Patents

Literature

51results about How to "Fixed will not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Culture method for plant seedlings

InactiveCN102939890AEasy to fixFixed will not affectAgriculture gas emission reductionCultivating equipmentsNutritional deficiencyButt joint

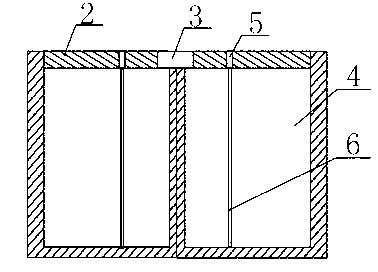

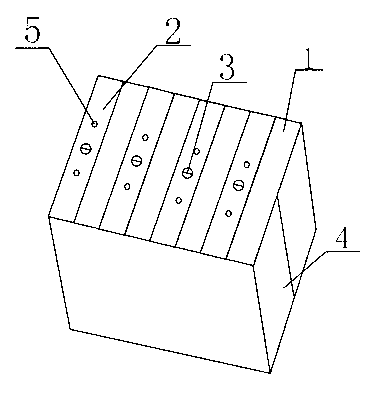

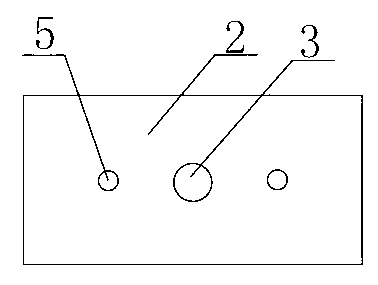

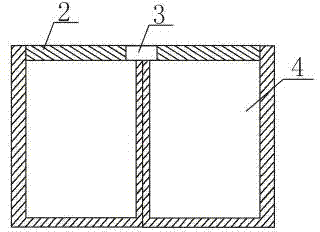

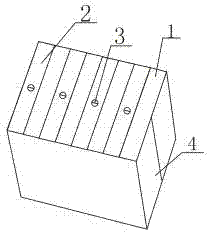

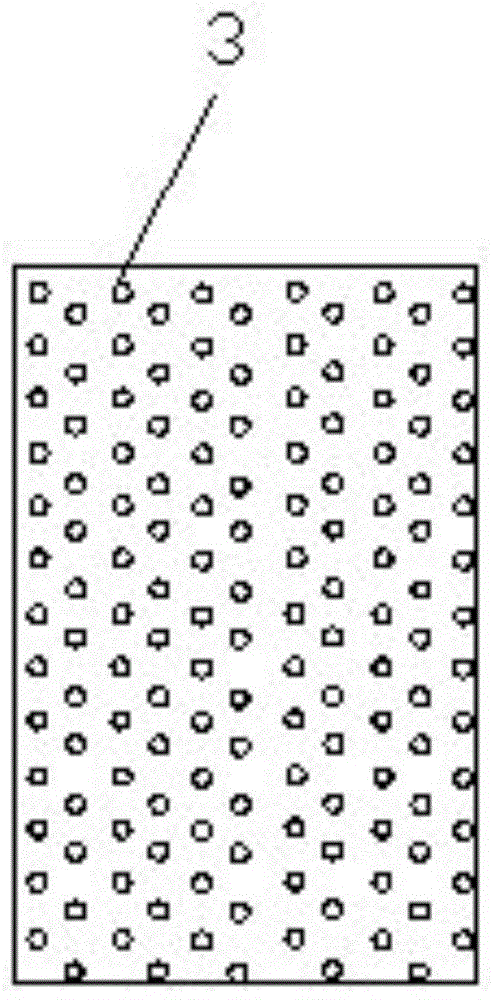

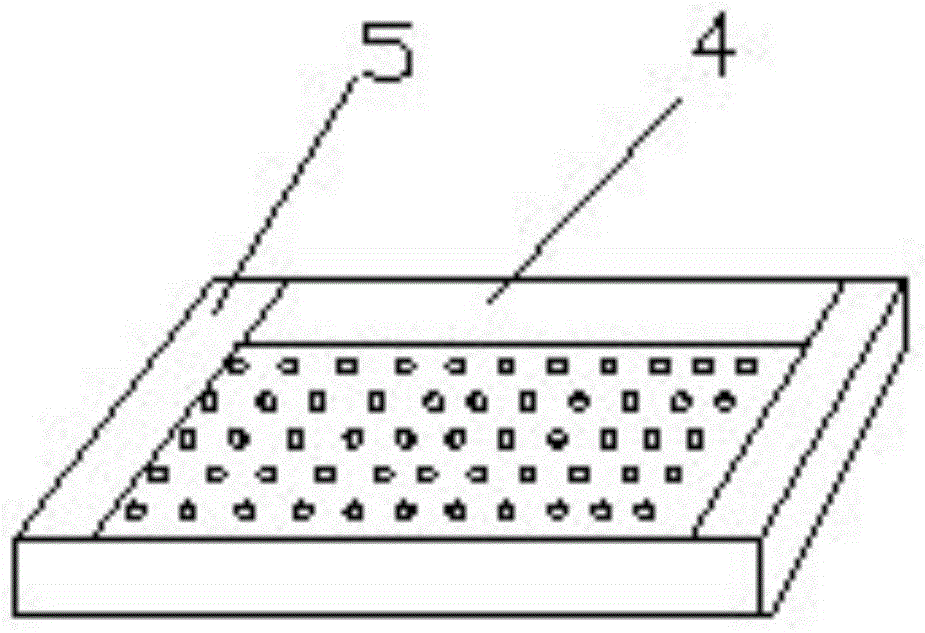

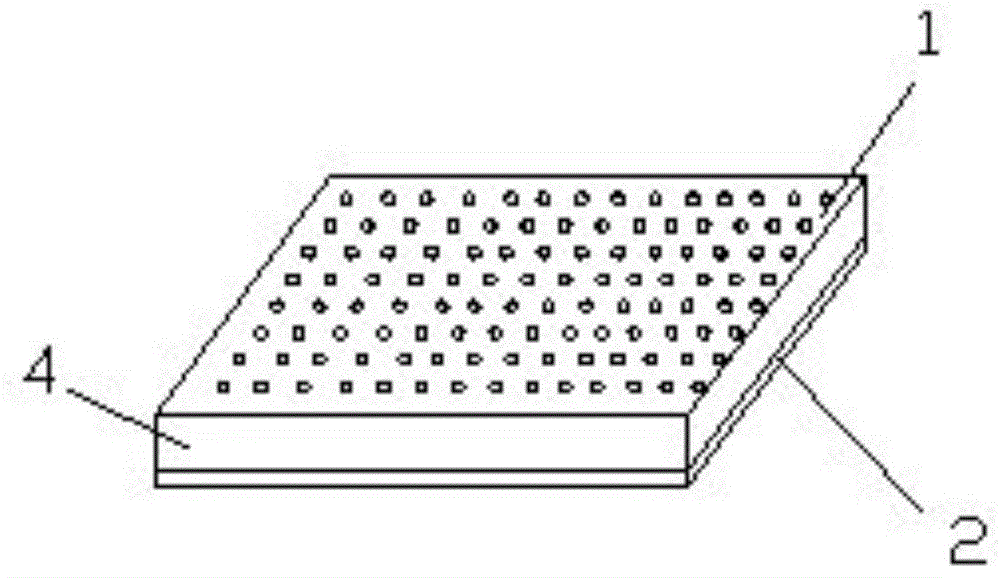

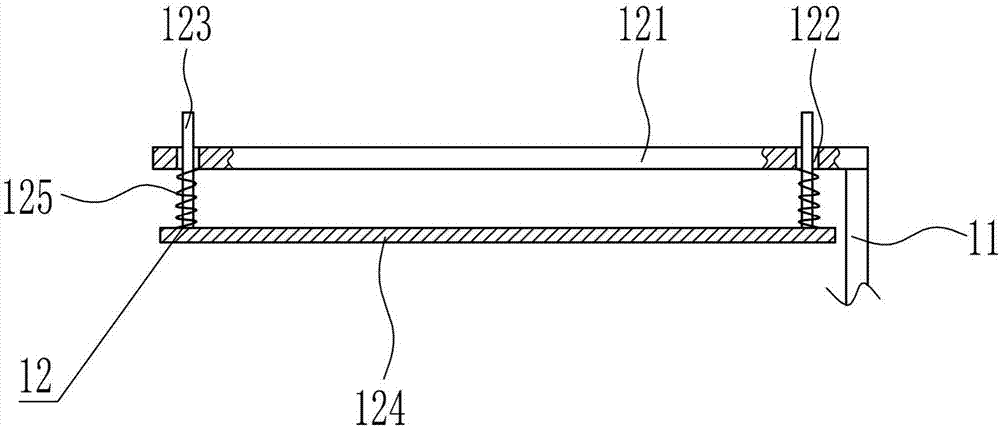

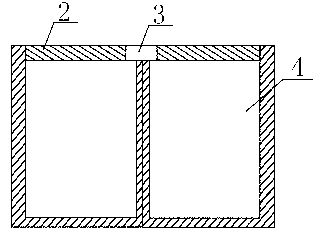

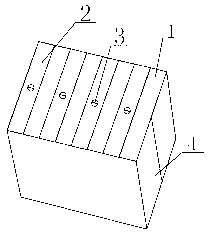

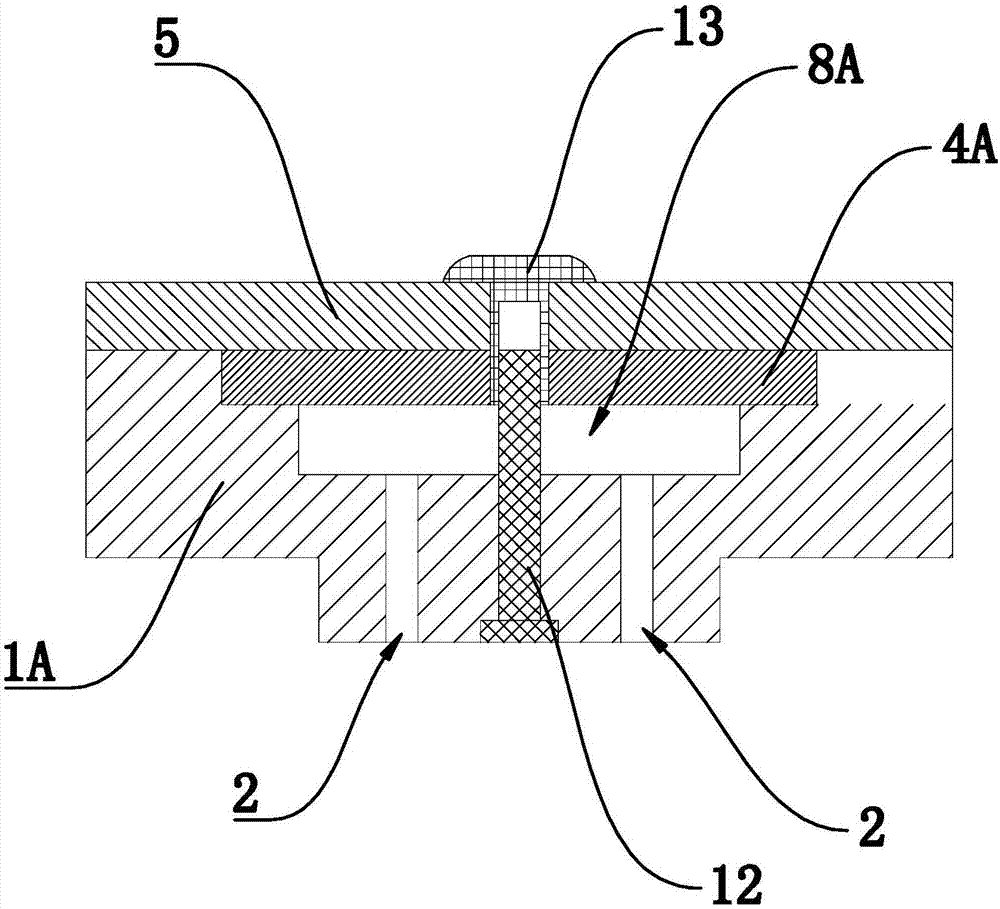

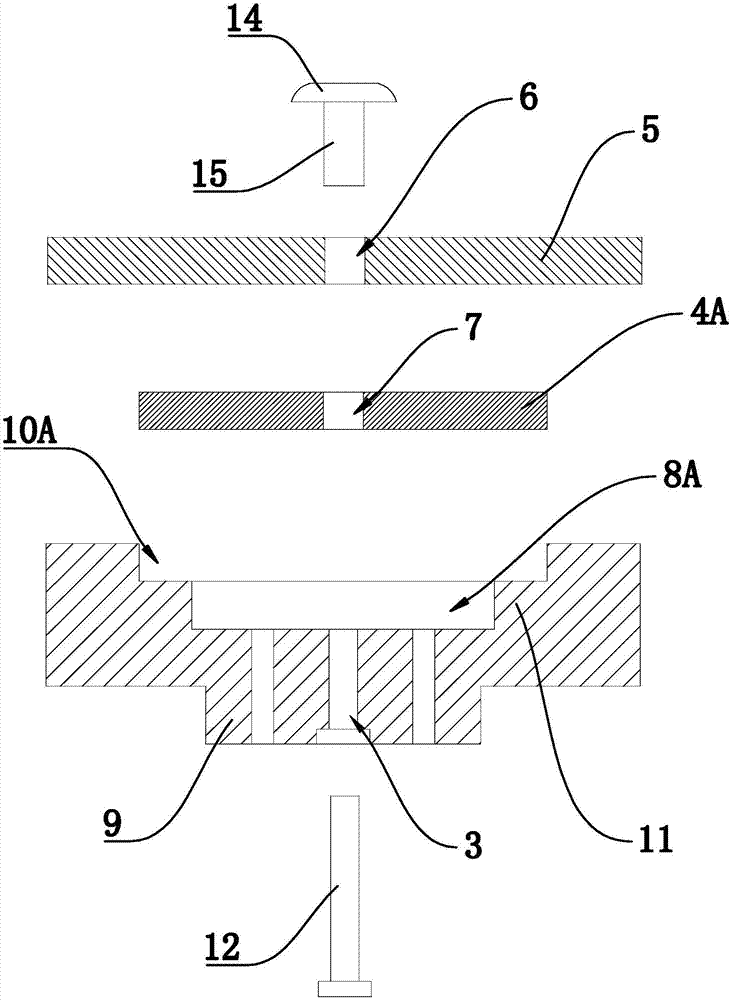

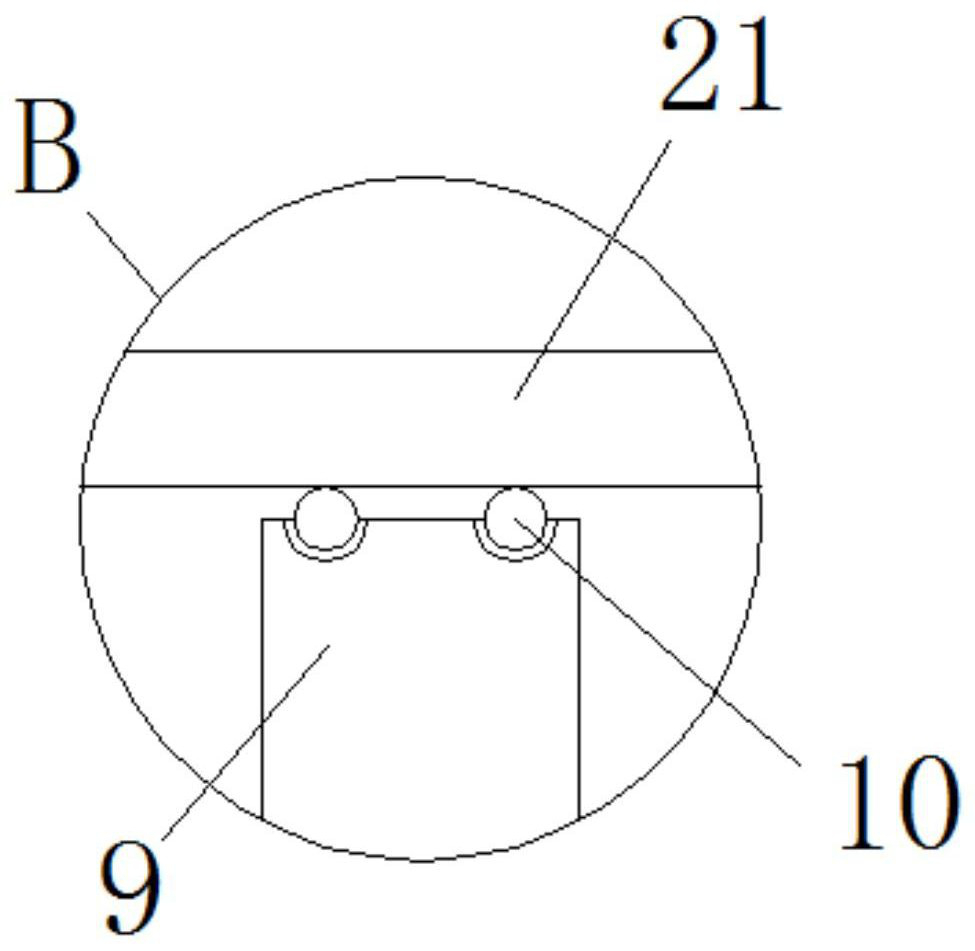

The invention relates to a culture method for plant seedlings. The plant seedlings are cultured by a ventilated root division culture device, the side surfaces of two culture bowls of the device are in butt joint, a cover plate and a culture plate are arranged on the two culture bowls, culture holes are formed in the culture plate, and vent holes are formed in the two sides of the culture holes. The culture method comprises the followings steps: the plant seedlings of 3 days are taken and cultured in a Hoagland's nutrient solution with the concentration of 50 percent for 2 days then in a Hoagland's nutrient solution with the concentration of 100 percent for 12 days, the plant seedlings growing consistently are taken, the stems of the plant seedlings are wrapped by nutrient cotton and fixed in the culture holes of the culture plate, the roots of the plant seedlings are divided into a group A and a group B, the group A is put into the culture bowl containing the Hoagland's nutrient solution, and the group B is put into the culture bowl containing a nutritional deficiency nutrient solution; the pH values of the nutrient solutions are regulated to 6 at 8 o'clock in the morning and 15 o'clock in the afternoon; the nutrient solutions are changed every other three days; and after 4-12 days, the plant seedlings are taken out. The operation is simple, and the personal errors are reduced, so that the research result is more accurate, the culture time is saved, and the working efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

Culture method for rice seedlings

InactiveCN102523977AEasy to fixFixed will not affectAgriculture gas emission reductionCultivating equipmentsSplit rootNutrient solution

The invention discloses a culture method for rice seedlings. The rice seedlings are cultured by using a split root culture device; the side faces of two culture bowls of the device are butted; a cover plate and a cultivation plate are arranged above the culture bowls; the cultivation plate is provided with culture holes; the culture method comprises the following steps of: culturing 3-day rice seedlings in kimura nutrient solution with concentration of 50 percent for 2 days; replacing the kimura nutrient solution with the kimura nutrient solution with concentration of 100 percent for 12 days;taking consistently grown seedlings and wrapping stem base parts by using culture cotton; fixing in the culture holes of the cultivation plate; grouping rice seedling roots into equal groups A and B,wherein the group A is placed in the culture bowl containing the kimura nutrient solution, and the group B is placed in the culture bowl containing the culture solution of element deficient; adjusting the pH of the culture solution to 6.0 from 8 a.m. to 15 p.m. each day; and replacing the culture solution after culturing for 3 days, and after culturing to 4-12 days, taking the stems and leaves ofthe rice seedlings, the group A of cultured rice seedling roots and the group B of cultured rice seedling roots. The culture method is easy to operate; the personal error is avoided; the culture timeis saved; and the working efficiency is increased.

Owner:HENAN UNIV OF SCI & TECH

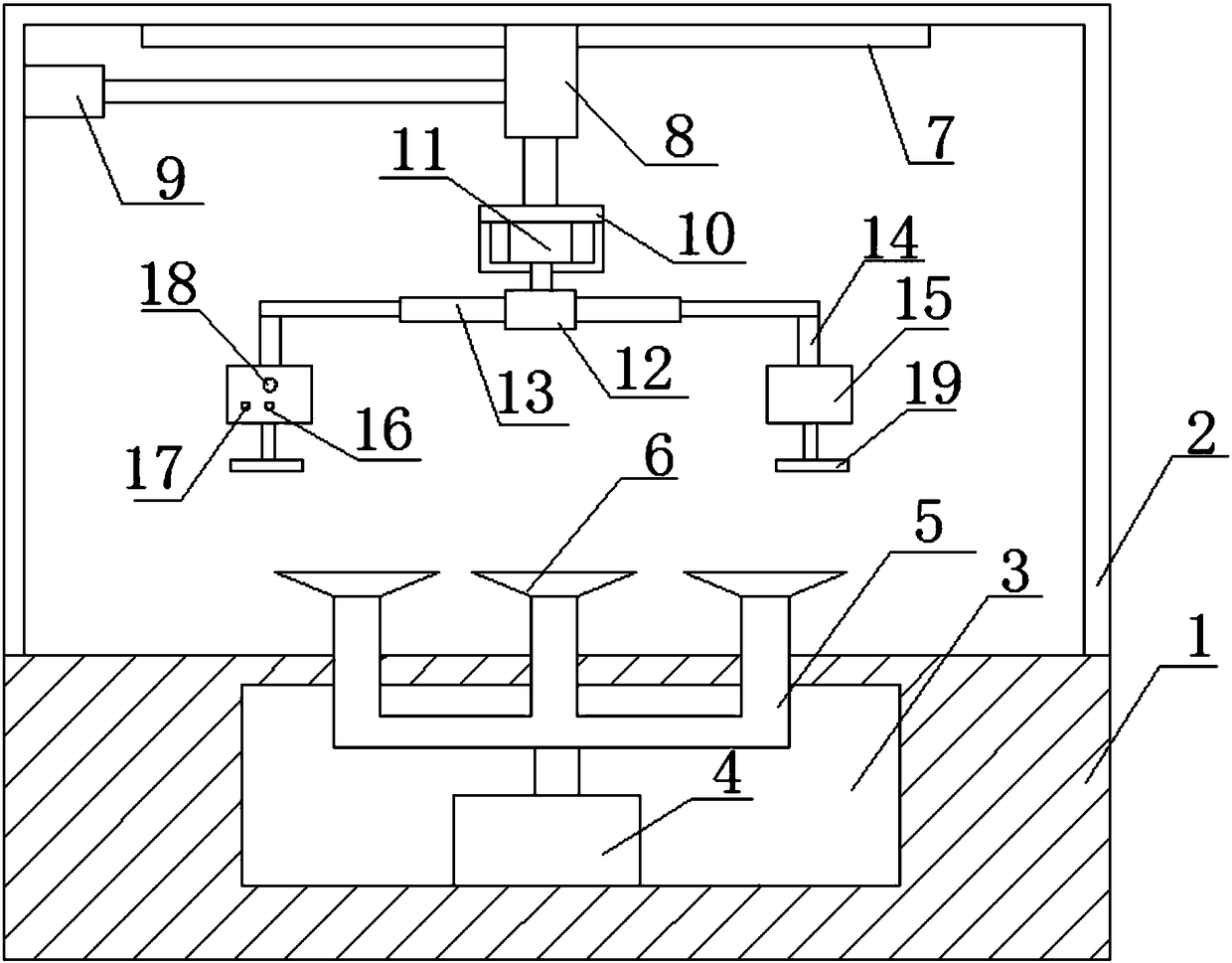

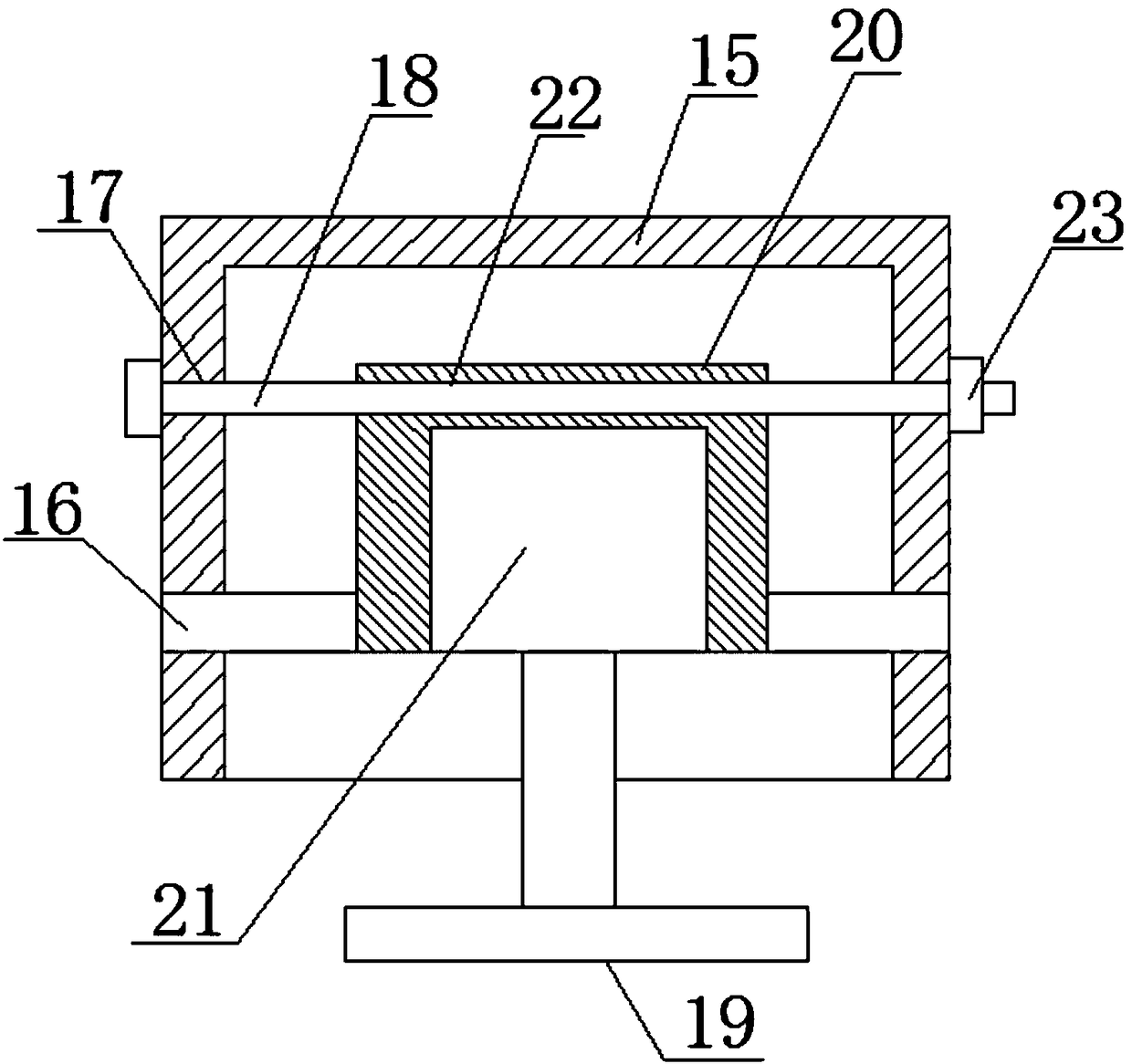

Special-shaped glass bevel edge polishing process processing system

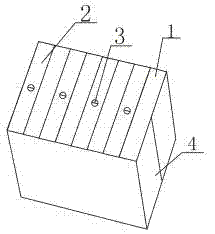

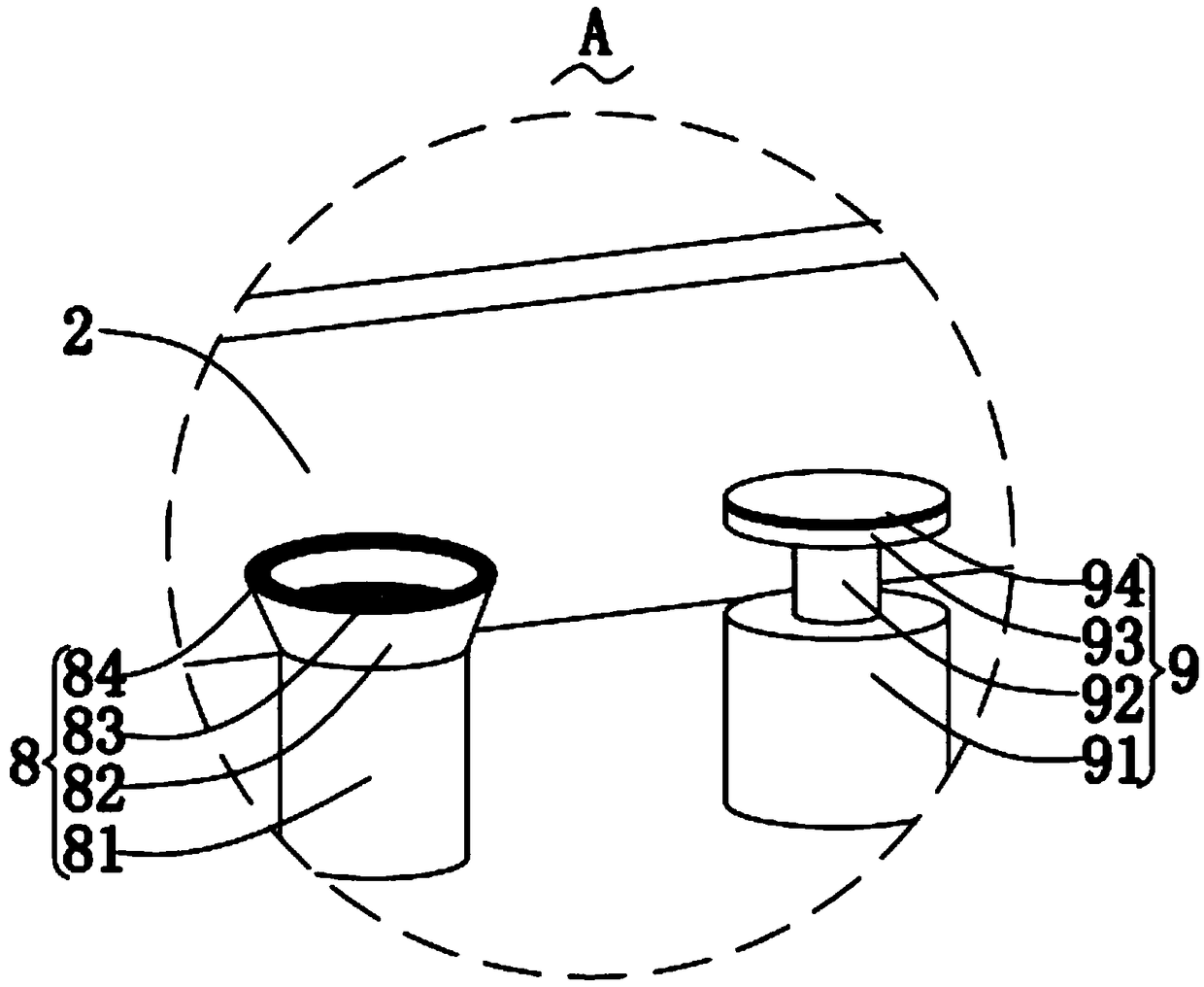

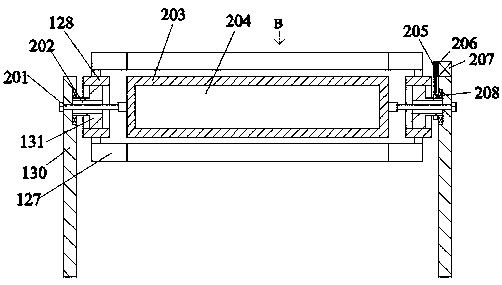

ActiveCN109176220AAvoid breakingIncrease contact areaEdge grinding machinesGrinding carriagesRubber ringEngineering

The invention relates to the technical field of glass polishing, in particular to a special-shaped glass bevel edge polishing process processing system. The special-shaped glass bevel edge polishing process processing system comprises a support frame, a fixing sleeve, an air suction structure, a first driving structure, a second driving structure, a third driving structure, a polishing structure,an adsorption structure and a blanking structure. A plurality of air cylinders are fixed inside the fixing sleeve. The ends, away from the fixing sleeve, of the air cylinders are provided with circular fixing discs. Special-shaped glass on the adsorption structure can be pushed out through the pushing effect of the air cylinders. The contact area of the circular fixing discs and the glass can be increased, so that the glass is not broken after being pushed in the pushing process; and because sponge pads are connected to the top ends of the fixing discs in a gluing mode and can play a bufferingrole during pushing, the glass is prevented from being broken when being pushed. The top end of the fixing sleeve is provided with a funnel-shaped suction disk, and the funnel-shaped suction disk canfirmly adsorb the glass without influencing bevel edge polishing of the glass. A rubber ring at the top end of the suction disk can increase the sealing property between the suction disk and the glass. A filter screen is arranged inside the suction disk and can prevent sundries from being sucked into a vacuum pump.

Owner:JIANGSU DEFULAI AUTOMOTIVE PARTS

Sound absorption wall

The invention discloses a sound absorption wall, which comprises an inner wall, alkali-free glass sound absorption cotton, metal acoustical boards and keels, wherein embedded elements are arranged in the inner wall; the keels are welded on the embedded elements; the metal acoustical boards are fixed on the keels through screw bolts and screw nuts; and a position between the inner wall and the metal acoustical boards is filled with the alkali-free glass sound absorption cotton. The metal acoustical board perforation rate of the sound absorption wall can reach 40 percent or above. Compared with the prior art, the sound absorption wall has the advantages that the sound absorption efficiency is greatly improved; the structural stability is very good; deformation is avoided; the service life is long; the metal sound absorption wall achieves a good fireproof effect, is nonflammable and has high sound absorption efficiency; the installing and fixing mode of the metal acoustical boards is simple; the single-piece fixation of the metal acoustical boards is realized; and the fixation of other metal acoustical boards cannot be influenced by the mounting or the dismounting of any one metal acoustical board.

Owner:STATE GRID CORP OF CHINA +1

Efficient circular board grinding device

InactiveCN108081052AReduce difficultyEasy to polishEdge grinding machinesGrinding carriagesEngineeringWood panel

The invention discloses an efficient circular board grinding device comprising a worktable, a slide rail is arranged at the upper end of the interior of a protection cover, a first telescopic device is arranged on the slide rail, a motor frame is arranged at the lower end of the first telescopic device, a first motor is arranged on the motor frame, a rotating seat is arranged at the output end ofthe first motor, and third telescopic devices are arranged symmetrically on the left and right of the rotating seat; connecting rods are arranged on the lower sides of the outer ends of the third telescopic devices, the lower ends of the connecting rods are provided with U-shaped frames, the U-shaped frames are internally provided with installation seats, the lower sides of the installation seatsare internally provided with second motors in an embedded mode, and polishing plates are arranged at the output ends of the second motors; and the lower ends of the front and rear sides of the installation seats are connected with the U-shaped frames through rotating shafts, the upper ends of the installation seats are provided with fixed through holes, each U-shaped frame is provided with two limiting holes, the limiting holes are provided with fixing bolts, and the installation seats are connected with the U-shaped frames through the cooperation of the fixing bolts and the fixed through holes. The efficient circular board grinding device is simple in structure, convenient to use, and high in grinding efficiency, and the work difficulty is reduced.

Owner:宁波斯凯勒智能科技有限公司

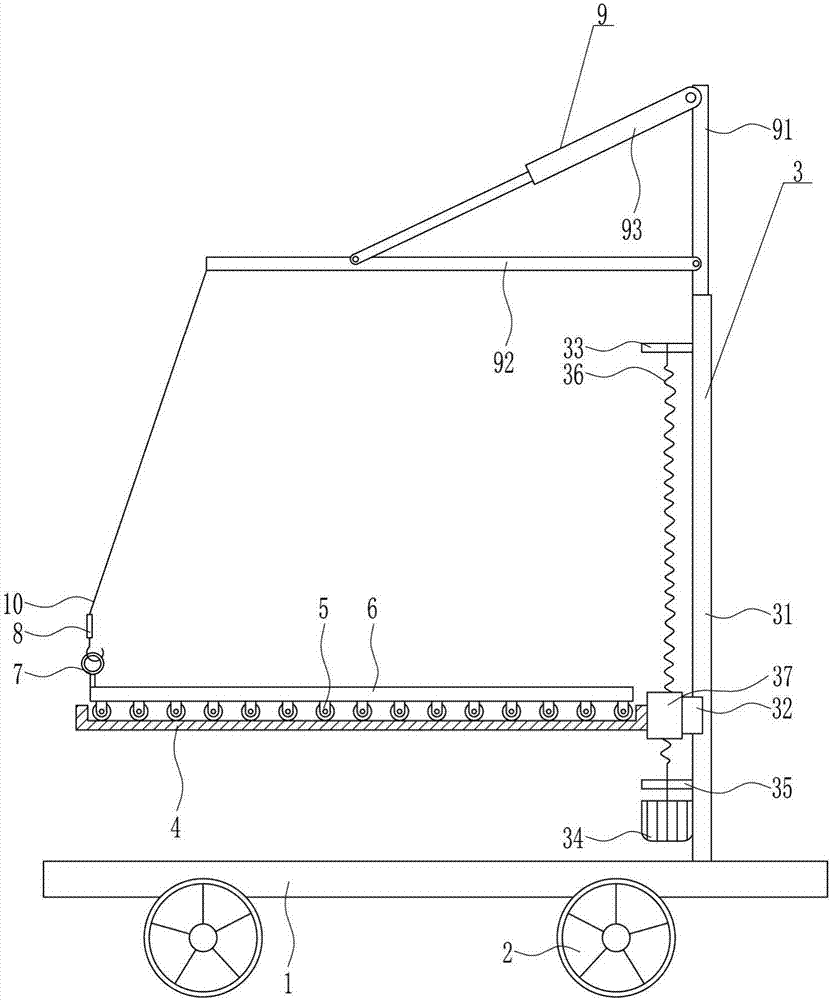

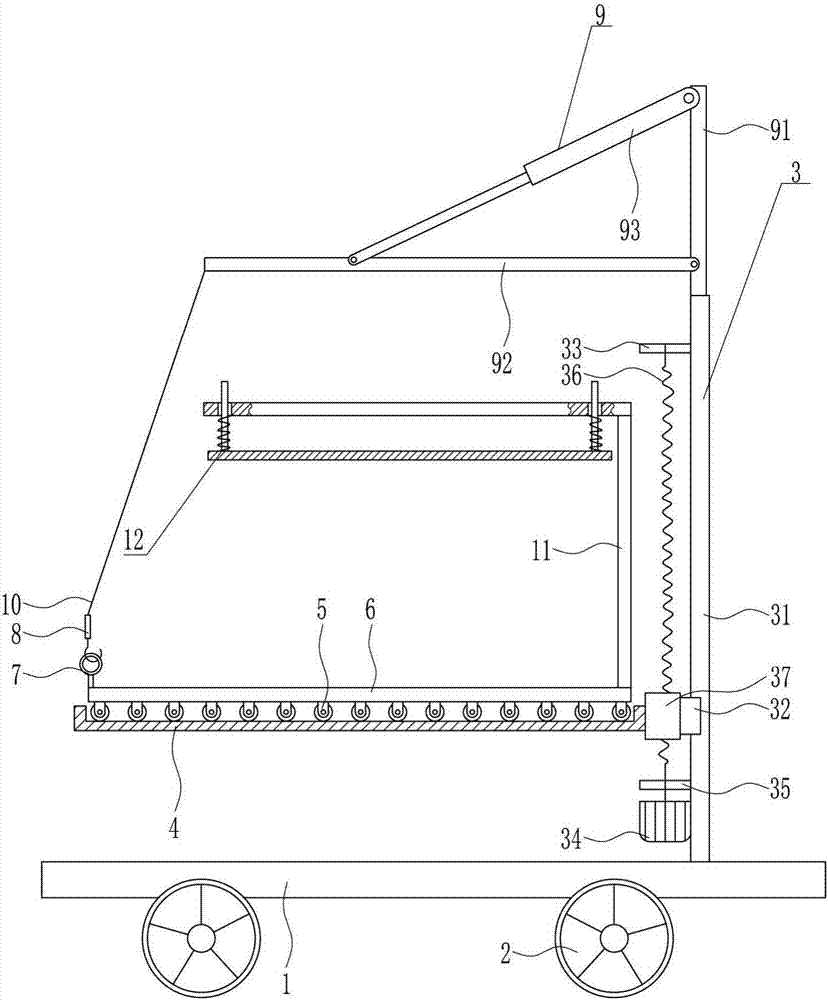

Cultural media book special truck-loading equipment

InactiveCN107128706APrevent fallingImprove work efficiencyLoading/unloadingHand carts with multiple axesEngineeringBilateral symmetry

The invention belongs to the technical field of cultural media and particularly relates to cultural medial book special truck-loading equipment so as to achieve the technical effects that manpower and time can be saved, books are not likely to be damaged, and economic losses can be reduced. In order to achieve the technical effects, the cultural medial book special truck-loading equipment provided by the invention comprises a bottom plate, vehicle wheels, a lifting mechanism, U-shaped plates, wheels, a carrying plate, a hanging ring and the like. The vehicle wheels are rotatably mounted at the bottom of the bottom plate in bilateral symmetry. The lifting mechanism is arranged on the right side of the top of the bottom plate. The U-shaped plates are connected to a lifting component of the lifting mechanism. The U-shaped plates are arranged horizontally. The carrying plate is horizontally arranged over the U-shaped plates. The wheels are rotatably mounted at the bottom of the carrying plate at equal intervals. The cultural medial book special truck-loading equipment can prevent books from falling in the truck-loading process of the books so as to protect the books against damage, and truck-loading is convenient.

Owner:浙江思远电子商务有限公司

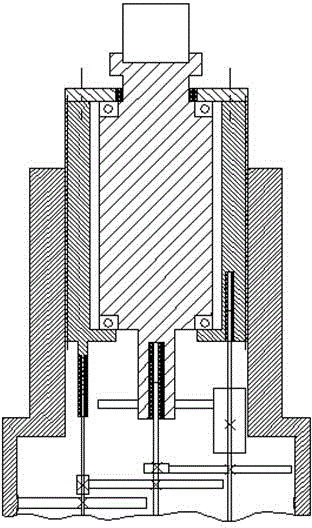

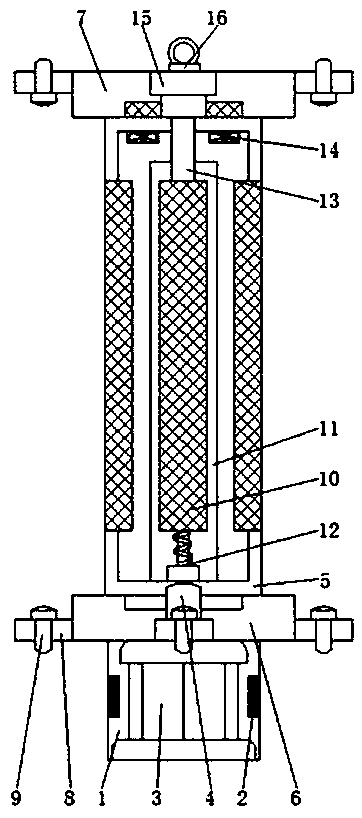

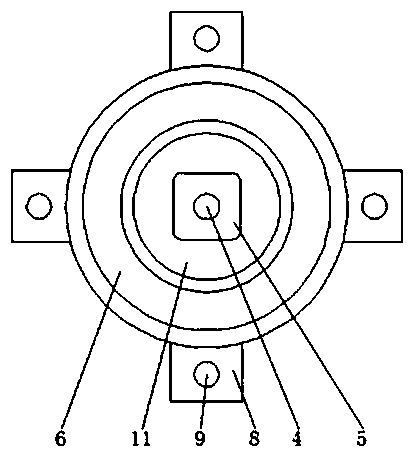

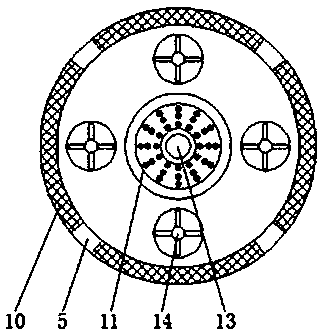

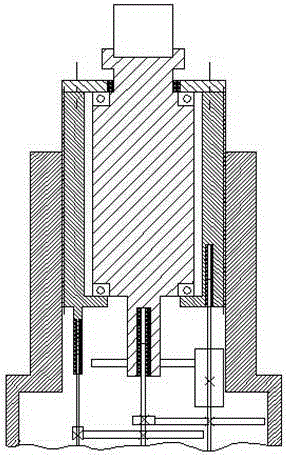

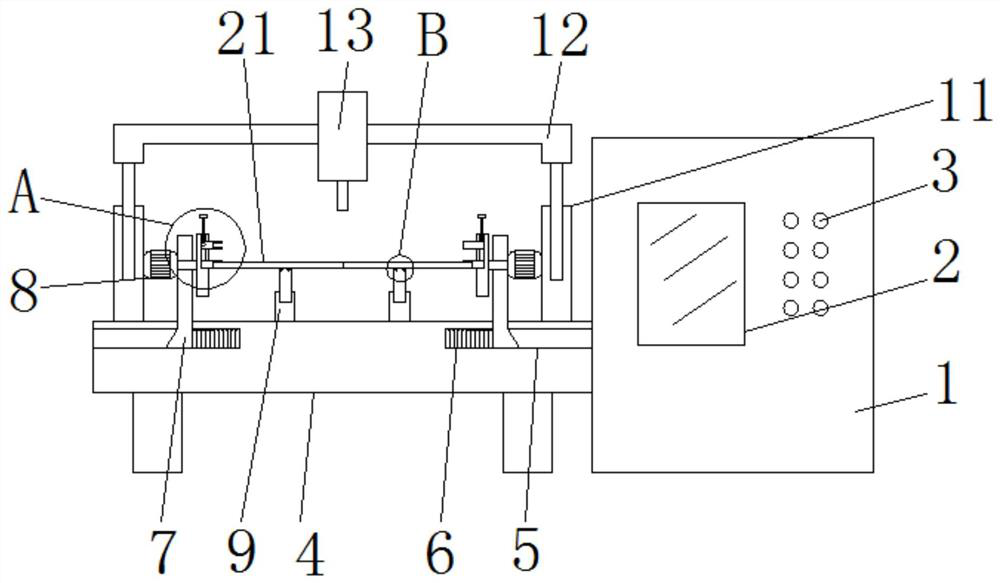

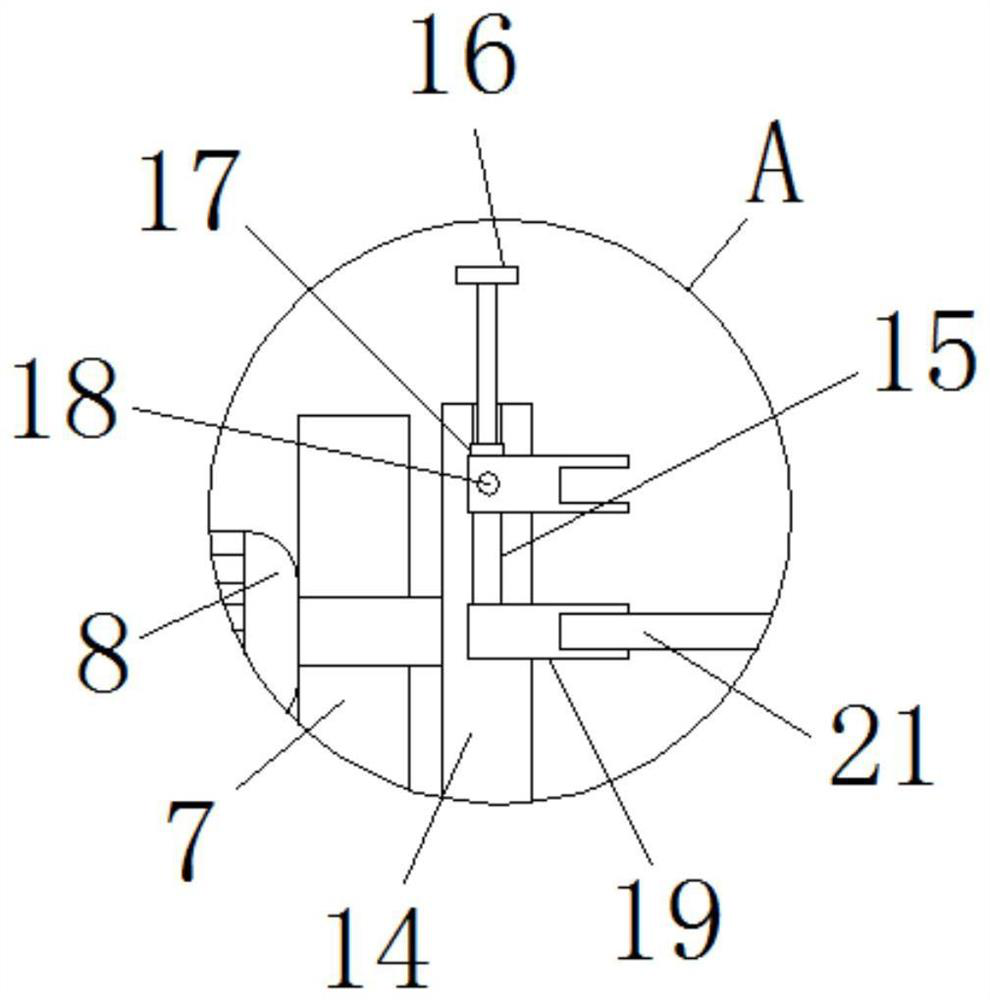

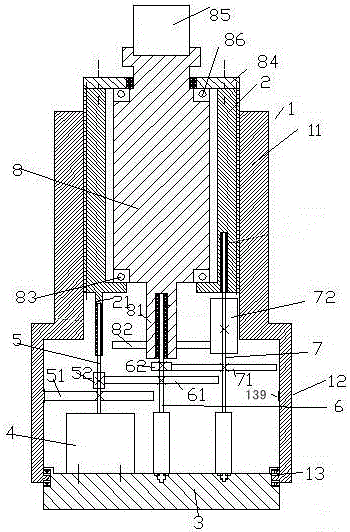

Four-axis driving-type helical gear processing mechanism

InactiveCN104400139AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusMotor driveEngineering

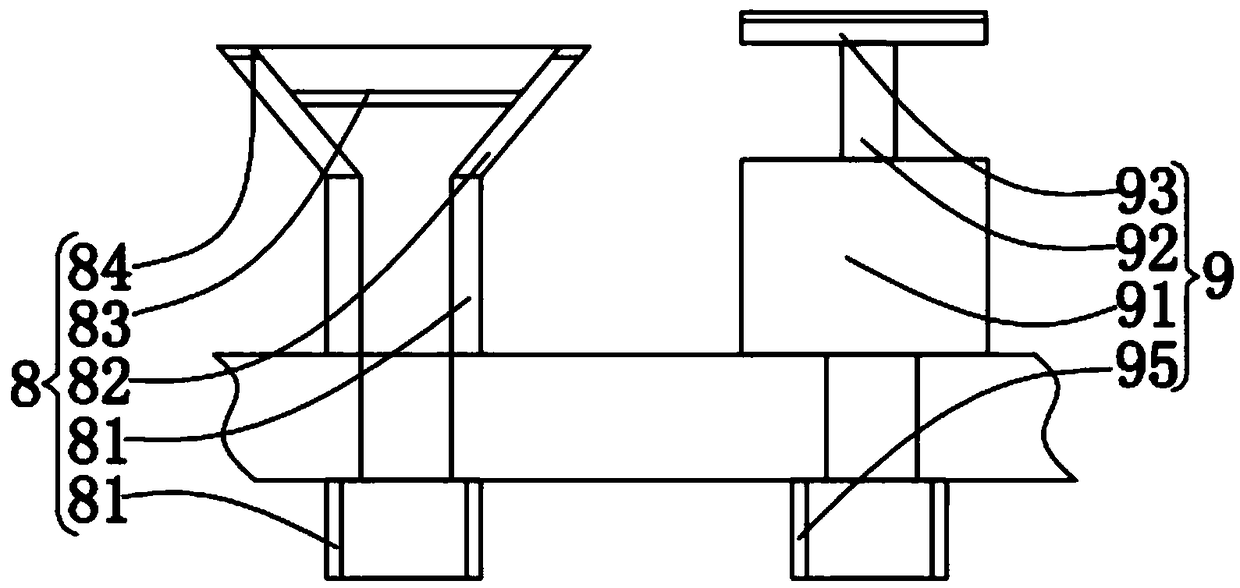

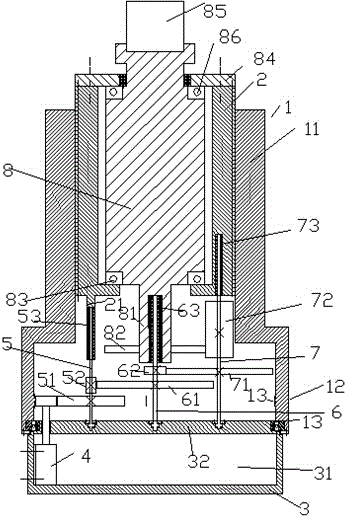

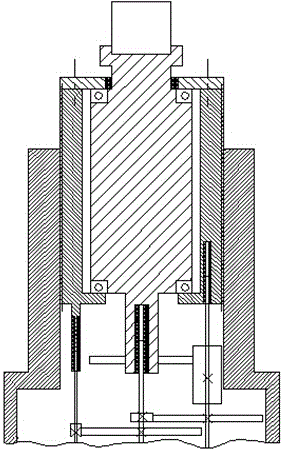

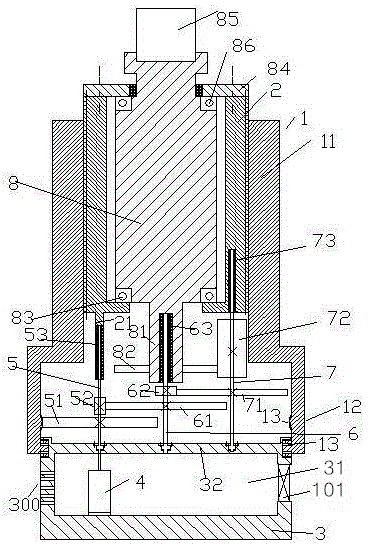

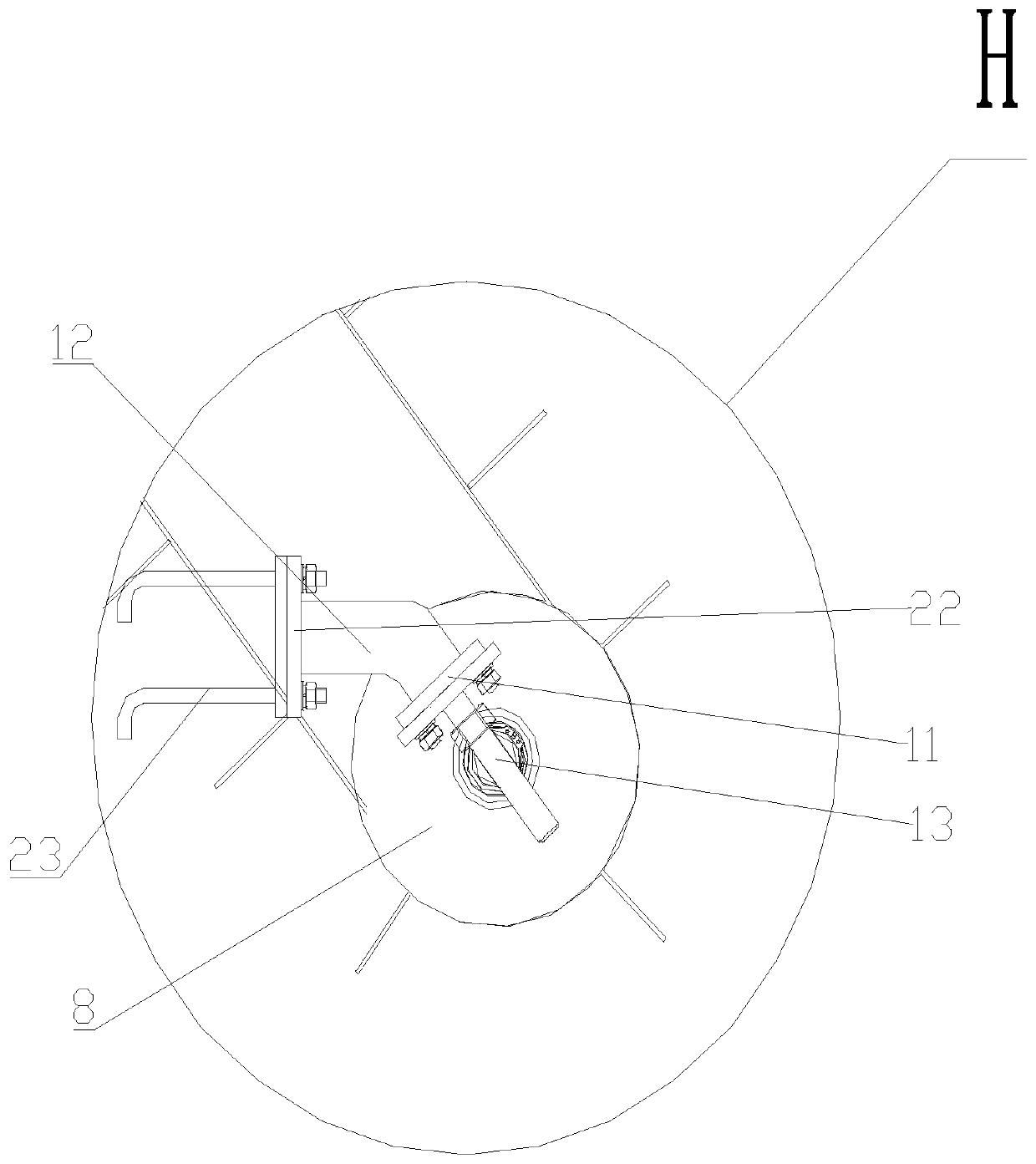

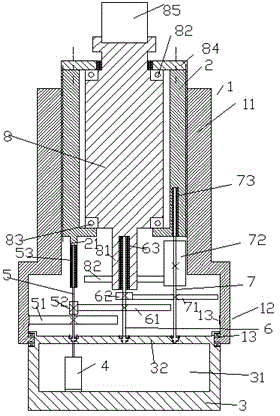

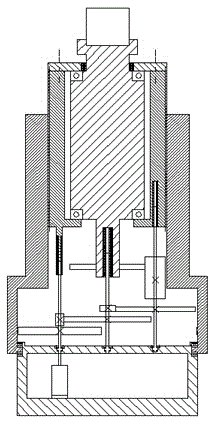

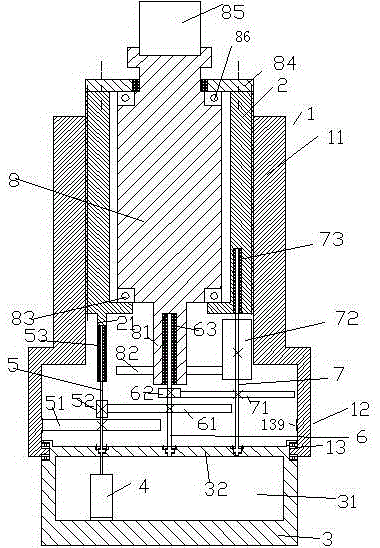

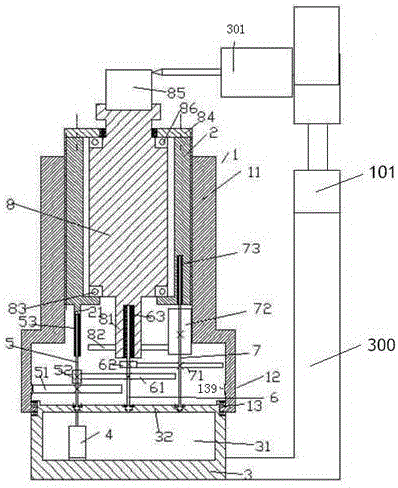

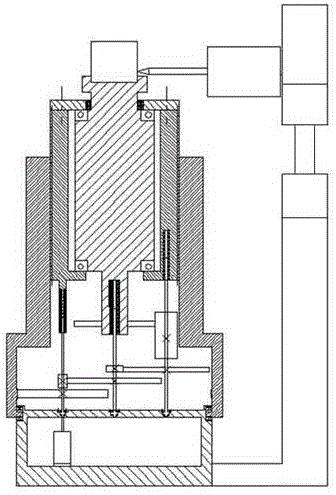

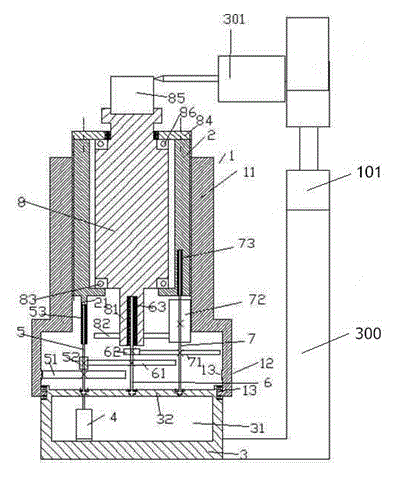

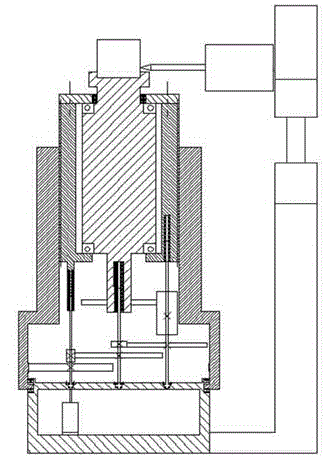

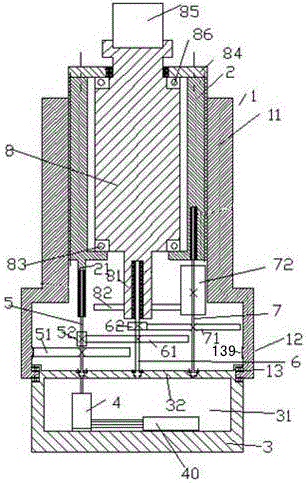

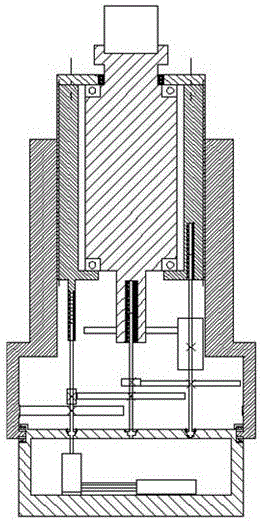

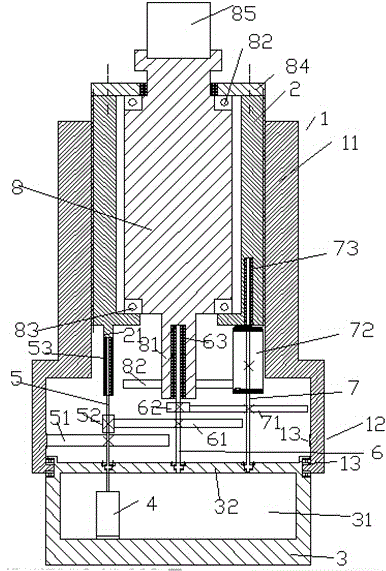

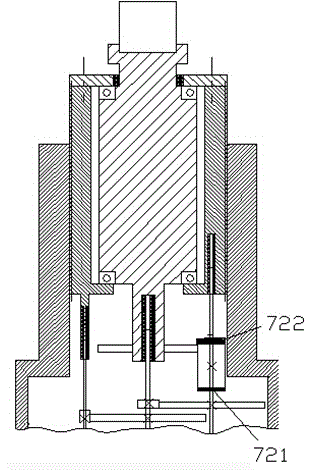

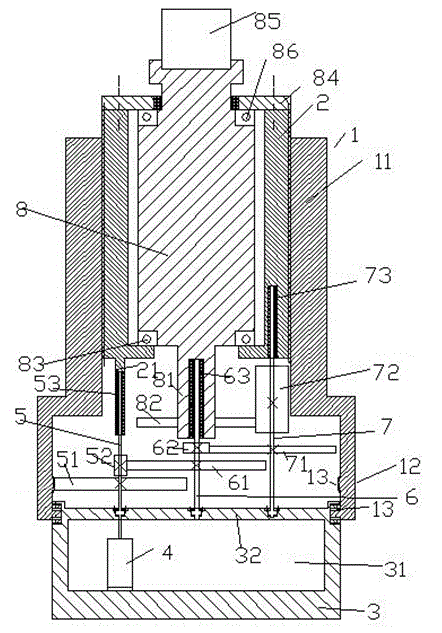

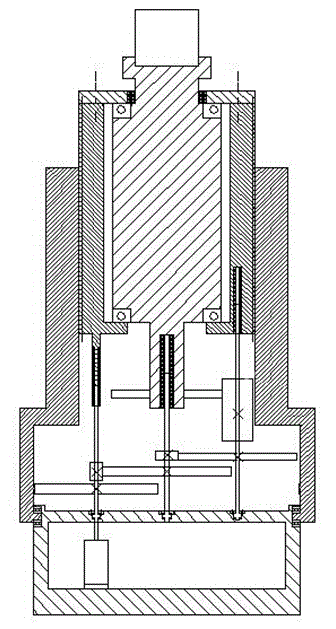

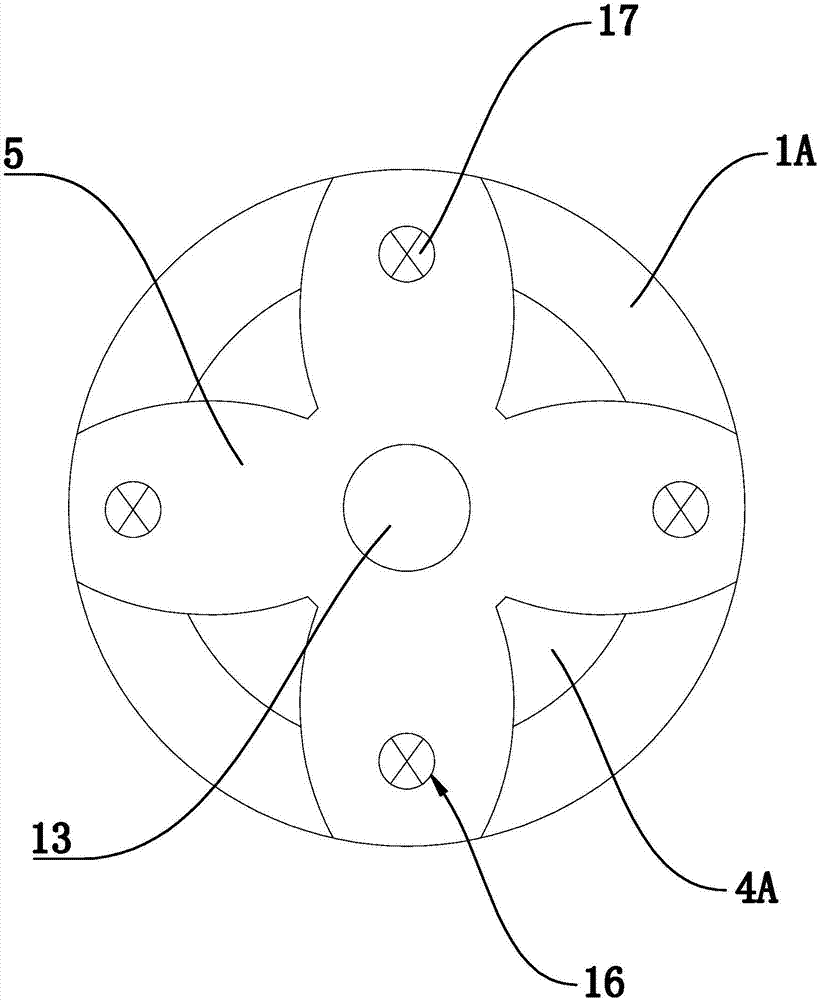

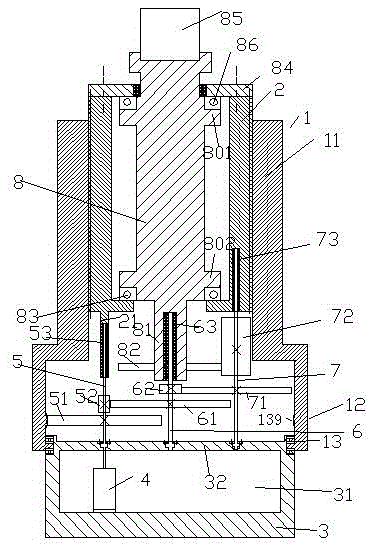

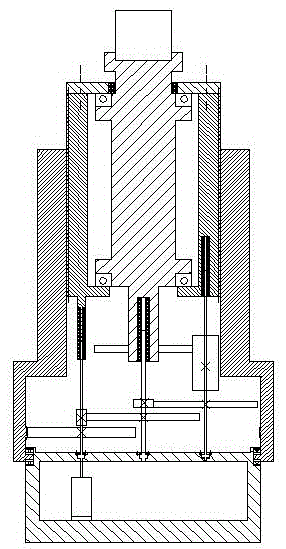

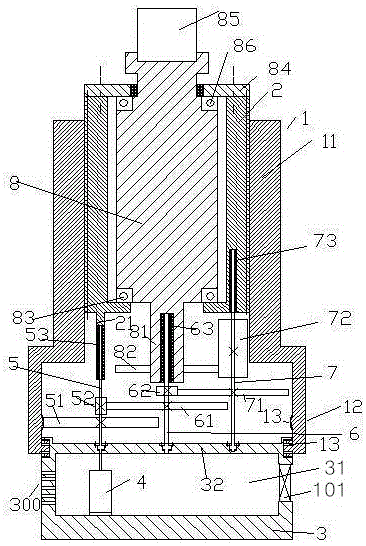

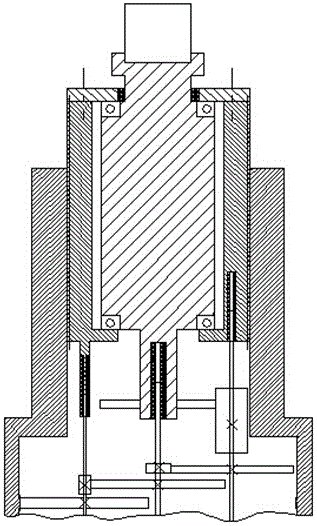

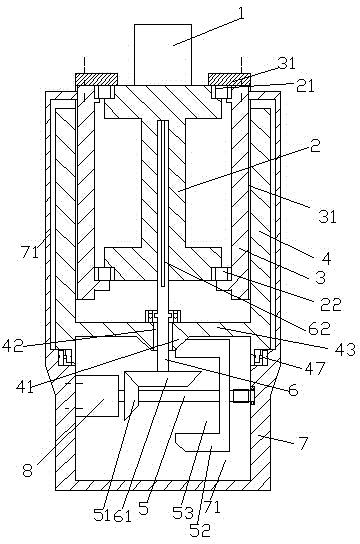

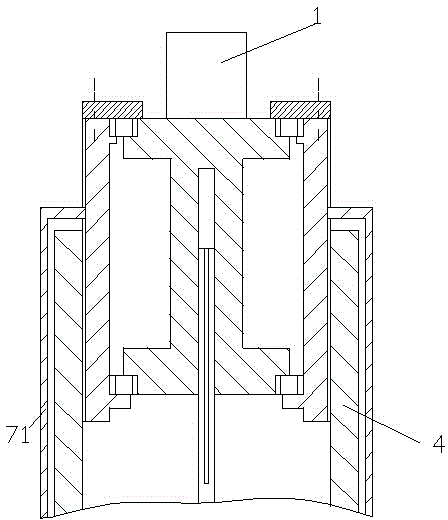

The invention provides a four-axis driving-type helical gear processing mechanism which is used for processing a blank (85). The four-axis driving-type helical gear processing mechanism comprises a base (3), a rotary internal thread piece (1), an external thread piece (2) and a cylindrical workpiece carrying piece (8), wherein the rotary internal thread piece (1) comprises an upper cylinder part (11) and a lower cavity part (12); the lower cavity part (12) is connected with the base (3) by virtue of a bearing device (13) in a circumferential rotation and axial fixation manner; the external thread piece (2) is cylindrical, and the outer periphery surface of the external thread piece (2) is provided with external threads jointed with internal threads in the upper cylinder part (11); the base (3) is internally provided with a cavity (31); the cavity (31) is provided with a top wall (32); the cavity (31) is internally provided with a driving motor (4); the driving motor (4) is connected with the lower end of a motor driving shaft.

Owner:SHENYUE FUJIAN CASTING

Spiral gear machining mechanism capable of quickly radiating heat

InactiveCN104400136AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringDrive motor

The invention relates to a spiral gear machining mechanism capable of quickly radiating heat, which is used for machining a blank (85). The spiral gear machining mechanism capable of quickly radiating heat comprises a base (3), a rotatable internal threaded piece (1), an external threaded piece (2) and a cylindrical workpiece bearing piece (8), wherein the rotatable internal threaded piece (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) is connected with the base (3) through a bearing device 13) in a circumferentially rotatable and axial fixed manner, the external threaded piece (2) is cylindrical, external threads are arranged on the external circumferential surface of the external threaded piece (2) and are jointed with internal threads in the upper cylindrical portion (11), and a cavity (31) is formed in the base (3), the cavity (31) has a top wall (32) and a driving motor (4) is installed in the cavity (31).

Owner:吕英芬

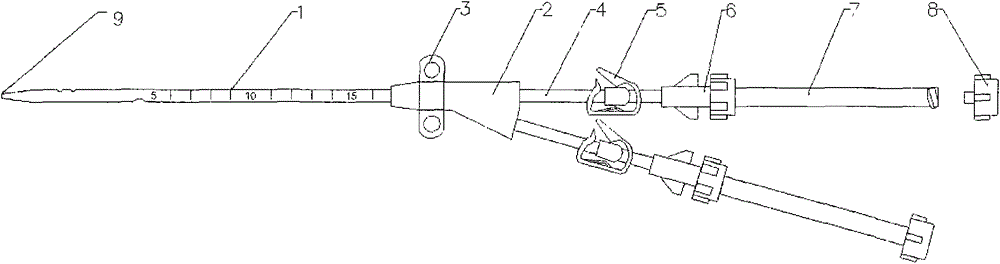

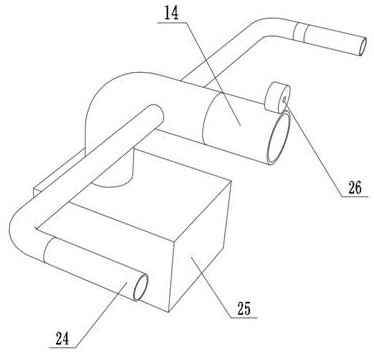

Hemodialysis catheter

A hemodialysis catheter comprises a catheter body, a connection seat, a fixing clamp, two extension pipes, catheter clamps, extension pipe connectors, lengthened fixing pipes, heparin caps and a tip end. The hemodialysis catheter is characterized in that the lower end of the catheter body is the tip end, the upper end of the catheter body is connected with a single hole formed in the lower end of the connection seat, and two holes formed in the upper end of the connection seat are connected with the two extension pipes respectively; the catheter clamps are arranged on the extension pipes, the extension pipe connectors are arranged at the other ends of the extension pipes, and the extension pipes are connected with the lengthened fixing pipes through the extension pipe connectors; the heparin caps cover the other ends of the lengthened fixing pipes. The hemodialysis catheter has the advantages that operation is convenient, firmness is good, safety and reliability are achieved, the lengthened fixing pipes externally connected with a dialysis pipeline can be frequently changed, fixing of the hemodialysis catheter can not be affected, the possibility of infection of an insertion opening can also be lowered, the condition that the extension pipes are damaged in the dialysis process and need to be replaced is avoided, and the pain of a patient is relieved.

Owner:SHANDONG KANGLI MEDICAL EQUIP TECH

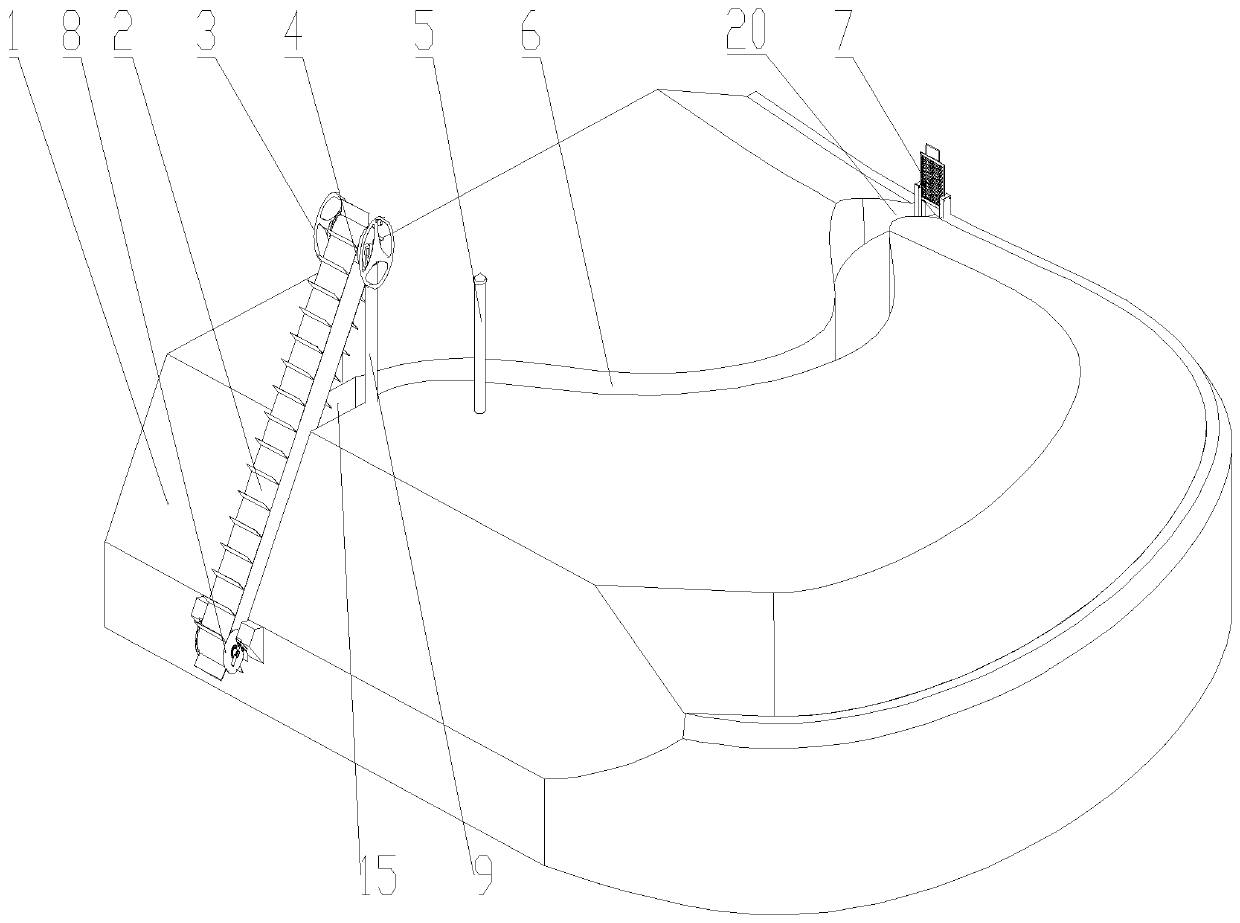

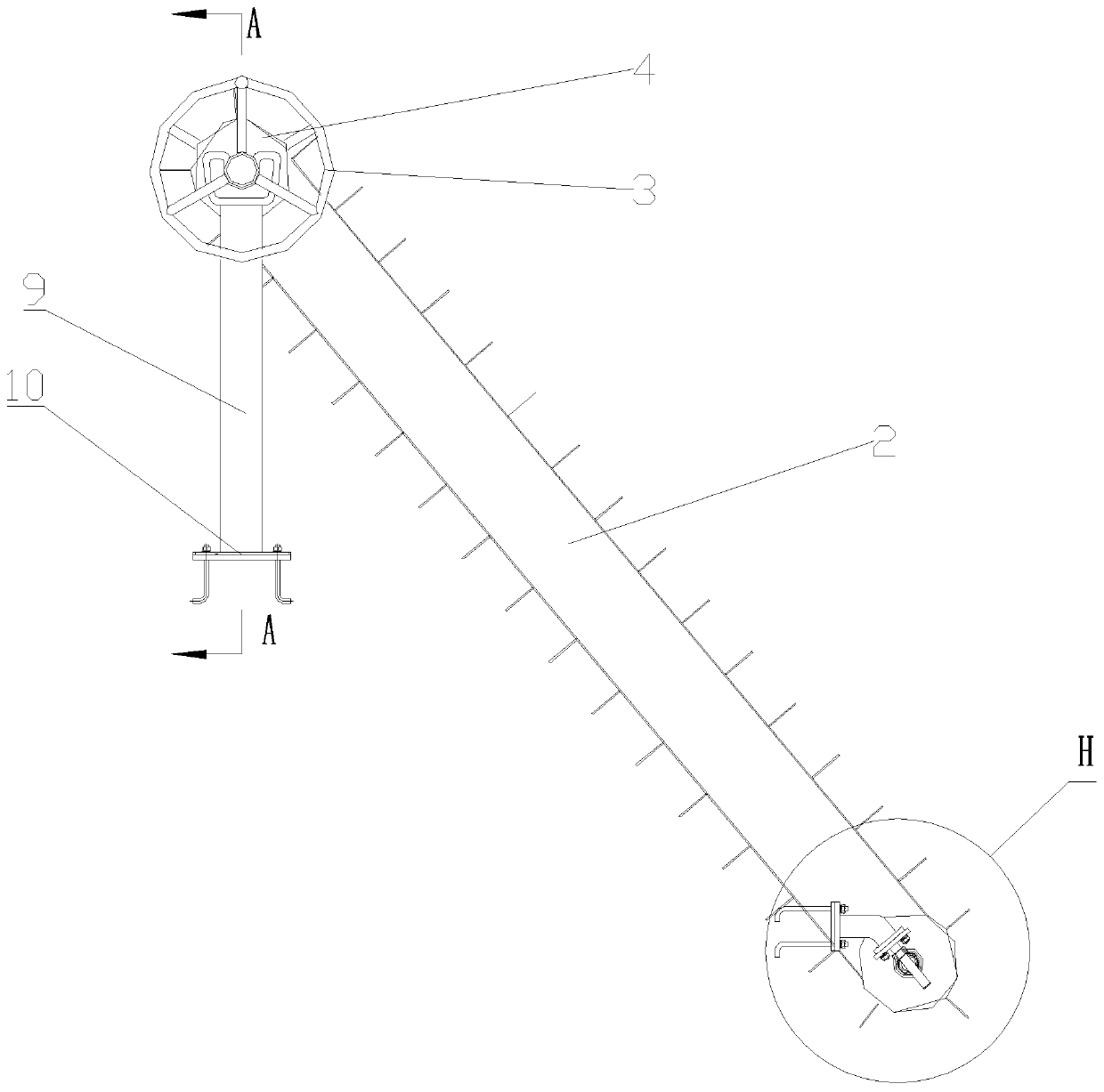

Keel-type intelligent fish catching apparatus

The invention belongs to the field of entertaining equipment and particularly relates to a keel-type intelligent fish catching apparatus, comprising a pond, a base, an attracting waterway, a water collecting pit, a fish collecting pit and a keel-type water conveyer; all the attracting waterway, the water collecting pit and the keel-type water conveyer are arranged on the base; the base is arrangedon the pond; one end of the attracting waterway is communicated with the water collecting pit; the other end of the attracting waterway is communicated with the fish collecting pit; the fish collecting pit is communicated with the pond; the keel-type water conveyer is used for conveying water in the pond to the water collecting pit. The keel-type intelligent fish catching apparatus is suitable for catching fishes by taking advantage of the habit that fishes are upstream, can provide more reactional enjoyment to tourists, can bring new experience to people on catching means, and can help develop the intelligence and improve people's interest in life.

Owner:唐山多玛乐园旅游文化有限公司

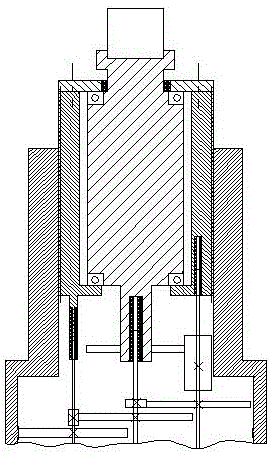

Spiral gear machining mechanism

InactiveCN104308278AGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringScrew thread

A spiral gear machining mechanism used during machining of a blank (85) comprises a base (3), a rotatable inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8). The rotatable inner threaded part (1) comprises an upper cylinder (11) and a lower cavity (12). The lower cavity (12) is connected to the base (3) in a circumferential rotatable and axial fixed manner. The outer threaded part (2) is cylindrical. The outer threads on the outer circumferential surface are connected with the inner threads in the upper cylinder (11) in a matched manner. A cavity (31) is arranged in the base (3) and provided with a top wall (32).

Owner:国网山东省电力公司沂源县供电公司

A helical gear machining mechanism

InactiveCN104308278BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusEngineeringScrew thread

A spiral gear machining mechanism used during machining of a blank (85) comprises a base (3), a rotatable inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8). The rotatable inner threaded part (1) comprises an upper cylinder (11) and a lower cavity (12). The lower cavity (12) is connected to the base (3) in a circumferential rotatable and axial fixed manner. The outer threaded part (2) is cylindrical. The outer threads on the outer circumferential surface are connected with the inner threads in the upper cylinder (11) in a matched manner. A cavity (31) is arranged in the base (3) and provided with a top wall (32).

Owner:国网山东省电力公司沂源县供电公司

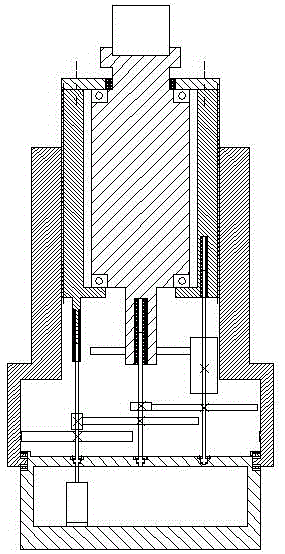

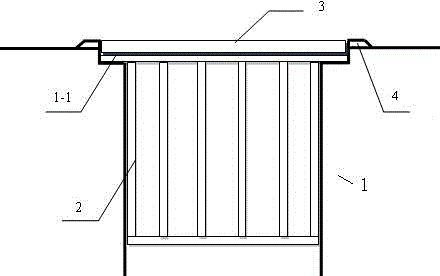

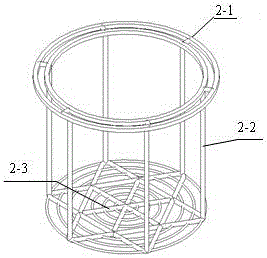

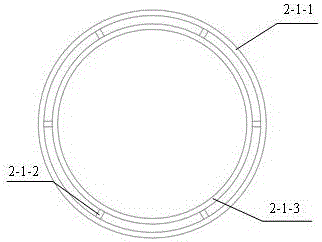

Sewer pipeline well with safety fall-proof measure and design method thereof

InactiveCN106567409APrevent drowningAvoid casualtiesArtificial islandsUnderwater structuresRoad surfaceDesign methods

Disclosed is a sewer pipeline well with a safety fall-proof measure. The sewer pipeline well comprises a sewer pipeline well body, and the sewer pipeline well body comprises an underground well fall-proof safety cage, a well cover, a well frame and a radius difference platform which is arranged on the underground well fall-proof safety cage; the well cover is arranged on the radius difference platform; the well frame is arranged around the well cover; the underground well fall-proof safety cage is perpendicular to a level road, and comprises an outer wing circle, six vertical supporting rib columns and a bottom safety plate; the outer wing circle is connected with the six vertical supporting rib columns in a welded mode, and the six vertical supporting rib columns are connected with the bottom safety plate in a welded mode; the outer wing circle comprises an outer square column circular ring, six horizontal supporting ribs and an inner square column circular ring; and the six horizontal supporting ribs are welded evenly between the outer square column circular ring and the inner square column circular ring. According to the sewer pipeline well with the safety fall-proof measure, a fixing mode that the radius difference platform is engaged with the outer wing circle is adopted, so that even though the well cover is washed away by water, the fixation of the sewer pipeline well is not affected.

Owner:SHENYANG JIANZHU UNIVERSITY

Culture method for rice seedlings

InactiveCN102523977BEasy to fixFixed will not affectAgriculture gas emission reductionCultivating equipmentsNutrient solutionSeedling

The invention discloses a culture method for rice seedlings. The rice seedlings are cultured by using a split root culture device; the side faces of two culture bowls of the device are butted; a cover plate and a cultivation plate are arranged above the culture bowls; the cultivation plate is provided with culture holes; the culture method comprises the following steps of: culturing 3-day rice seedlings in kimura nutrient solution with concentration of 50 percent for 2 days; replacing the kimura nutrient solution with the kimura nutrient solution with concentration of 100 percent for 12 days;taking consistently grown seedlings and wrapping stem base parts by using culture cotton; fixing in the culture holes of the cultivation plate; grouping rice seedling roots into equal groups A and B,wherein the group A is placed in the culture bowl containing the kimura nutrient solution, and the group B is placed in the culture bowl containing the culture solution of element deficient; adjusting the pH of the culture solution to 6.0 from 8 a.m. to 15 p.m. each day; and replacing the culture solution after culturing for 3 days, and after culturing to 4-12 days, taking the stems and leaves ofthe rice seedlings, the group A of cultured rice seedling roots and the group B of cultured rice seedling roots. The culture method is easy to operate; the personal error is avoided; the culture timeis saved; and the working efficiency is increased.

Owner:HENAN UNIV OF SCI & TECH

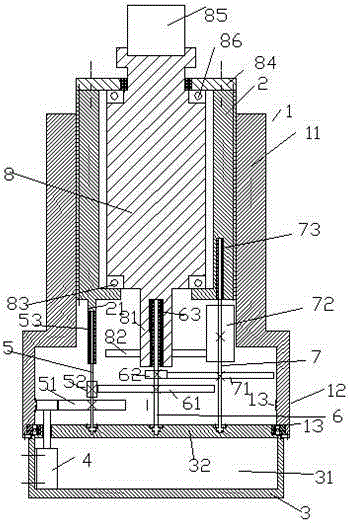

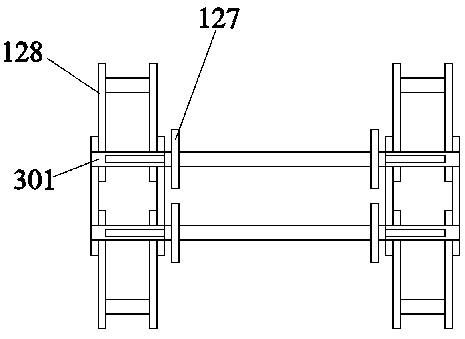

A lifting helical gear processing equipment

InactiveCN104439533BGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethMilling cutterEngineering

Spiral gear machining equipment capable of ascending and descending is used when a blank (85) is machined. The spiral gear machining equipment comprises a base (3), a stand column (300), a milling head (301), a rotary inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8), wherein the base (3) is fixedly connected with the lower end of the stand column (300), a lifting device (101) is installed at the upper end of the stand column (300), a milling head (301) is installed at the upper end of the lifting device (101) and can mill the blank (85) through rotation of a milling cutter, the rotary inner threaded part (1) comprises an upper barrel part (11) and a lower cavity part (12), the lower cavity part (12) is rotationally connected with the base (3) in the peripheral direction and fixedly connected with the base (3) in the axial direction trough a bearing device (13), and the outer threaded part (2) is cylindrical.

Owner:刘佳艺

Rice milling and humidifying device

The invention discloses a rice milling and humidifying device, which comprises a protection box and a rotating shaft, wherein the left side and the right side of the protection box are respectively provided with a heat dissipation port, a motor is arranged in the protection box, the top end of the rotating shaft is provided with a main body, the rotating shaft is positioned at the upper end of themotor, the bottom surface of the main body is provided with a base, the top of the main body is provided with a top base, the outer sides of the base and the top base are both fixed with a mounting plate, the middle of the mounting plate is provided with a fixing rod, the outer side of the main body is provided with an atomizing port, the inside of the main body is provided with a liquid storagepipe, a heating pipe is arranged at the bottom of the liquid storage pipe, a liquid injection pipe is arranged above the liquid storage pipe, a fan is arranged at the outer side of the liquid injection pipe, a piston is arranged above the liquid injection pipe, and an annular buckle is arranged above the piston. The rice milling and humidifying device is provided with the mounting plate and the motor, can uniformly and finely humidify the interior of the rice milling machine, has strong stability and is not easy to shake when in use.

Owner:ZHUSHAN COUNTY PEIFENG GRAIN OIL IND TRADE

A four-axis transmission type helical gear machining mechanism

InactiveCN104400139BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusMotor driveDrive motor

The invention provides a four-axis driving-type helical gear processing mechanism which is used for processing a blank (85). The four-axis driving-type helical gear processing mechanism comprises a base (3), a rotary internal thread piece (1), an external thread piece (2) and a cylindrical workpiece carrying piece (8), wherein the rotary internal thread piece (1) comprises an upper cylinder part (11) and a lower cavity part (12); the lower cavity part (12) is connected with the base (3) by virtue of a bearing device (13) in a circumferential rotation and axial fixation manner; the external thread piece (2) is cylindrical, and the outer periphery surface of the external thread piece (2) is provided with external threads jointed with internal threads in the upper cylinder part (11); the base (3) is internally provided with a cavity (31); the cavity (31) is provided with a top wall (32); the cavity (31) is internally provided with a driving motor (4); the driving motor (4) is connected with the lower end of a motor driving shaft.

Owner:SHENYUE FUJIAN CASTING

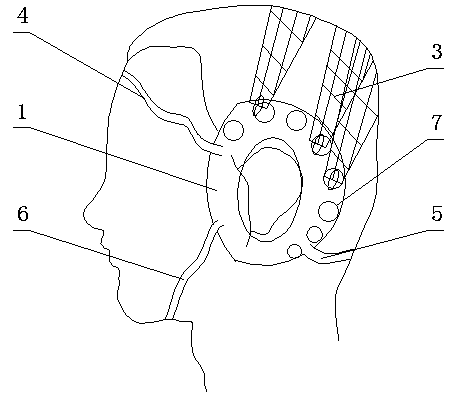

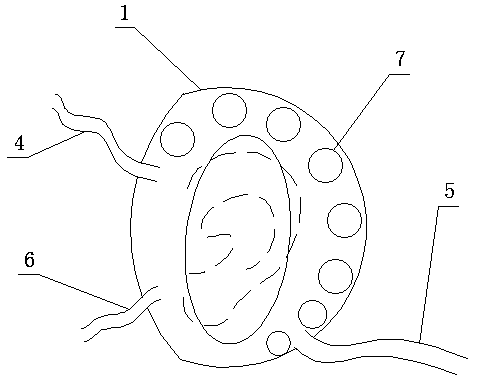

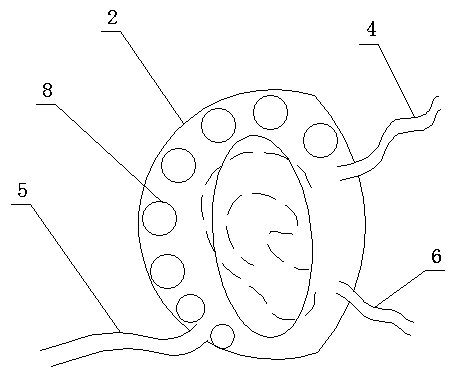

Head dressing fixing device

PendingCN108938200ASimple structureImprove stabilityHead bandagesNeck bandagesMedical productForehead

The invention relates to a head dressing fixing device, and belongs to the technical field of medical products. The head dressing fixing device is formed by a left ear ring, a right ear ring and elastic net sheets, wherein the left ear ring and the right ear ring are circular cotton sheets, the middles of the left ear ring and the right ear ring are each provided with an elliptic through hole forthe human ears to penetrate, and the left ear ring and the right ear ring are each provided with a forehead tying band, a mandible tying band and a nape tying band; left buttons are arranged on the upper right semi-side of the left ear ring at intervals, right buttons are arranged on the upper left semi-side of the right ear ring at intervals, and the elastic net sheets covering and fixing brain dressings are connected between the left buttons and the right buttons. According to the head dressing fixing device, the elastic net sheets are overlapped and crossed at the dressing positions, and the stability of the dressings is improved; cotton sheets are sewn on the elastic net sheets at intervals, the supplying condition of scalp blood of a patient can be effectively improved, and recovery of the illness state is facilitated; a drainage tube is conveniently fixed and prevented from being shifted.

Owner:GONGAN COUNTY PEOPLES HOSPITAL

Spiral gear machining equipment capable of ascending and descending

InactiveCN104439533AGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethMilling cutterEngineering

Spiral gear machining equipment capable of ascending and descending is used when a blank (85) is machined. The spiral gear machining equipment comprises a base (3), a stand column (300), a milling head (301), a rotary inner threaded part (1), an outer threaded part (2) and a cylindrical workpiece bearing part (8), wherein the base (3) is fixedly connected with the lower end of the stand column (300), a lifting device (101) is installed at the upper end of the stand column (300), a milling head (301) is installed at the upper end of the lifting device (101) and can mill the blank (85) through rotation of a milling cutter, the rotary inner threaded part (1) comprises an upper barrel part (11) and a lower cavity part (12), the lower cavity part (12) is rotationally connected with the base (3) in the peripheral direction and fixedly connected with the base (3) in the axial direction trough a bearing device (13), and the outer threaded part (2) is cylindrical.

Owner:刘佳艺

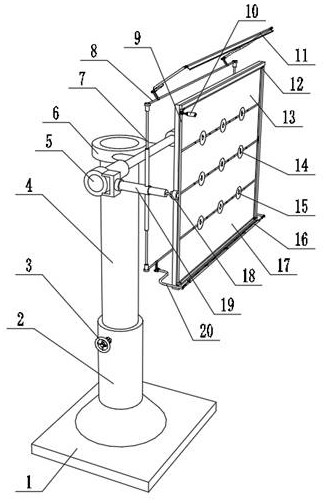

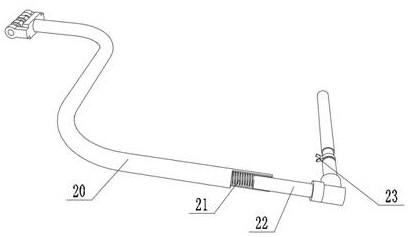

Medical film display device convenient to use

InactiveCN112666715AEasy to turn left and rightHeight adjustableOptical elementsDisplay boardDisplay device

The invention discloses a medical film display device convenient to use, relates to the technical field of medical film display, and aims to solve the problem that films are inconvenient to fix. The device specifically comprises a base and a display board, and is characterized in that a fixing mechanism is arranged on the outer wall of the bottom of the display board, a display area is arranged on the outer wall of one side of the display board, two or more adsorption areas are arranged on the outer wall of the display area, and detectors are fixed to the inner walls of one side of the adsorption areas through screws; and an air suction pipe I and two air suction pipes II are clamped on the inner walls of one side of the adsorption areas. The display area is arranged, the fixing mechanism and the adsorption areas are arranged on the display area, the third spring is used for extruding the arc-shaped pressing plate, so that the arc-shaped pressing plate makes contact with the display area, a user clamps the film on the arc-shaped pressing plate, the edge of the film makes contact with the adsorption areas, at the moment, the detector detects the film and the air suction pump is started, and air is extracted from the two air suction pipes II and the air suction pipe I to form negative pressure to adsorb the film so that fixation is completed.

Owner:张兴宏

A Helical Gear Machining Mechanism with Adjustable Machining Speed

ActiveCN104400140BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusDrive motorEngineering

The invention discloses a spiral gear processing mechanism with an adjustable processing speed. The spiral gear processing mechanism is used when a blank (85) is processed, and comprises a base (3), a rotatable internal thread element (1), an external thread element (2) and a cylindrical work-piece bearing element (8), wherein the rotatable internal thread element (1) comprises an upper cylinder section (11) and a lower chamber section (12); the lower chamber section (12) and the base (3) can circumferentially rotate and axially fixedly connected through a bearing device (13); the external thread element (2) is in a cylindrical shape; external threads are arranged at the outer circumference surface and are jointed with internal threads in the upper cylinder section (11); a hollow cavity (31) is formed in the base (3), and is provided with a top wall (32); a drive motor (4) is arranged in the hollow cavity (31).

Owner:ZHENXIN TAISHAN SPEED CHANGING GEAR BOXES

Spiral gear machining mechanism capable of flexibly limiting vertical motion

ActiveCN104439535AGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethDrive motorSpur gear

A spiral gear machining mechanism capable of flexibly limiting vertical motion is used for machining a blank (85) and comprises a base (3), a rotatable internal thread part (1), an external thread part (2) and a cylindrical workpiece bearing part (8). The rotatable internal thread part (1) comprises an upper cylinder part (11) and a lower chamber part (12), the lower chamber part (12) is connected with the base (3) through a bearing device (13) in the mode that the lower chamber part (12) can be rotated in the circumferential direction and fixed in the axial direction, the external thread part (2) is cylindrical, an external thread is arranged on the outer circumferential face of the external thread part (2) and connected with an internal thread in the upper cylinder part (11), a cavity (31) is formed in the base (3) and provided with a top wall (32), and a driving motor (4) is installed in the cavity (31).

Owner:扬州安特自动化科技有限公司

Spiral gear machining mechanism capable of conducting lubricating oil renewal

ActiveCN104400138AGuaranteed accuracyConstant proportional relationshipGear lubrication/coolingFeeding apparatusEngineeringSpur gear

The invention relates to a spiral gear machining mechanism capable of conducting lubricating oil renewal, which is used for machining a blank (85). The spiral gear machining mechanism capable of conducting lubricating oil renewal comprises a base (3), a rotatable internal threaded piece (1), an external threaded piece (2) and a cylindrical workpiece bearing piece (8), wherein the rotatable internal threaded piece (1) comprises an upper cylindrical portion (11) and a lower chamber portion (12), the lower chamber portion (12) is connected with the base (3) through a bearing device 13) in a circumferentially rotatable and axial fixed manner, the external threaded piece (2) is cylindrical, external threads are arranged on the external circumferential surface of the external threaded piece (2) and are jointed with internal threads in the upper cylindrical portion (11), and a cavity (31) is formed in the base (3).

Owner:中山迈雷特智能装备有限公司

Resin button and processing method thereof

The invention provides a resin button and a processing method thereof. The resin button prepared according to the method comprises a button body, the button body is provided with longitudinal button eyelets, the resin button further comprises a decorative cover and a connecting part, a longitudinal connecting through hole is formed in the axis of the button body, and the button eyelets are distributed at the outer side of the connecting through hole with the connecting through hole being the center; the decorative cover comprises a shielding sheet and a decorative sheet, the decorative sheet and the shielding sheet are placed in a longitudinally stacked mode, the shielding sheet covers the button body, a first axle hole is formed in the axis of the decorative sheet, a second shaft hole isformed in the axis of the shielding sheet, and the connecting part penetrates through the first shaft hole, the second shaft hole and the connecting through hole to fix the decorative sheet and the shielding sheet to the upper end of the button body; a thread accommodation cavity is arranged between the shielding sheet and the button body, and a sewing thread exposed at the upper end of the buttonbody can be accommodated in the thread accommodation cavity and shielded by the shielding sheet.

Owner:HAINING SHENGXIANG WIRE

A helical gear processing mechanism with two ring-shaped protrusions on the workpiece bearing shaft

ActiveCN104439532BGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethGear wheelScrew thread

The invention provides a spiral gear machining mechanism with a workpiece bearing shaft provided with two annular protrusions. The spiral gear machining mechanism is used for machining a blank (85) and comprises a base (3), a rotary inner thread piece (1), an outer thread piece (2) and the cylindrical workpiece bearing shaft (8). The rotary inner thread piece (1) comprises an upper cylinder portion (11) and a lower cavity portion (12). The lower cavity portion (12) is connected with the base (3) through a bearing device (13) in a peripherally rotating and axially fixed mode. The outer thread piece (2) is cylindrical. The outer peripheral surface of the outer thread piece (2) is provided with outer threads jointed with inner threads in the upper cylinder portion (11). The base (3) is internally provided with a cavity (31), and the cavity (31) is provided with a top wall (32).

Owner:广州优云机械制造有限责任公司

A Helical Gear Machining Mechanism Capable of Rapid Heat Dissipation

InactiveCN104400136BGuaranteed accuracyConstant proportional relationshipGearingFeeding apparatusDrive motorEngineering

Owner:吕英芬

An automatic mobile welding machine

ActiveCN111482759BEasy to weldLow costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention discloses an automatic mobile welding machine, comprising a control box, a display screen, control buttons, a welding platform, a servo motor, an automatic expansion rod and a welding machine body. The front surface of the control box is fixedly connected with a display screen, and the control box The front surface of the box is screwed with a control button, the upper surface of the welding platform is provided with a connecting groove, the upper surface of the welding platform is welded and fixed with a connecting rod, and the upper surface of the connecting rod is provided with a connecting ball, and the welding platform The upper surface is welded and fixed with an automatic telescopic rod, the upper surface of the automatic telescopic rod is welded and fixed with a support slide bar, and the upper surface of the support slide bar is provided with a welding machine body, and the output end of the servo motor is welded and fixed with a connecting plate. The lower end of the threaded rod is welded and fixed with a bearing. The automatic mobile welding machine is provided with a servo motor, a connecting plate, a second spring, a connecting rod, a connecting ball and a threaded rod, which reduces the workload of the staff and improves the welding efficiency of the whole device.

Owner:湛江市创安人防工程有限公司

Worm machining mechanism lower in weight

A worm machining mechanism lower in weight is used for machining a blank (1) into a worm. The machining mechanism comprises a blank bearing part (2), a sleeve (3) with an external thread, a driving sleeve (4) with an internal thread and a rack (7). An upper ring-shaped flange (211) is arranged at the upper end of the blank bearing part (2), a lower ring-shaped flange (212) is arranged at the lower end of the blank bearing part (2), a ring-shaped cavity (23) is formed between the upper ring-shaped flange (211) and the lower ring-shaped flange (212), and the blank bearing part (2) with the ring-shaped cavity (23) makes the weight of the worm machining mechanism be reduced.

Owner:JIANGSU HUAXIA HEAVY IND

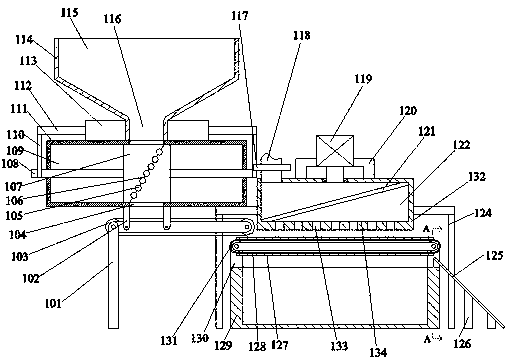

Construction waste cleaning device

InactiveCN110523463AImprove cleaning effectEasy to cleanConstruction waste recoverySolid waste disposalBuilding materialConstruction waste

The invention discloses a construction waste cleaning device. The device includes a support, a conveyor driven by a motor to operate is arranged in the support, and the crushing devices for preliminarily crushing the building materials are arranged at the front side and the rear side of the conveyor. A supporting vertical rod is arranged at the right side of the support, a water liquid spraying device for periodically spraying the water liquid is arranged in the supporting vertical rod, and a cleaning device for transporting the construction waste for the efficient cleaning is arranged at thelower side of the water liquid spraying device. The device is simple in structure, and by adopting the crushing devices, the water liquid spraying device and the cleaning device, the construction waste can be preliminarily crushed through the device to improve the cleaning effect, on the premise that the normal transportation of the construction waste is not affected, the construction waste is fully cleaned in a mode of spraying and washing with the water directly from top to bottom, and a cleaned solution can be collected so as to be recycled conveniently.

Owner:齐嘉蕾

A helical gear machining mechanism driven by a motor

ActiveCN104439531BGuaranteed accuracyConstant proportional relationshipFeeding apparatusGear teethGear wheelElectric machinery

A spiral gear machining mechanism driven by a motor is used for machining blanks (85). The spiral gear machining mechanism comprises a base (3), a rotary internally threaded piece (1), an externally threaded piece (2) and a cylindrical workpiece bearing piece (8). The rotary internally threaded piece (1) comprises an upper cylinder portion (11) and a lower cavity portion (12). The lower cavity portion (12) can rotate relative to the base (3) in the circumferential direction through a bearing device (13) and can be fixedly connected with the base (3) in the axial direction. The externally threaded piece (2) is cylindrical, and external threads located on the circumferential face of the outer circle of the externally threaded piece (2) are in joint with internal threads located in the upper cylinder portion (11). A drive motor (4) is arranged in the lower cavity portion (12) and located on the upper side of the base (3) and connected with the lower end of a first shaft (5).

Owner:山东格新精工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com