Automatic stamping mechanism for stretching forming of cylindrical battery steel shell

A stretch forming, cylindrical battery technology, used in forming tools, feeding devices, manufacturing tools, etc., to avoid burns to workers, enhance air flow speed, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

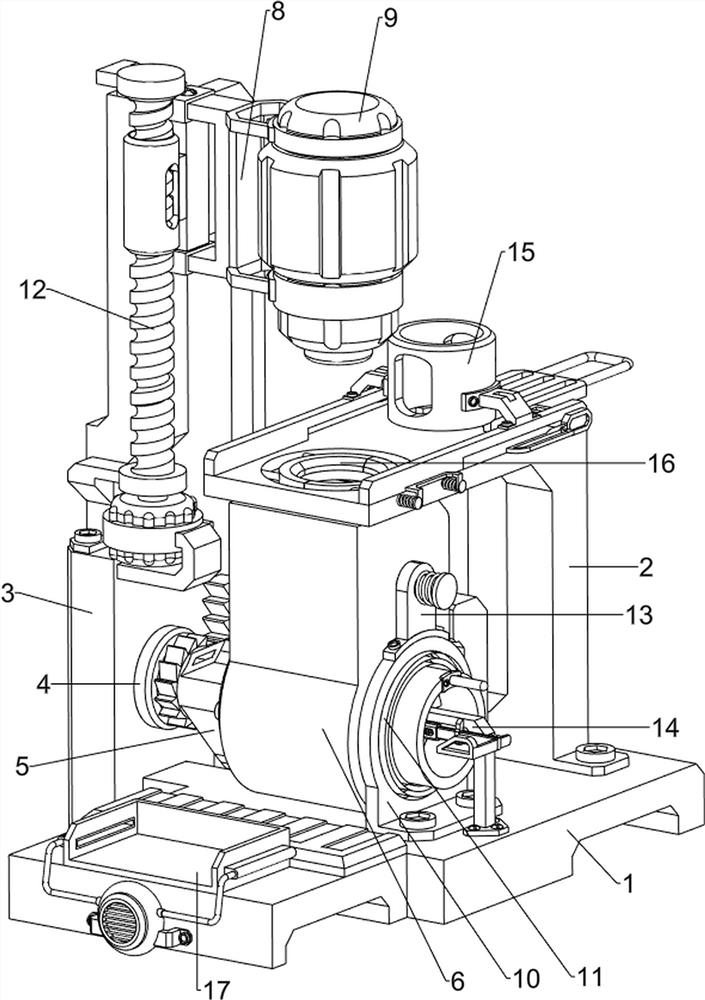

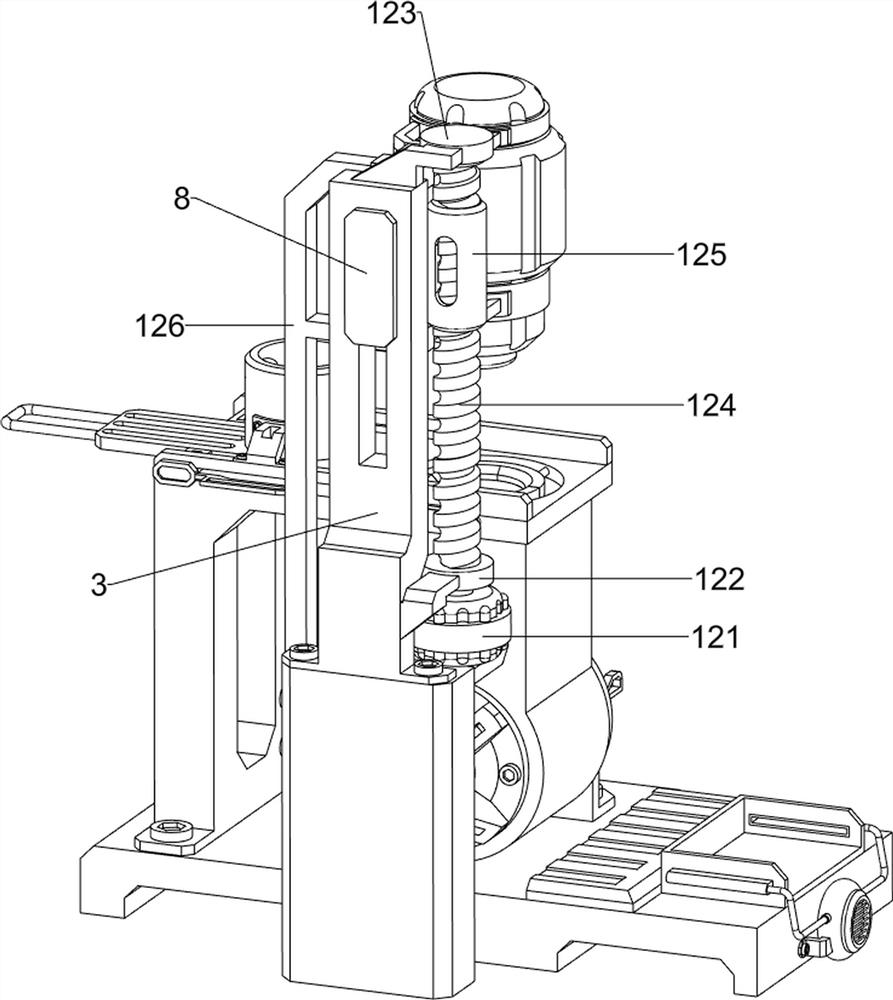

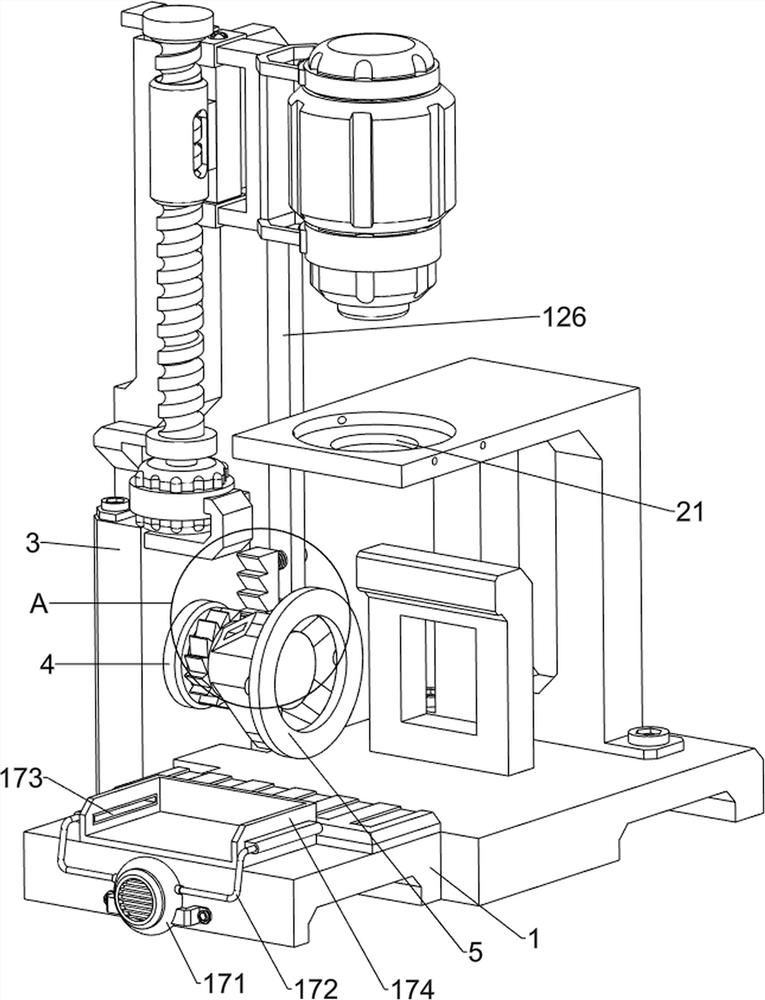

[0030] An automatic punching mechanism for drawing and forming a cylindrical battery steel shell, such as figure 1 , image 3 and Figure 7 As shown, it includes a base 1, a placing frame 2, a mounting plate 3, a bearing connecting seat 4, a connecting shaft frame 5, a die 6, a flat-top piston 7, a first connecting frame 8, a punching machine 9, a ring-type fixing frame 10, The return spring 11, the driving mechanism 12 and the ejecting mechanism 14 are connected with the placing frame 2 at the middle position of the top of the base 1, the left side of the placing frame 2 is provided with a feeding opening 21, and the rear side of the base 1 is connected with a mounting plate 3, and the mounting plate 3 The front side is connected with the bearing connecting seat 4, the bearing connecting seat 4 is rotatably connected with the connecting shaft frame 5, and the front side of the connecting shaft frame 5 is connected with a mold 6, which can assist the round steel sheet to be p...

Embodiment 2

[0035] On the basis of Example 1, as figure 1 , Figure 5 and Image 6 As shown, it also includes an anti-displacement mechanism 13, the anti-displacement mechanism 13 includes a mounting seat 131, a plug 132 and a second spring 133, the top of the ring-type fixing frame 10 is connected with a mounting seat 131, and the mounting seat 131 is slidably connected There is a pin 132, and a second spring 133 is connected between the pin 132 and the mounting seat 131. The second spring 133 plays a role in buffering and restoring the pin 132. A positioning groove 134 is opened on the upper side of the front part of the mold 6, and the pin 132 can be connected with the positioning groove. 134 is clamped and fixed, and the end of the plug 132 is designed with a round head, so that the plug 132 can be pushed and squeezed by the mold 6 .

[0036] When the mold 6 starts to turn counterclockwise, the mold 6 will squeeze the pin 132, so that the pin 132 slides forward, the pin 132 moves ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com