Bush press-in machine

A press-in machine and bushing technology, which is applied in the field of press-fitting machines, can solve problems such as low efficiency, and achieve the effects of avoiding potential safety hazards, shortening reclaiming time, and increasing frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

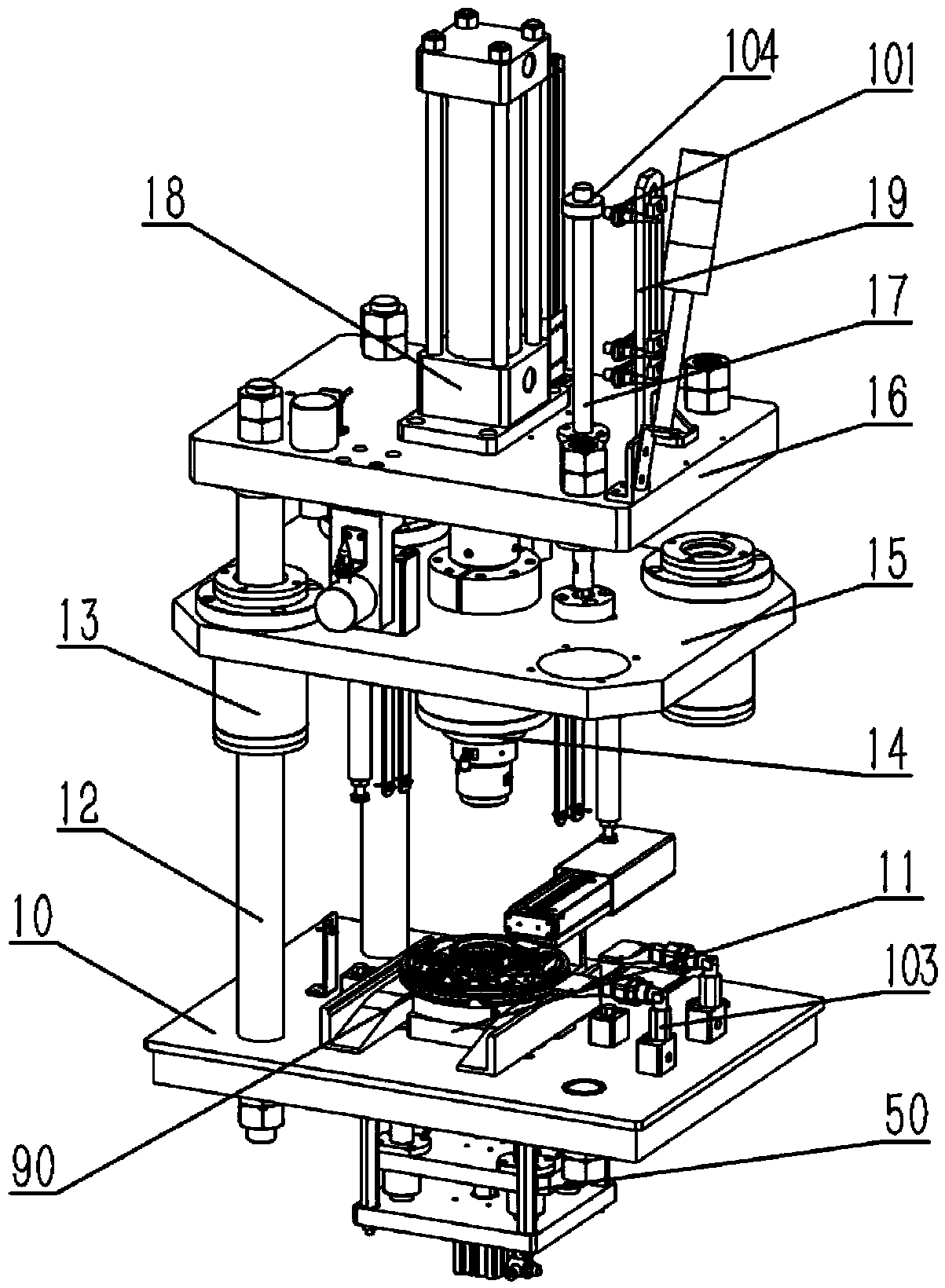

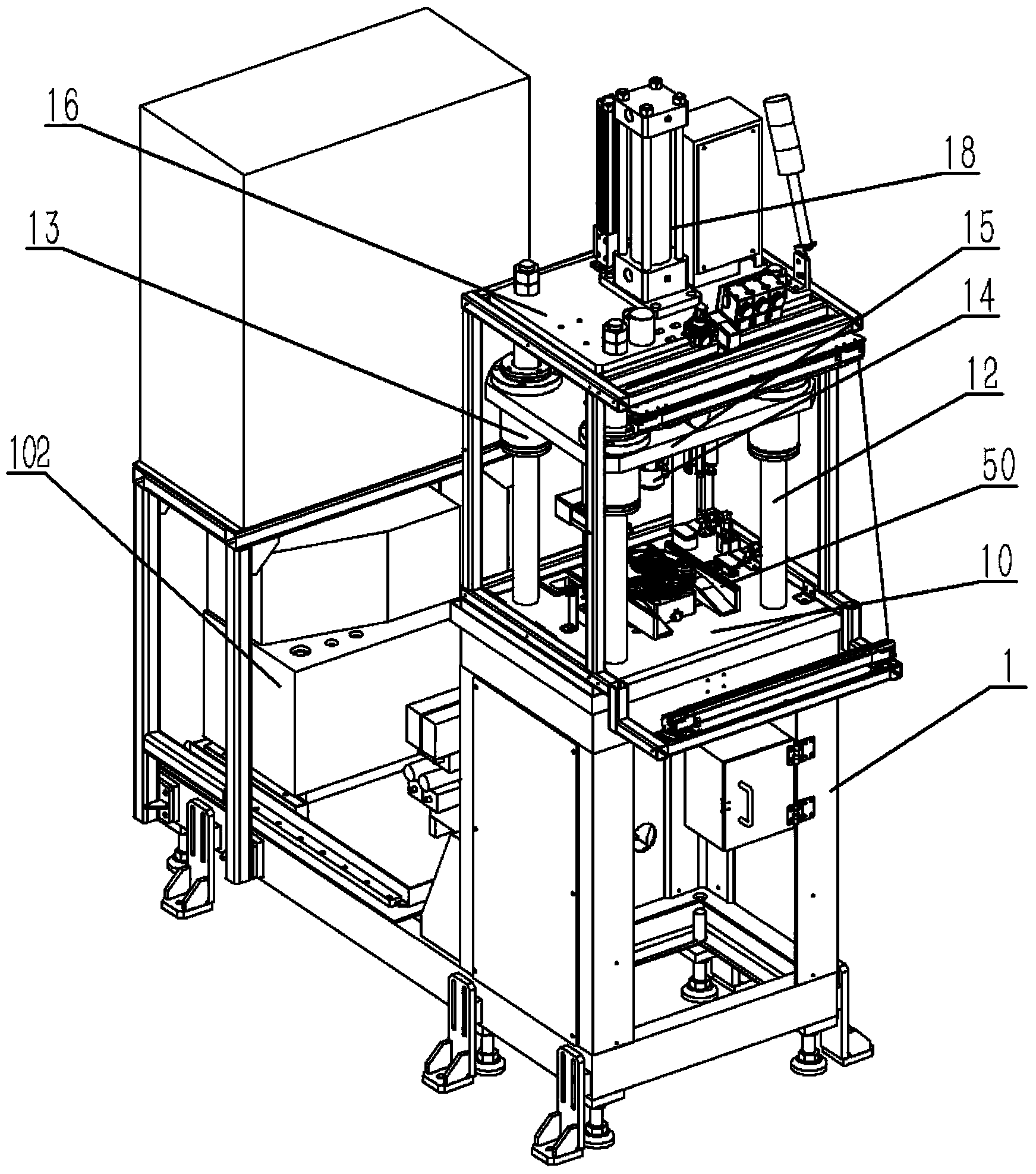

[0018] Example: see Figures 1 to 4 As shown, the bushing press-in machine includes a frame 1, and the frame 1 is fixed with a workbench 10, and the workbench 10 is fixed with a workpiece placement table 11. The first guide shaft 12 is fixed on the workbench 10, and the first guide shaft 12 is fixed on the worktable 10. The upper end of the shaft 12 is fixed on the top plate 16, the first linear shaft 13 is inserted and sleeved on the first guide shaft 12, the first linear shaft 13 is fixed on the middle plate 15, and the lower end surface of the middle plate 15 is fixed with a stamping The head 14 and the upper end surface of the middle plate 15 are fixed with the piston rod of the hydraulic cylinder 18, and the hydraulic cylinder 18 is fixed on the top plate 16; a discharge mechanism 50 is provided under the workbench 10, and the discharge mechanism 50 is located at the stamping head 14 directly below the .

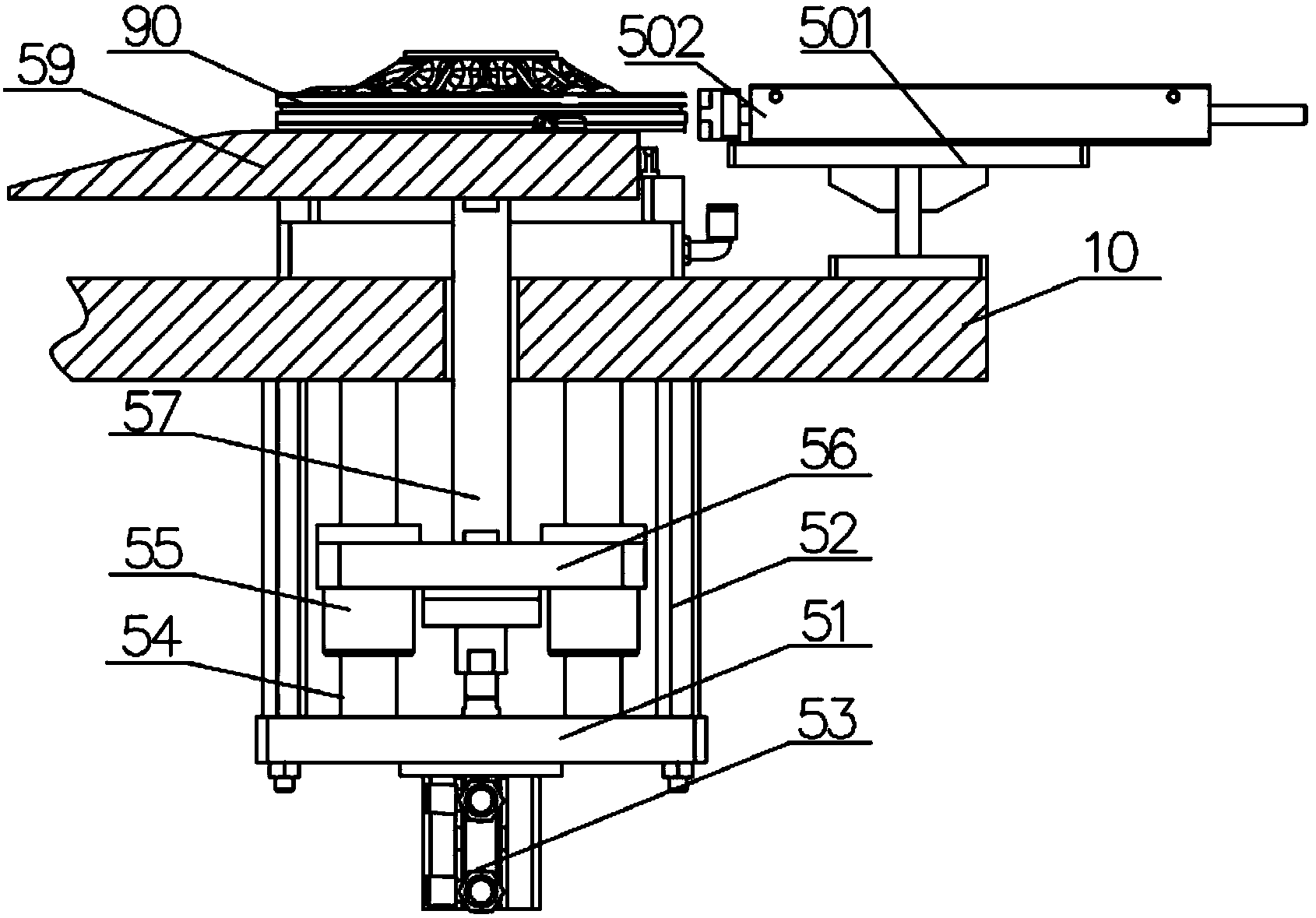

[0019] The structure of the discharge mechanism 50 is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com