Cut leaf tobacco microwave vacuum drying equipment

A microwave vacuum drying and equipment technology, which is applied in the field of tobacco processing, can solve the problems affecting the uniformity of the moisture of the outlet silk, not considering the drying and dehydration law of the silk, and not considering the technological requirements of the silk, so as to achieve accelerated dehydration rate and puffing. Good effect, maintain the effect of leaf silk aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

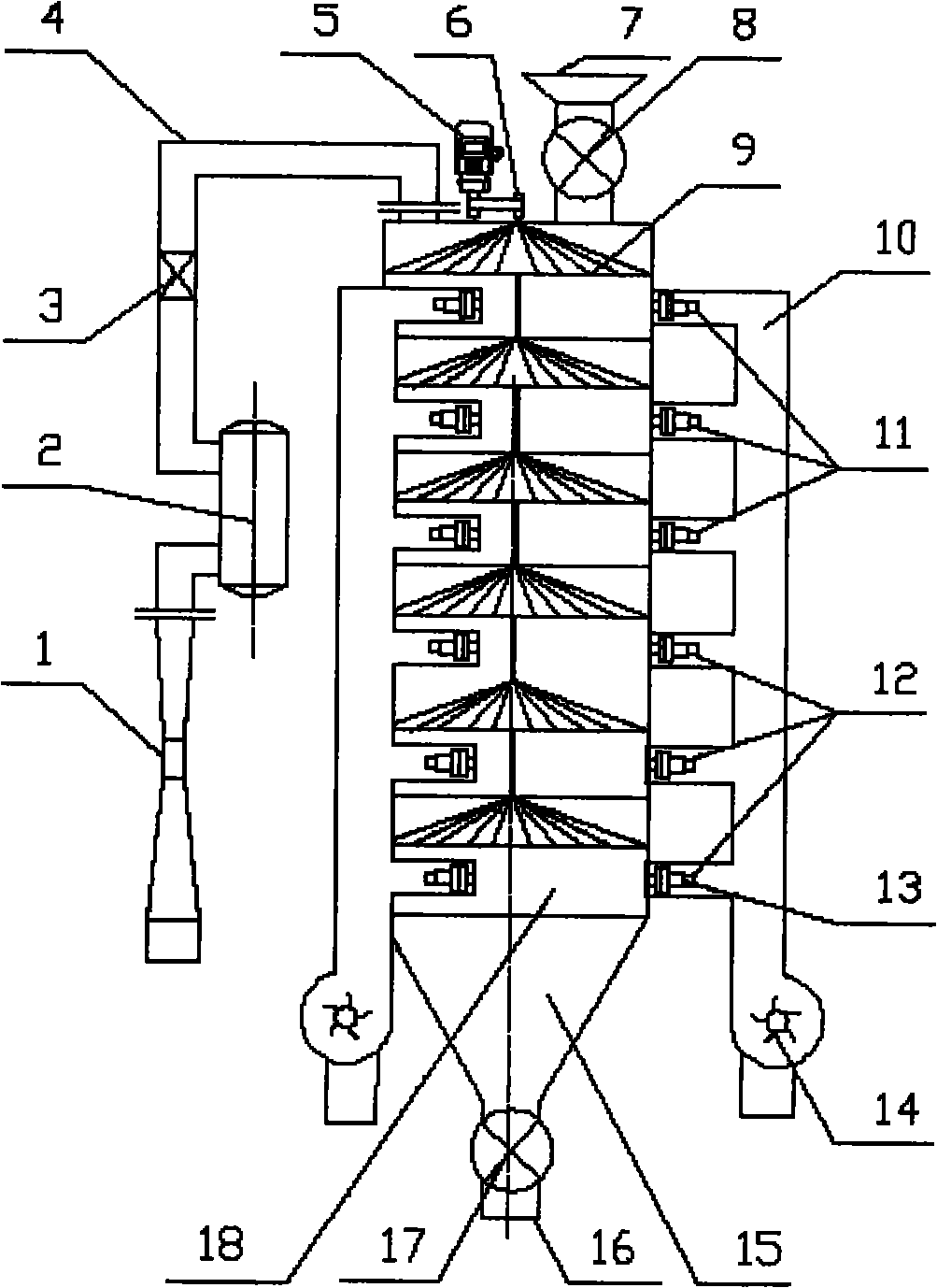

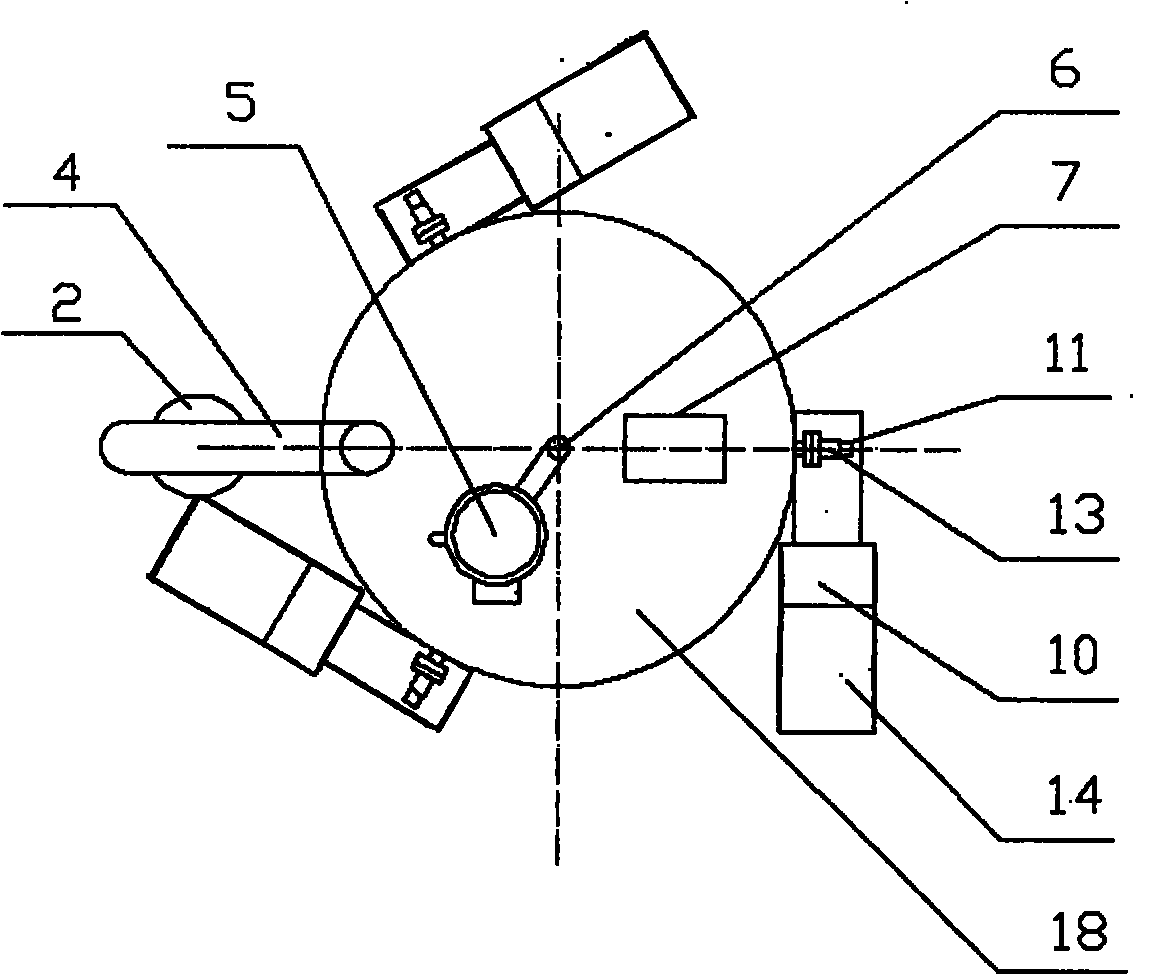

[0025] The present invention will further describe leaf silk microwave vacuum drying equipment below in conjunction with accompanying drawing:

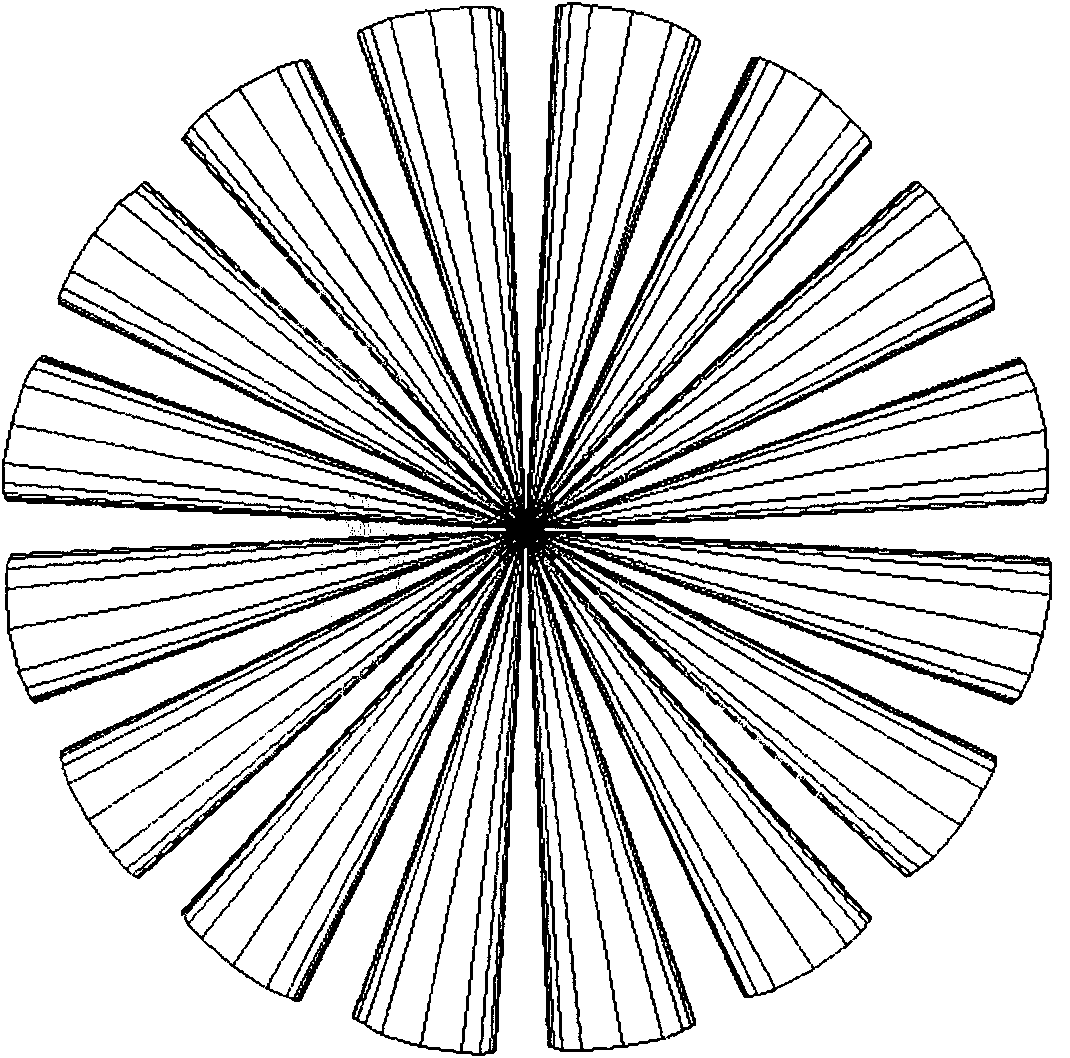

[0026] Such as figure 1 , 2 Shown: the shredded leaf microwave vacuum drying equipment of the present invention comprises a vertical cylindrical drying cavity (18), a vacuum system and a microwave heating system connected with the drying cavity, and the top and bottom of the drying cavity are respectively arranged There is a material inlet (7) and a material outlet (16), and a material dispersion mechanism is arranged in the drying chamber (18). The material dispersion mechanism consists of a rotating shaft (6) arranged on the axis of the drying chamber and a The multi-layer material dispersing disc (9) on the rotating shaft is composed of the rotating shaft (6) driven by the motor (5). The microwave heating system is divided into a continuous microwave heating unit arranged at the upper part of the cavity and a pulsed microwave heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com