Double-track feeding structure

A feeding and double-track technology, applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of reduced efficiency of the whole machine, slow feeding speed, and long retrieving time, so as to reduce retrieving time and speed up Feeding speed, conveying precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

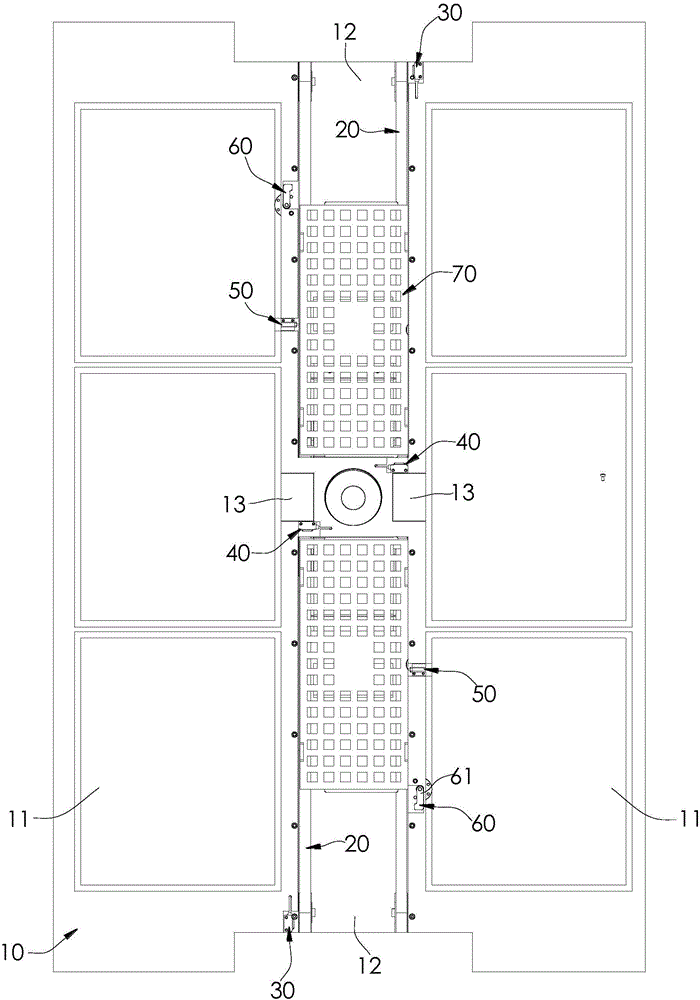

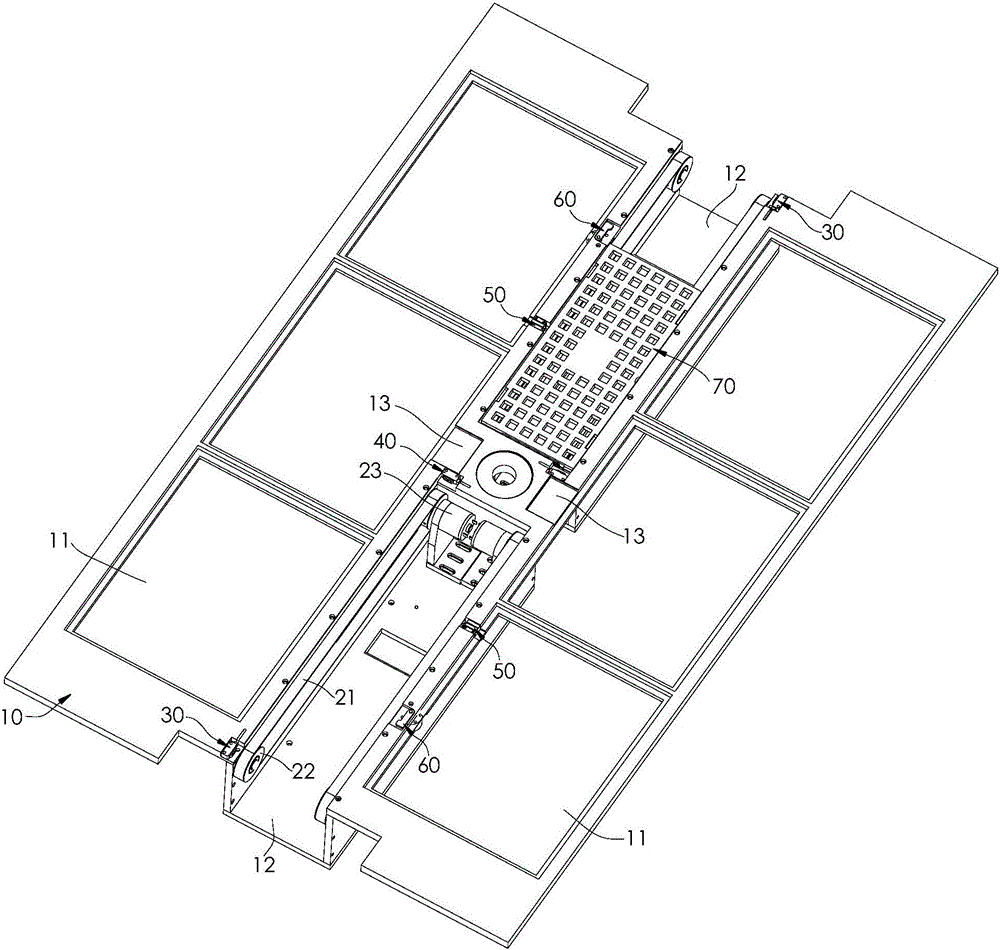

[0018] Such as figure 1 and figure 2 As shown, the double-track feeding structure of the present invention includes an underframe 10 and two conveying mechanisms 20, and the underframe 10 is provided with two feeding troughs 12 for conveying the tray 70 and two rows of burning stations 11 , the two feeding troughs 12 extend from the two ends of the chassis 10 in the lengthwise direction to the middle of the chassis 10, and the two feeding troughs 12 are isolated from each other; each feeding trough 12 is provided with a feeding sensor 30 And the in-position sensor 40, the feed sensor 30 is located at one end of the feed chute 12 near the end of the chassis 10, and the in-position sensor 40 is located at the end of the feed chute 12 near the middle of the chassis 10; Two rows of burning stations 11 are respectively located on opposite sides of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com