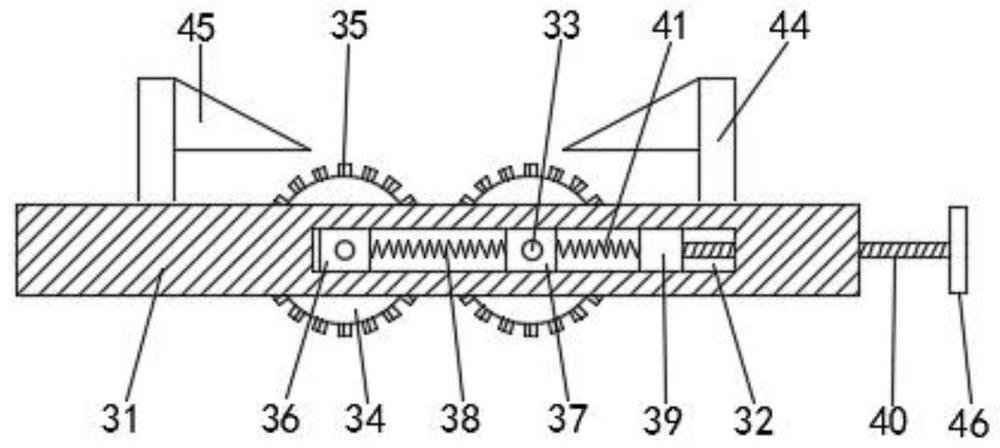

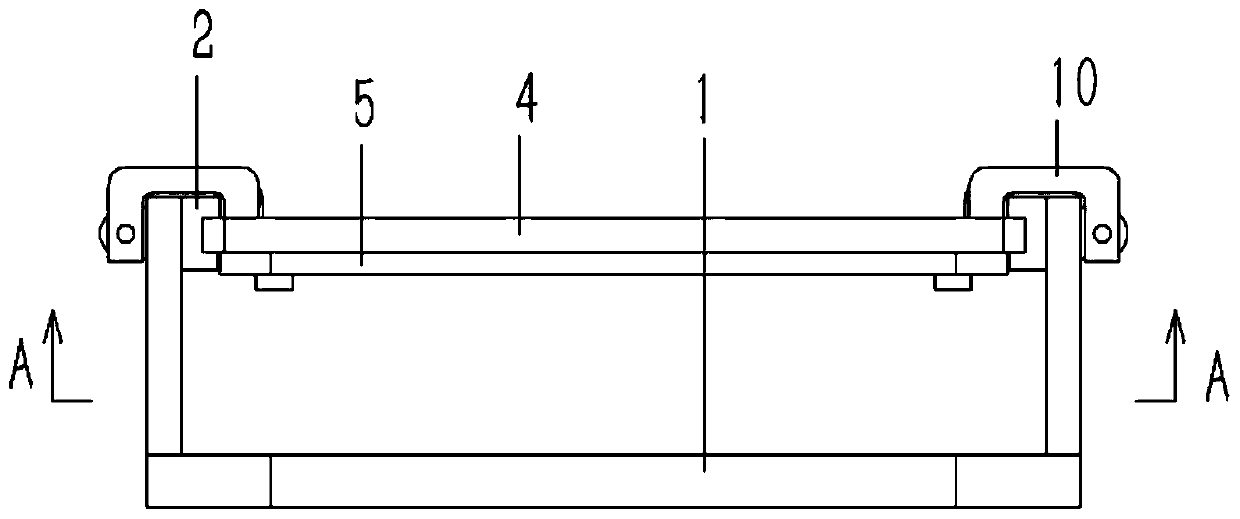

Double-track feeding structure

ActiveCN105692047APrecise deliverySave time for retrievingConveyorsControl devices for conveyorsEngineeringChassis

Owner:PROSYST ELECTRONICS TECH

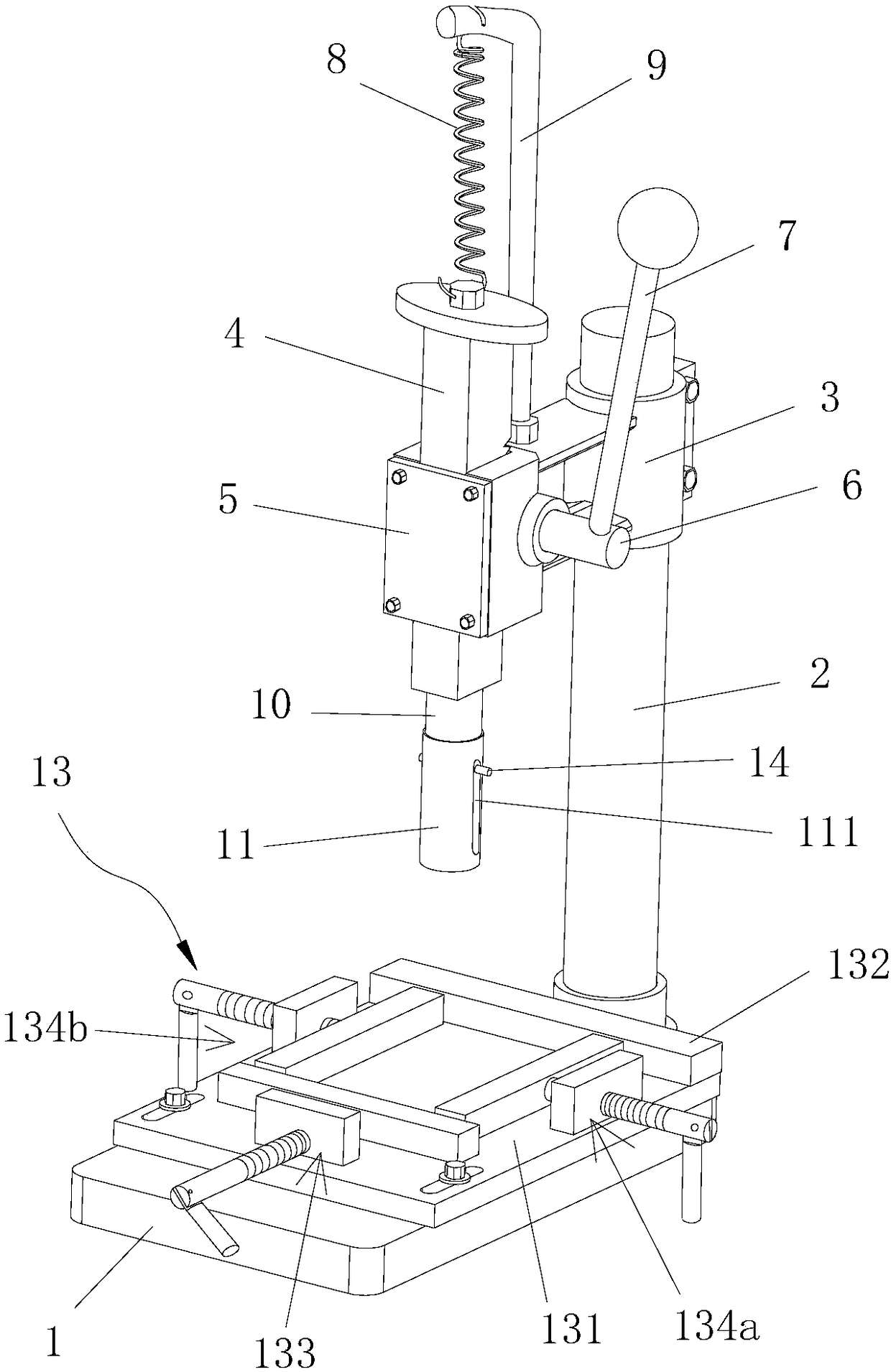

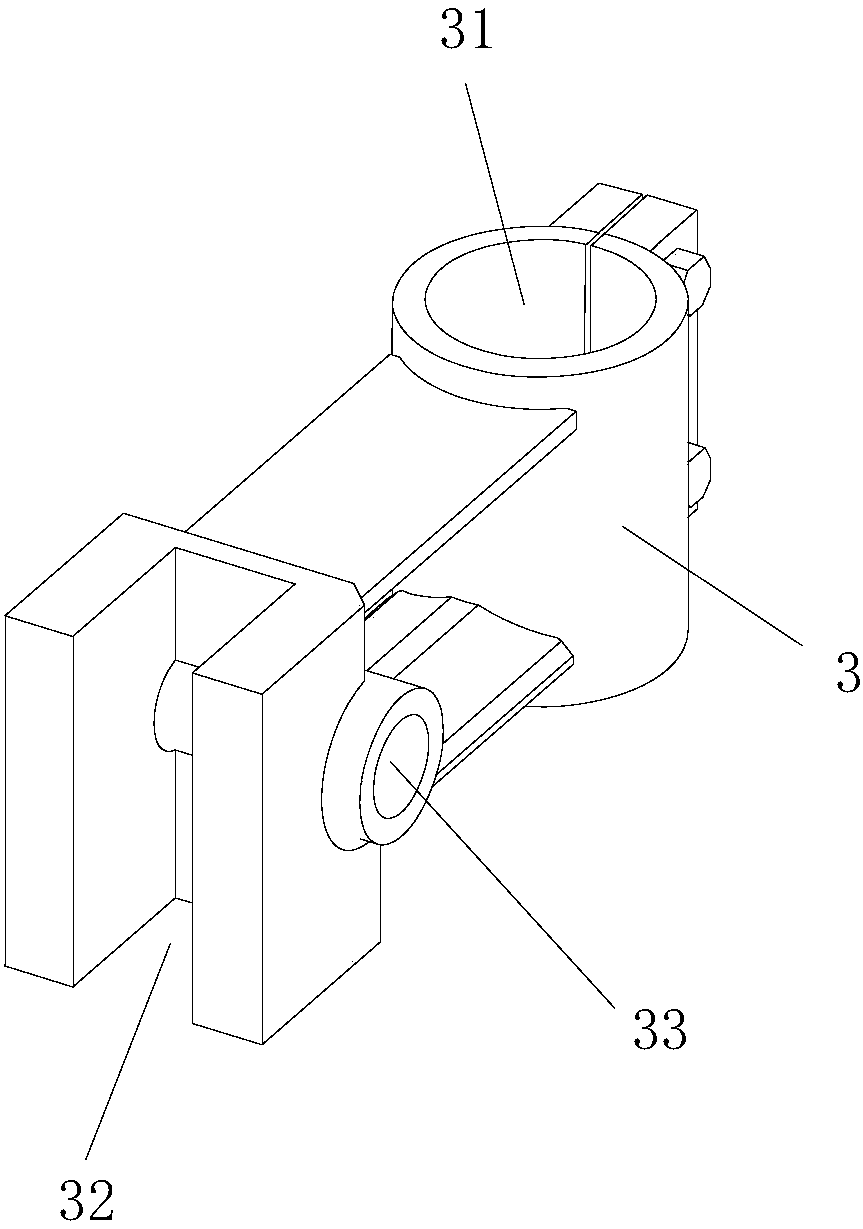

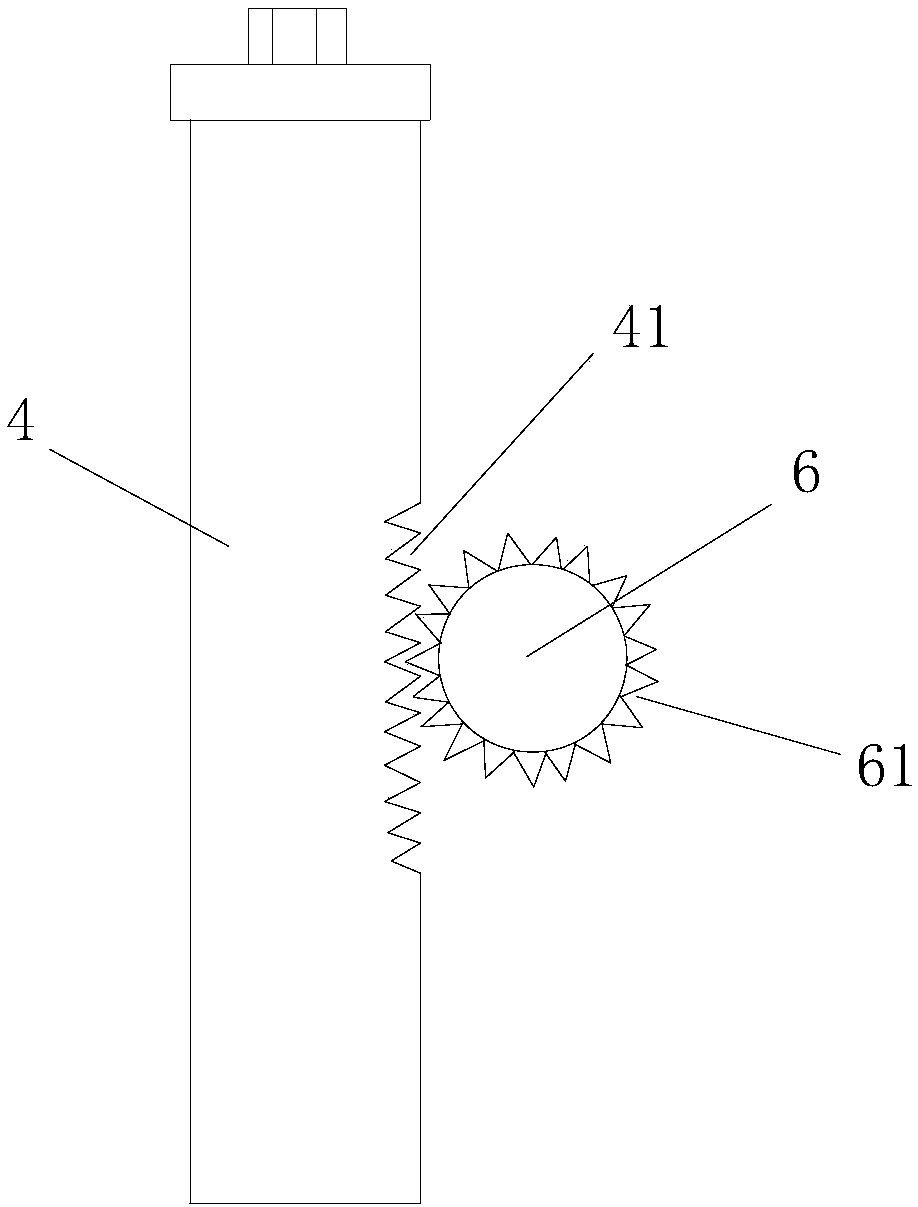

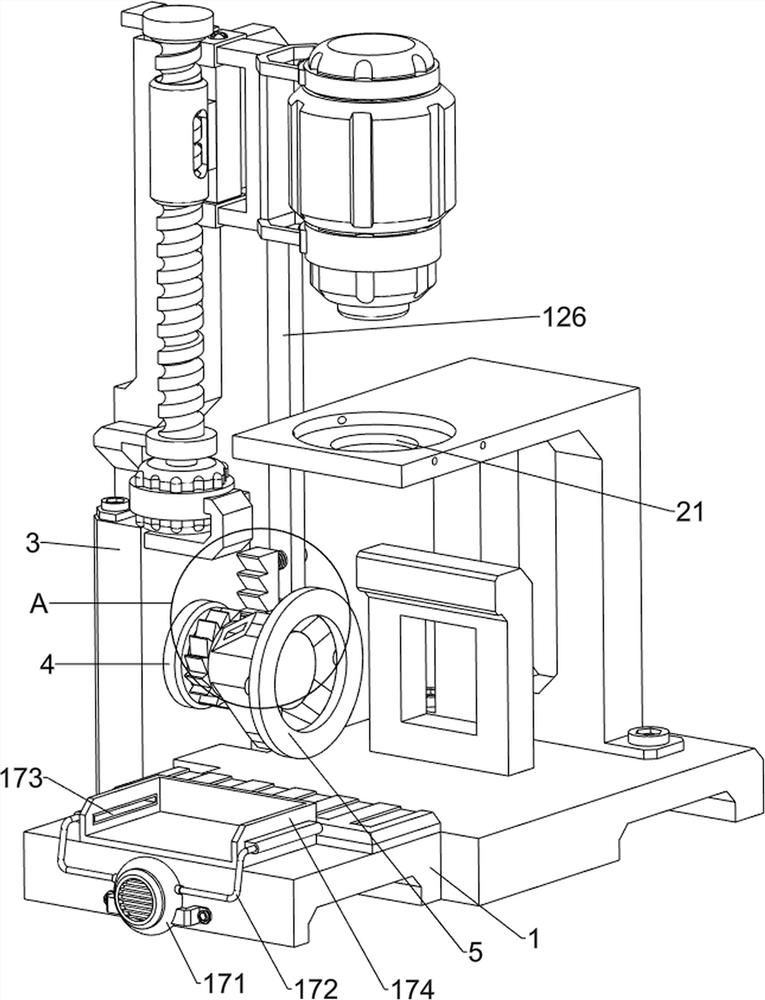

Quick magnet pressing machine

PendingCN108481257AEasy to press and installSimple structureMetal-working hand toolsEngineeringUltimate tensile strength

The invention discloses a quick magnet pressing machine. The quick magnet pressing machine comprises a base, a supporting column, a machine body seat, a rack, a cover plate, a rotary shaft, an operation hand shank, a spring, a spring installation rod, a pressing rod, a positioning guide pipe, an attraction magnet and a positioning fixture device; the pressing rod is arranged at the bottom of the rack and inserted into the positioning guide pipe; the positioning guide pipe can move up and down relative to the pressing rod; a limiting structure is arranged between the pressing rod and the positioning guide pipe; the attraction magnet is fixedly connected to the bottom of the pressing rod and located in the positioning guide pipe; and the positioning fixture device is arranged at the top of the base and located below the positioning guide pipe. According to the quick magnet pressing machine, the structure is simple, operation is convenient, assembling steps are simplified, time and effortare saved, positioning is accurate, the polarities of to-be-pressed magnets can be quickly distinguished without making marks on the to-be-pressed magnets, in addition, the multiple to-be-pressed magnets can be placed in the positioning guide pipe at a time, the taking time is saved, the assembling efficiency is substantially improved, and the labor intensity is relieved.

Owner:东莞市富强磁业科技有限公司

Movable disposable molding die with side wall

The invention discloses a movable disposable molding die with a side wall, which comprises a base. Support pads are welded at four corners of the bottom outer wall of the base, and a lower pressing plate is fixed on the top outer wall of the base through screws. A stamping groove is arranged on the top outer wall of the lower pressing plate. Vertically arranged support plates are welded on both sides of the top outer wall of the base, and top plates with same horizontal are welded on the top outer walls of the two support plates. Sliding slots are arranged at opposite sides of the outer wall of the two support plates, and the inner walls of the two support plates are slidingly connected with a same moving block. A groove is arranged at the bottom outer wall of the moving block, and the inner wall of the groove is slidingly connected with a slide block. An upper pressing plate is fixed at the bottom outer wall of the slide block through a screw. The movable disposable molding die with side wall plays a double buffer function, avoids the damage of the die caused by overpressure, improves the service life of the die, is convenient to carry out the material collection, saves the material collection time, and improves the production efficiency.

Owner:十堰市雄振汽车零部件有限公司

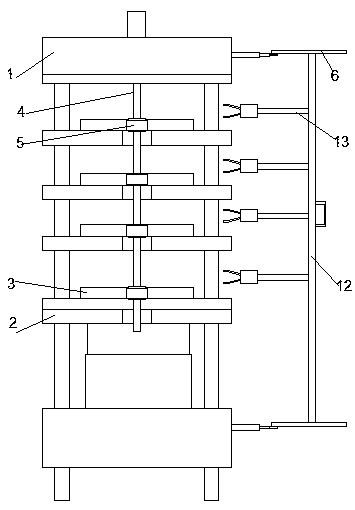

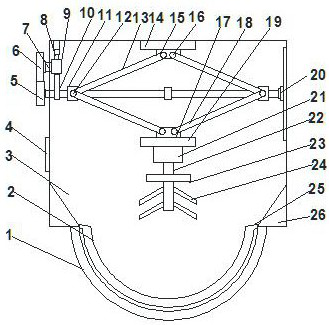

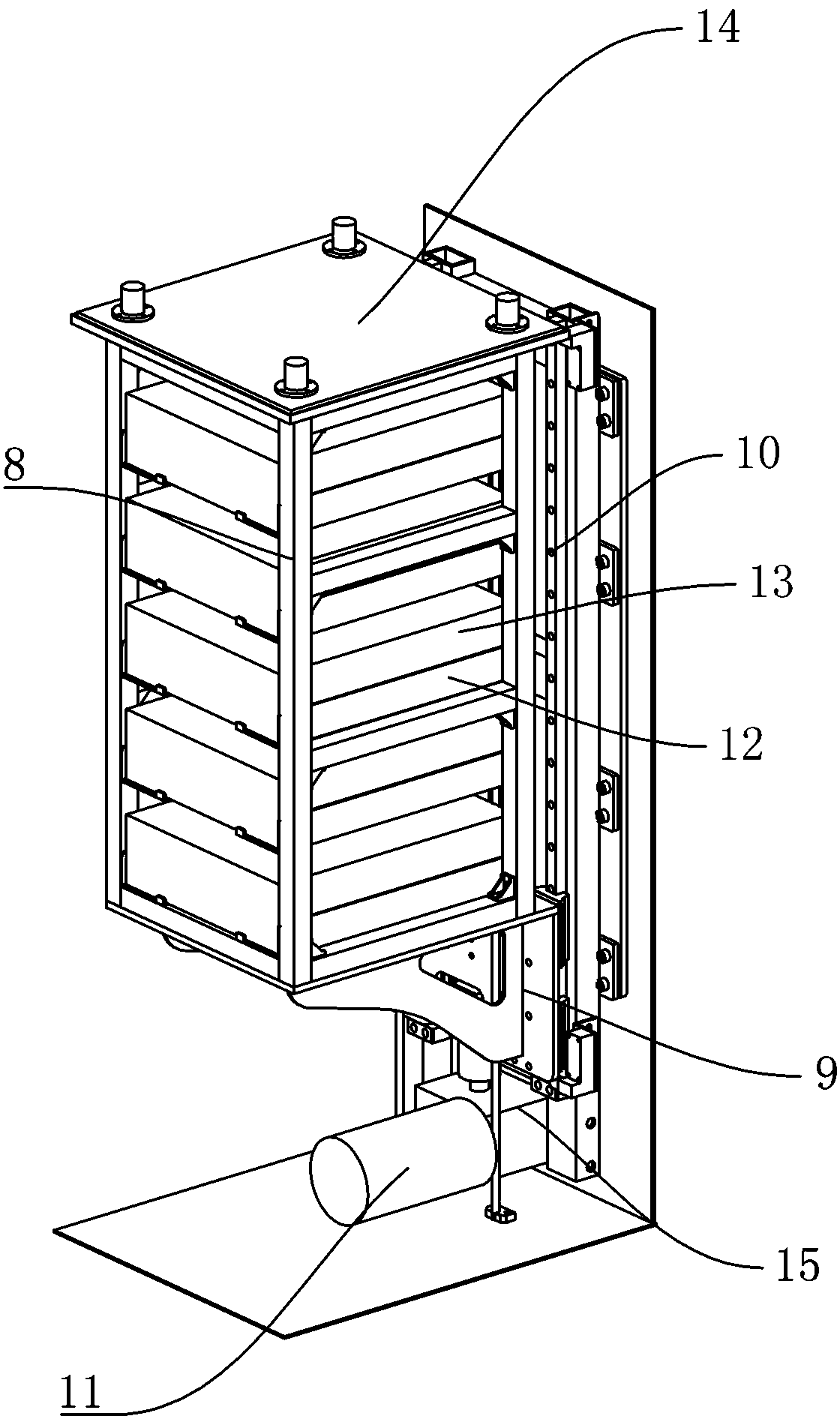

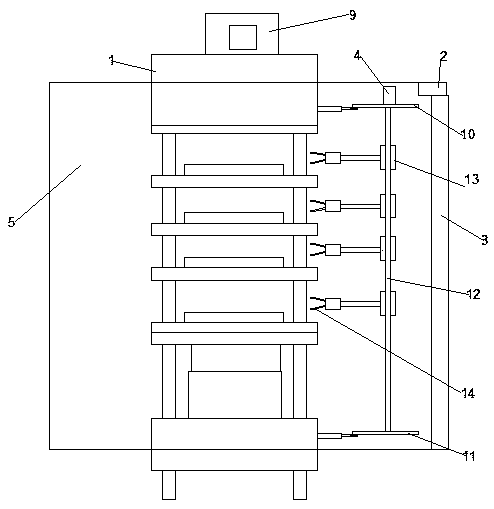

Automatic stripping structure of pressing plate for automatic hot press

The invention discloses an automatic stripping structure of a pressing plate for an automatic hot press. The structure comprises a rack which comprises a base, a top seat and four stand columns connecting the top seat and the base, wherein a bottom oil cylinder is arranged on the base; a bottom plate is arranged at the upper end of the bottom oil cylinder; a lower heating plate is arranged on thebottom plate; an upper heating plate is arranged on the top seat; a plurality of middle heating plates are arranged among four columns between the upper and lower heating plates; mold base plates arearranged on the lower and middle heating plates; a servo motor which drives discharging connecting columns to rotate is arranged on the top seat; a plurality of discharging connecting blocks which eject products in corresponding mold base plates are arranged on each discharging collecting column; a steering material taking rack is arranged on the side wall of the rack; and the steering material taking rack is rotatably fixed to a telescopic rod on the top seat and the base. The structure provided by the invention is simple in structure and reasonable in design, and can take down a formed product from a mold quickly, so that the material taking time is shortened, and the production speed is increased.

Owner:NANTONG HAILITE RUBBER & PLASTIC MACHINERY

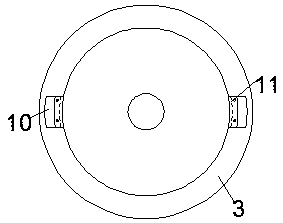

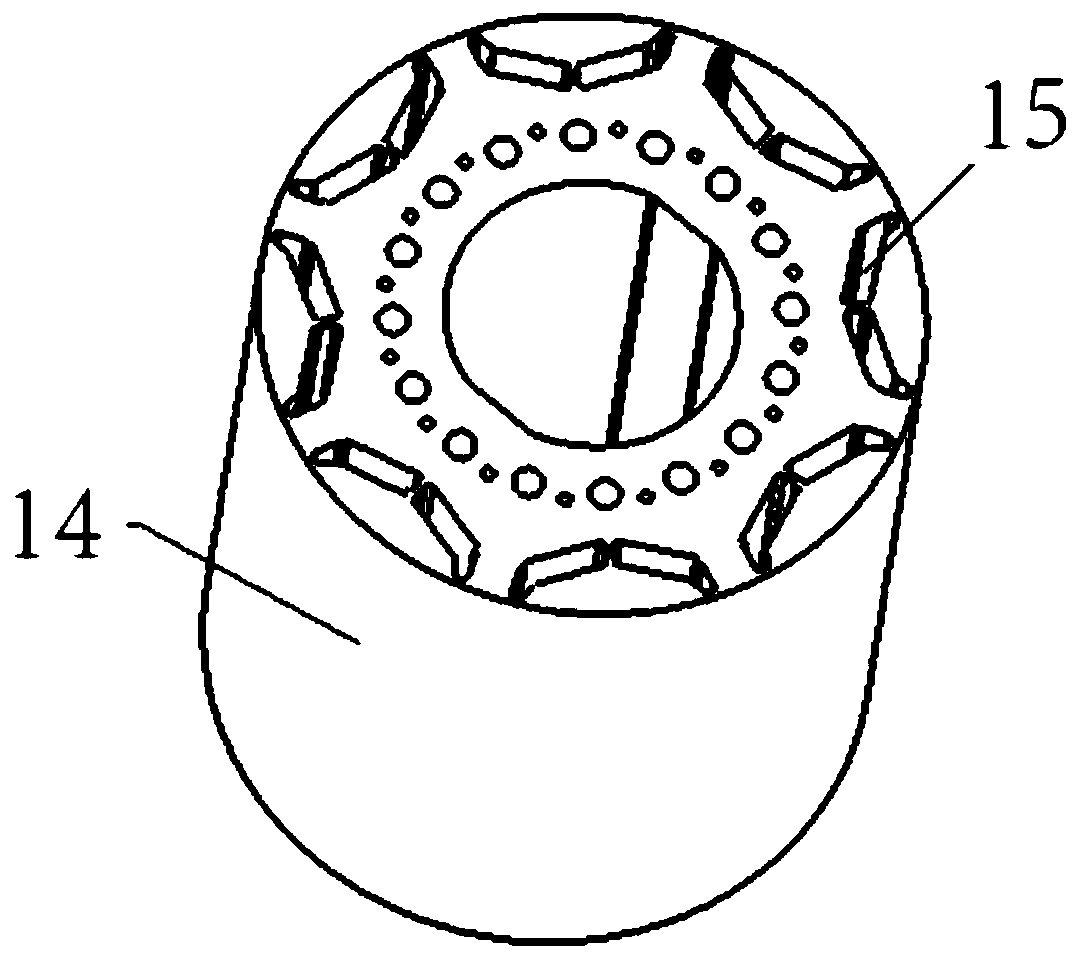

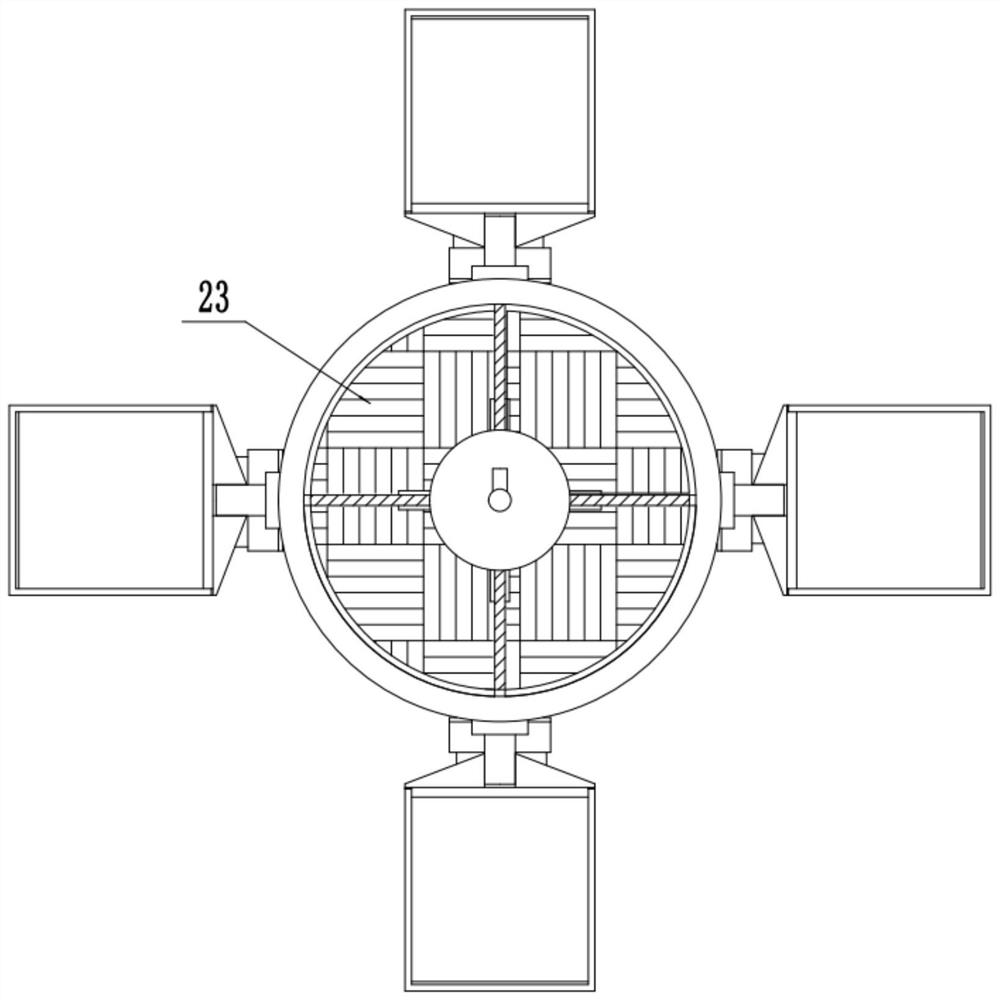

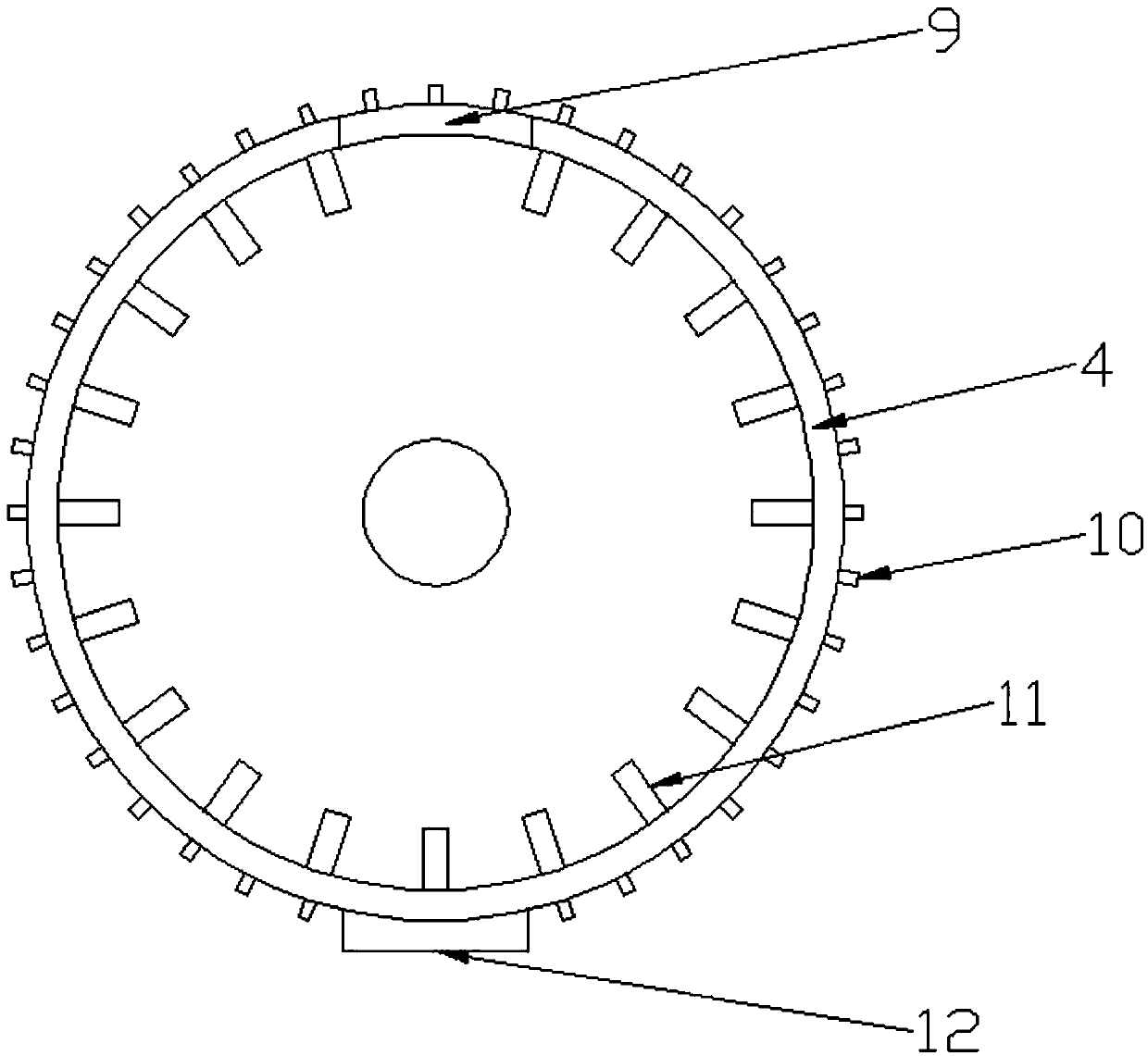

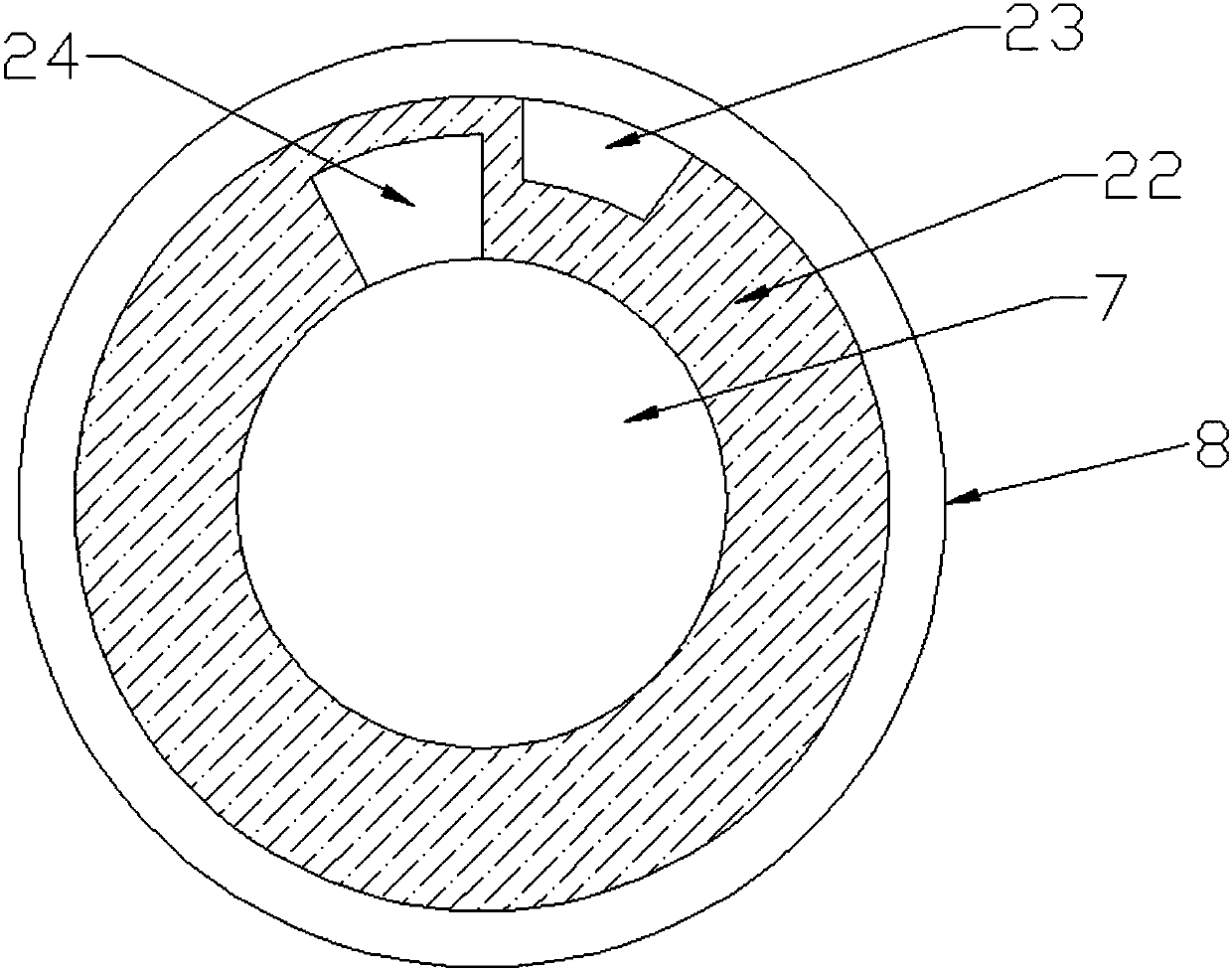

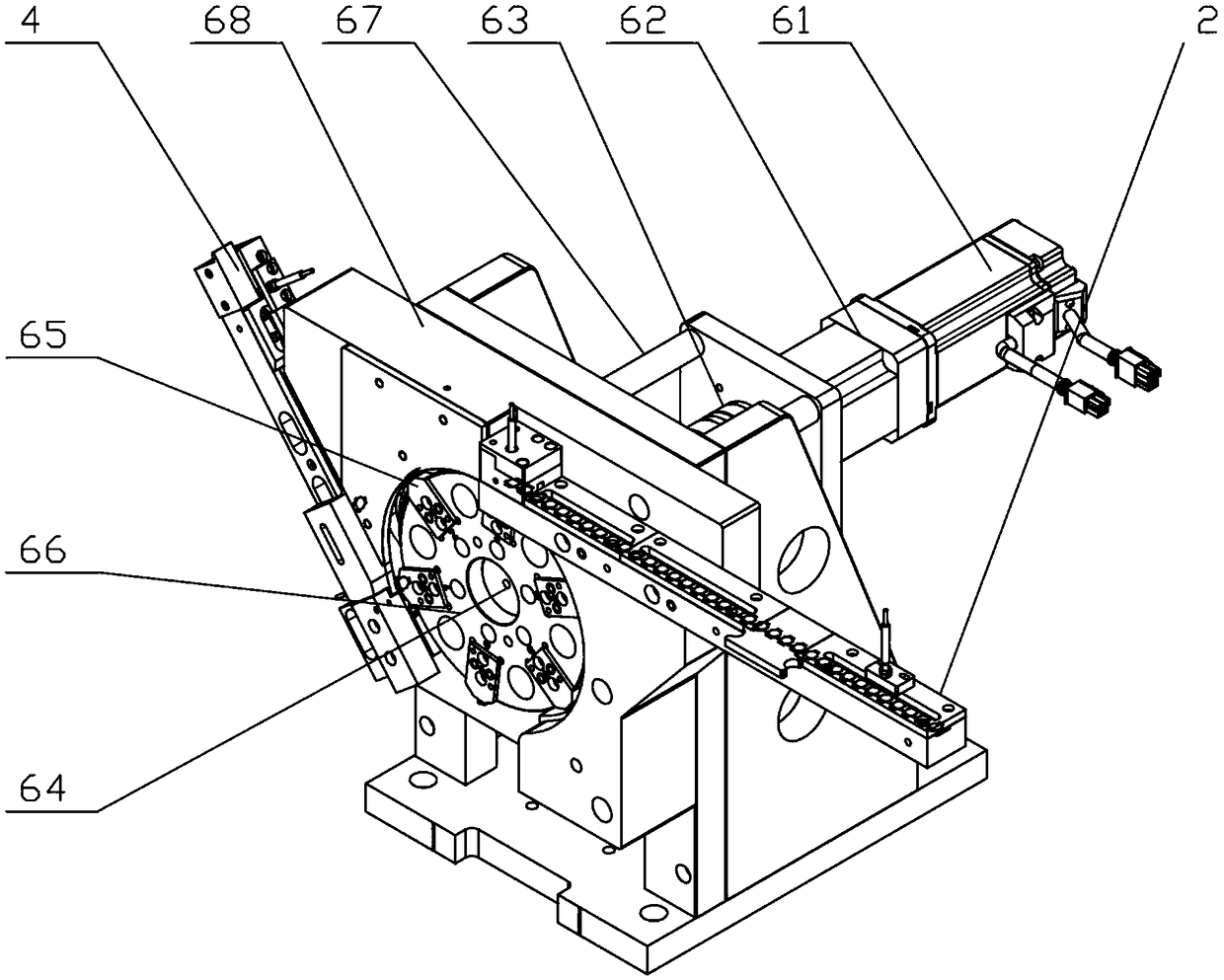

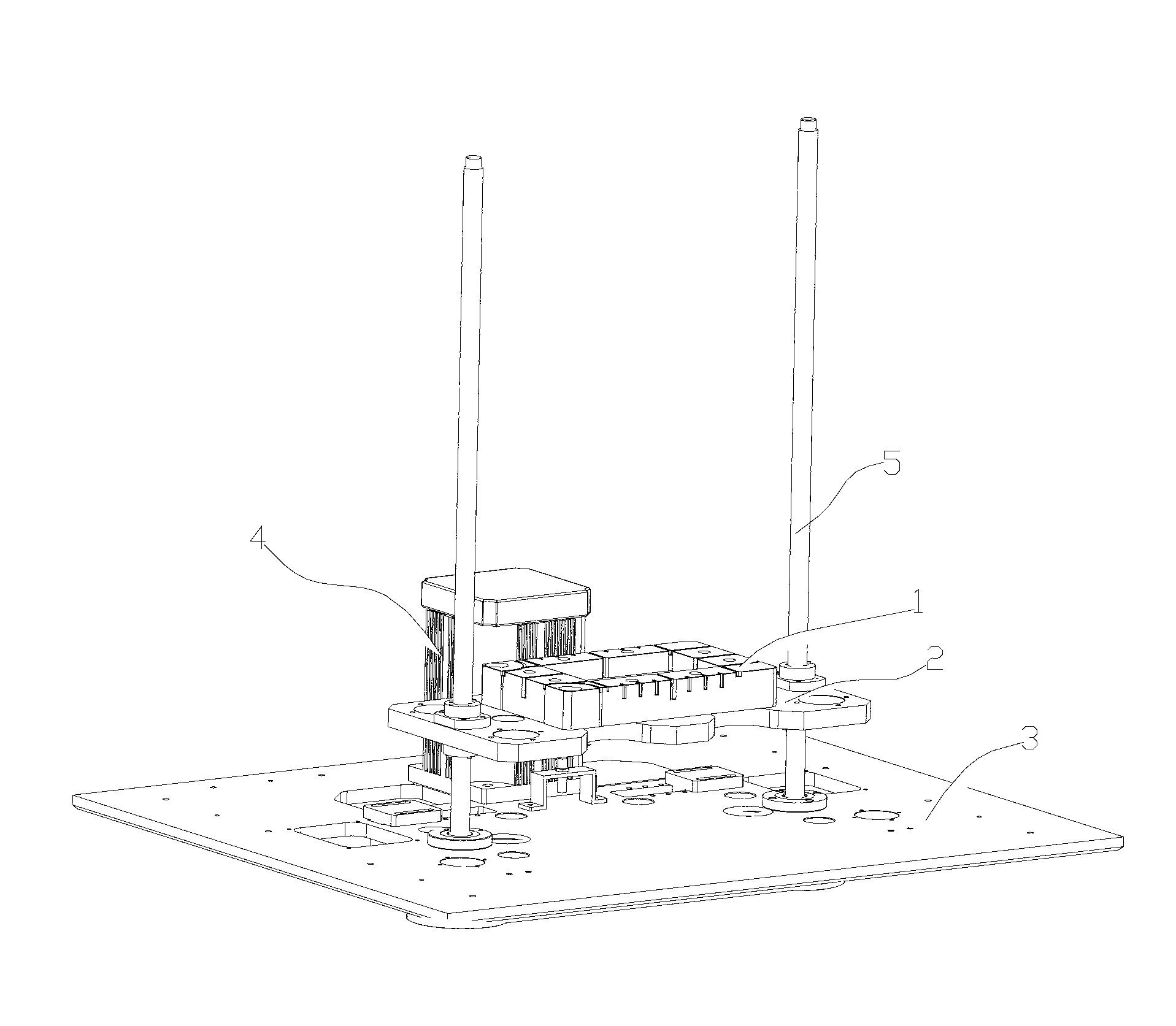

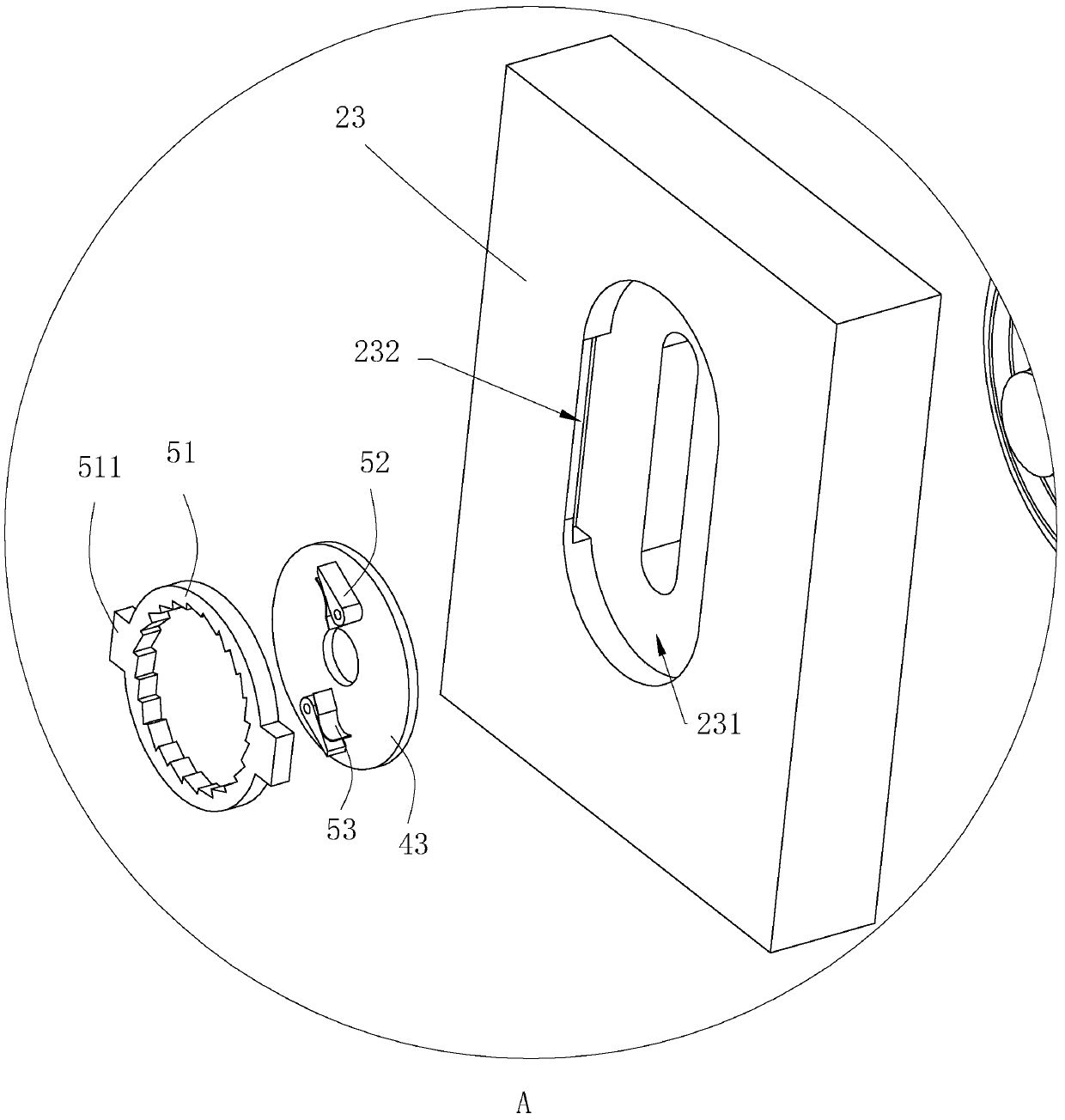

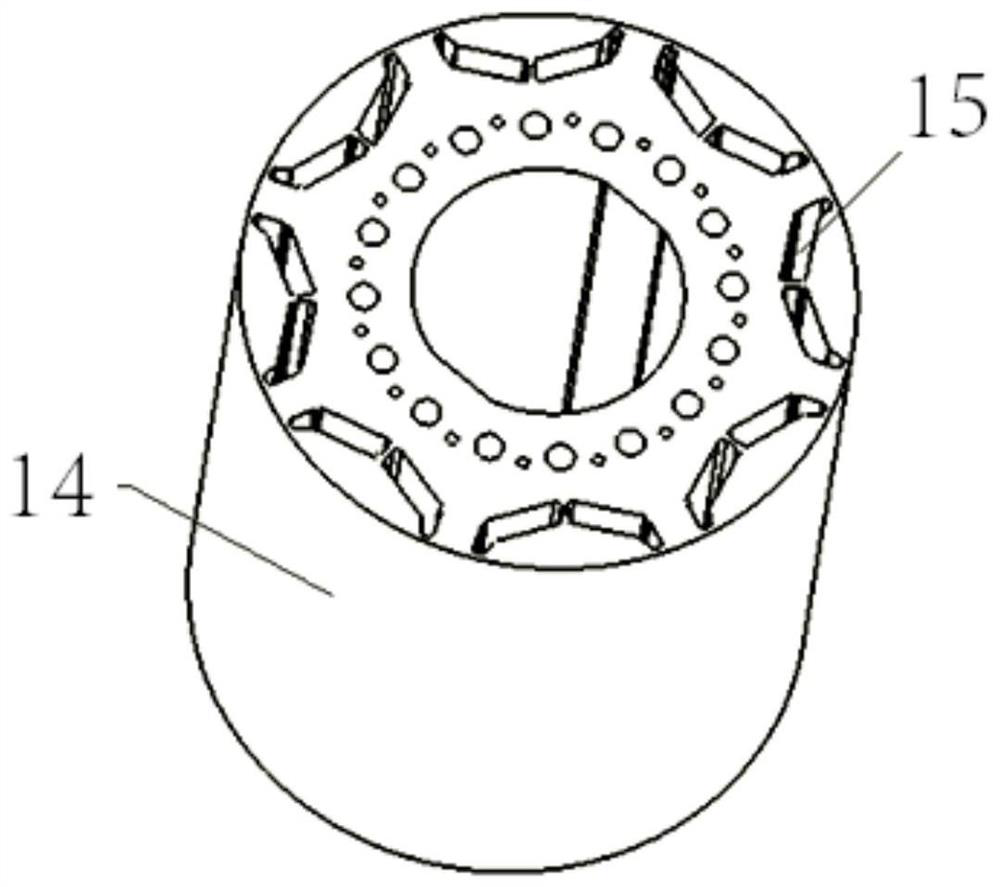

New energy motor rotor magnetic steel feeding assembly mechanism

ActiveCN110653601AAvoid collision riskMeet the installationAssembly machinesManufacturing stator/rotor bodiesElectric machineNew energy

The invention discloses a new energy motor rotor magnetic steel feeding assembly mechanism. The new energy motor rotor magnetic steel feeding assembly mechanism is characterized in that a storage binfor storing N pieces of magnetic steel is included, a discharging opening of the storage bin is located above a vibration feeding mechanism, every time the M pieces of magnetic steel are fed into thevibration feeding mechanism, the vibration feeding mechanism is connected with J arranging mechanisms through a material conveying mechanism, J is greater than or equal to 1, K pieces of magnetic steel arranged by the arranging mechanisms are taken at a time by the material conveying mechanism, and K is greater than or equal to 1. According to the new energy motor rotor magnetic steel feeding assembly mechanism, a vibration disk and a food supplementing bin, and a material storing mechanism performs feeding by a method of transferring by a conveyor belt line to form a buffer zone with rapid reflection; upward shaping is adopted in a shaping mechanism, five pieces are fed at a time without causing magnetic steel damage actions such as collision and vibration; a four-axis robot is adopted totake materials, the K pieces of magnetic steel are taken at a time, so that according to the structure of a rotor core, multiple pieces can be inserted at a time, or continuous multiple-time insertion is carried out without taking the materials, the material taking time is shortened, and the efficiency and stability of magnetic steel insertion are greatly improved.

Owner:COMAU SHANGHAI ENG

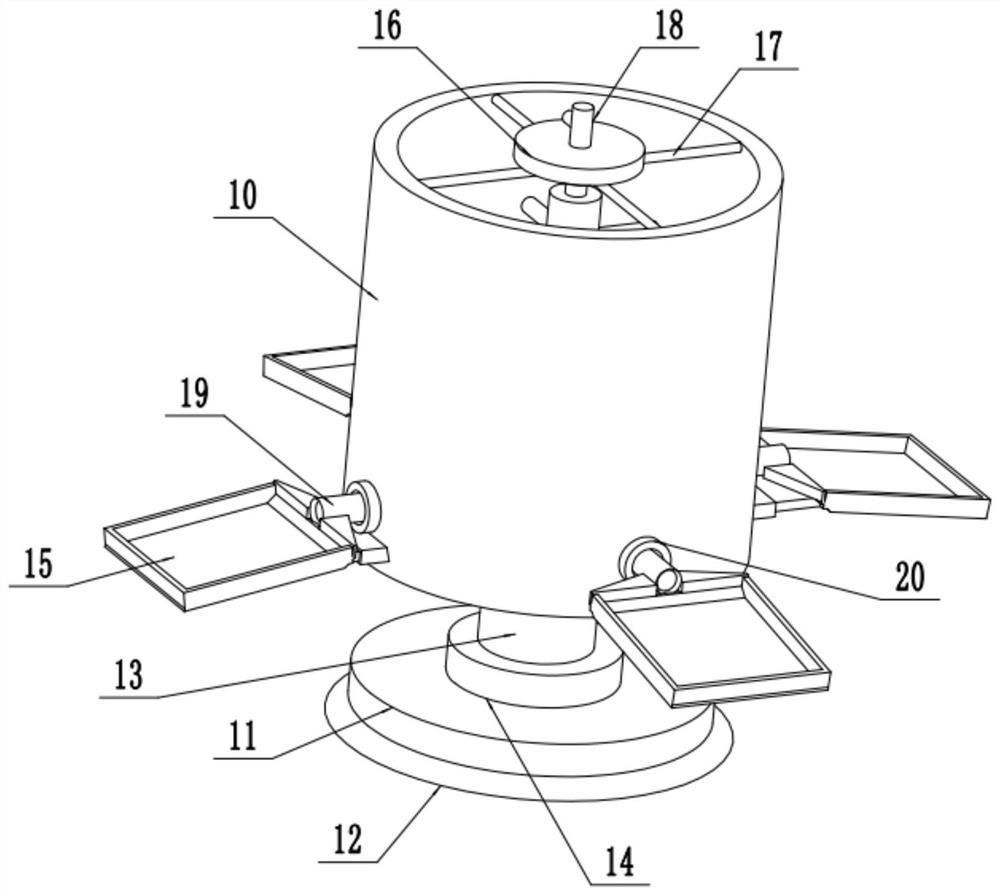

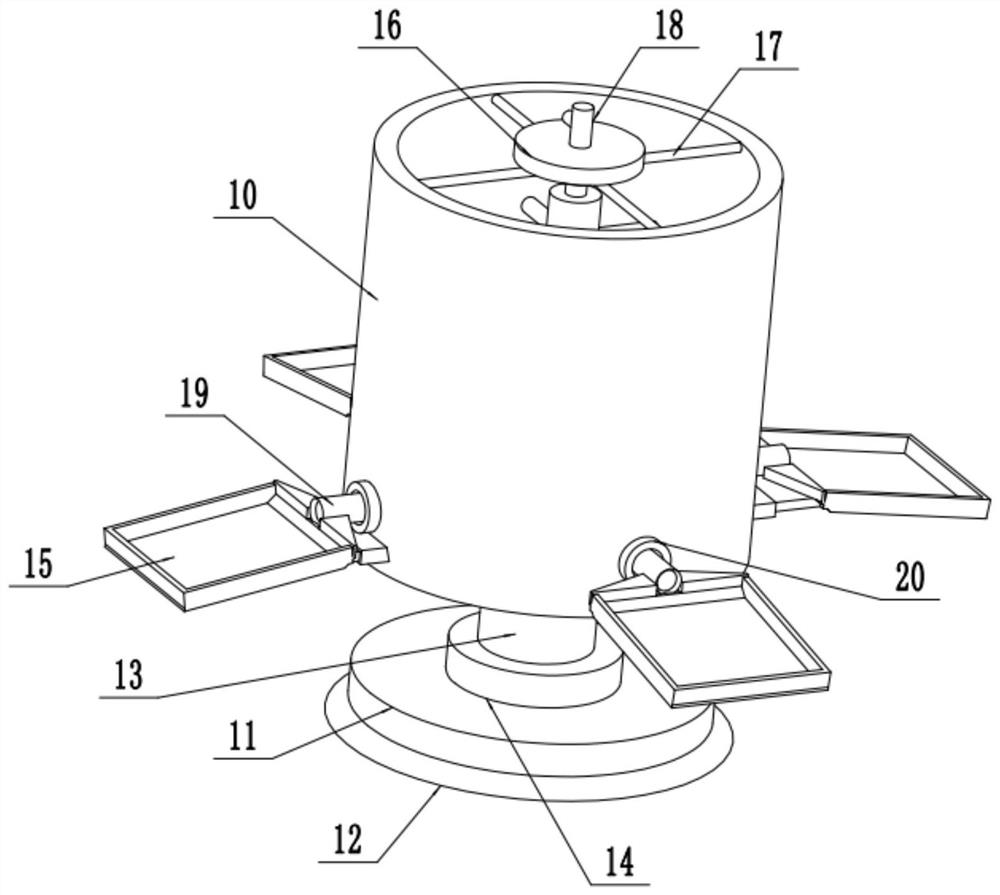

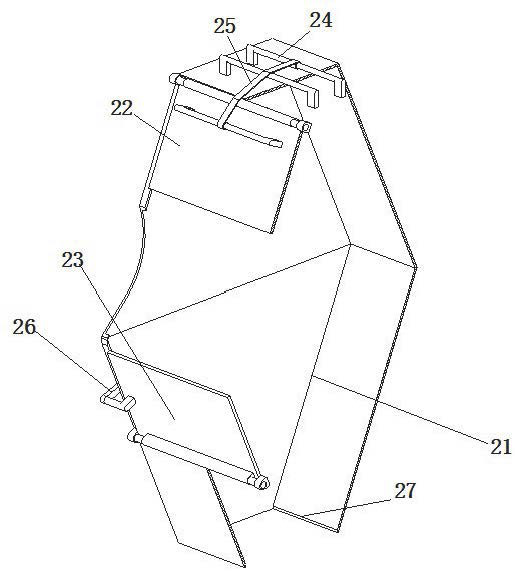

Automatic discharging type continuous feeding device for decoration wall building

ActiveCN112064987ARealize automatic dischargeSave time for retrievingRotary stirring mixersBuilding constructionsArchitectural engineeringStructural engineering

The invention relates to the technical field of decoration equipment, and discloses an automatic discharging type continuous feeding device for decoration wall building. The automatic discharging typecontinuous feeding device for decoration wall building comprises a charging basket and a base; four groups of inserting holes are annularly formed in the lower portion of the outer side wall of the charging basket in an equally spaced mode; wall building tool discs which are in the form of rectangular structures are arranged on the outer sides of the inserting holes; disc barrels are fixedly connected to the middle parts of the right ends of the wall building tool discs; left-right penetrating structures are arranged in the disc barrels; the disc barrels are connected to the interiors of theinserting holes in an inserted mode; the upper sides of the inner ends of the disc barrels are of inclined plane structures; discharging grooves which are in the form of flared structures are respectively and downwardly formed in the positions, corresponding to the inserting holes, on the upper sides of the inner bottoms of the charging baskets; sealing plates are arranged in the discharging grooves; lifting rods with the bottom ends in contact with the inclined plane structures in a matched mode are downwardly and fixedly connected to the centers of the bottoms of the sealing plates; and discharging passages are downwardly formed in the discharging grooves in the sides, far away from the center of the charging basket, of the lower portions of the sealing plates. The automatic dischargingtype continuous feeding device for decoration wall building has the advantages that automatic discharging and continuous feeding are achieved, the material taking time is saved, and the working efficiency is enhanced.

Owner:周狄超

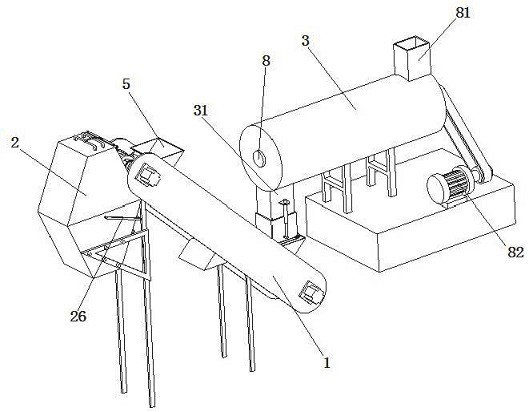

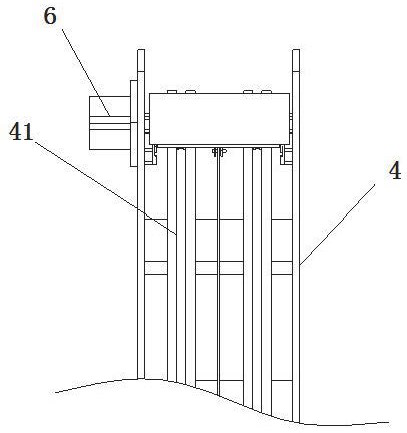

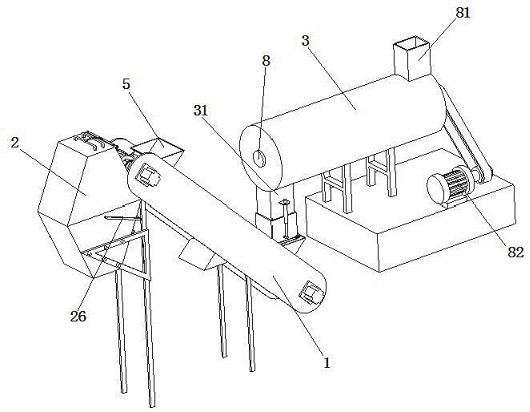

Powder lifting device for commercial concrete production

ActiveCN112407787ARealize continuous feedingSave time for retrievingConveyorsCement mixing apparatusAgricultural engineeringChain link

The invention relates to the technical field of material transportation, in particular to a powder lifting device for commercial concrete production. An obliquely-arranged lifting device, a dust coverand a mixing barrel are included, the lifting device comprises an obliquely-arranged sliding frame, feeding hoppers and a driving assembly, and the dust cover is provided with a baffle plate assembly. The end, located over the bottom end of the sliding frame, of the mixing barrel downwards communicates with a dustproof feeding barrel, the sliding frame comprises a long-strip-shaped inclined bearing frame and two long-strip-shaped inclined protection plates, the inclined bearing frame is provided with an annular sliding way, annular sliding rails are arranged on one sides of the two inclined protection plates correspondingly, and all the feeding hoppers are provided with sliding bases. By means of the powder lifting device, continuous feeding of the feeding hoppers is achieved, the time for the hoppers to repeatedly move up and down for material taking is shortened, the material lifting efficiency is improved, the length of a chain is shortened through the driving assembly, the tensilestrength of the chain is improved, and the diffusion and flying conditions of powder are reduced.

Owner:平邑中联水泥有限公司

Efficient pole piece cutting device for battery production

InactiveCN113843334AAvoid damageEfficient separationSievingMetal-working feeding devicesBristleCell fabrication

The invention discloses an efficient pole piece cutting device for battery production and relates to the technical field of battery manufacturing. The efficient pole piece cutting device comprises an outer shell, wherein a baseplate is fixedly connected with the inner wall of the left side of the outer shell; a mounting block is fixedly connected with the outer wall of the baseplate; a second mold is fixedly mounted on the outer wall of the mounting block; a first mold is arranged corresponding to the right side of the second mold; a dust removal device is arranged at the bottom of the first mold, and comprises a square frame, rotating shafts, first square blocks, second square blocks, rotating rollers and bristles; the square frame is fixedly mounted in the middle of the inner wall of the outer shell through connecting rods; adjusting grooves are formed in both the front side wall and the rear side wall of the square frame; the first square blocks are fixedly mounted at the left ends of the adjusting grooves; second square blocks are slidably connected into the adjusting grooves; first springs are fixedly connected between the first square blocks and the second square blocks; the rotating rollers are fixedly mounted on the outer sides of the rotating shafts; and the bristles are fixedly mounted on the outer sides of the rotating rollers. Consequently, pole pieces can be effectively separated from powder impurities, and the classified collection can be facilitated.

Owner:李晓洋

Wax block forming machine for wax therapy rehabilitation

InactiveCN111700724AAchieve recyclingLow costTherapeutic coolingTherapeutic heatingTemperature controlTherapy rehabilitation

The invention discloses a wax block forming machine for wax therapy rehabilitation, and belongs to the field of medical instruments and equipment. The wax block forming machine is used for manufacturing wax cakes for wax therapy and comprises a wax melting box, a wax cake manufacturing box and a controller, the wax melting box is located at the upper end of the wax cake manufacturing box, and a plurality of trays which are arranged in a layered mode and used for containing the wax cakes are installed in the wax cake manufacturing box; the interior of the wax cake manufacturing box is at leastdivided into two temperature areas, each temperature area is subjected to temperature adjustment through an independent temperature control system, and the wax cakes are manufactured through an independent feeding system; and the temperature control systems and the feeding system are controlled through the controller. Therefore, the wax blocks in multiple temperature intervals can be prepared in single equipment, the flexibility of preparing the wax blocks by the single equipment is improved, and the purchase cost of units such as hospitals is reduced.

Owner:临沂职业学院

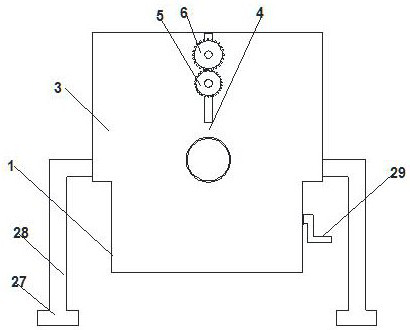

A kind of blanking device for nano-zinc oxide production and processing

ActiveCN111907944BEasy accessEnhance pick and place effectLarge containersGrain treatmentsElectric machineGear wheel

The invention discloses a cutting device for the production and processing of nano-zinc oxide, which includes a cutting box, a processing box and a double-headed threaded rod; The arc-shaped adjustment box on the top is rotated. After rotating to any arc, the zinc oxide particles inside the adjustment box will fall along the end edge of the adjustment box to the inside of the lower material box. The feeding hole is used to feed the material; when the zinc oxide is damp and agglomerated and cannot fall, first start the forward and reverse motor to drive the upper drive rod and the driving gear to rotate, so that the thread blocks at both ends of the double-ended thread rod are turned inward or outward Move, extend the crushing knife on the lower side of the crushing motor into the interior of the adjustment box to break the agglomerated zinc oxide particles, which can break the agglomerated zinc oxide particles and prevent the agglomerated zinc oxide particles from passing through Feeding hole blanking.

Owner:安徽省含山县锦华氧化锌厂

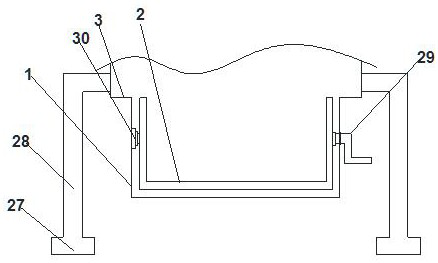

Transverse medicinal material machining cleaning device

InactiveCN108031684AAvoid residueImprove cleaning efficiencyCleaning using liquidsFree rotationOperational safety

The invention discloses a transverse medicinal material machining cleaning device. The transverse medicinal material machining cleaning device comprises a shell, a feeding hopper, a motor, an inner cylinder and supporting legs; a horizontal sleeve is arranged on the outer side of a rotating shaft in a sleeving manner, a lubricating oil cavity is formed in the sleeve, multiple inner check blocks onthe same horizontal straight line are fixed to the position, on the side wall of the rotating shaft, in the lubricating oil cavity, multiple outer check blocks in the same horizontal direction are fixed to the position, on the inner wall of the sleeve, in the lubricating oil cavity, floating balls are fixed to the two sides of a feeding and discharging opening, and a balancing weight is fixed tothe position, corresponding to the feeding and discharging opening, under the inner cylinder. The check blocks are arranged between the rotating shaft and the sleeve, it is ensured that the rotating shaft drives the sleeve to rotate, the sleeve can do a certain-angle free rotation on the rotating s haft, when the inner cylinder stops, manual rotation is facilitated, the position of the feeding anddischarging opening is adjusted, medicinal materials in the inner cylinder can be rapidly poured out, inner medicinal material residue is avoided, material taking time is saved, the medical materialcleaning efficiency is improved, and operation is safe and easy.

Owner:COMMON TECH DEV CO LTD

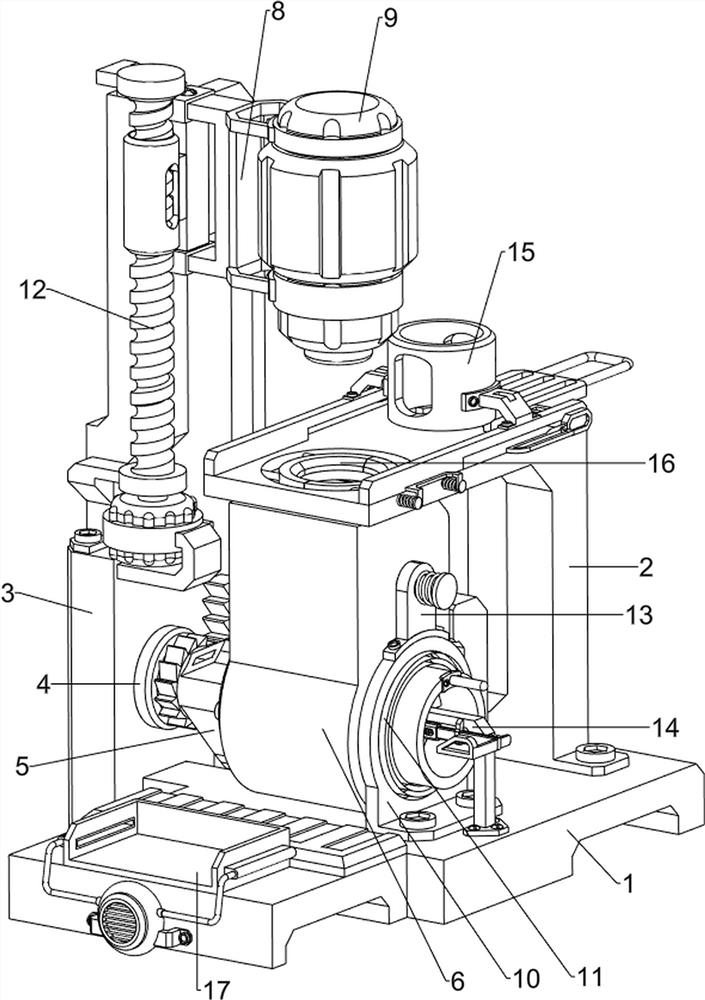

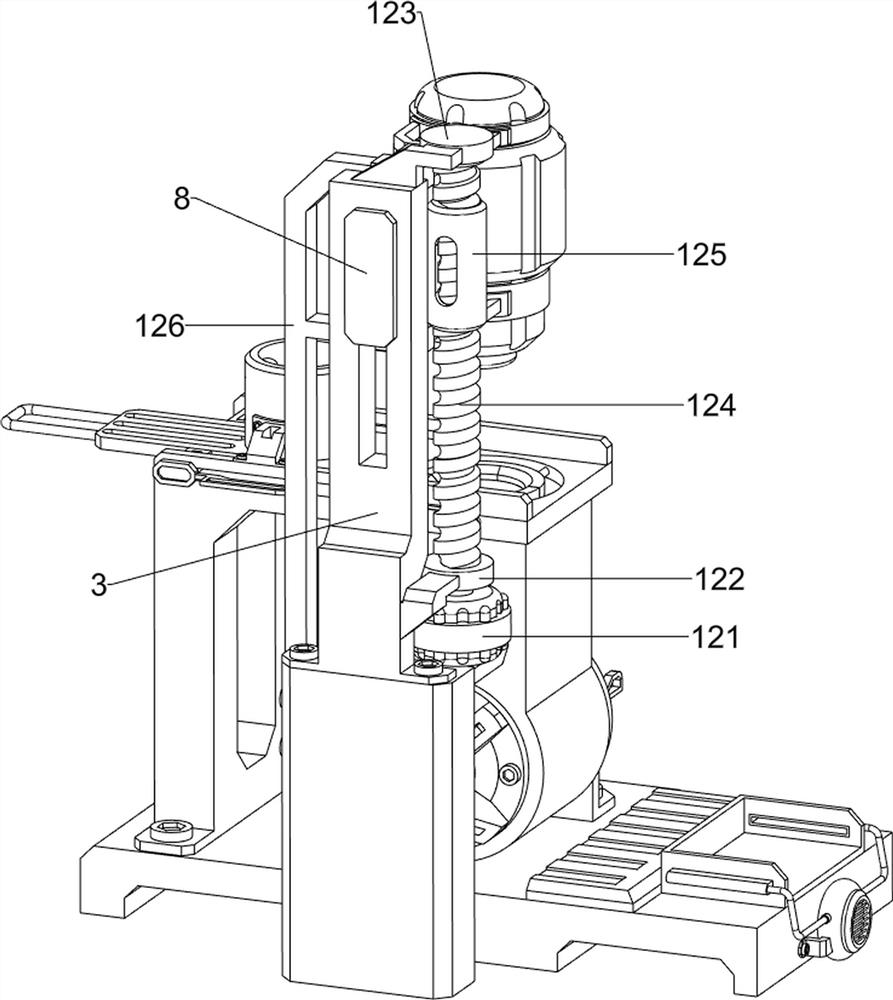

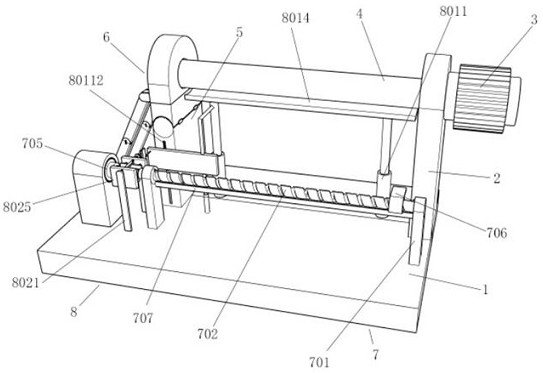

Automatic stamping mechanism for stretching forming of cylindrical battery steel shell

ActiveCN114632861ASave time for retrievingAchieve the effect of automatic dischargeShaping toolsMetal-working feeding devicesElectrical batteryClassical mechanics

The invention relates to an automatic stamping mechanism, in particular to an automatic stamping mechanism for stretching forming of a cylindrical battery steel shell. The invention provides the automatic stamping mechanism for stretching and forming the cylindrical steel shell of the cylindrical battery, which can automatically discharge. An automatic stamping mechanism for stretching forming of a cylindrical battery steel shell comprises a base, a containing frame, a mounting plate, a bearing connecting base, a connecting shaft frame, a die and the like, the containing frame is connected to the middle of the top of the base, the mounting plate is connected to the rear side of the base, the bearing connecting base is connected to the front side of the mounting plate, and the connecting shaft frame is rotationally connected to the bearing connecting base. The front side of the connecting shaft bracket is connected with a mold. The wedge-shaped block is extruded through the touch rod, so that the bevel baffle does not limit the round-head rod any more, the automatic discharging effect is achieved under pushing of the flat-top piston, the time for workers to take materials is effectively shortened, and the working efficiency is improved.

Owner:新乡市正元电子材料有限公司

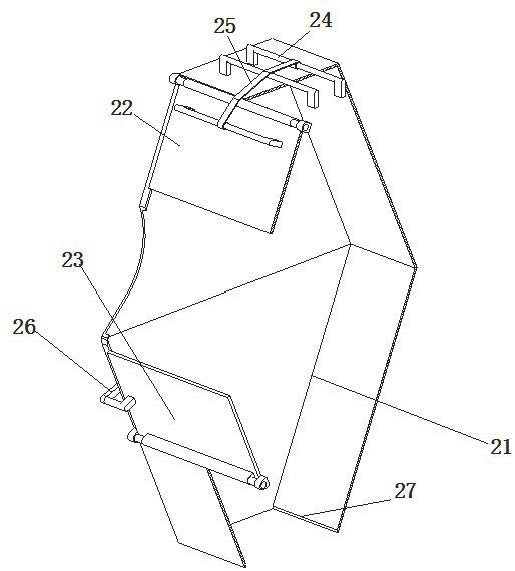

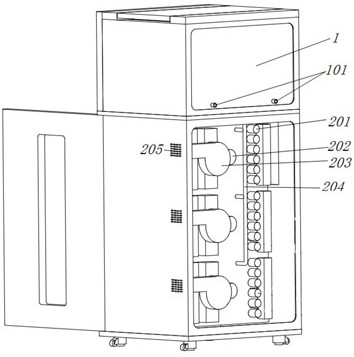

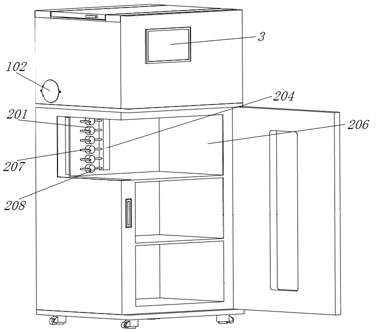

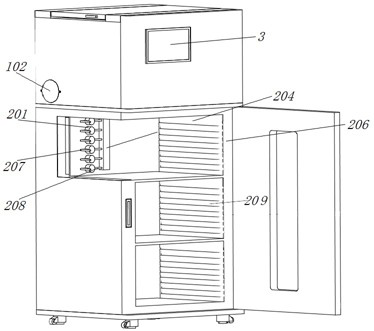

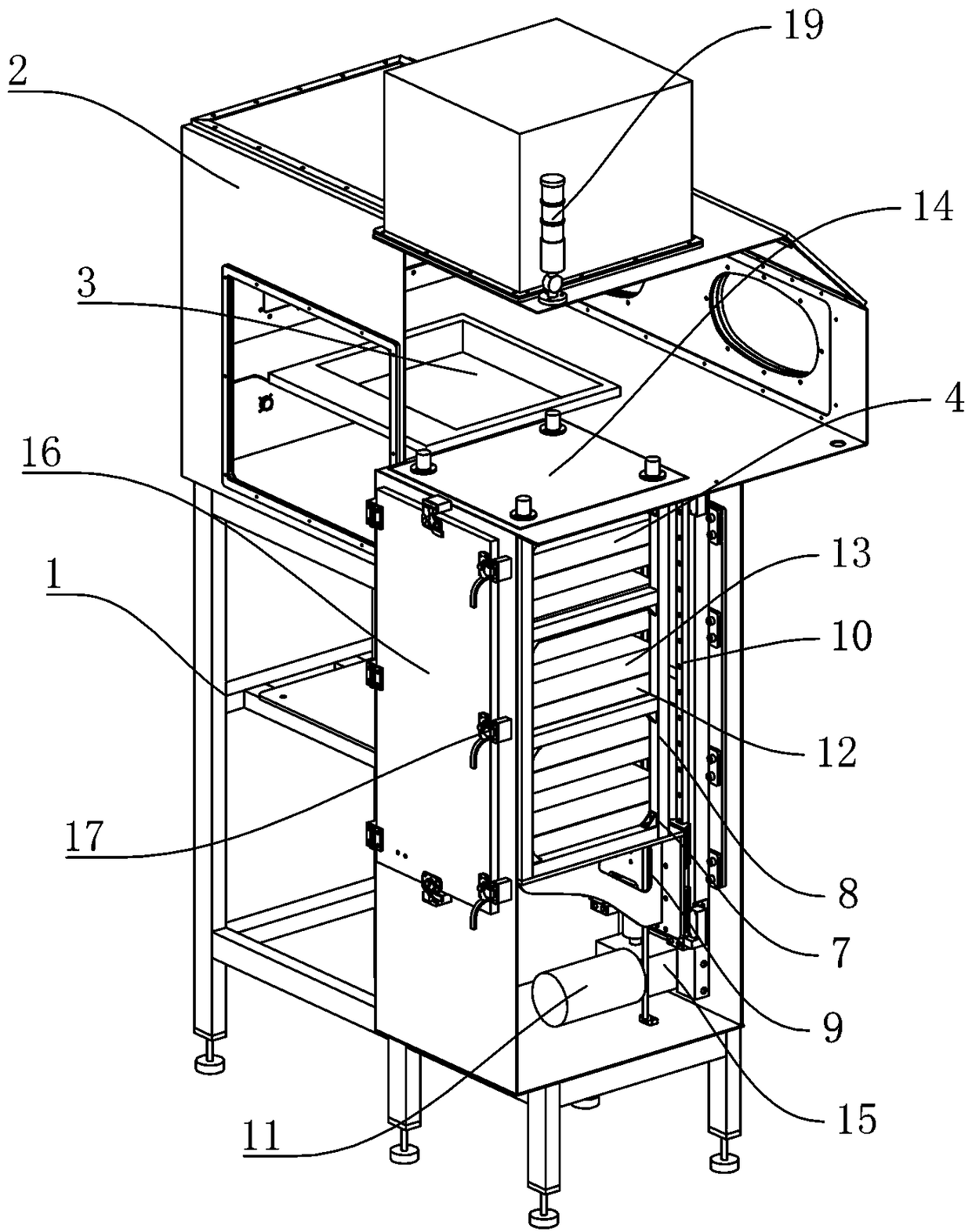

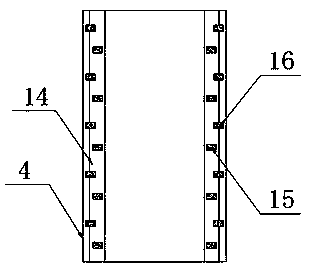

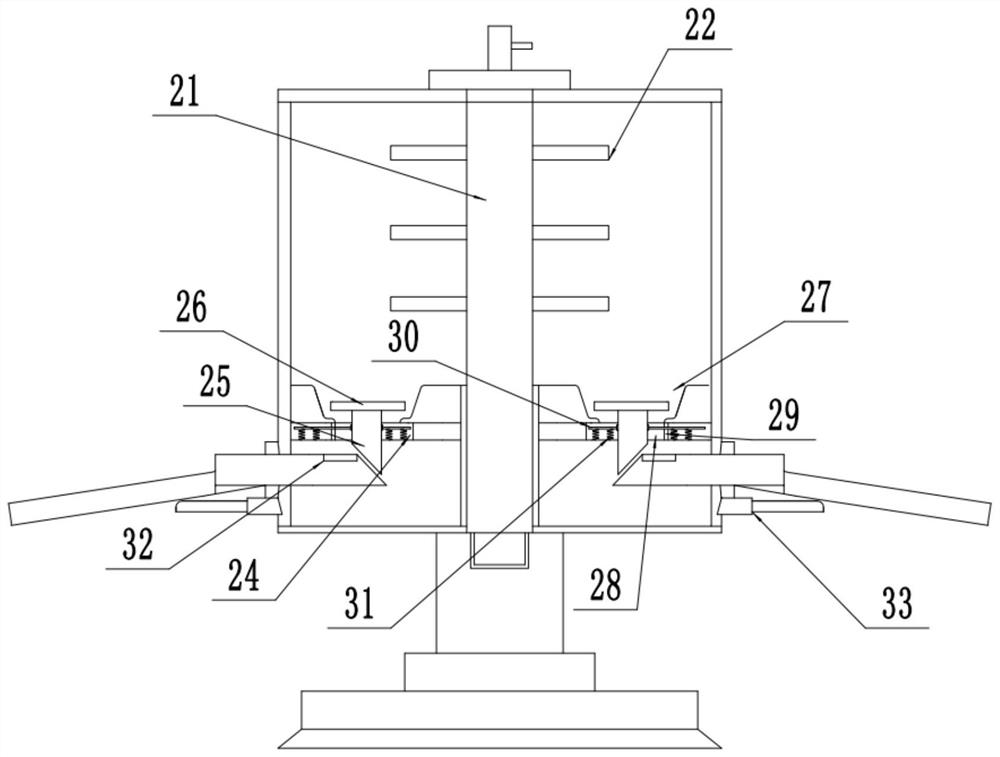

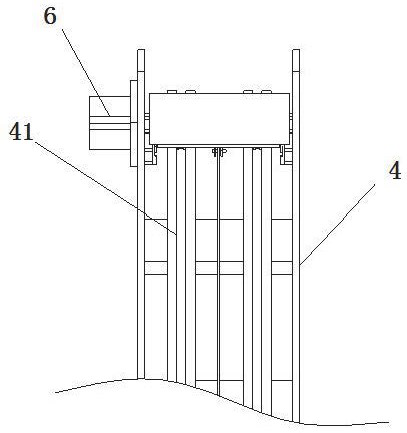

Multilayered glove box

PendingCN108327972AReduce the number of workpiece removalsSave time for retrievingPackaging under special atmospheric conditionsReciprocating motionGlovebox

The invention discloses a multilayered glove box. The multilayered glove box comprises a rack. A box body is arranged on the rack. A packaging chamber and a material picking chamber are formed in thebox body in an enclosed manner. The material picking chamber is formed below the packaging chamber. The rack is provided with a vacuum packaging machine, wherein the vacuum packaging machine is matched with the packaging chamber. The box body is provided with glove openings and an observation window. A mounting opening is formed between the packaging chamber and the material picking chamber. A material conveying mechanism is arranged between the packaging chamber and the material picking chamber through the mounting opening. The material conveying mechanism comprises a stacking bracket, a lifting platform, a liner track and a driving mechanism. Multiple storage plates are vertically put in the stacking bracket. A material tray is arranged on each storage plate. The stacking bracket is vertically arranged on the linear track in a sliding manner through the lifting platform. The stacking bracket is driven by the driving mechanism to perform reciprocating motion between the packaging chamber and the material picking chamber through the mounting opening. According to the multilayered glove box, the material conveying mechanism is arranged between the packaging chamber and the materialpicking chamber through the mounting opening, multiple workpieces can be packaged one time and then taken out in a centralized manner; the number of times of taking out the workpieces is reduced; andwork efficiency is improved.

Owner:BAIQIDA INTELLIGENT TECH NINGBO CO LTD

Automatic Tea Straightening Machine

ActiveCN104012688BSave time for retrievingIncrease productivityPre-extraction tea treatmentReciprocating motionEngineering

Owner:安徽绿源机械科技股份有限公司

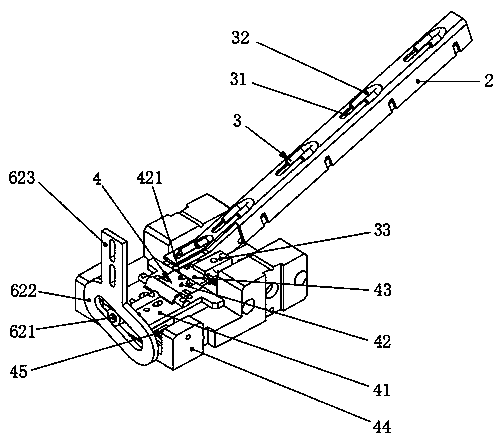

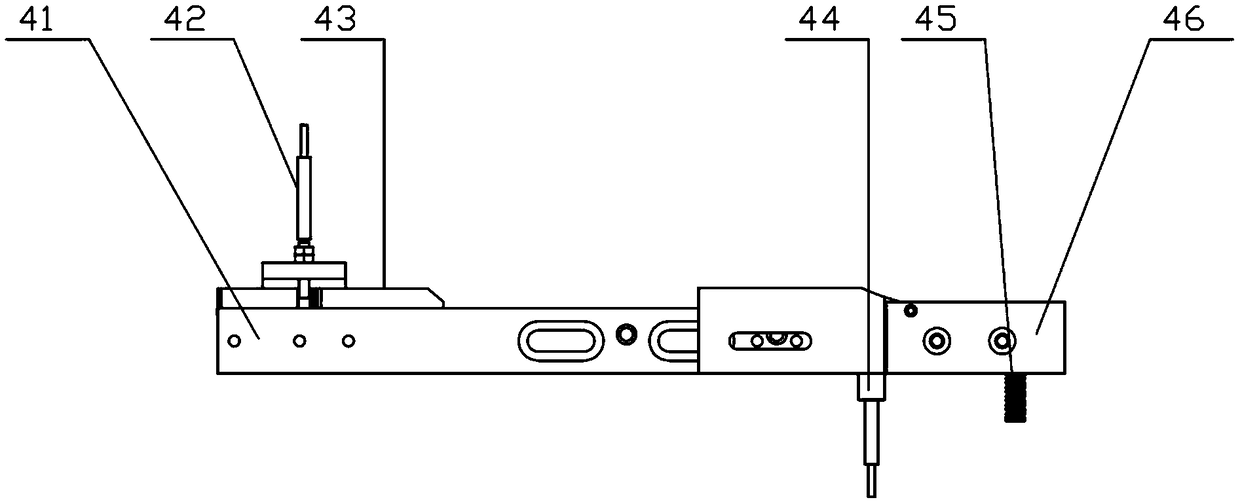

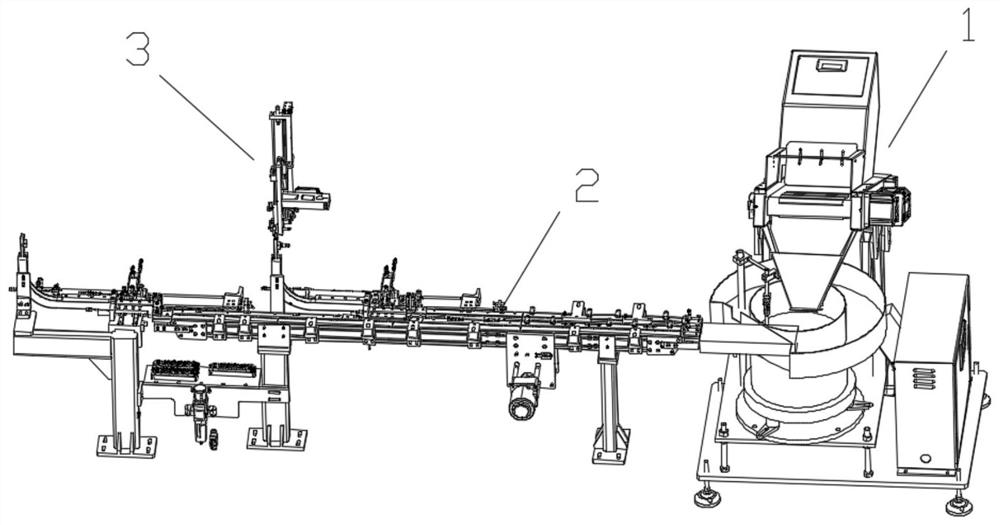

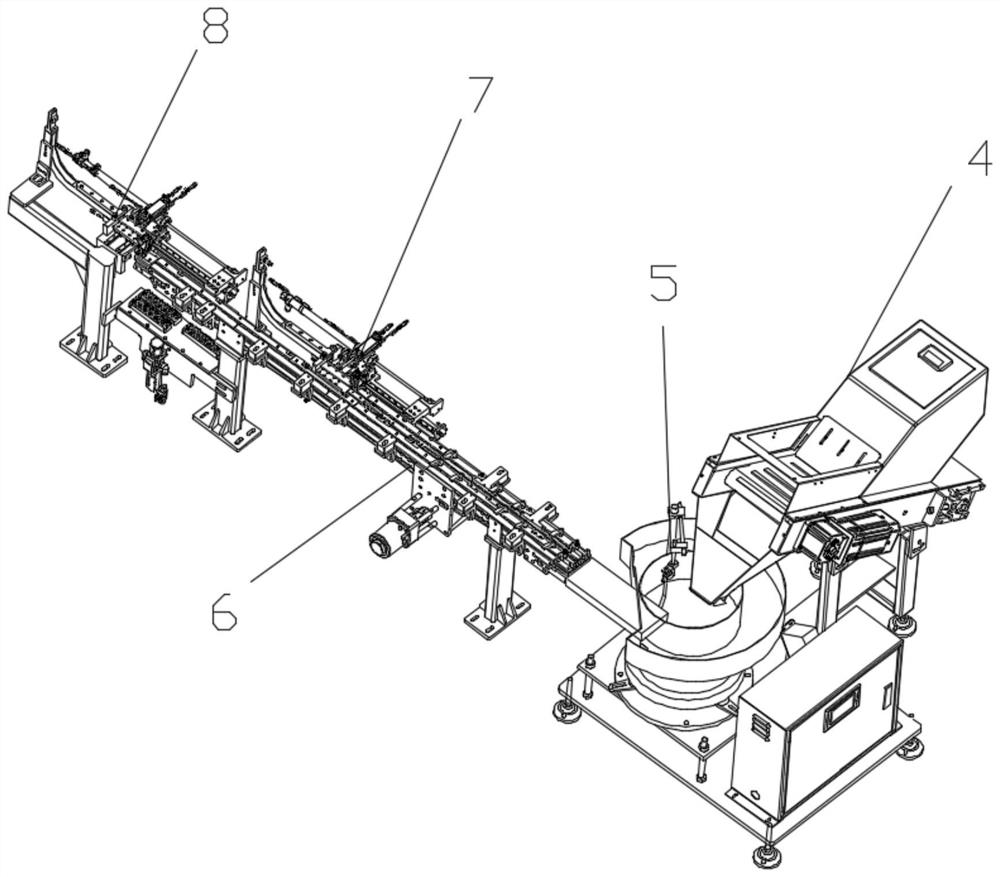

Automatic screw conveying device and automatic assembling equipment with same

ActiveCN109531120ASimple structureSave time for retrievingMetal working apparatusEngineeringMachining

The invention discloses an automatic screw conveying device and automatic assembling equipment with the same. The automatic screw conveying device comprises a bottom mounting base, a conveying groovewhich is formed in the upper end of the bottom mounting base and is used for conveying screws, a material taking mechanism used for receiving the screws, and a driving mechanism which is used for driving the material taking mechanism to horizontally move so as to convey the screws to a machining station, wherein the material taking mechanism comprises a sliding seat which is slidably connected tothe bottom mounting base, a feeding lower hinge which is rotationally connected to the sliding seat and is arranged towards the conveying groove, and notches which are formed in one end, facing the conveying groove, of the feeding lower hinge and are used for containing the screws. Thus, the purpose of automatically and continuously conveying the screws is achieved.

Owner:SHENZHEN SKYWORTH PRECISION TECH

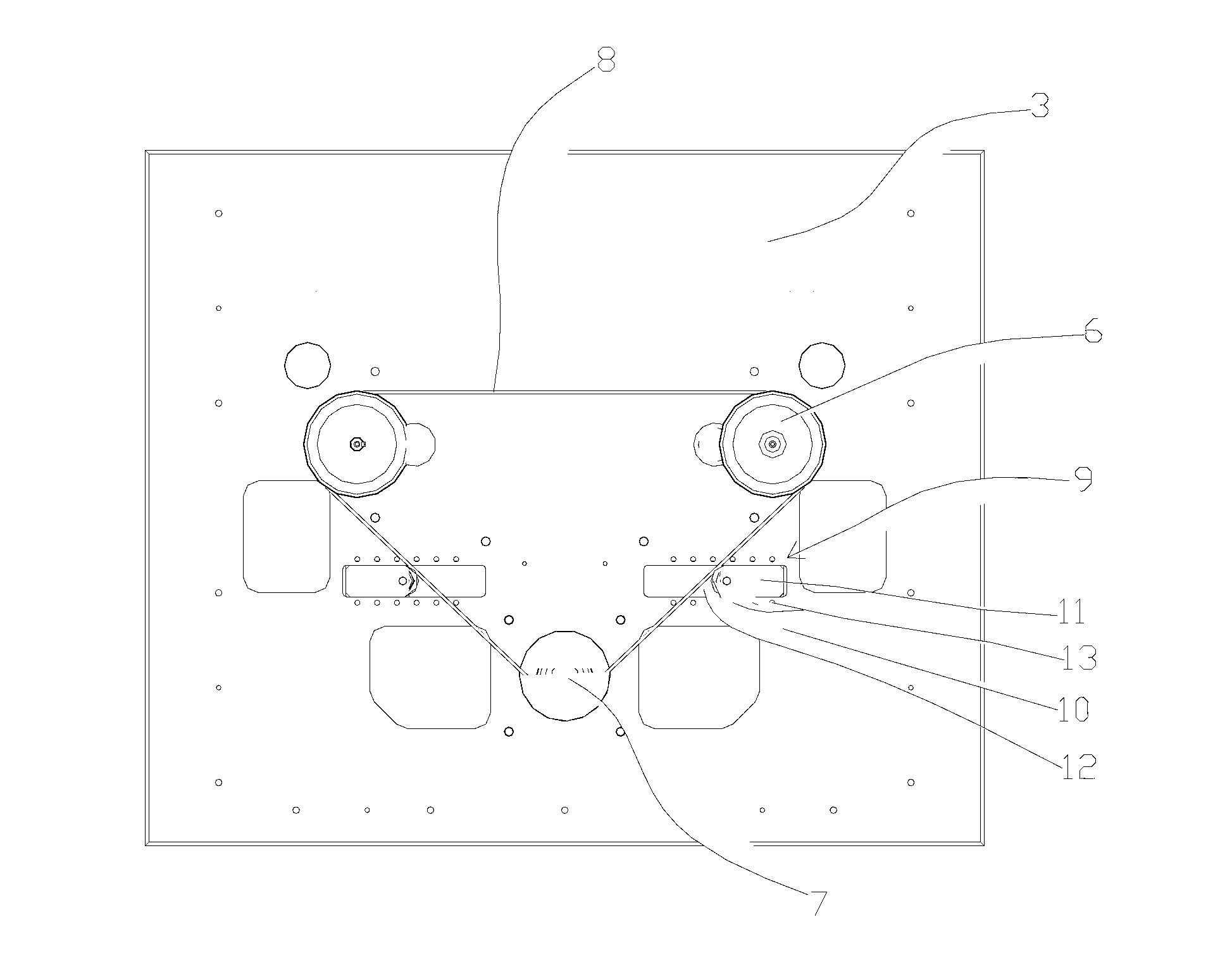

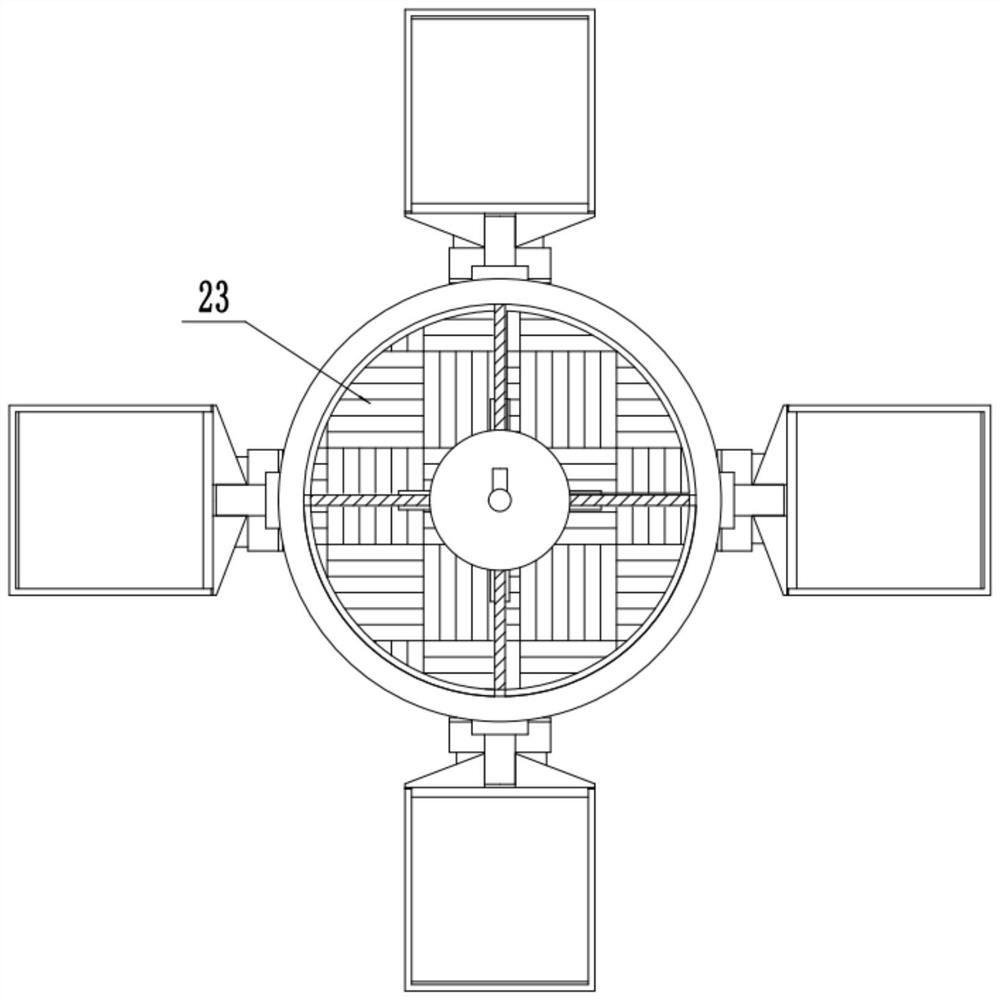

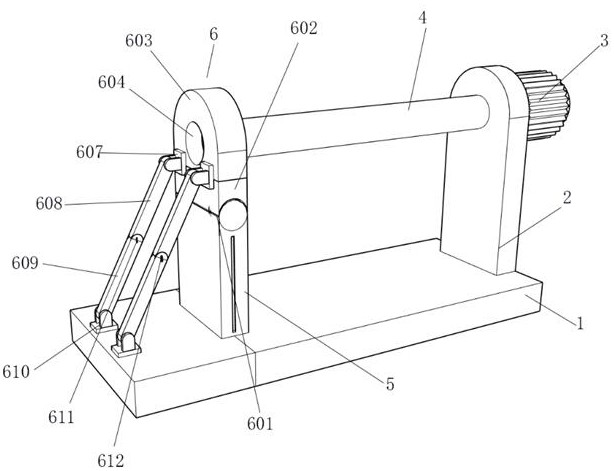

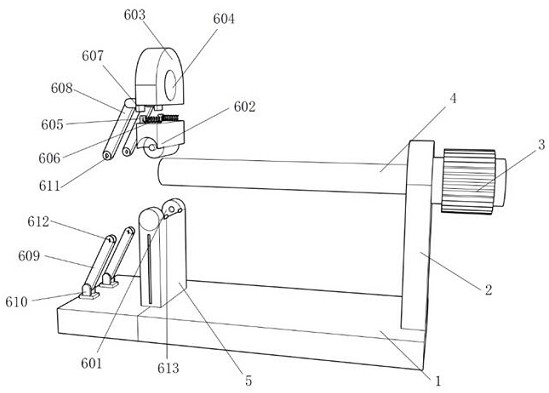

All-in-one machine for assembling and detecting inner and outer frames of scissor foot

PendingCN109093357ASave time for retrievingImprove work efficiencyMetal working apparatusEngineering

The invention discloses an all-in-one machine for assembling and detecting inner and outer frames of a scissor foot, which comprises a rack, a scissor foot inner frame vibration disc, an inner frame vibration disc bracket, a scissor foot outer frame vibration disc, an outer frame vibration disc bracket, a rotation disc part and a human-computer interface. The scissor foot inner frame vibration disc and the scissor foot outer frame vibration disc are respectively arranged on the right side and the left side of the rack; the scissor foot inner frame vibration disc is arranged in the inner framevibration disc bracket; the scissor foot outer frame vibration disc is arranged on the outer frame vibration disc bracket; the human-computer interface is located between the scissor foot inner framevibration disc and the scissor foot outer frame vibration disc; the scissor foot inner frame vibration disc and the scissor foot outer frame vibration disc respectively generate 30-140 HZ of frequencyvibration through solenoid drive so as to drive the scissor foot inner frame and the scissor foot outer frame products to wriggle to specified material paths in the scissor foot inner frame vibrationdisc and the scissor foot outer frame vibration disc; and the rotation disc part is used for respectively receiving and assembling the scissor foot inner frame and the scissor foot outer frame products.

Owner:苏州邦冠自动化设备有限公司

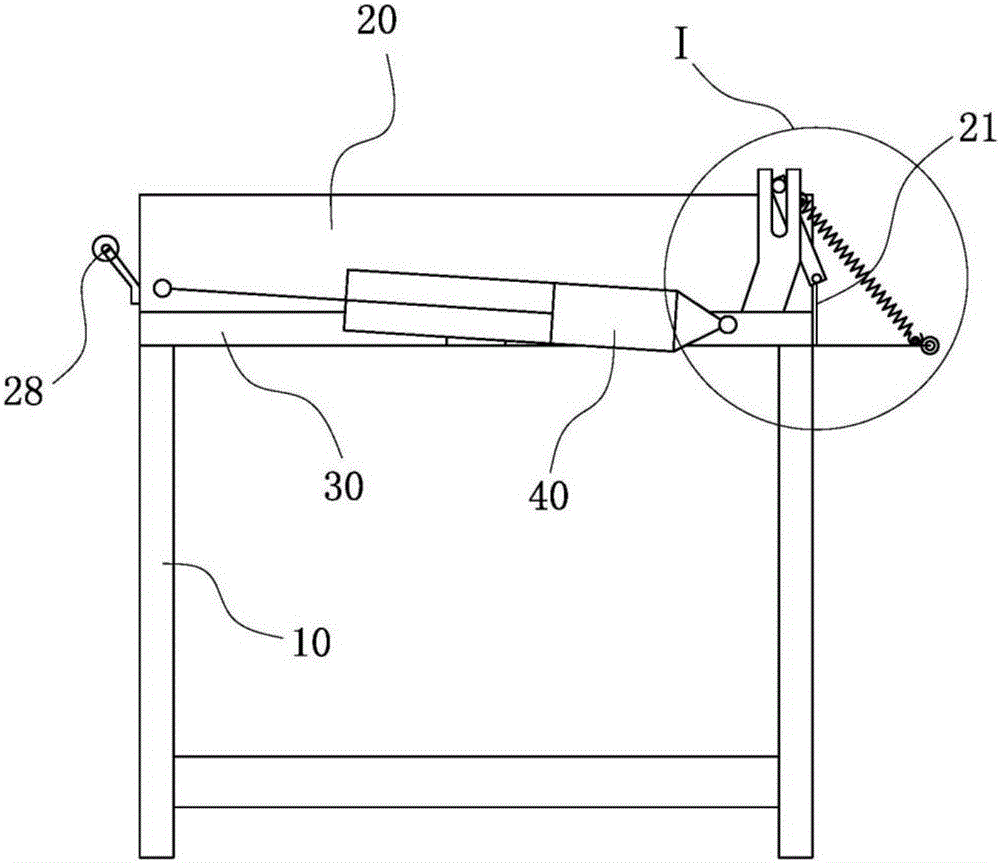

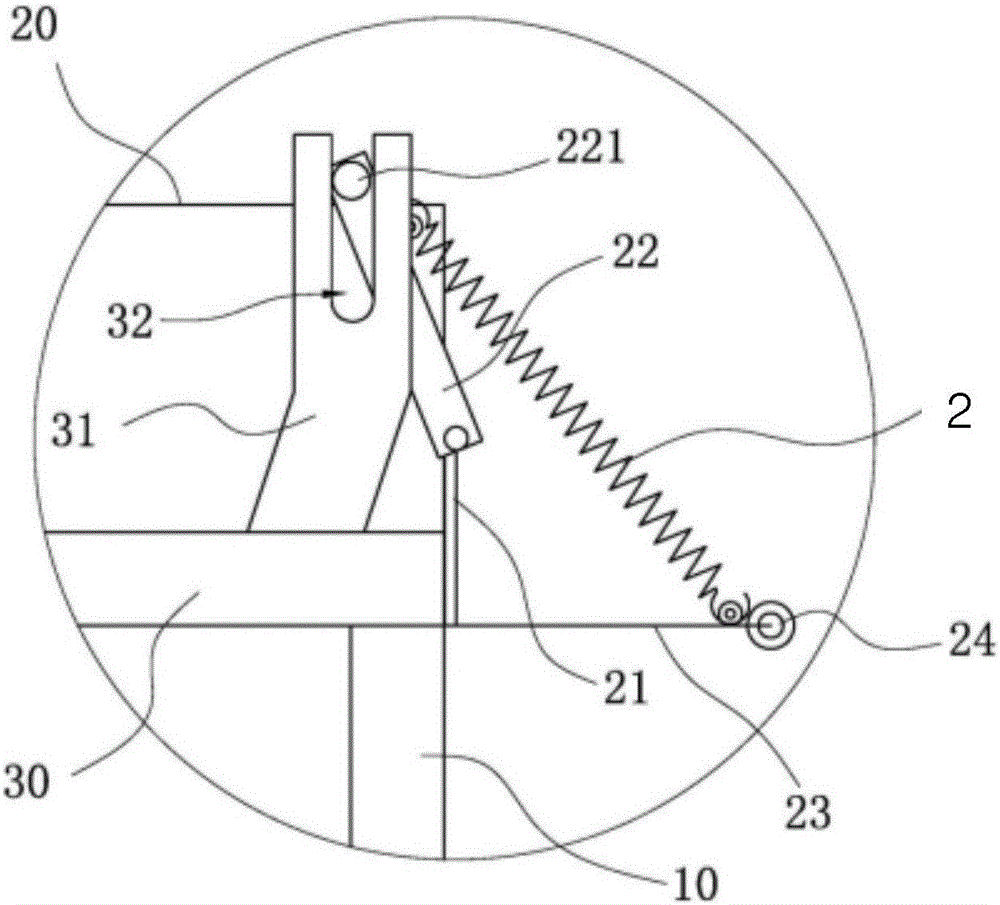

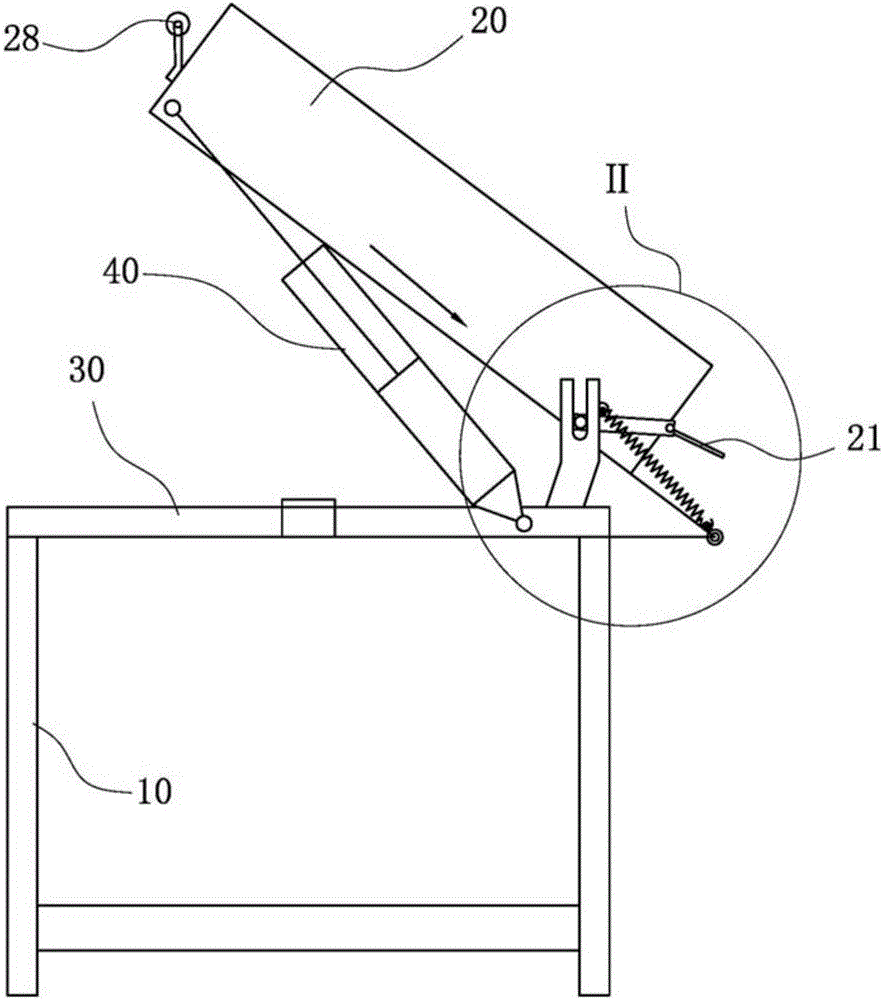

Welding bench capable of automatically storing materials

InactiveCN103317280ASave time for retrievingHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringEconomic benefits

The invention discloses a welding bench capable of automatically storing materials. The welding bench comprises a bench panel, a fixing plate, a bottom plate, a transmission motor and two vertically arranged parallel screw rods, the bench panel is fixedly arranged on the fixing plate, the parallel screw rods are symmetrically arranged on two sides of the fixing plate, bottom ends of the two parallel screw rods penetrate the bottom plate and then are provided with transmission wheels, the transmission motor is fixed on the bottom plate, an output end of the transmission motor penetrates the bottom plate and is then connected with a belt pulley, a feed belt is sleeved on the belt pulley and the transmission wheels, and a feed belt tensioning structure is arranged between the belt pulley and each of the transmission wheels. By the aid of the welding bench, continuous material fetching of workers is not required, plenty of material fetching time after welding is saved, automation degree is high, a large amount of manpower and material resources are saved, welding quality is guaranteed, and considerable economic benefit is created for an enterprise.

Owner:SUZHOU KEBER PRECISION MACHINERY

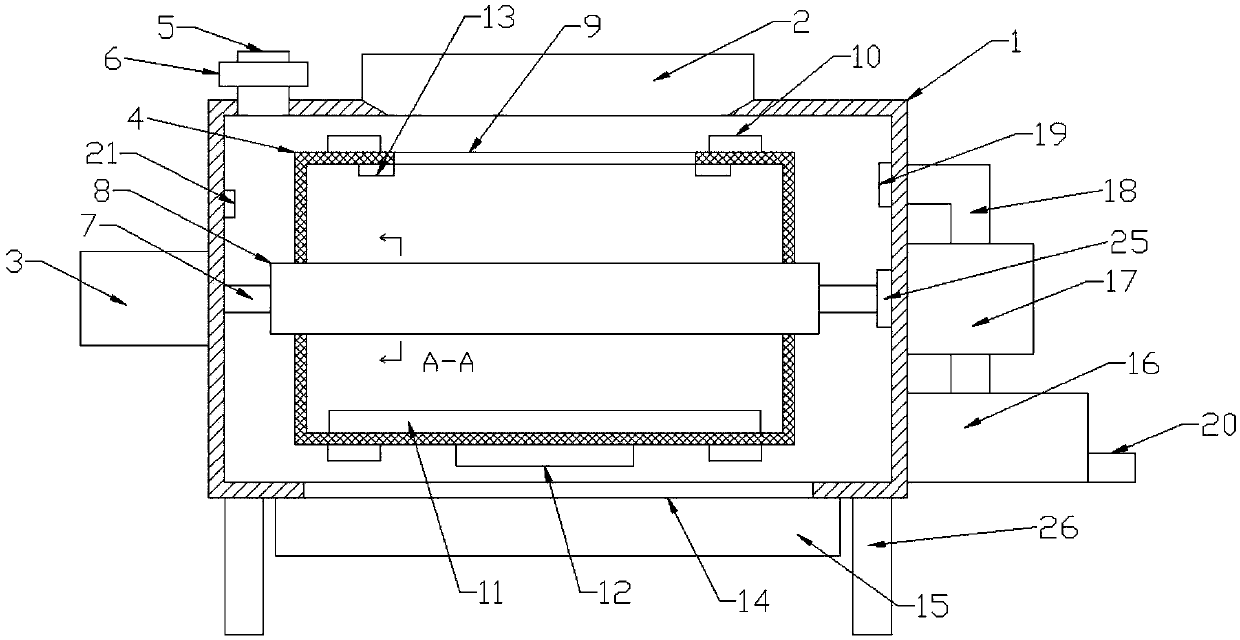

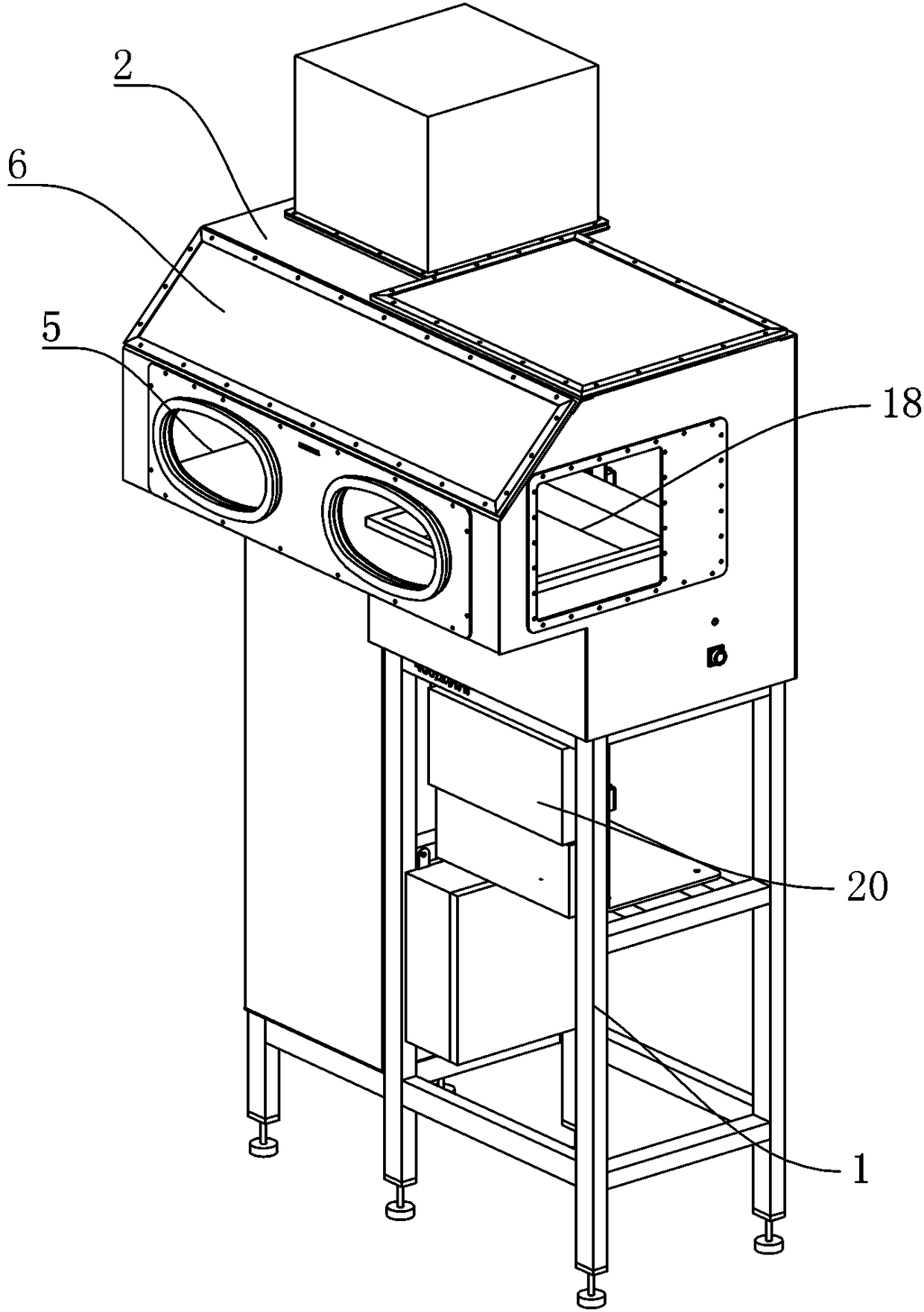

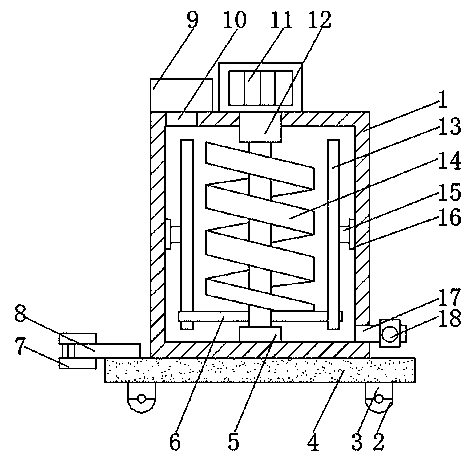

Automatic hot press

The invention discloses an automatic hot press which comprises a top base and a bottom base. Multiple middle heating plates and a bottom plate to which a lower-layer heating plate is fixed are arranged among multiple stand columns between the top base and the bottom base. The bottom plate is arranged on an oil cylinder of the bottom base, the middle heating plates and the lower-layer heating plateare provided with die base plates correspondingly, a sealing cover with a movable door is arranged between the top base and the bottom base, a taking frame is arranged at the position corresponding to the closed movable door, the upper end of the sealing cover is provided with a guide rail, the two sides of the sealing cover are provided with waste gas sucking cooling boxes comprising cooling boxbodies and waste gas exhaust pipes, the bottoms of the waste gas exhaust pipes are provided with small holes, the waste gas exhaust pipes are provided with cooling coil pipes, gas sucking pipes are arranged on the outer sides of the cooling box bodies, and a gas sucking pump sucks waste gas in the gas sucking pipes into a waste gas processing box. The automatic hot press is simple in structure, reasonable in design, capable of collecting waste gas produced by hot pressing for centralized processing, capable of automatically taking out products and saving taking time, and meanwhile beneficialto body health of workers.

Owner:NANTONG HAILITE RUBBER & PLASTIC MACHINERY

Automatic discharging device for combined foot pad injection mold

InactiveCN110640981ASave time for retrievingIncrease productivityCoatingsEngineeringMechanical engineering

The invention discloses an automatic discharging device for a combined foot pad injection mold. The automatic discharging device comprises a conveying platform of the injection mold. A lower mold of afoot pad mold is arranged on the conveying platform, longitudinal grooved rails are arranged on two sides of the lower mold, columns are fixed to the front and back ends of each grooved rail, the lower ends of the columns are fixed to the conveying platform, a horizontal positioning plate is arranged on the upper side of the lower mold, a plurality of positioning holes are formed in the positioning plate, and two sides of the positioning plate are inserted into the channels of the grooved rails; a clamping plate leans against the lower end surface of the positioning plate, a plurality of through holes opposite to the positioning holes are formed in the clamping plate, slots extending backward are formed in the inner walls of the back ends of the through holes, two sides of the front end of the clamping plate are inserted to a guide block, and the guide block is fixed to the lower end surface of the positioning plate. The automatic discharging device can automatically reclaim from theinjection mold at one time to shorten the reclaiming time, so that the production efficiency is improved.

Owner:东莞市嘉宏机电科技有限公司

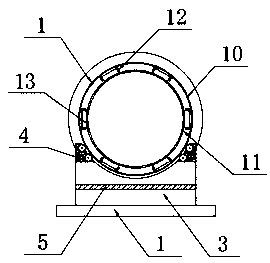

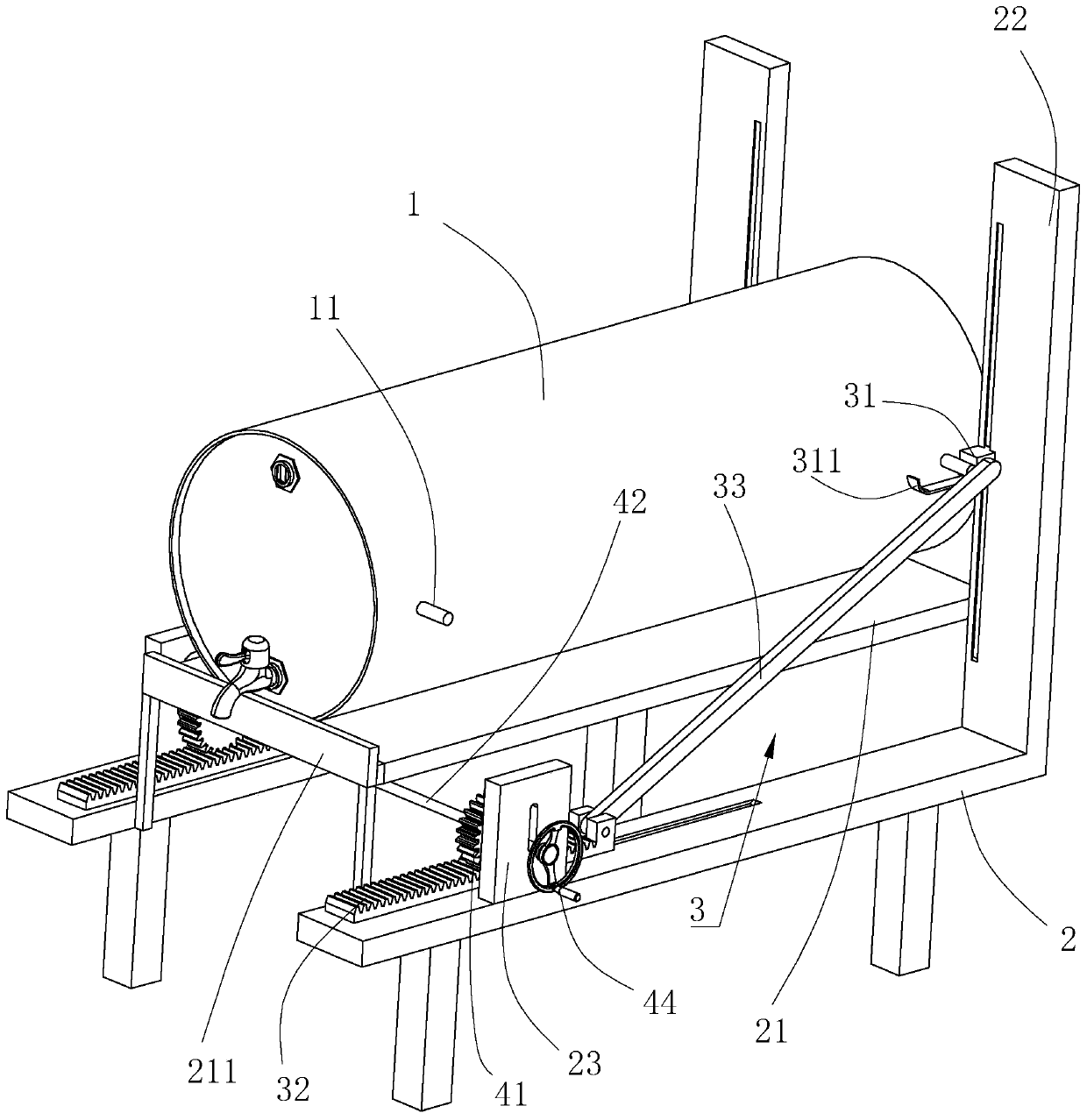

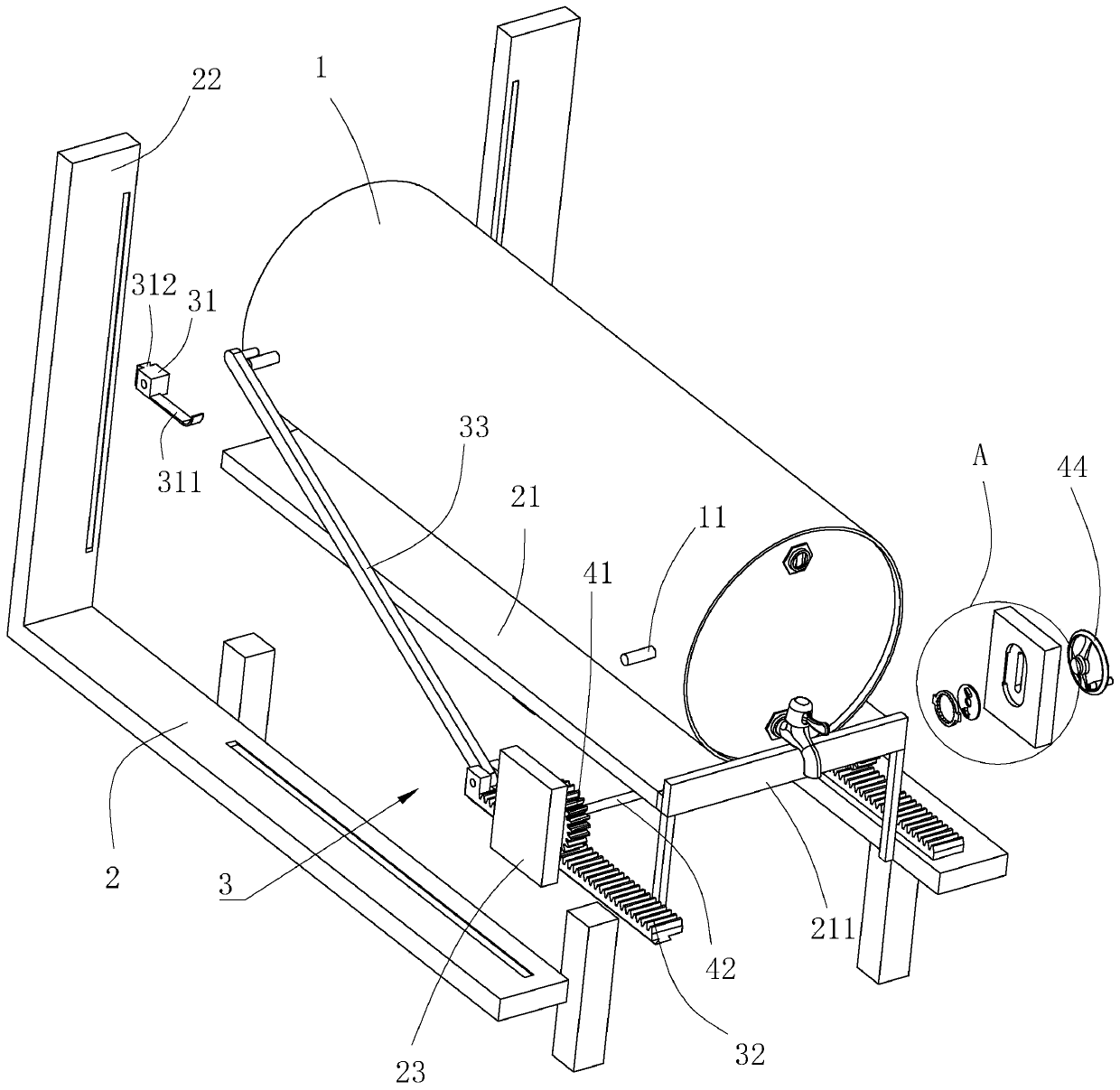

Ore drying device for mining

InactiveCN110779290ASmooth rotationDry evenly and fullyDrying chambers/containersDrying machines with non-progressive movementsMining engineeringGear wheel

The invention discloses an ore drying device for mining, and particularly relates to the field of ore drying. The ore drying device comprises a drying cylinder and a bottom plate, wherein the bottom plate is positioned at the bottom of the drying cylinder; a heating cavity is formed between the drying cylinder and the bottom plate; the heating cavity is fixedly connected with the bottom plate; a connecting plate is fixedly arranged at the top of the heating cavity; the connecting plate is positioned on the periphery of the drying cylinder; a gear is fixedly arranged on the periphery of one endof the drying cylinder; a motor is arranged at the bottom of the gear; the motor is fixedly arranged at the top of the bottom plate; the motor is positioned at one end of the heating cavity; the drying cylinder comprises an outer cylinder and an inner cylinder; the inner cylinder is movably arranged in an inner cavity of the outer cylinder; a stop block is fixedly arranged on the inner wall of the outer cylinder; a connecting block is movably arranged in the stop block; the connecting block is fixedly arranged on the outer surface of the inner cylinder; and a sliding groove is formed in the top of the connecting plate. According to the ore drying device, the drying cylinder can be conveniently rotated for drying, the overall rotation of the drying cylinder is smoother, the ore can be fully and uniformly dried, and the drying effect is improved.

Owner:徐州盛阳工程机械有限公司

Garbage crusher for environmental protection

The invention discloses a garbage crusher for environmental protection. The garbage crusher comprises a crushing chamber, wherein the upper surface of the crushing chamber is fixedly connected with amotor, and the output end of the motor penetrates through the crushing chamber and extends to the interior of the crushing chamber; the inner side wall of the crushing chamber is fixedly connected with two symmetrical first bearings, and the inner rings of the first bearings are fixedly connected with rotating rods; the side surfaces, close to each other, of the two rotating rods are fixedly connected with crushing rods, and the inner bottom wall of the crushing chamber is fixedly connected with a second bearing; a spiral crushing rod is arranged in the crushing chamber, and the bottom end ofthe spiral crushing rod is fixedly connected with the inner ring of the second bearing; the end, away from the second bearing, of the spiral crushing rod is fixedly connected with the output end of the motor, and the lower part of the outer surface of the spiral crushing rod is fixedly connected with two symmetrical linkage rods; and a feeding inlet is formed in the upper surface of the crushing chamber. The garbage crusher for environmental protection can overall and fully crush the garbage, is convenient and quick to move, facilitates material picking, and can meet the needs of the society.

Owner:严元海

An automatic discharge type continuous feeding device for wall decoration

ActiveCN112064987BRealize automatic dischargeSave time for retrievingRotary stirring mixersBuilding constructionsEngineeringStructural engineering

The invention relates to the technical field of decoration equipment, and discloses an automatic discharge type continuous feeding device for decoration and masonry, comprising a material bucket and a base; The outer side of the hole is provided with a wall-laying tool disk with a rectangular structure, the middle of the right end of the wall-laying tool disk is fixedly connected with a disk cylinder, the inside of the disk cylinder is set as a left and right through structure, the disk cylinder is inserted into the inside of the jack, and the disk The upper side of the inner end of the barrel is set as an inclined surface structure, and the upper side of the inner bottom of the barrel corresponding to the position of the jack is respectively provided with a lowering trough with a trumpet-shaped structure, and a sealing plate is arranged inside the lowering trough. The bottom center of the plate is fixedly connected downward with a lifting rod whose bottom end and the inner end of the drum cooperate with each other to contact the inclined surface structure. . The advantages of the present invention are: automatic material discharge, continuous material feeding, saving material reclaiming time and improving work efficiency.

Owner:周狄超

A powder lifting device for commercial concrete production

ActiveCN112407787BRealize continuous feedingSave time for retrievingConveyorsCement mixing apparatusClassical mechanicsEngineering

The present invention relates to the technical field of material transportation, in particular to a powder material lifting device for commercial concrete production, which includes a lifting device arranged obliquely, a dust cover and a mixing barrel. The lifting device includes a sliding frame arranged obliquely, a feeding The bucket and the drive assembly, the dust cover is provided with a baffle plate assembly, the end of the mixing tube located directly above the bottom end of the sliding frame is downwardly connected with the dust-proof feeding tube, and the sliding frame includes a long strip inclined Supporting bracket and two long strip-shaped inclined guards, the inclined supporting bracket is provided with an annular slideway, one side of the two inclined guards is provided with an annular slide rail, and all feeding hoppers are equipped with sliding bases. The invention realizes the continuous feeding of the feeding hopper, reduces the time for the hopper to repeatedly move up and down to take the material, improves the efficiency of material lifting, shortens the length of the chain of the drive assembly, improves the tensile strength of the chain, and reduces the situation of powder scattering and flying.

Owner:平邑中联水泥有限公司

Single-shaft winding machine for intelligent electronic product winding

The invention relates to the technical field of winding equipment, discloses a single-shaft winding machine for winding of intelligent electronic products, and solves the problem that linear equipment is likely to be wound at one position and then knotted, the single-shaft winding machine comprises a base, a first side plate is installed at the top end of the base, one side of the first side plate is rotationally connected with a winding shaft, and the winding shaft is rotationally connected with the winding shaft. An output shaft of a first motor is mounted at one end of the winding shaft, and the first motor is fixedly connected with the first side plate; in the working process, an output shaft of an arranged second motor rotates forwards to drive a movable screw rod to rotate, the bottom end of a movable ring is connected with a limiting strip in a clamped mode, so that the movable ring cannot rotate along with the movable screw rod, the movable ring is driven by the movable screw rod to transversely move, linear equipment penetrates through the position between two rotating rollers, and the linear equipment is driven to rotate. And after the movable ring moves, the linear equipment is driven to move, so that the linear equipment is uniformly wound on the outer side of the winding shaft, and the winding regularity is improved.

Owner:扬州瑞福智能科技有限公司

Processing technology for solid wood compound reinforcement door

InactiveCN107415015ASave picking timeImprove reclaiming efficiencyPretreated surfacesWood working apparatusPollutantSolid wood

The invention discloses a processing technology for a solid wood compound reinforcement door. According to the processing technology for the solid wood compound reinforcement door, the working efficiency is improved greatly by improving a production line and adopting the production line with an annular material circulating track; paint-spraying quality is effectively improved by adopting a multi-shaft reciprocating paint-spraying system to conduct paint-spraying procedure operation; by adopting a sander to conduct sanding treatment on the surface of a plain door, improvement of surface flatness of the plain door is facilitated, removing of pollutants or sundries on the surface of the plain door is further facilitated, and a good basis is provided for the flatness of paint spraying; PUA-X coating is adopted as bottom layer coating and surface layer coating, environmental protection is facilitated, the UV drying mode is adopted to dry the bottom layer coating, and accelerating of the drying speed of bottom painting is facilitated; a natural light condition drying mode is adopted to dry the surface layer coating, and guarantee for hardness of the surface layer coating is facilitated; and before spraying the surface layer coating, fine sanding and polishing are conducted on the surface of the dried bottom layer painting, and uniform adhering of the surface layer coating is facilitated.

Owner:合肥荣事达电子电器集团有限公司

Essence preparation method

The invention relates to an essence preparation method. Raw material barrels for containing different raw materials are sequentially marked with numbers and then sorted according to the serial numbers, a paper raw material ratio table is made to facilitate viewing in a warehouse, the corresponding raw material barrels are looked for in the warehouse according to data on the raw material ratio table, and in the extraction process, raw materials with the corresponding mass are directly extracted into the raw material barrels according to the display of an electronic scale. Thus, the number of storage barrels is reduced, the extraction time is greatly shortened, and the work efficiency is improved.

Owner:广州宝士迪香精香料有限公司

New energy motor rotor magnetic steel feeding assembly mechanism

ActiveCN110653601BImprove efficiencyImprove stabilityAssembly machinesManufacturing stator/rotor bodiesElectric machineNew energy

The invention discloses a new energy motor rotor magnetic steel feeding and assembly mechanism, which is characterized in that it includes a silo for storing N pieces of magnetic steel, and the discharge port of the silo is located above the vibrating feeding mechanism. Feed M pieces of magnetic steel into the vibrating feeding mechanism for the first time, and the vibrating feeding mechanism is connected with J whole material mechanisms through the material conveying mechanism, J≥1, and the feeding mechanism will feed the K pieces of magnetic steel sorted by the whole material mechanism once Take away, K≥1. The present invention adopts the vibrating plate to add the feeding bin, and the material storage mechanism is fed by belt line transmission to form a fast-reflecting buffer area; the shaping mechanism adopts upward shaping, and five pieces of materials are fed at one time, without collision vibration and other damage The action of the magnetic steel: use a four-axis robot to take the material, and take K pieces of magnetic steel at one time, so that according to the structure of the rotor core, multiple pieces can be inserted at one time, or inserted multiple times in a row without taking material, shortening the time of taking The material time is shortened, which greatly improves the efficiency and stability of inserting magnets.

Owner:COMAU SHANGHAI ENG

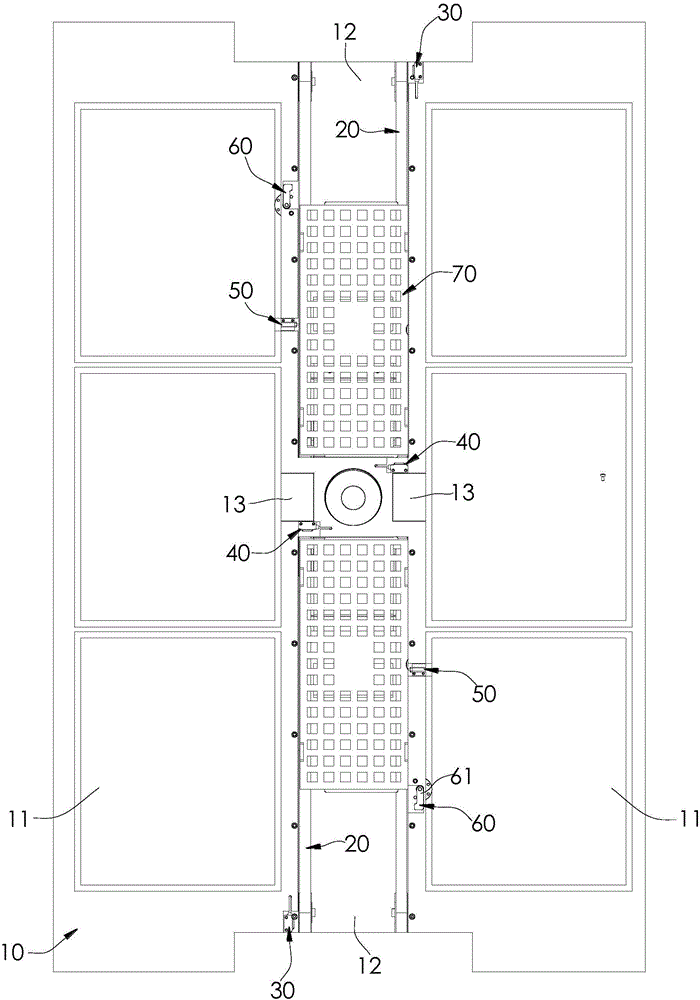

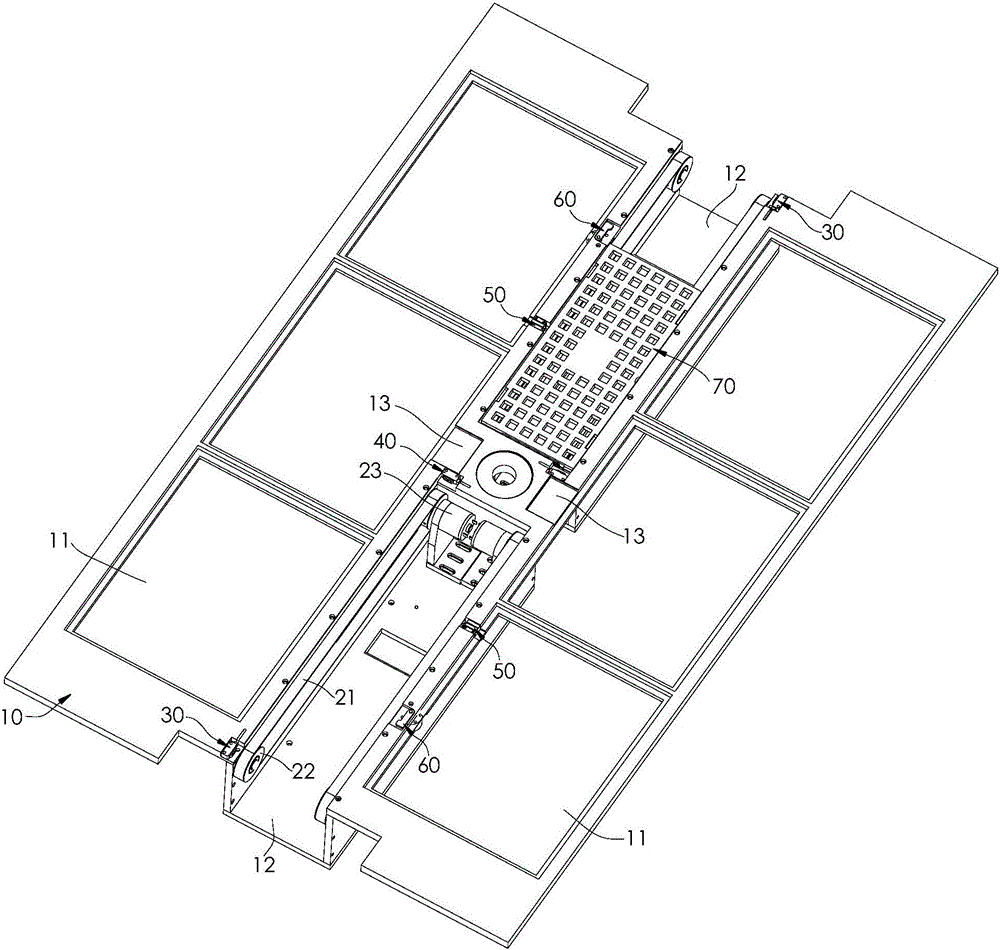

an automatic feeding system

Owner:BOZHON PRECISION IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com