Single-shaft winding machine for intelligent electronic product winding

A technology of intelligent electronic products and winding machines, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., can solve the problems of knotting and winding of linear equipment, and improve the neatness, The effect of increasing the friction and improving the winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

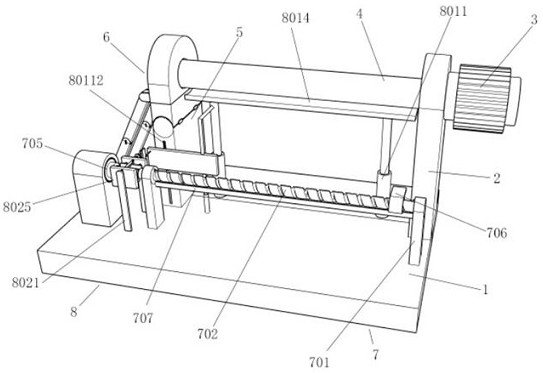

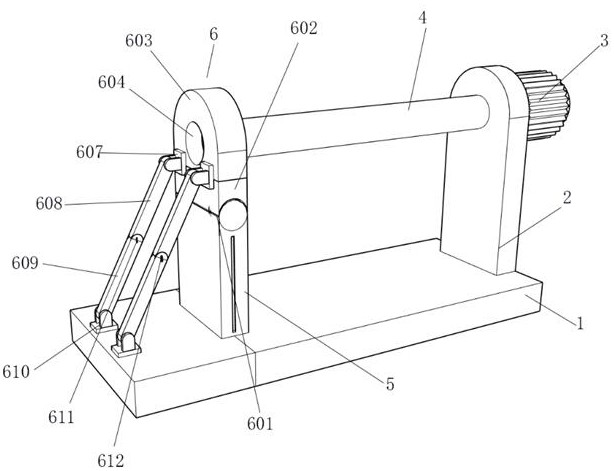

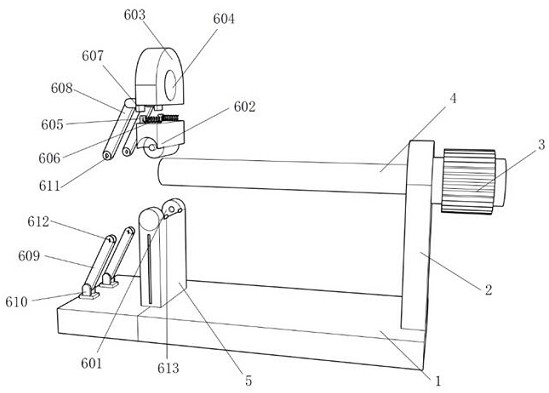

[0031] Embodiment one, by Figure 1-Figure 8 Given, the present invention includes a base 1, the top of the base 1 is equipped with a first side plate 2, one side of the first side plate 2 is rotatably connected with a bobbin 4, and one end of the bobbin 4 is mounted with the output shaft of the first motor 3 , the first motor 3 is fixedly connected to the first side plate 2, the top of the base 1 is also equipped with a second side plate 5, the top of the second side plate 5 is equipped with a discharge assembly 6, and the top of the base 1 is installed with a moving assembly 7 .

Embodiment 2

[0032] Embodiment 2, on the basis of Embodiment 1, the moving assembly 7 includes a first support plate 701 symmetrically installed on the top of the base 1, a moving screw 702 is installed between the two first support plates 701, and one of the first support plates A first contact 703 is installed on one side of 701, a second contact 704 is installed on one side of the other first support plate 701, a second motor 705 is installed on one end of the moving screw 702, and the second motor 705 is fixed to the base 1 Connection, the outer thread of the moving screw 702 is connected with a moving ring 706, one side of the first support plate 701 is installed with an adjustment assembly 8, the bottom end of the moving ring 706 is provided with a limit groove 708, and one side of the moving ring 706 is symmetrically installed with a connection plate 709, the bottom of the connecting plate 709 below is provided with a connecting groove 710, and a rotating roller 711 is symmetrically ...

Embodiment 3

[0034] Embodiment 3, on the basis of Embodiment 2, the adjustment assembly 8 includes an active unit 801 and an adjustment unit 802, wherein the active unit 801 includes a first movable cylinder 8011 symmetrically arranged below the winding shaft 4, the first movable cylinder 8011 and the base 1 Fixed connection, the inside of the first movable cylinder 8011 is equipped with a second spring 8012, the top of the second spring 8012 is equipped with a pressure rod 8013, the pressure rod 8013 is inserted into the inside of the first movable cylinder 8011, and the top of the pressure rod 8013 is installed with Pressing plate 8014, the top of pressing plate 8014 is close to the bottom of bobbin 4, and the front of one of pressing bar 8013 is equipped with connecting rod 8015, and the bottom end of connecting rod 8015 is equipped with mounting plate 8016, and the bottom end of mounting plate 8016 is installed with Bottom rods 8018 and 8108 are plugged into the inside of 8107, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com