Essence preparation method

A preparation method and essence technology, applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of reducing work efficiency, difficult to find and recycle raw material barrels, etc., to improve work efficiency, shorten the time for taking materials, reduce Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

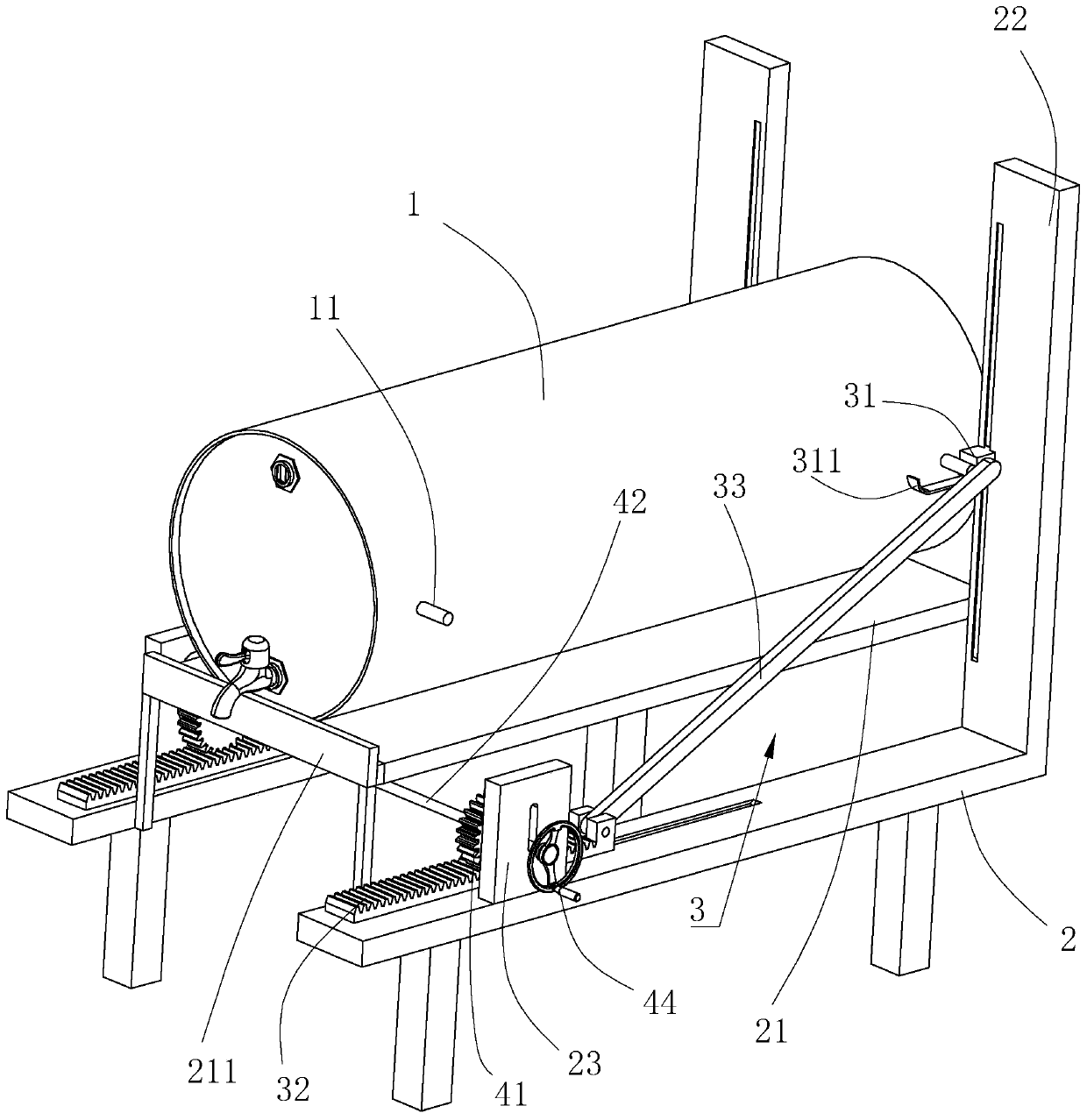

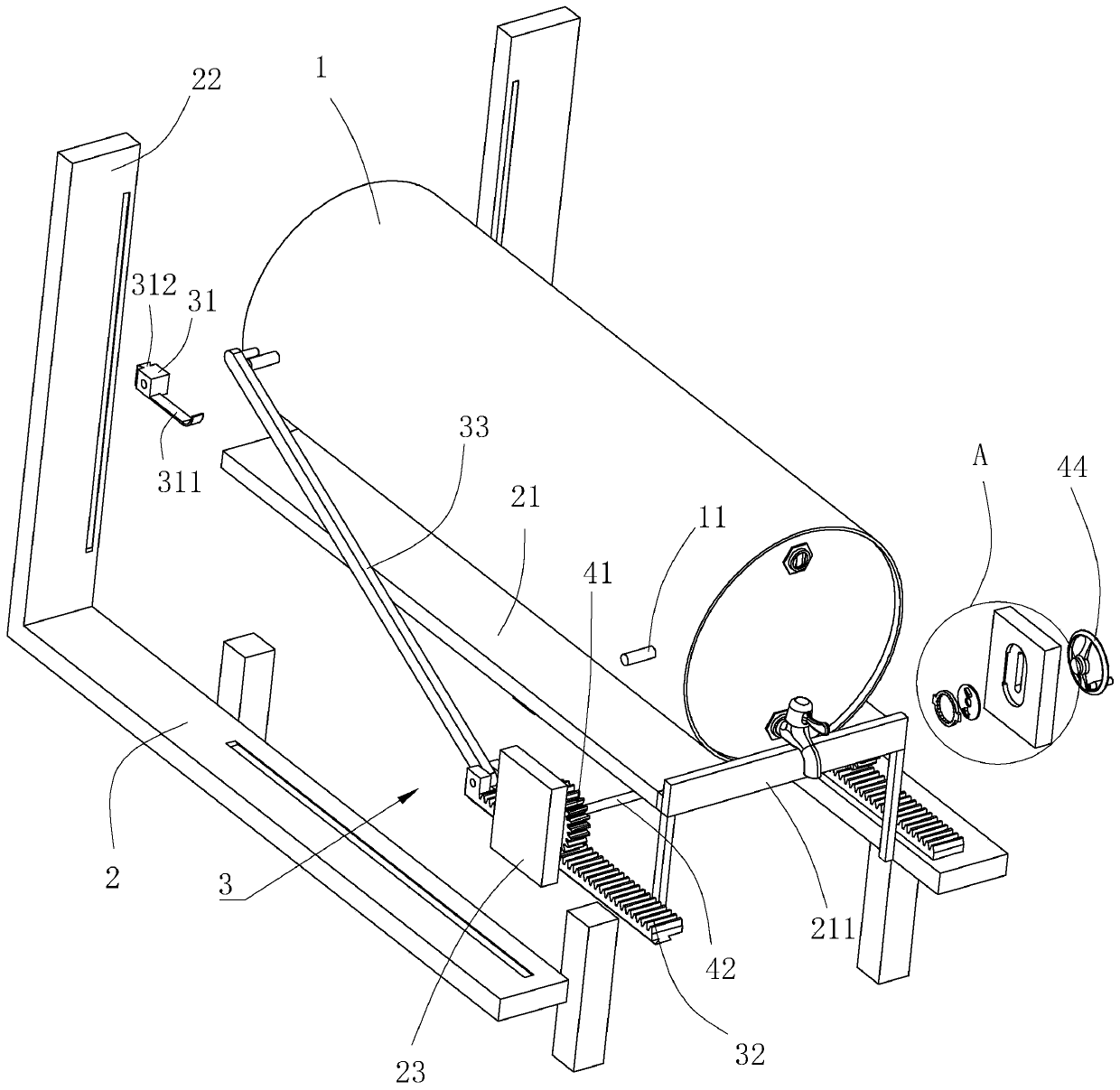

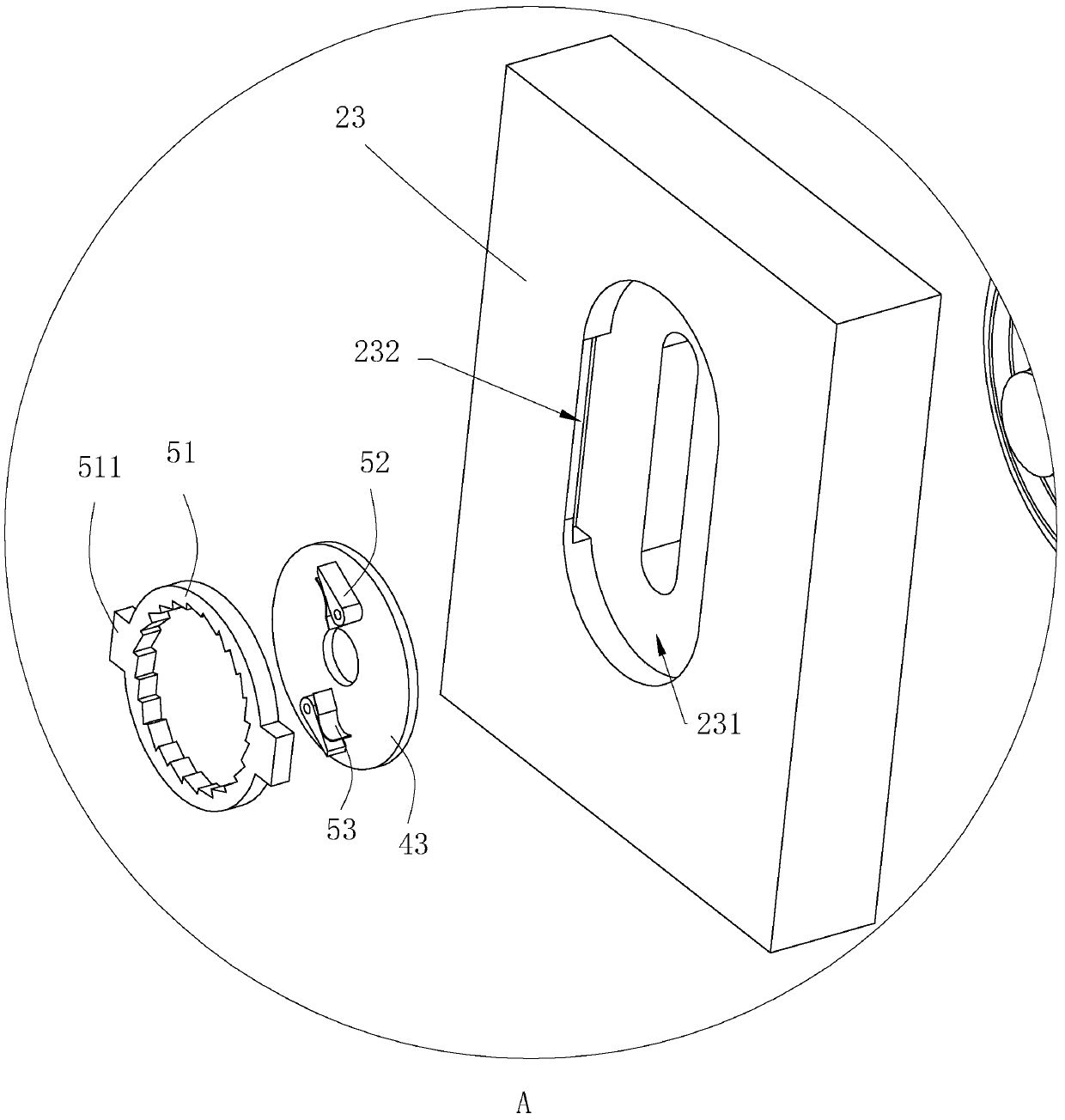

[0042] Such as Figure 1 to Figure 2 As shown, a flavor preparation method disclosed in the present invention includes a raw material barrel and a material transport vehicle. The raw material barrel includes a cylindrical barrel body 1 and a bracket 2 located below the barrel body 1. End caps are installed on both ends of the barrel body 1, and discharge ports are installed on the end caps, and the discharge ports are blocked by screw caps. There is a certain distance between the discharge port and the inner wall of the barrel body 1. When discharging, the end cover is removed and a conventional faucet is connected, and the axis of the barrel body 1 is placed horizontally to facilitate discharging. The outer peripheral surface of the barrel body 1 is fixed with at least two sets of limiting columns 11 oppositely arranged along the axis of the barrel body 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com