Camellia seed stir-frying processing device for preparing camellia oil

A processing device and technology for camellia seeds, which are applied in the directions of oil/fat production, fat production, etc., can solve the problems of uneven stirring, high cost of manual stirring, low manual operation efficiency, etc., and achieve uniform heating, convenient operation, and improved The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

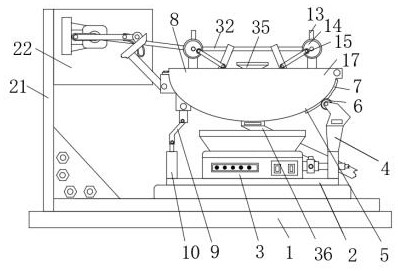

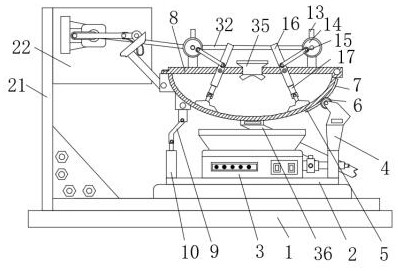

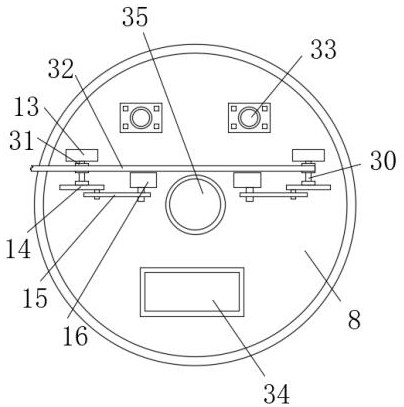

[0025] refer to Figure 1-6 , a camellia seed frying processing device for tea oil preparation, comprising a processing seat 1, a welding plate 2 is fixedly installed on the top of the processing seat 1, a gas stove 3 is fixedly installed on the top of the welding plate 2, and a gas stove 3 is fixedly installed on the top of the welding plate 2 A support rod 4 is fixedly installed, and the top of the support rod 4 is slidably connected to a frying pan 5, and the frying pan 5 is located directly above the gas stove 3, and the bottom of the frying pan 5 is fixedly connected to a connecting rod 9, and the bottom of the connecting rod 9 slides elastically Connected with fixed seat 10, the top of frying pan 5 is rotatably connected with pot cover 8, and the top of pot cover 8 is fixedly installed with two fixed plates 13 that are arranged symmetrically, and one side of fixed plate 13 is connected with rotating disk 14 in rotation, and the rotating disk One side of 14 deviates from ...

Embodiment 2

[0027]This embodiment is improved on the basis of Embodiment 1: the top of the support rod 4 is fixedly connected with a pulley 6, the bottom of the frying pan 5 is fixedly connected with a slide rail 7, and the pulley 6 and the slide rail 7 are slidably connected. When the rail 7 can push the wok 5 to swing, it provides a rail for the wok 5 to move laterally, which improves the stability of the wok 5 moving. Sliding groove, the bottom of the sliding rod 11 extends into the sliding groove and is fixedly connected with the limiting plate, the bottom of the limiting plate is fixedly connected with the supporting spring 12, the bottom of the supporting spring 12 is fixedly connected with the bottom inner wall of the sliding groove, and the supporting spring 12 Just can support connecting rod 9, when frying pan 5 swings simultaneously, can provide elastic support for frying pan 5, the bottom of the first telescoping sleeve 16 is provided with sliding hole 19, and the top inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com