Automatic screw conveying device and automatic assembling equipment with same

A conveying device and screw technology, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of affecting processing efficiency, easy material jamming, and high noise, so as to save material retrieving time, alleviate impact force, and simplify structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

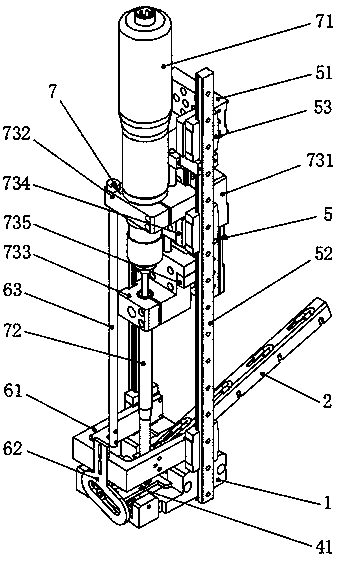

[0024] Embodiment: The embodiment of the present invention provides an automatic screw delivery device, such as figure 1 As shown, the bottom mounting base 1 is included, and the upper end of the bottom mounting base 1 is provided with a conveying groove 2 for conveying screws. The conveying groove 2 is docked with the vibrating plate screw feeder at the front end of the assembly line. The horizontal plane is preferably at an included angle of 25 degrees, so that the screw slides forward by its own gravity.

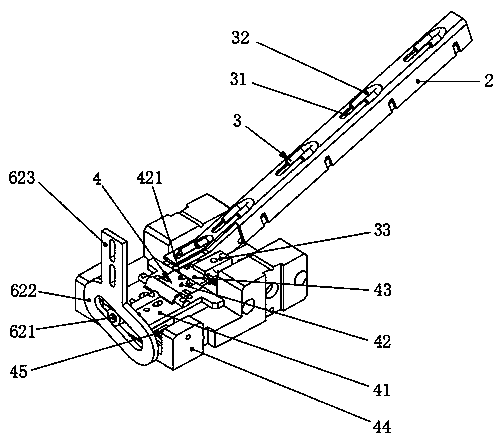

[0025] like figure 2 As shown, in a further embodiment, the conveying trough 2 is provided with an auxiliary transmission assembly 3, and the auxiliary conveying assembly 3 includes an air groove 31 arranged at the upper end of the conveying trough 2 and an air groove 31 adapted to the An air nozzle 32 , the air outlet of the air nozzle 32 is inclined towards the air groove 31 , and the bottom mounting base 1 is provided with a nozzle air inlet 33 connected to the air n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com