Automatic discharging device for combined foot pad injection mold

A technology of automatic discharge device and injection mold, applied in the direction of coating, etc., can solve the problems of time-consuming, affecting production efficiency, and large number of foot pads, so as to improve production efficiency and shorten the time for taking materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

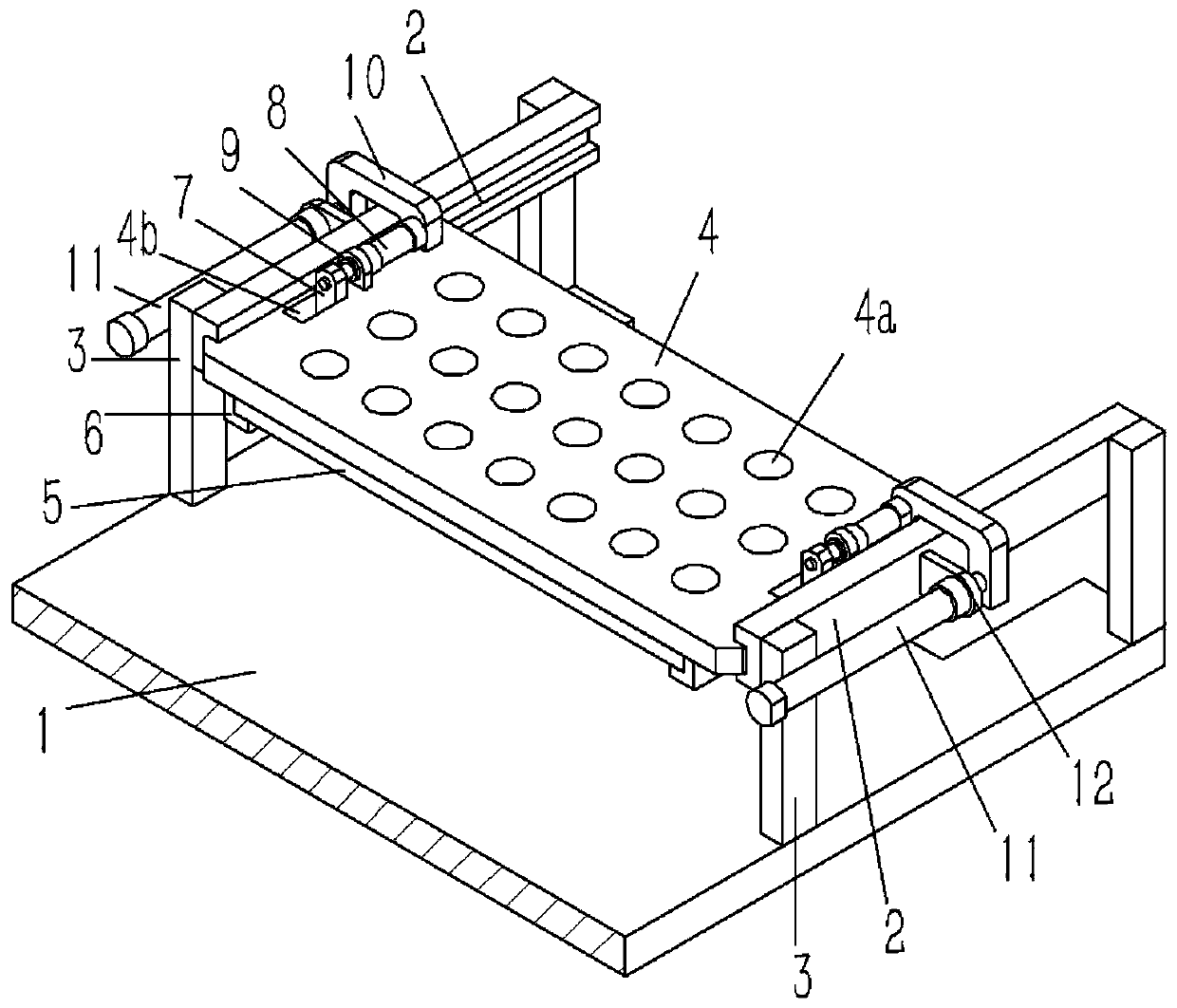

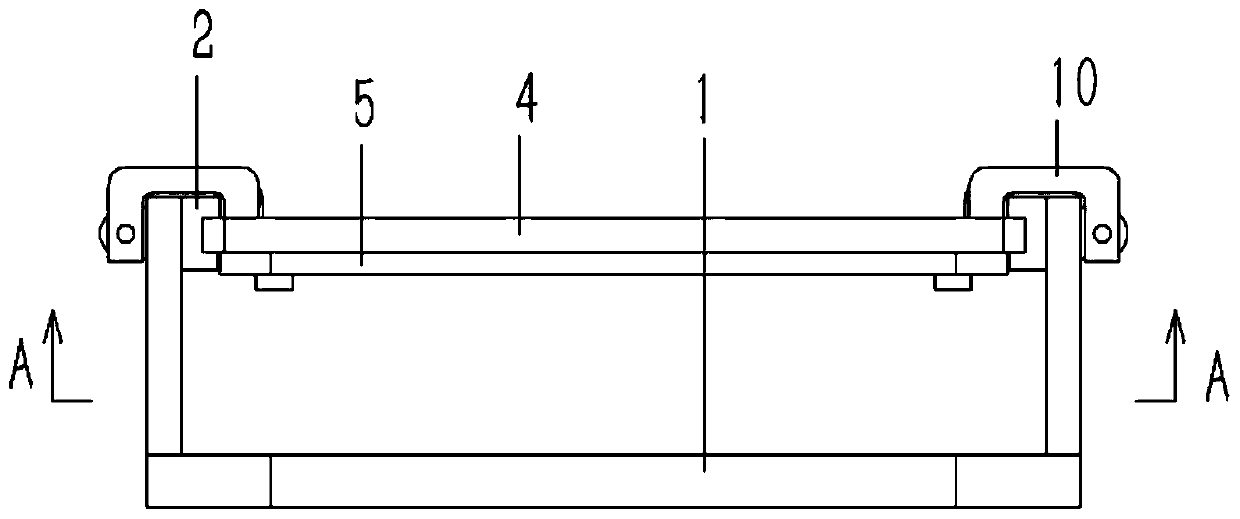

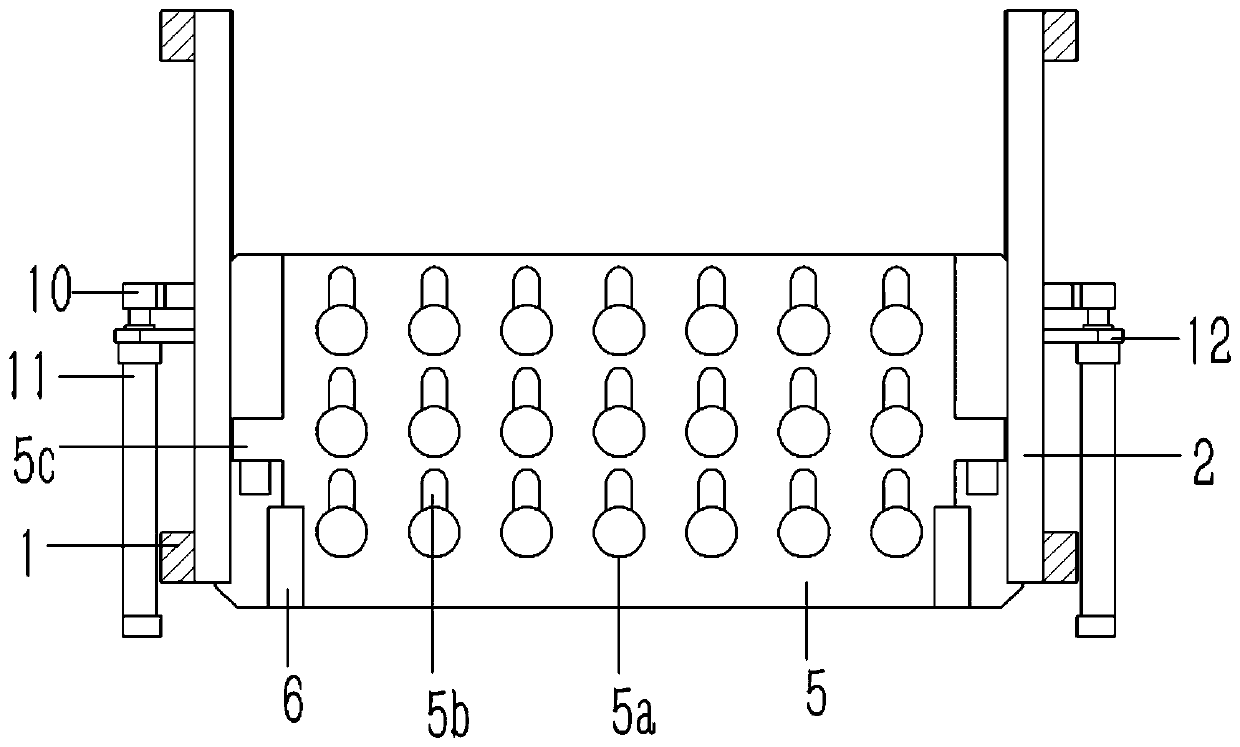

[0019] Example: see Figures 1 to 4 As shown, an automatic discharge device for a combined foot pad injection mold includes a conveying platform 1 of the injection mold, the conveying platform 1 is provided with a lower mold of the foot pad mold, and the two sides of the lower mold are arranged on longitudinal groove rails 2, The front and rear ends of the groove rail 2 are fixed with columns 3, and the lower ends of the columns 3 are fixed on the conveying platform 1. The upper side of the lower mold is provided with a horizontal positioning plate 4, and several positioning holes 4a are formed on the positioning plate 4 for positioning. Both sides of the plate 4 are inserted in the channel of the groove rail 2; the lower end surface of the positioning plate 4 is against the clamping plate 5, and the clamping plate 5 is formed with a plurality of through holes 5a opposite to the positioning holes 4a, and the through holes 5a A card slot 5b extending backward is formed on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com