Automatic Tea Straightening Machine

A tea stripping machine, fully automatic technology, applied in the direction of tea treatment before extraction, can solve the problems of tea damage, affect the quality of tea, and it is difficult to ensure that the tea is taken clean, so as to improve production efficiency and save the time for taking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

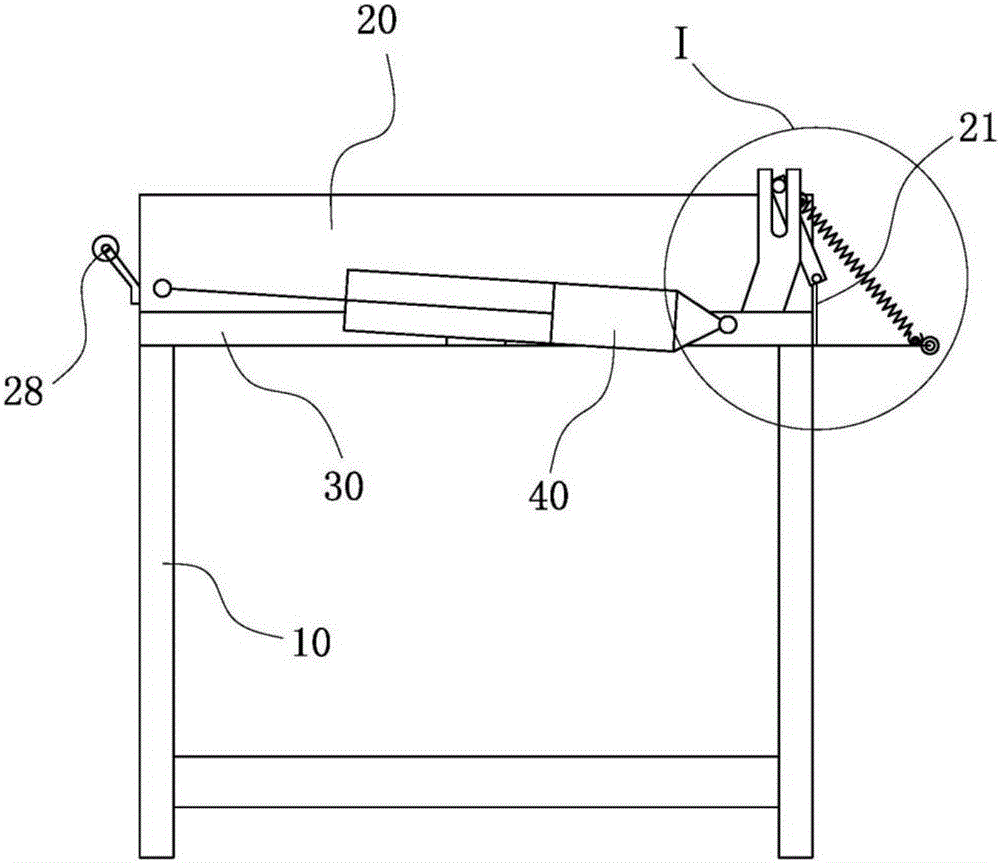

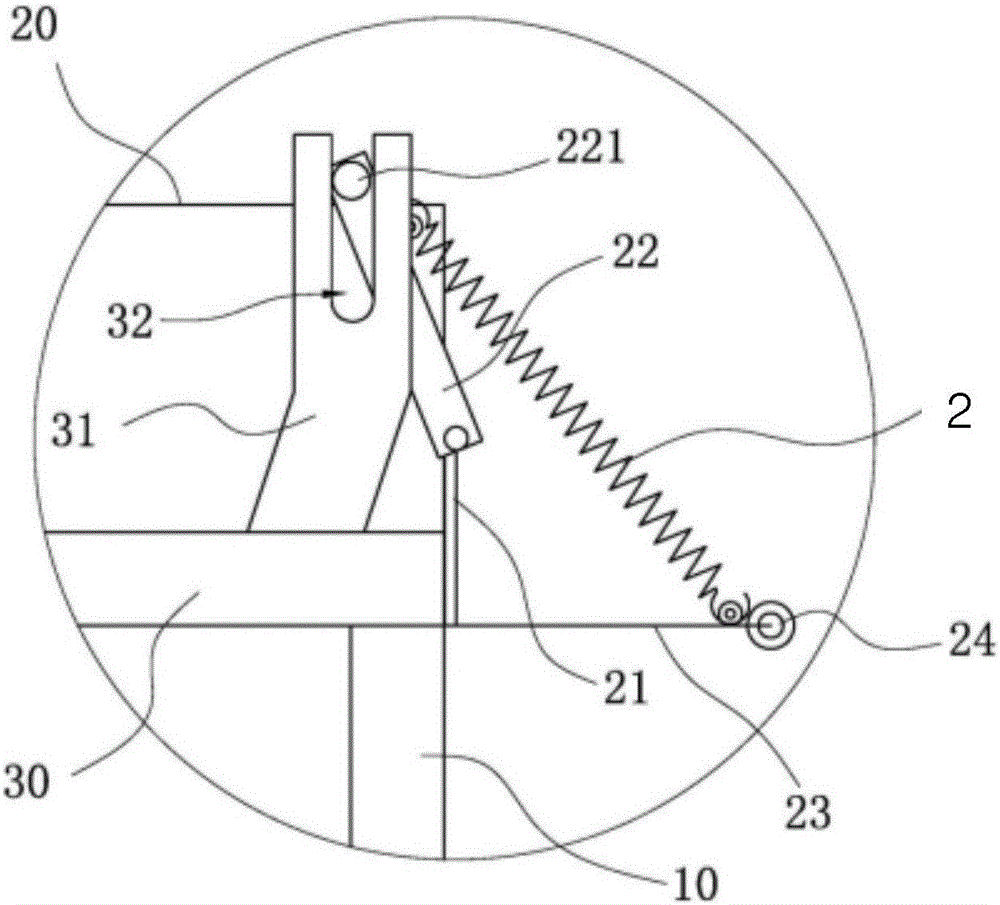

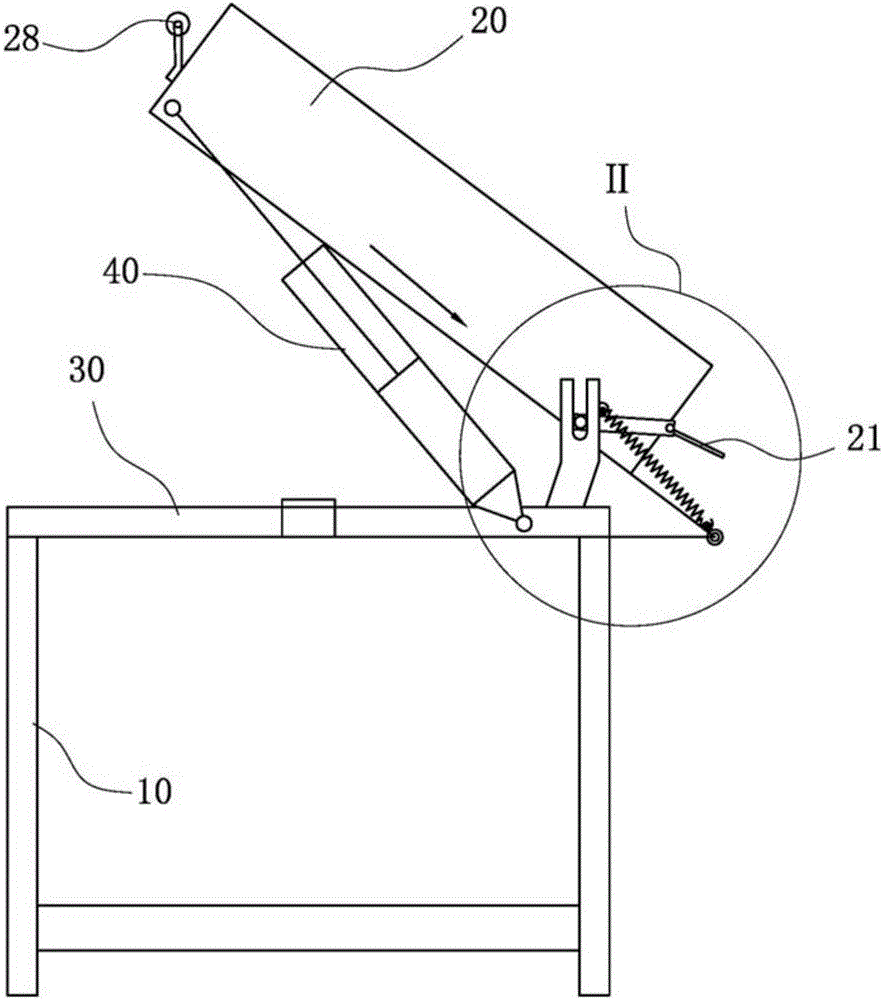

[0012] Such as figure 1 , 3 As shown, a fully automatic tea stripping machine includes a stripping pot 20 provided on the frame 10, and at least two strip-shaped stripping grooves are arranged side by side on the striping pot 20, and the bottom of the stripping pot 20 is A heating device is provided, and the frame 10 is also provided with a driving mechanism for driving the slitting pot to reciprocate, the reciprocating direction of the slicing pot 20 is perpendicular to the groove length direction of the slitting groove, and the slicing pot The pot 20 is installed on the sliding seat 30, and the sliding seat 30 is slidably arranged on the frame 10. The driving mechanism drives the sliding seat 30 to reciprocate. The side is hinged with the sliding seat 30 through a horizontal hinge shaft 24, and the side wall of the slitting pot 20 on one side of the hinged side is provided with a discharge door 21 for opening and closing the sliver groove end. When the stripping pot 20 was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com