Powder lifting device for commercial concrete production

A commercial concrete and powder technology, which is applied to clay preparation devices, raw material supply devices for sale, cement mixing devices, etc., can solve problems such as inability to realize continuous feeding of hoppers, low feeding efficiency, and manual pouring, so as to ensure good health , improve efficiency, improve the effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

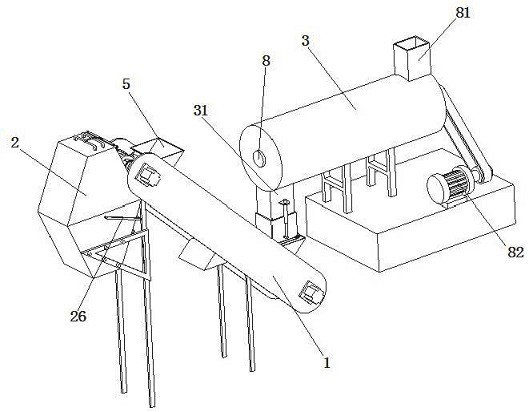

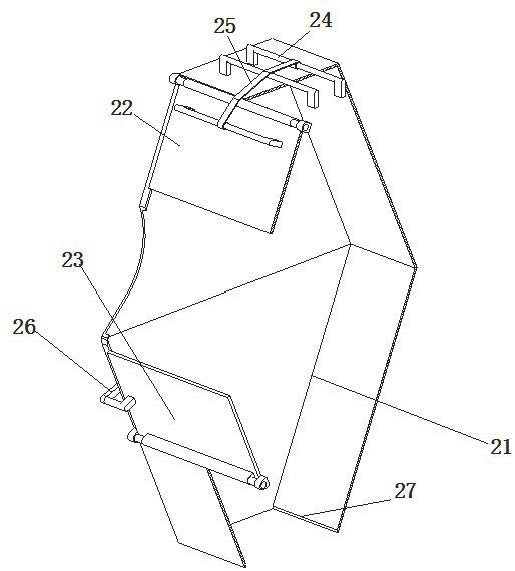

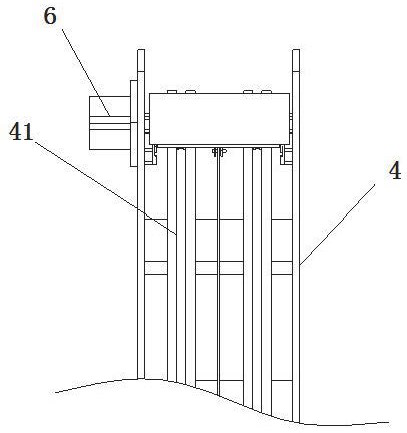

[0034] refer to Figure 1 to Figure 10 The powder hoisting device for commercial concrete production shown includes a hoisting device 1 installed on an incline, a dust cover 2 and a mixing barrel 3 installed on the top of the hoisting device 1, and the hoisting device 1 includes an obliquely arranged Sliding frame 4, several feeding hoppers 5 slidingly matched with sliding frame 4 and drive assembly 6 installed on the end of sliding frame 4, described dust cover 2 is fixedly installed on the top of sliding frame 4, and described dust cover 2 A baffle plate assembly for blocking the gap is provided, the mixing tube 3 is erected above the bottom end of the sliding frame 4, and the end of the mixing tube 3 located directly above the bottom end of the sliding frame 4 is connected with a dust-proof feeding tube 31 downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com