Steam stalk moistening method and equipment for implementing same

A treatment method and stem moistening technology, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of adding a vacuum resurfacing device, complicated procedures, and complicated technological processes, so as to improve the moisture penetration performance, remove the storage process, and simplify the process. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

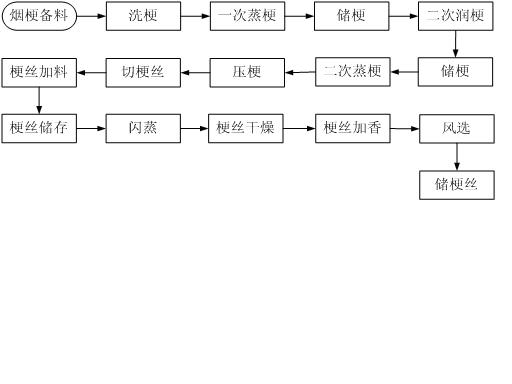

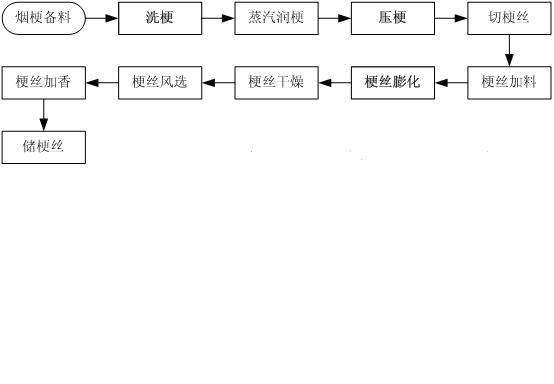

[0036] Such as figure 2 As shown, the tobacco stem treatment technological process adopting the steam moistening stem treatment method of the present invention comprises the following steps:

[0037] A. Tobacco stem material preparation: unpack the bagged or boxed tobacco stem material, remove dust and impurities, including a set of metering units for stabilizing the flow.

[0038] B. Stem washing: Send the tobacco stem material into the stem washing machine for stem washing treatment to remove the dust on the surface of the tobacco stem and the heavy metal, sand and stone mixed in the tobacco stem.

[0039] C. Steam stalks: Send the tobacco stem material with a moisture content of about 12% (the surface moisture of the washed stalks must be greater than 12%) into the steam stalk moistening machine, and at the same time fill in hot water at the feeding port; Conveying, within 1-5 minutes, it continuously passes through a closed chamber filled with saturated steam with a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com