Multilayered glove box

A glove box and glove opening technology, applied in the field of glove boxes, can solve the problems of long time-consuming and low work efficiency when picking and placing workpieces, and achieve the effects of reducing the number of times, reducing the time for picking materials, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

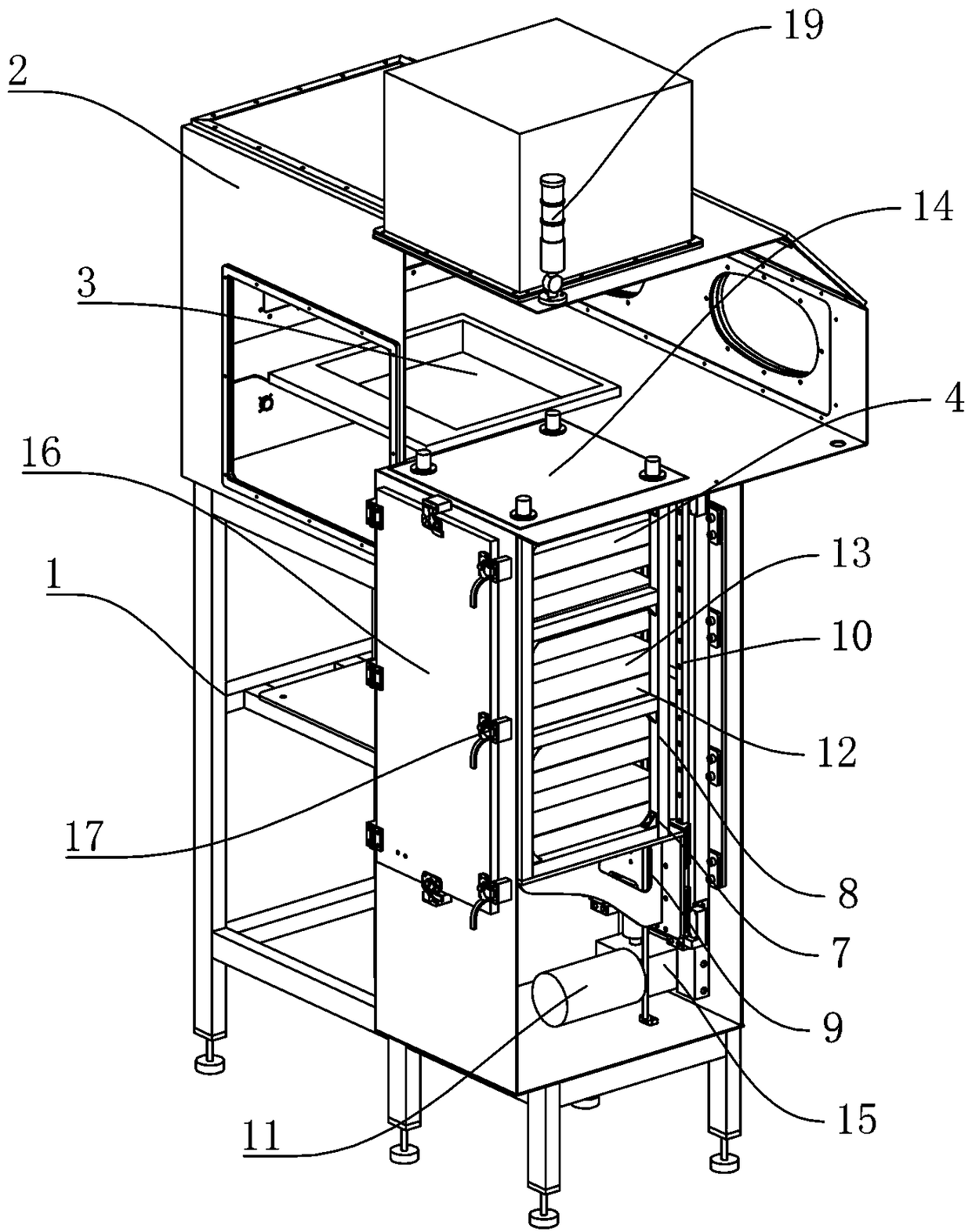

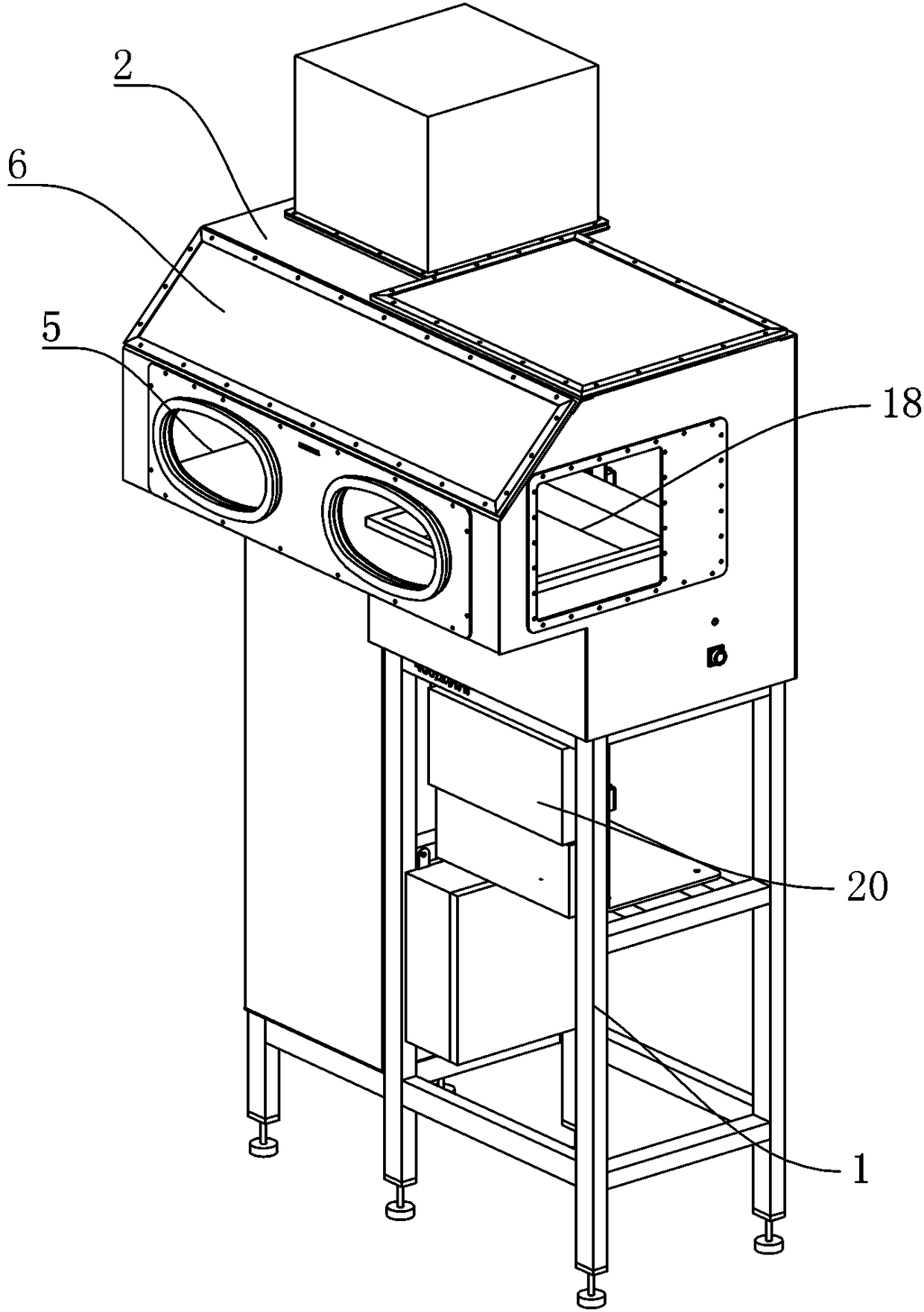

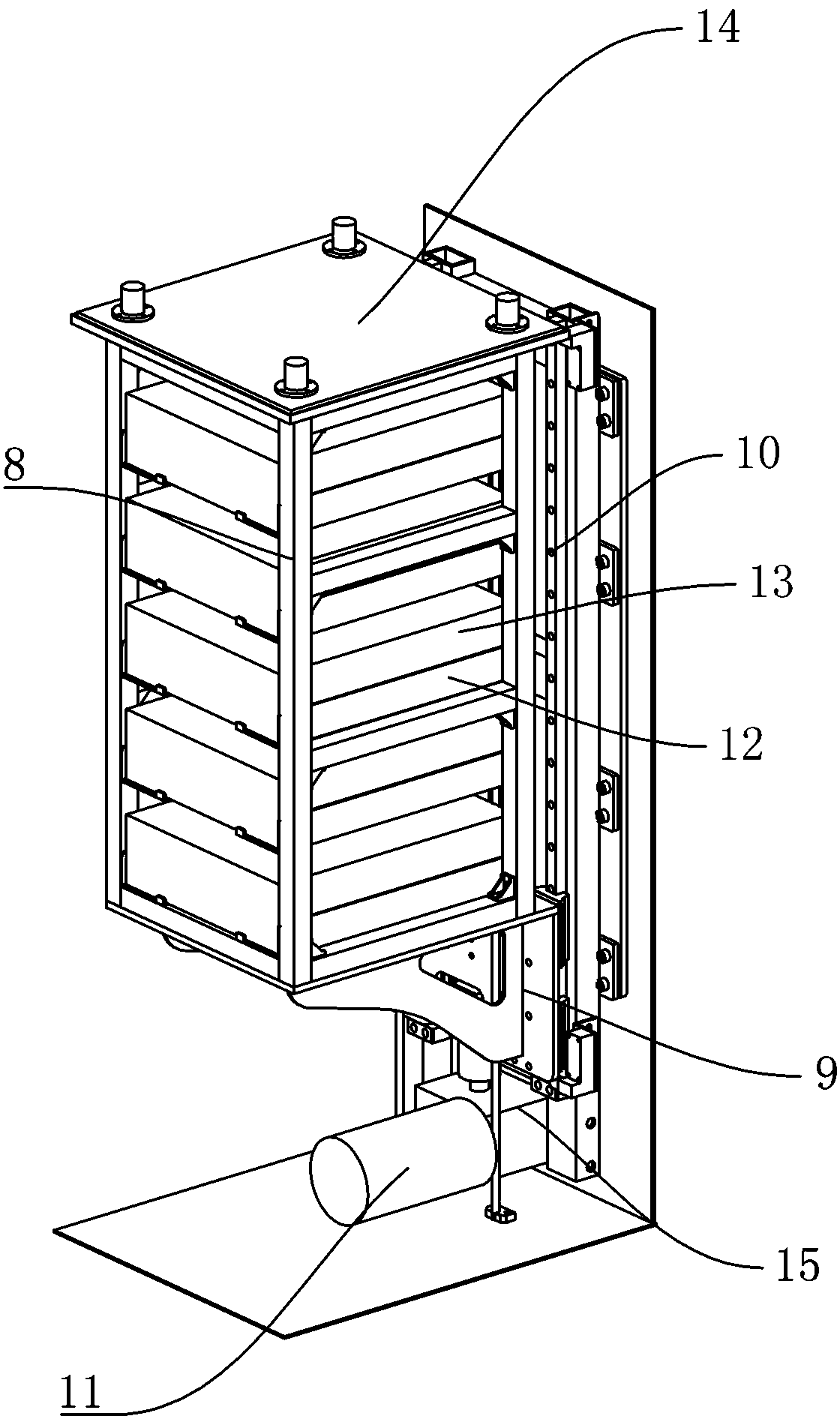

[0024] Example, see Figure 1 to Figure 3 Shown: a multi-layer glove box, including a frame 1, a box body 2 is arranged on the frame 1, and a packing room 3 and a reclaiming room 4 are airtightly arranged in the box body 2. The packing room is used for packaging workpieces The reclaiming chamber is used to take out the packaged workpieces. The reclaiming chamber 4 is located below the packaging chamber 3. The frame 1 is equipped with a vacuum packaging machine matched with the packaging chamber 3, and the packaging station of the vacuum packaging machine is located in the packaging chamber 3. Inside, one side of the box body is provided with a box door that is matched with the forming mechanism, and the box door is provided with a feed port 18 that connects the forming mechanism with the packaging chamber 3. The wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com