Automobile three-piece spoiler gluing and adhering assembly automation line

A three-piece spoiler technology, which is applied to motor vehicles, transportation and packaging, and devices for coating liquid on the surface, can solve the problems of low product qualification rate and low assembly efficiency, so as to improve processing efficiency and reduce Labor cost, the effect of enhancing the adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

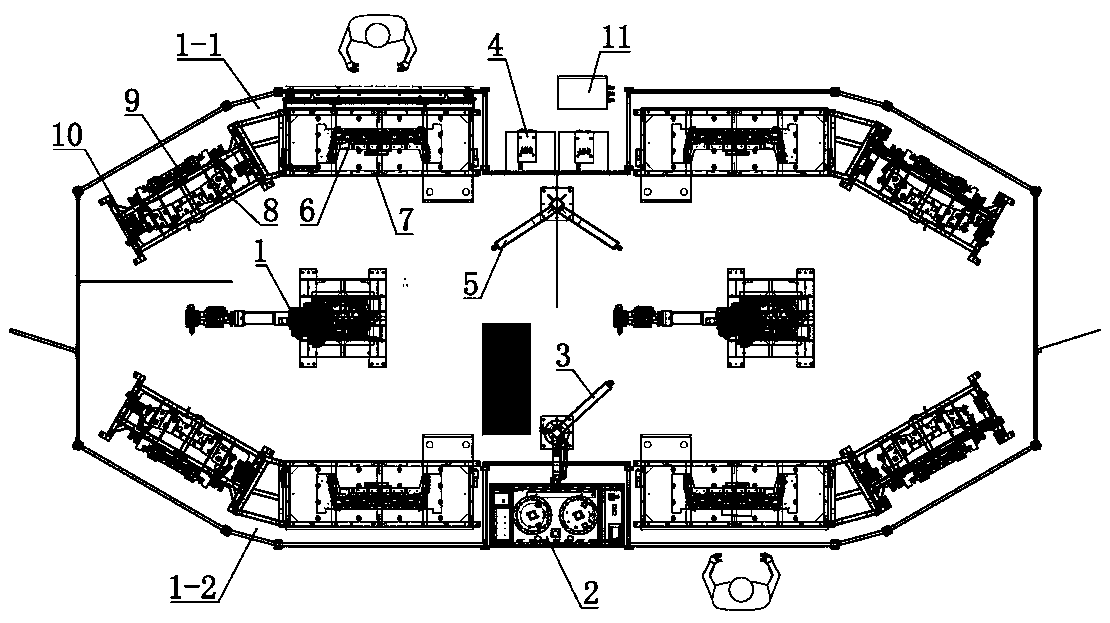

[0014] Such as figure 1 The shown automatic assembly line for gluing and bonding three-piece spoilers for automobiles includes a symmetrically arranged first assembly station 1-1, a second assembly station 1-2 and a robot between the two assembly stations 1; A glue machine 2 with a rubber hose 3 and a plasma flame treatment device 4 with a flame spray gun 5 are provided on one side of the two assembly stations; each assembly station includes a first inner plate tire mold 6 Fixed mount 7, and the second fixed mount 10 that is provided with upper plate tire mold 8, outer plate tire mold 9.

[0015] The first fixed frame 7 and the second fixed frame 10 are provided with limit blocks, which are used to limit the placement positions of the inner plate tire mold 6, the upper plate tire mold 8 and the outer plate tire mold 9; Combined air cylinder and turnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com