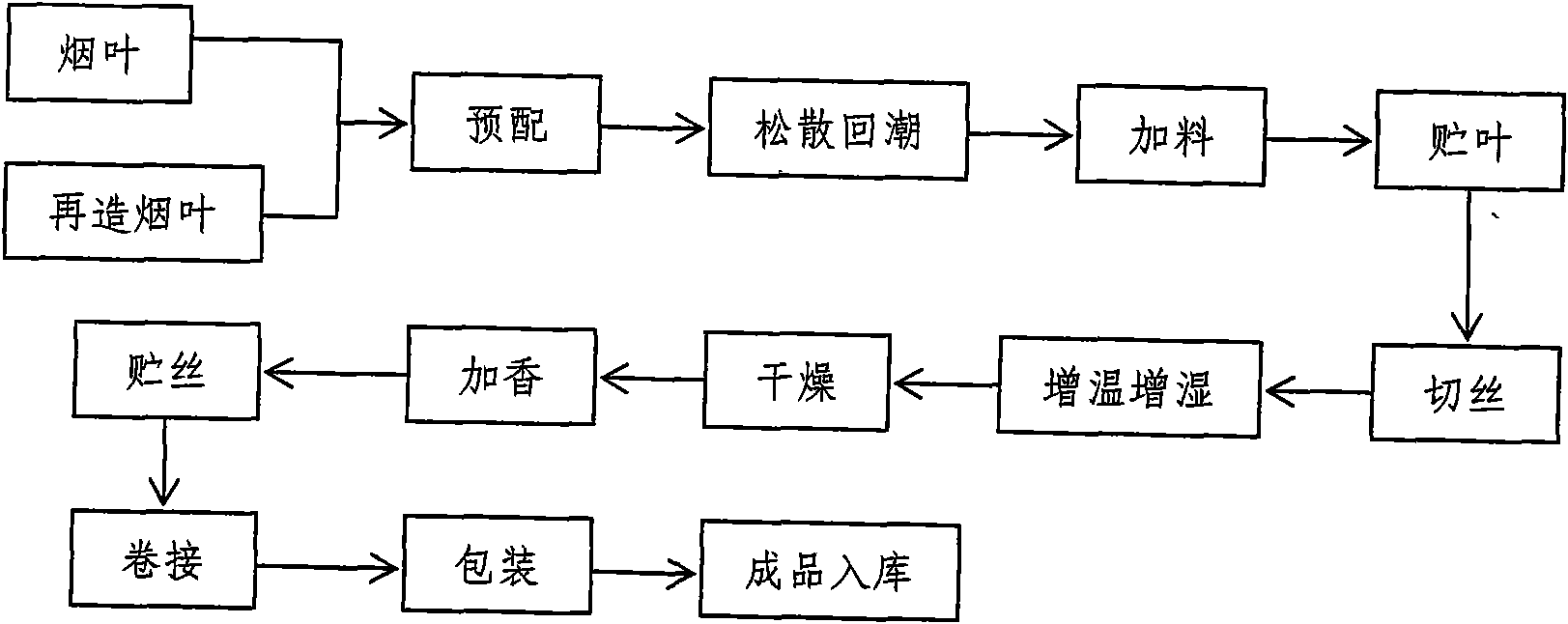

Use method of reconstituted tobacco in production of cigarettes

A technology for reconstituting tobacco leaves and cigarettes, which is applied in the directions of tobacco, application, and preparation of tobacco, can solve the problems of uneven tow, sheet running, adhesion, etc., and achieves improved mixing uniformity, enhanced blending performance, and enhanced controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

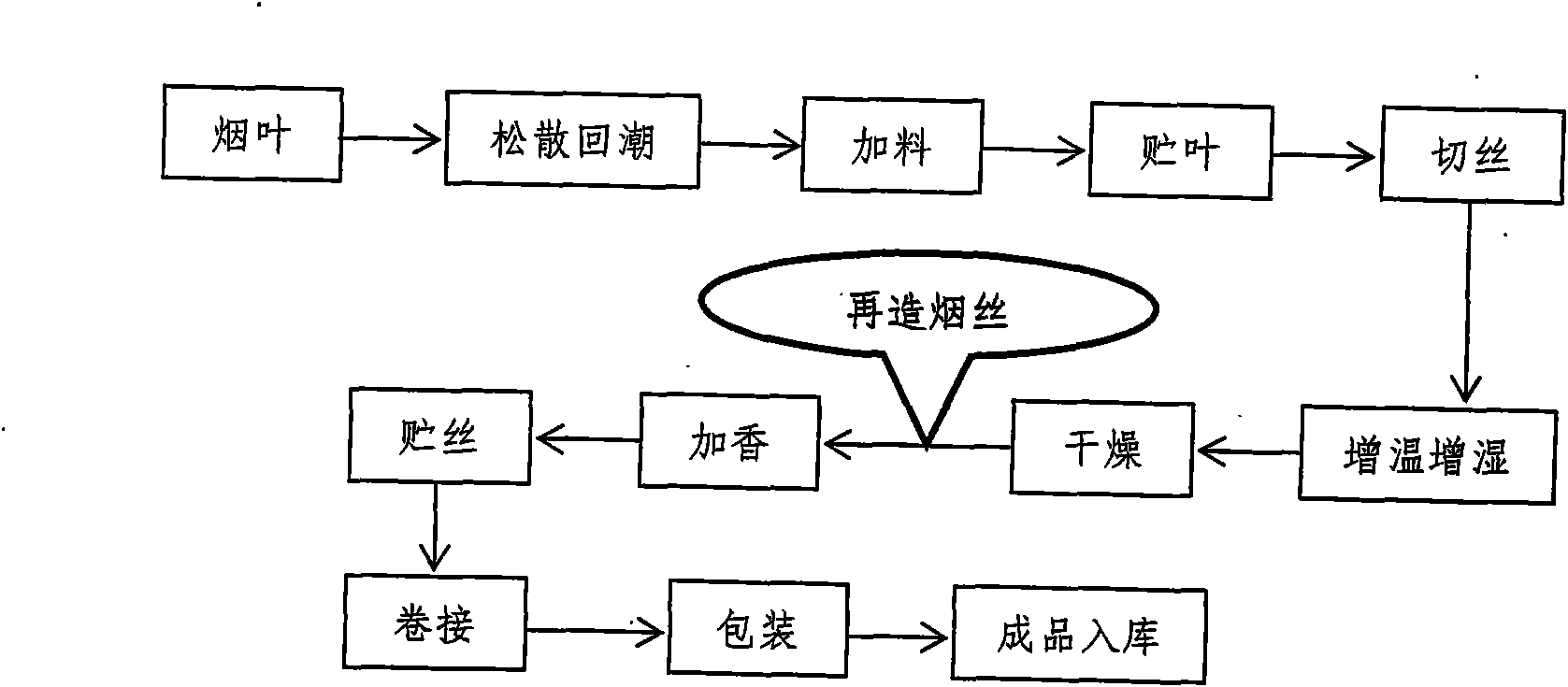

[0018] Such as figure 2 As shown, using existing slitting equipment in the papermaking industry, the whole reconstituted tobacco leaves of the papermaking method are cut into flat paper webs of 500 mm × 353 mm through slitting and cross-slitting devices. Lay the obtained flat paper webs in stacks of 400 sheets one by one on the existing shredding machine copper bar chain of the cigarette company, operate the shredding machine, and cut it into wires with a specification size of 20mm×1mm. The obtained reconstituted shredded tobacco is blended with shredded tobacco leaves after the cigarette shred drying process and before the flavoring process at a weight ratio of 5%, and then coiling and packaging are carried out according to the normal production process of cigarettes.

Embodiment 2

[0020] Using the existing coiling equipment in the papermaking industry, the whole reconstituted tobacco leaves of the papermaking method are rolled into roll paper, and then reconstituted tobacco leaves are cut into flat sheets of 250mm×353mm through rewinding and slitting. Lay the obtained flat paper webs in stacks of 500 on the copper bar chains of the existing shredding machine of the cigarette enterprise, operate the shredding machine, and cut it into wires with a specification size of 20mm×1mm. The obtained reconstituted shredded tobacco is blended with shredded tobacco leaves after the cigarette shred drying process and before the flavoring process at a weight ratio of 10%, and then coiling and packaging are carried out according to the normal production process of cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com