Culture method for plant seedlings

A cultivation method and seedling technology are applied in the field of plant seedling cultivation using a plant root-dividing cultivation device, which can solve the problems of inconvenience in fixing plant seedlings, inconvenient operation, inaccurate test results and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

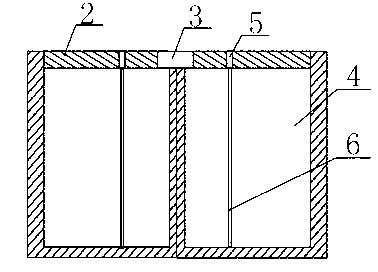

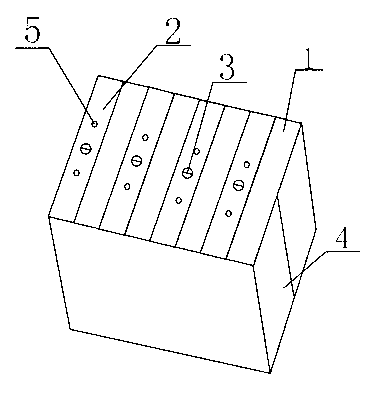

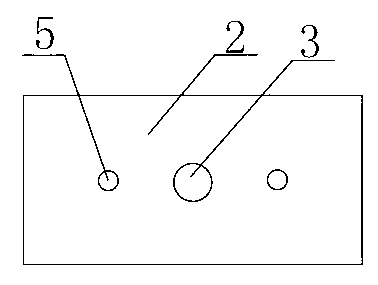

[0064] A method for cultivating plant seedlings. The plant seedlings are cultivated by using an aeration-type split-root cultivation device. The aeration-type split-root cultivation device includes two symmetrically arranged cultivation bowls 4, a cultivation plate 2 and a cover plate 1. The cultivation bowl 4 is the upper end Open cuboid, the sides of two cultivation bowls 4 are docked, and the height of the docked sides is 2.0 cm lower than the height of the remaining sides, and a plurality of cover plates 1 and cultivation plates perpendicular to the low sides are arranged above the opening ends of the two cultivation bowls 4 2. The cover plate 1 and the cultivation plate 2 are alternately arranged, and the middle part of the cultivation plate 2 is provided with a cultivation hole 3, the aperture of the cultivation hole 3 is 2.5 cm, and the cultivation hole 3 is arranged above the butt joint surface of the two cultivation pots 4, Two ventilation holes 5 are symmetrically arr...

Embodiment 2

[0081] A method for cultivating plant seedlings. The plant seedlings are cultivated by using an aeration-type split-root cultivation device. The aeration-type split-root cultivation device includes two symmetrically arranged cultivation bowls 4, a cultivation plate 2 and a cover plate 1. The cultivation bowl 4 is the upper end Open cuboid, the sides of two cultivation bowls 4 are docked, and the height of the docked sides is 2.0 cm lower than the height of the remaining sides, and a plurality of cover plates 1 and cultivation plates perpendicular to the low sides are arranged above the opening ends of the two cultivation bowls 4 2. The cover plate 1 and the cultivation plate 2 are arranged alternately, and a cultivation hole 3 is provided in the middle of the cultivation board 2. The aperture of the cultivation hole 3 is 3.0 cm. Two ventilation holes 5 are symmetrically arranged on both sides of the cultivation hole 3, and the two ventilation holes 5 are respectively located ab...

Embodiment 3

[0098] A method for cultivating plant seedlings. The plant seedlings are cultivated by using an aeration-type split-root cultivation device. The aeration-type split-root cultivation device includes two symmetrically arranged cultivation bowls 4, a cultivation plate 2 and a cover plate 1. The cultivation bowl 4 is the upper end Open cuboid, the sides of two cultivation bowls 4 are docked, and the height of the docked sides is 2.0 cm lower than the height of the remaining sides, and a plurality of cover plates 1 and cultivation plates perpendicular to the low sides are arranged above the opening ends of the two cultivation bowls 4 2. The cover plate 1 and the cultivation plate 2 are arranged alternately, and a cultivation hole 3 is arranged in the middle of the cultivation board 2. The aperture of the cultivation hole 3 is 4.0 cm. Two ventilation holes 5 are symmetrically arranged on both sides of the cultivation hole 3, and the two ventilation holes 5 are respectively located ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com