Bypass bus bar manufacturing mechanism, bus bar supply mechanism and method for machining bus bar through stitch welding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

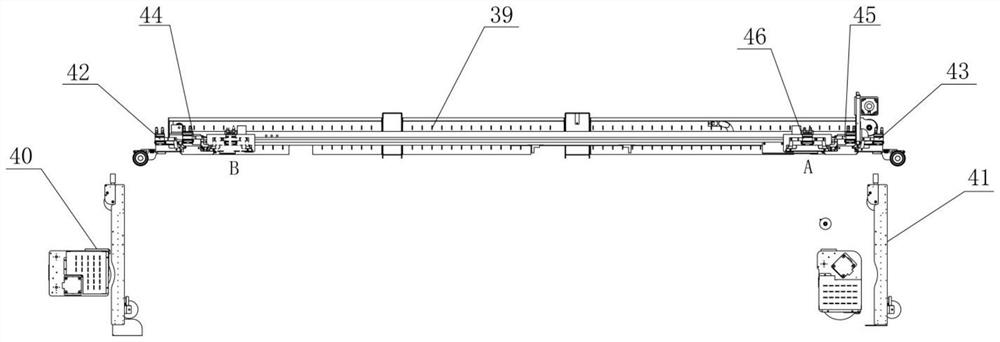

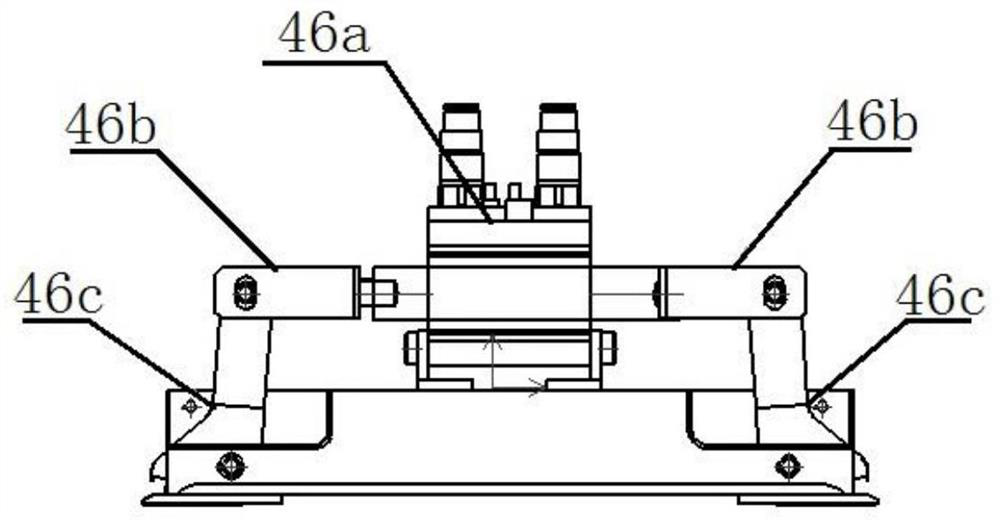

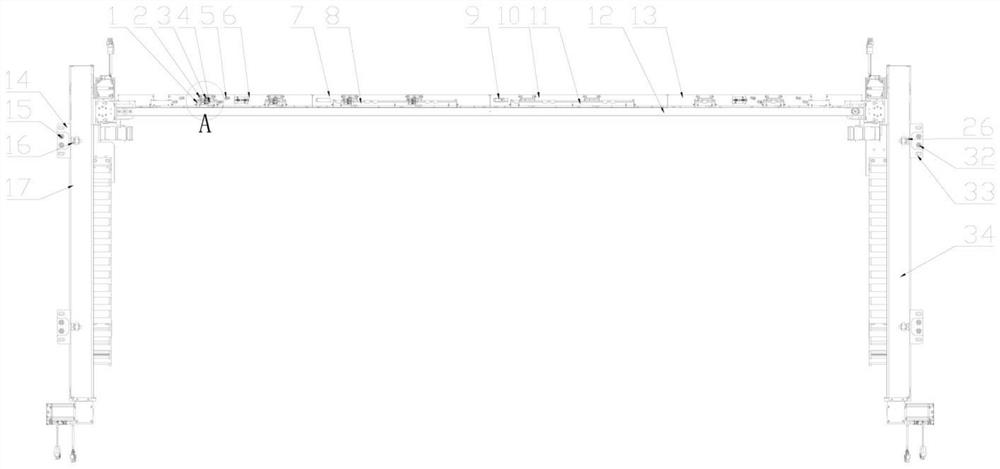

[0027] Such asfigure 1 , figure 2 As shown, the embodiment of the present invention provides a bypass tape making mechanism, which mainly includes a displacement mechanism 39, a first tape supply mechanism 40, a second tape supply mechanism 41, a first fixed clamp hand 42, a second fixed clamp Clamp hand 43, the first cutter mechanism 44, the second cutter mechanism 45, drawstring mechanism 46.

[0028] The first tape supply mechanism 40 and the second tape supply mechanism 41 are respectively arranged on both sides of the displacement mechanism 39 for installing the bus tape roll. The first fixed clamp hand 42 and the second fixed clamp hand 43 are installed on the displacement mechanism 39 to respectively clamp the confluence belts on both sides, and the first cutter mechanism 44 and the second cutter mechanism 45 are installed on the displacement mechanism 39. Corresponds to the first fixed clamp hand 42 and the second fixed clamp hand 43 respectively and is used to cut t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com