Method and device for preparing expanded stem granule

A technology for expanding tobacco stems and granules, which is used in the preparation of tobacco, tobacco, tobacco processing, etc., can solve the problems of not overcoming the influence of raw material differences in product quality, no solution, and low moisture content of tobacco stems, so as to ensure stability. the effect of reducing differences in quality, reducing differences in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

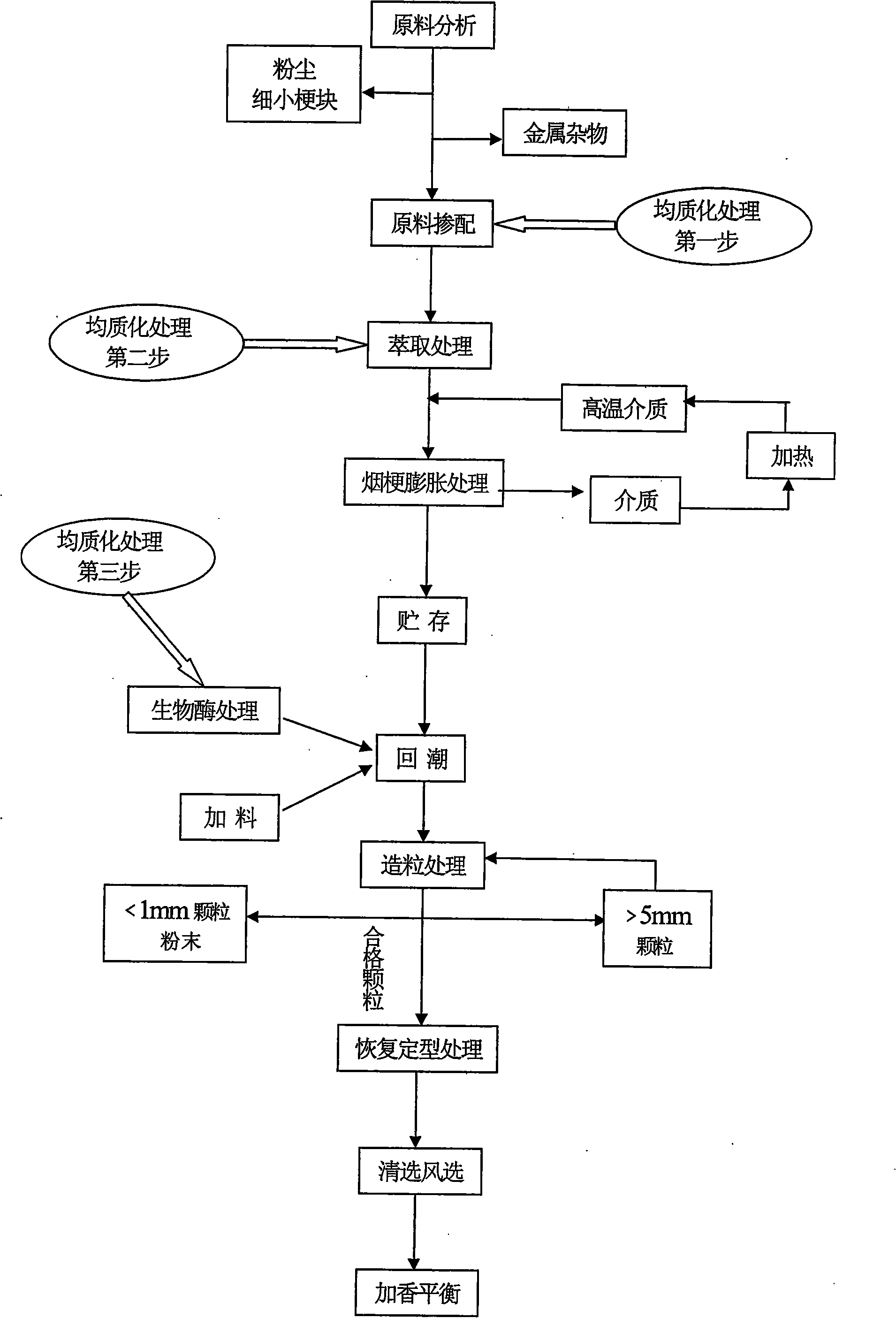

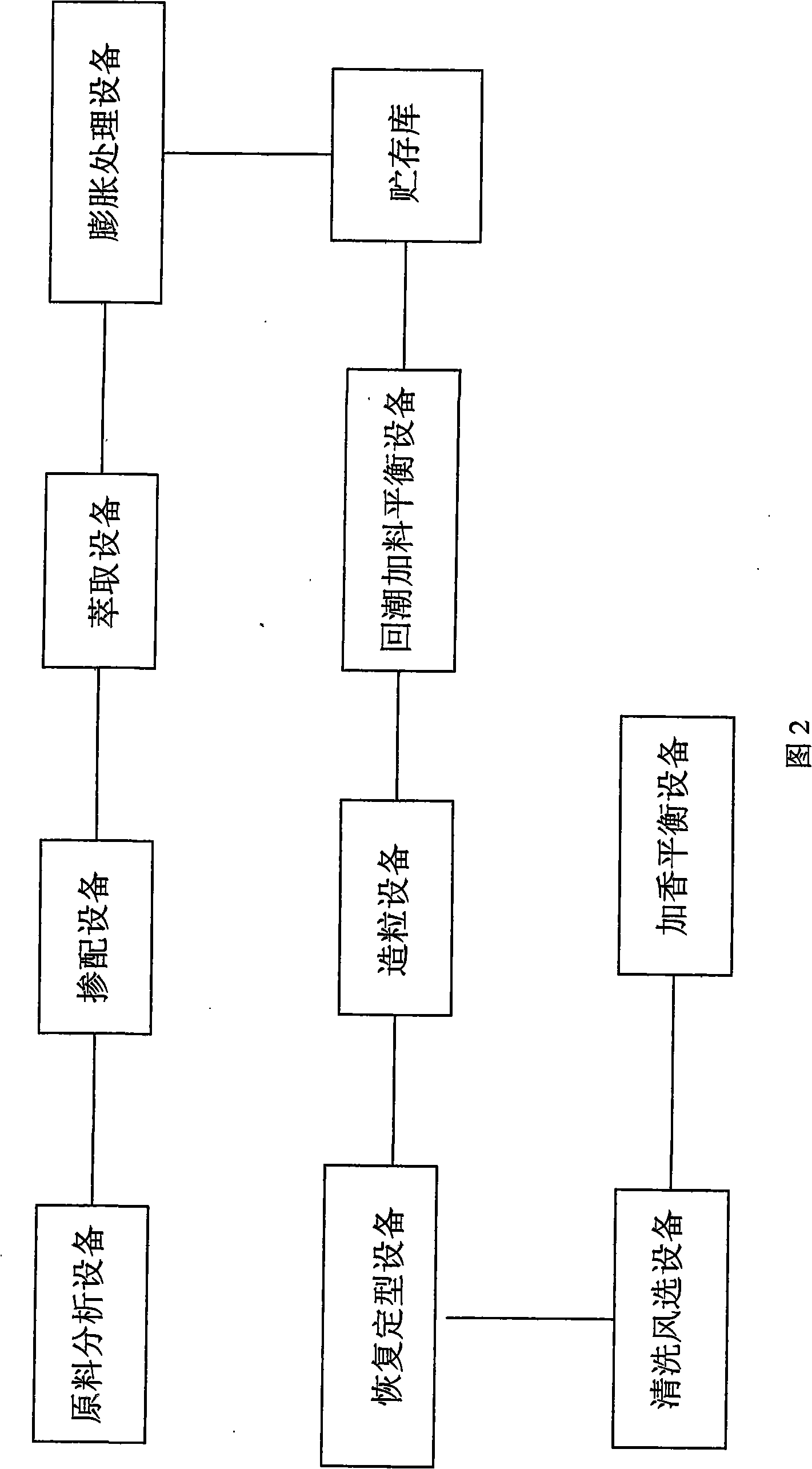

[0075] As shown in Figure 2, the equipment for preparing expanded tobacco stem particles of the present invention includes raw material analysis equipment, blending equipment, extraction equipment, expansion treatment equipment, storage, moisture regain and feeding balance equipment, granulation equipment, recovery and shaping equipment, cleaning Choose winnowing equipment and flavoring balance equipment.

[0076] First scan 04 Kunming Hongda C4L, 04 Lijiang Yun 87B1K, 05 Sanming Cuibi No. 1 X3F, 04 Jinan Song K326X3F, 05 Hongheyun 87X4F, 03 Liangshan K326C3F, 04 Bijie K326X2L, 03 Qujing Hongda B2K with a near-infrared spectrum analyzer , 05 Kunming K326B3L, 04 Chengdu K326C1L, 03 Hongheyun 85B3K, 04 Luoyang China Tobacco 101B3F, 05 Guizhou Guiyan No. 11 C2L, 05 Qujing K326B2R, 04 Daliyun 87B1K, 03 Chuxiong K326X2L, a total of 16 kinds of different origins and different years , the content of total sugar, reducing sugar, nicotine and total nitrogen in different grades and type...

Embodiment 2

[0096] Repeat Example 1, with the following differences: by batch 2 corresponding blending proportions, the tobacco stem raw materials are mixed and transported to the supercritical CO 2 Extraction is carried out in the extraction tank, and the moisture content of the tobacco stems is determined to be 15.2% after extraction.

[0097] After the tobacco stems are evenly mixed with the microwave solid particle medium, they enter the 50kw microwave expansion cavity, and the set time is 80 seconds.

[0098] After the expanded tobacco stems are cooled to room temperature, they are packed into sacks and stored in a ventilated and cool storage warehouse for 2 months.

[0099] The qualified tobacco stem particles with a particle size of 1-5mm screened out are sent to a 60kw microwave recovery chamber, and the set action time is 64 seconds.

[0100] The added flavor is 0.5% of the weight of the tobacco stem particles, and the composition and dosage of the flavor are shown in Table 4. ...

Embodiment 3

[0105] Repeat embodiment 1, have following difference: by batch 3 corresponding blending ratio batching.

[0106] Ethyl acetate was selected as the extractant, the weight ratio of the tobacco stems to the extractant was 1:8, the extraction temperature was set at 20°C, the extraction time was 168h, and the extraction was performed twice. After the extraction, the moisture content of the tobacco stems was determined to be 16.0%.

[0107] After the tobacco stems are evenly mixed with the microwave solid particle medium, they enter the 50kw microwave expansion cavity, and the set time is 80 seconds.

[0108] After the expanded tobacco stems are cooled to room temperature, they are packed into sacks and placed in a ventilated, shady and cool storage warehouse for storage for 3 months.

[0109] Qualified tobacco stem particles with a particle size of 1-5mm screened out are sent to a 60kw microwave recovery chamber, and the set action time is 64 seconds.

[0110] The added flavor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com