Solid state fermentation device

A technology of solid-state fermentation and fermentation box, which is applied in the field of material fermentation device and solid-state fermentation device, can solve the problems of insufficient oxygen supply for materials, low fermentation yield, and inability to achieve continuous fermentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

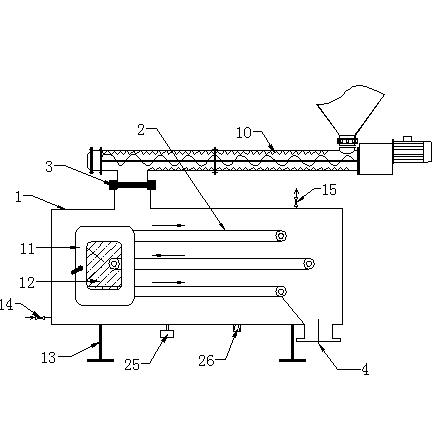

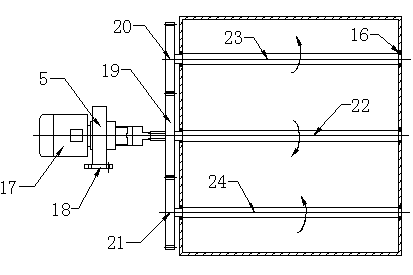

[0012] Such as figure 1 , figure 2 As shown, the solid-state fermentation device of the present invention includes a fermentation box body 1, which is a sealed clean box, and the fermentation box body 1 is supported by a plurality of feet 13; the left side of the fermentation box body 1 There is an air inlet 14 that can lead into sterile air, a feed port 3 and an exhaust port 15 are provided above the fermentation box body 1, and a discharge port 4 is provided below the fermentation box body 1. The fermentation box body 1 The inner fermentation bed 2 has three layers, or more than three layers. The fermentation bed 2 in this embodiment is divided into an upper fermentation bed, a middle fermentation bed, and a lower fermentation bed. . Each layer of fermentation bed 2 includes an annular mesh track and two rotating shafts arranged in parallel. Both ends of the rotating shaft are respectively supported on the fermentation box body 1 by bearings 16, and the ring mesh crawler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com