Structural lattice with flow-mixing coordination in nuclear fuel assemblies

A technology of nuclear fuel assembly and function, which is applied in the direction of reactor fuel elements, moderator/core structure, nuclear engineering, etc., can solve the problem of coordination between the clamping system and the mixing system, the weakening of the mixing performance of the structural lattice, Problems such as flow turbulence, to achieve the effect of achieving coordination, reducing pressure loss, and increasing critical heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

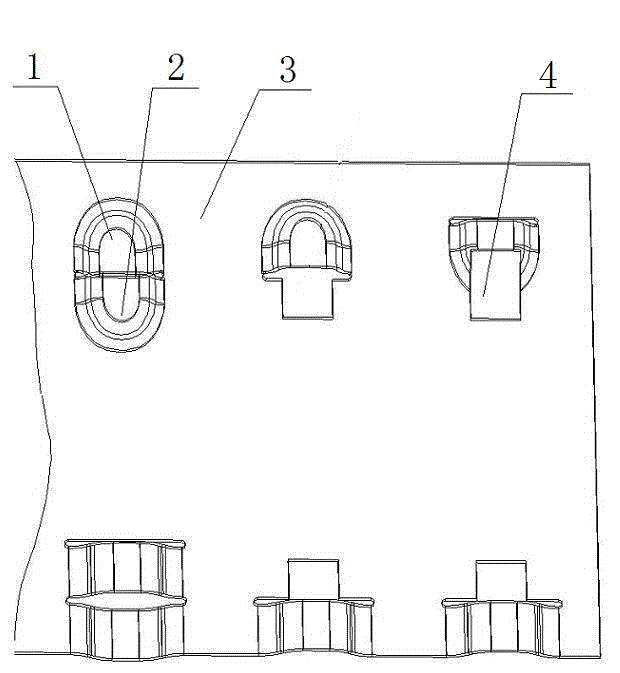

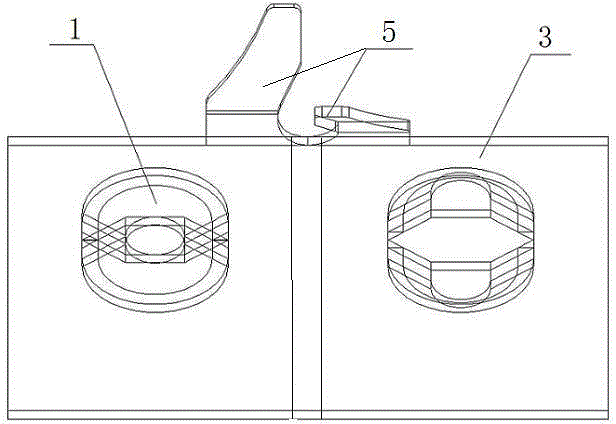

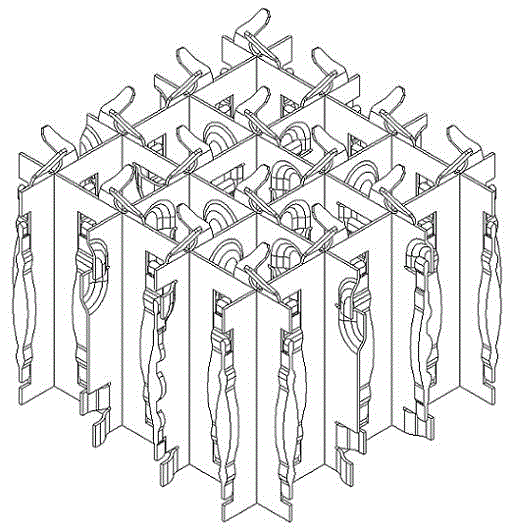

[0020] Such as figure 1 , figure 2 , image 3 As shown, based on the structural lattice with flow and mixing coordination in nuclear fuel assemblies, it includes a lattice composed of several strips 3 interwoven vertically with each other, and a pair of mixing strips are arranged on both sides of the top of the intersection of the strips 3 Each strip 3 of the wings 5 is recessed to form a half-button-shaped rigid-convex structure-2, and the opening end of the rigid-convex structure-2 faces the bending direction of the corresponding mixing wing 5. According to the bending direction of the mixing wings 5 at the top of the grid strip 3, a half-button structure is stamped on the just convex position on the strip 3, and the half-button shape opens upwards towards the bending direction of the mixing wings, and is formed at the crossing position of the strip 3. Stirring wings with cross orientation.

[0021] The strip provided with the rigid convex structure 1 2 is indented t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com