Efficient pole piece cutting device for battery production

A technology of cutting device and battery, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of damage, different lengths, skewed pole pieces, etc., to improve safety, ensure uniformity, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

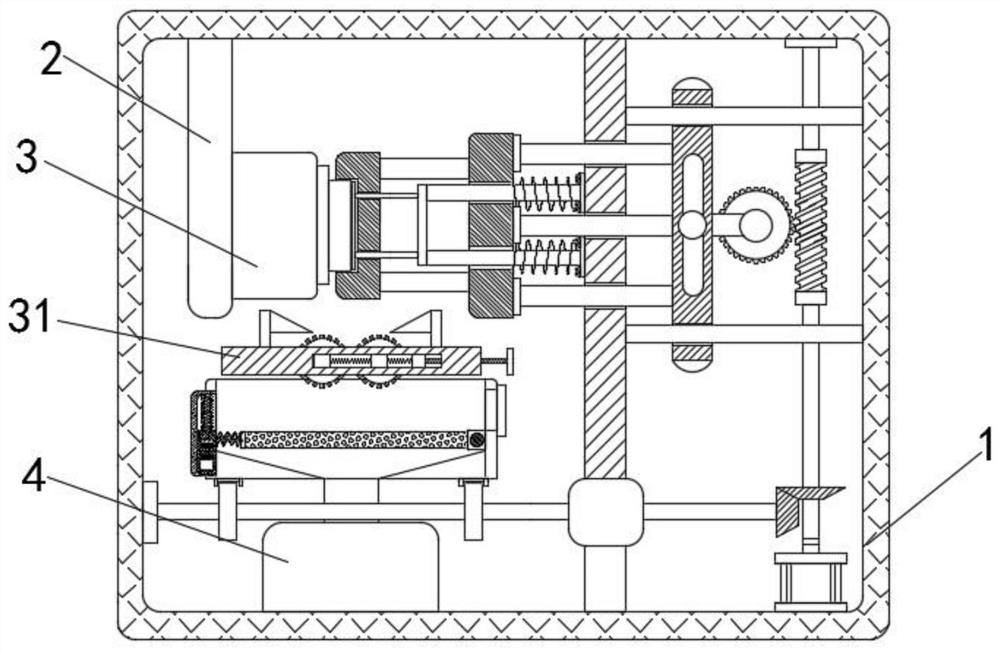

[0044] Such as Figure 1-5 As shown, a high-efficiency battery production pole piece cutting device includes a casing 1, the left inner wall of the casing 1 is fixedly connected with a bottom plate 2, and the outer wall of the bottom plate 2 is fixedly connected with a mounting block 3, and the mounting block 3 The outer wall is fixedly equipped with a second mold 17, and the right side of the second mold 17 is correspondingly provided with a first mold 16,

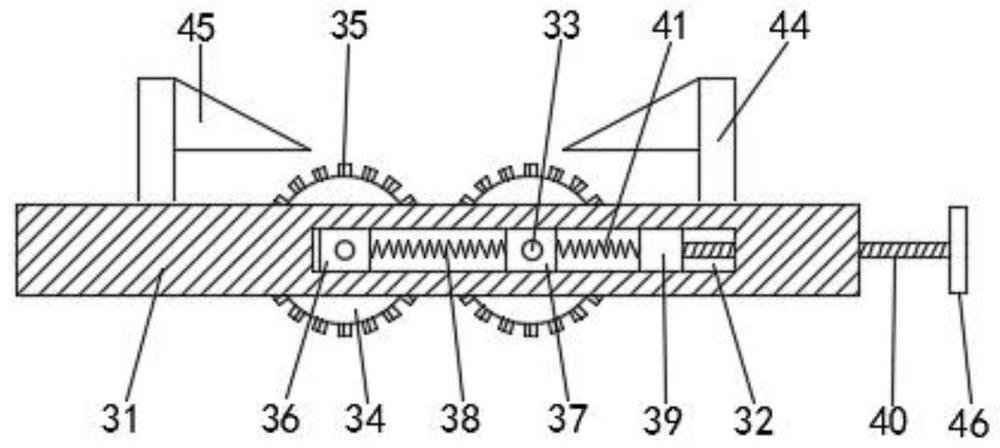

[0045] Described first mold 16 and the bottom of second mold 17 are provided with dedusting device, and described dedusting device comprises square frame 31, rotating shaft 33, first square 36, second square 37, rotating roller 34, bristle 35 and driving motor 42, The square frame 31 is fixedly installed in the left middle part of the inner wall of the housing 1 through the connecting rod 43, and the front and rear side walls of the square frame 31 are provided with adjustment grooves 32, and the left end of the adjustmen...

Embodiment 2

[0050] On the basis of Example 1, such as Figure 5-12 Shown:

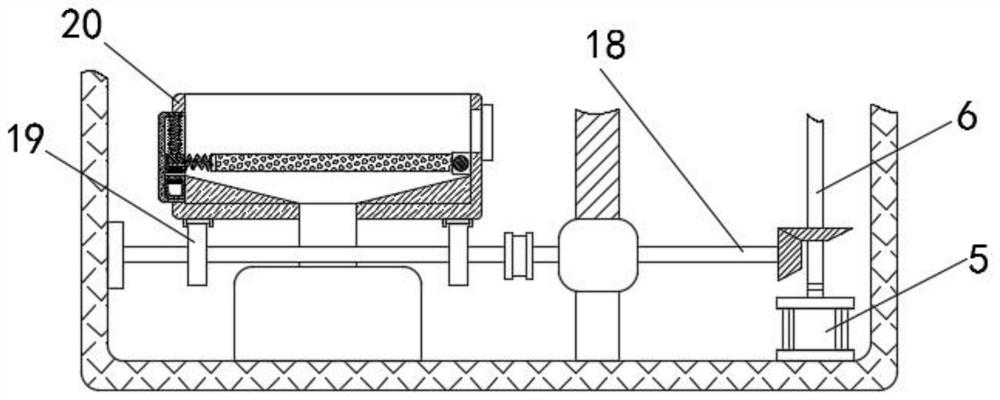

[0051] The worm 6 is connected with a transmission rod 18 through bevel gear transmission, the outer wall of the transmission rod 18 is sleeved with an eccentric wheel 19, the upper surface of the eccentric wheel 19 is placed with a collection box 20, and the right inner wall of the collection box 20 is movably connected with a filter plate 22, The left side of collection box 20 is fixedly connected with mounting plate 30, and the right side of mounting plate 30 is provided with mounting groove 23, and the inside of mounting groove 23 is slidably connected with slide block 25, and the inside of slide block 25 is fixedly installed with magnetic piece 26, slides The outer wall of the block 25 is fixedly connected with a breaking plate 28 , the other end of the breaking plate 28 is fixedly connected with the filter plate 22 , and the bottom end of the mounting plate 30 is fixedly equipped with an electromagnet 27 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com